Manufacturing/CNC Tech Program Review

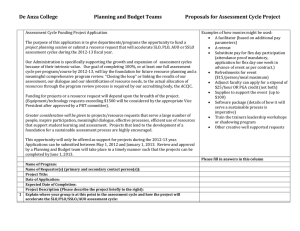

advertisement

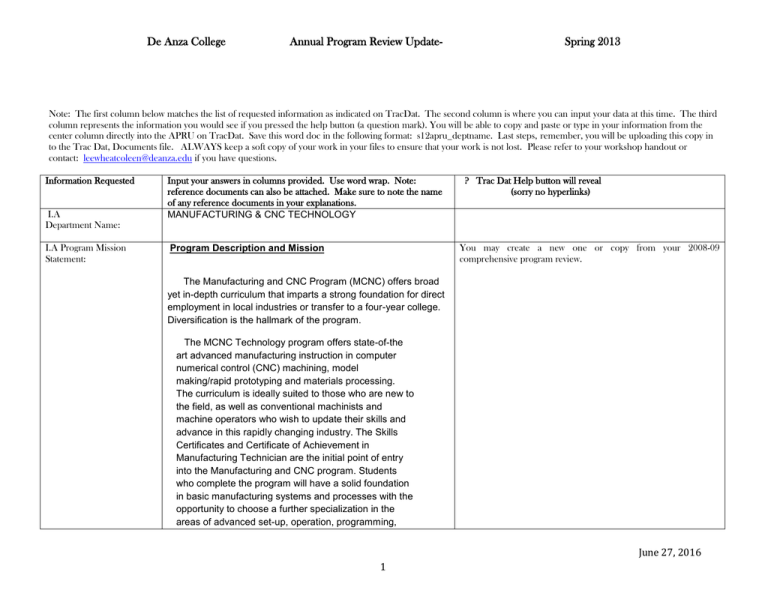

De Anza College Annual Program Review Update- Spring 2013 Note: The first column below matches the list of requested information as indicated on TracDat. The second column is where you can input your data at this time. The third column represents the information you would see if you pressed the help button (a question mark). You will be able to copy and paste or type in your information from the center column directly into the APRU on TracDat. Save this word doc in the following format: s12apru_deptname. Last steps, remember, you will be uploading this copy in to the Trac Dat, Documents file. ALWAYS keep a soft copy of your work in your files to ensure that your work is not lost. Please refer to your workshop handout or contact: leewheatcoleen@deanza.edu if you have questions. Information Requested I.A Department Name: I.A Program Mission Statement: Input your answers in columns provided. Use word wrap. Note: reference documents can also be attached. Make sure to note the name of any reference documents in your explanations. MANUFACTURING & CNC TECHNOLOGY ? Trac Dat Help button will reveal (sorry no hyperlinks) You may create a new one or copy from your 2008-09 comprehensive program review. Program Description and Mission The Manufacturing and CNC Program (MCNC) offers broad yet in-depth curriculum that imparts a strong foundation for direct employment in local industries or transfer to a four-year college. Diversification is the hallmark of the program. The MCNC Technology program offers state-of-the art advanced manufacturing instruction in computer numerical control (CNC) machining, model making/rapid prototyping and materials processing. The curriculum is ideally suited to those who are new to the field, as well as conventional machinists and machine operators who wish to update their skills and advance in this rapidly changing industry. The Skills Certificates and Certificate of Achievement in Manufacturing Technician are the initial point of entry into the Manufacturing and CNC program. Students who complete the program will have a solid foundation in basic manufacturing systems and processes with the opportunity to choose a further specialization in the areas of advanced set-up, operation, programming, June 27, 2016 1 De Anza College Annual Program Review Update- Spring 2013 metrology and inspection The program is also a primary choice for many Silicon Valley engineers, designers, planners and purchasers who wish increase their “hands on” skills and overall knowledge of the design and manufacturing process in order to advance their careers. Examples of career possibilities include: Computer Numerical Control Machinist, Product Model Maker, Computer Numerical Control Programmer, CNC/Research & Development Machinist, Systems Technician, Manufacturing / Engineering and Industrial Engineering Technician. DeAnza College’s Manufacturing and CNC Technology program offers state-of-the-art classroom and lab facilities. Students have the opportunity to work with CNC lathes, vertical machining centers with 4th axis rotary capabilities, as well as the only 4 axis horizontal machining center in use at a college in the state of California. The students also have access to coordinate measuring machines, inspection equipment, conventional machining equipment and two CAD/CAM programming labs. Manufacturing and CNC Technology offers an accelerated day program, designed for those who need to reenter the workforce quickly. Courses are also offered in the evening to accommodate incumbent workers. The program is also approved by the California Department of Apprenticeship Standards, which currently teaches apprenticeship classes for the International Association of Machinists and Aerospace Workers, with current June 27, 2016 2 De Anza College Annual Program Review Update- Spring 2013 programs approved at Stanford Linear Accelerator (SLAC) and Stanford University. The DeAnza MCNC program also has the distinguished honor of being one of two college institutions in California having a “Haas Technical Education Center” accredited program, with the other being Cal-Poly SLO. For the third consecutive year, the department coordinator sits on the board of the 2012-13 North American Haas Educational Council, representing 407 community colleges using over 2350 CNC machines in the USA. As of the winter quarter of 2013, DeAnza officially became the first community college in the United States to represent DMG/Mori Seiki as a “DMG Mori Seki University Educational Partnership Program”. The partnership brought in over $820,000 of 5 axis advanced manufacturing equipment, simulators and educational media. At this time, the only other DMG/Mori Seiki educational partners in the United States are UC Davis, UC Berkeley and Massachusetts Institute of Technology (MIT). As a welcome addition during the fall 2012 quarter, Gosiger Inc, one of the largest distributors of advanced machine tools in the United States, became the second major corporation to partner with the MCNC program. This second partnership brought in an additional $629,000 by adding an Okuma multi axis mill turn and a Nomura swiss screw machine, making the total value of the two partnership agreements $1.45 million. To enhance this advanced technology, Siemens Corporation has granted 100 NX CAM software seats, valued at $59,000 per seat (there are no student versions, only commercial seats available), with classes approved and scheduled for the fall quarter of 2013. DeAnza is also the only certified Mastercam June 27, 2016 3 De Anza College Annual Program Review Update- Spring 2013 CAD/CAM community college training provider in Northern California and is a member of the educational certification committee. The program maintains strong industry connections with equipment manufactures, software developers, and distributors who recognize the program as one of the elite in the country. The main strengths of the MCNC program are our close ties to industry, as well as ties to high school and four-year college programs. Major companies such as NASA, Grumman Marine Division, Loral Space Systems, Lockheed Space Systems, Apple Inc. as well as local manufacturing job shop facilities are closely involved in our advisory committee. These companies depend on the MCNC program to enhance the skills of their existing and future employees in high tech manufacturing. The program also has articulating agreements with the CCOC (Central County Occupational Center) and the Industrial Technology program at San Jose State. Many students can gain employment by achieving a skills certificate, which is recommended by our advisory board and our most popular certificate. Unfortunately this certificate is not transcribed and does not show on many data sheets. With the partnership of DMG/Mori Seiki, Okuma, Nomura and the implementation of the equipment in the advanced manufacturing program, the skills certificate has been changed to a Certificate of Achievement and will begin being offered in the Fall quarter of 2013. June 27, 2016 4 De Anza College Annual Program Review Update- Spring 2013 Skills Certificate (not transcribed) – CAD/CAM – Mastercam - 13.5 units Skills Certificate (not transcribed) – CNC Machine Operator - 13.5 units The following is the amount of skills certificate earned during the 2011-12 year. Skills Certificate CNC Machine Operator - 61 I.A What is the primary mission of your program? CAD/CAM Mastercam – 16 CAREER / TECHNICAL Basic Skills, Transfer. Career/Technical, Learning Resources/Academic Services, personal enrichment, N/A I.B.1 Choose a secondary mission of your program. TRANSFER Basic Skills, Transfer. Career/Technical, Learning Resources/Academic Services, personal enrichment, N/A I.B.1 Number of Certificates of Achievement Awarded 1 If applicable, enter the number of certificates of achievement awarded during the current academic year. Please refer to: http://research.fhda.edu/factbook/deanzadegrees/dadivisions.htm I.B.1 Number Certif of Achievement-Advanced awarded: 9 I.B.1 Number AA and/or AS Degrees awarded: 11 Leave blank if not applicable to your program If applicable, enter the number of certificates of achievement awarded during the current academic year. Please refer to http://research.fhda.edu/factbook/deanzadegrees/dadivisions.htm leave blank if not applicable to your program If applicable, enter the number of certificates of achievement awarded during the current academic year. Please refer to http://research.fhda.edu/factbook/deanzadegrees/dadivisions.htm I.B.2a Academic Services and LR: # Faculty Served leave blank if not applicable to your program Only for programs that serves staff or students in a capacity other than traditional instruction, e.g. tutorial support, service learning, etc. 0 = no change; (X)= decreased; X = increased; blank= N/A June 27, 2016 5 De Anza College Annual Program Review Update- I.B.2a Academic Services and LR: # Student Served N/A I.B.2a Academic Services and LR: # Staff Served N/A II.A.1-Growth and Decline of targeted student populations Due to budget constraints, the elimination of the Treasure Island and So. California MCNC Job Corps component (a very large off campus program) during 2007-2009 makes it possible to compare only 2009-10 to 2010-2011. The data from the April 2012 DeAnza College Program Review show a targeted population growth increase of 10% and our targeted population are more successful than our non-targeted populations (93% versus 92%).Comparing data from 2010-11 to 2011-12, our 2013 program review shows an additional targeted increase of 14%. The success rate of targeted population was once again more successful than our non-targeted group. (89% versus 87%). Due to budget constraints, the elimination of the Treasure Island and So. California MCNC Job Corps component (a very large off campus program) during 2007-2009 makes it possible to compare only 2009-10 to 2010-2011. The data from the April 2012 DeAnza College Program Review showed the gap lowering by 10% in 2010-11. Data from the 2013 DeAnza College Program Review (2011-2012) shows the gap lowering by an additional 8%. The MCNC faculty will continue with the existing plan of actively providing counseling on course selection and scheduling to students, as well as increased exposure of the DeAnza manufacturing program. Recent progress speaking at career days at Mt, Pleasant H.S. and Independence H.S. , as well as an articulation program with the CCOC, has opened up more career opportunities to underrepresented populations, which has helped the department attain our goal of lowering the equity gap. II.A.2 Trends in equity gap: II.A.3 Closing the student equity gap: II.A.4 Overall The data from 2010-11 to 2011-12 shows an increase of 2% in Spring 2013 not applicable to your program Only for programs that serves staff or students in a capacity other than traditional instruction, e.g. tutorial support, service learning, etc. 0 = no change; (X)= decreased; X = increased; blank= not applicable to your program Only for programs that serves staff or students in a capacity other than traditional instruction, e.g. tutorial support, service learning, etc. 0 = no change; (X)= decreased; X = increased; blank= not applicable to your program Briefly, address student success data relative to your program Growth or decline in targeted populations (Latina/o, African Ancestry, Pacific Islander, Filipino) refer to the sites: (Program reviews 2008 - 2010 available at: http://research.fhda.edu/programreview/DAProgramReview/DeAnza_PR_ Div_pdf/DeAnzaProgramReviewDiv.htm AND program review data 201011 & 2011-12 at http://www.deanza.edu/ir/program-review.html) Refer to http://www.deanza.edu/president/EducationalMasterPlan20102015Final.pdf, p.16. Briefly address why this has occurred. What progress or achievement has the program made relative to the plans stated in your program’s 2008 -09 Comprehensive Program Review, Section III.B, towards decreasing the student equity gap? See IPBT website for past program review documentation: http://deanza.edu/gov/IPBT/program_review_files.html If a rationale for your strategies was not stated in the 2008-2009 CPRU, then briefly explain now. Briefly address the overall enrollment growth or decline of a June 27, 2016 6 De Anza College growth/decline in # students: II.B Changes imposed by internal/external regulations II. C Progress in “Main Areas of Improvement” II. D CTE Programs: Impact of External Trends: Annual Program Review Update- the overall enrollment. In order to increase enrollment we would have to increase the number of sections, which at this time is dependent on class size and budget restrictions. None In 2008-09 internships and apprenticeships were an area we working to improve as we moved into the future. The department goal was to work as closely as possible with our advisory group members to create short term internships and longer term apprenticeship positions, resulting in permanent employment.. This would allow the students to gain “real world” experience while attending MCNC classes. At that time the current economic condition did not allow these positions to become reality. But, with the manufacturing sector rebounding at a fast pace, the MCNC department has helped place apprentices at Northrop Grumman, multiple local shops and seven interns at NASA/Ames. The MCNC department will continue to seek more partners and add to these numbers as the job market grows. Another main area for improvement was maintaining our computers and network system that allows us to teach at the highest level possible. With measure C funds, the replacement of new computers occurred in the first lab Fall of 2012 and the second lab Winter 2013. This has enabled the program to begin offering advanced manufacturing CAD/CAM classes in the Fall of 2013. Employment opportunities for Manufacturing and CNC Technology program graduates exist in large manufacturing facilities and small, independent design shops. Individuals with a background in manufacturing technology can also parlay their skills into other related positions in the industry: CAD/CAM programmers, PLC programmers, and tool makers. Spring 2013 comparison between all student populations and their success. Address program changes implemented as a response to changes in College/District policy, state laws, division/department/program level requirements or external agencies regulations? How did the change(s) affect your program? (e.g. any curriculum, program reorganization, staffing etc.) Based on the 2008-09 Comprehensive Program Review, Section I.C. "Main Areas for Improvement", briefly address your program's progress in moving towards assessment or planning or current implementation of effective solutions. Career Technical Education (CTE) programs, provide regional, state, and labor market data, employment statistics, please see "CTE Program Review Addenda" at: www.deanza.edu/gov/IPBT/resources.html Identify any significant trends that may affect your program relative to: 1) Curriculum Content; 2) Future plans for your program e.g. enrollment management plans. According to the California Employment Development Department’s Labor Market Information data for the San JoseSunnyvale-Santa Clara MSA, there are projected to be 131 June 27, 2016 7 De Anza College Annual Program Review Update- Spring 2013 combined annual openings for the period 2006-2016 for individuals with this set of skills. The strongest demand will be for machinists with 57 annual openings and a steady growth rate of 6.1%. There will also be demand for computer-controlled machine tool operators with 45 annual openings and growth rate of 18.5%. There will be a limited demand for tool and die makers with only 2 annual openings. While the above is a sampling of the main career opportunities available, the MCNC program serves a variety of other careers. Over the years the program has provided Mechanical Engineers, Industrial Engineers, Program Managers, Manufacturing Planners and Purchasers with career advancing knowledge and skills. These jobs represent a significant number of current career positions, as well as job growth in the Bay Area. In addition to the San Jose-Sunnyvale-Santa Clara MSA, the Manufacturing and CNC program provides training to many other areas. DeAnza offers the only manufacturing and CNC program in the surrounding counties. As of 2011 DeAnza serves a vast area, such as Monterey, San Benito, Santa Cruz, San Mateo and San Francisco Counties where no existing Manufacturing and CNC programs exist. II. E CTE Programs: Advisory Board Input: Developing an advanced manufacturing program to advance new and incumbent workers: As a recommendation of our advisory group, the MCNC department is in the first phase of integrating the advanced manufacturing program with our industry partners. With the addition of the DMG/Mori Seiki Educational Partnership, Gosiger Inc. (Okuma and Nomura) and Siemens NX Cam software, the MCNC department is one of the most advanced manufacturing programs at a community college in the country. With continued support from companies such as HAAS Automation, Sandvick Coromat, Mastercam and Blasercut, the college continues to train at a high level using advanced technology equipment, such as touch probes, carbide tools, high Career Technical Education (CTE), provide recommendations from this year's Advisory Board (or other groups outside of your program, etc.) Briefly, address any significant recommendations from the group. Describe your program's progress in moving towards assessment or planning or current implementation of effective solutions. June 27, 2016 8 De Anza College III.A. 1 PLOAC Summary Annual Program Review Update- speed machining, advanced cad-cam software and coolants. As supported by our advisory, the addition of this program will supply the labor market with higher skilled employees capable of selection, set-up and operation of advanced manufacturing equipment. Due to the change in the certificate and degree program approved for Fall 2013, as well as our significant course changes due to repeatability, our PLO outcome statements will be evaluated and re written in the Summer. Therefore, as of this time we have not entered any PLO assessments…The assessments will be completed before Spring 2014. III.A.2 Enhancement based on PLOAC assessment None III.B.1 SLOAC Summary 80% The remaining classes have been deleted, with the exception of courses added to the new certificate and degree program. These courses will be assessed before Spring 2013 III.B.2 Enhancement based on SLOAC assessment None IV. A Budget Trends Planning, implementation and assessment are major parts of training highly skilled students for the current workforce. When lack of funds becomes an issue within the program, one or more of the areas will be affected. The result would be students finishing the program without the necessary skills to compete for high wage employment. Fortunately, there have been and continue to be generous external donations and consignments, which have allowed the department to implement “hands on” training and assess students needs to become extremely desirable employees. Unfortunately, internal funding has dropped to a point to where as the donated and consigned equipment can not be used to its full potential. Spring 2013 Give the percentage of Program Level Outcome statements assessed to date. Run report entitled “XXX PLOAC work” and scroll to the bottom of the report for counts. Then calculate #Reflections & Analysis/#PLO statement times 100. This percentage may be over 100% or 0%. All courses and programs are to be assessed before the Comprehensive Program Review in Spring 2014. State an enhancement that was enacted this year as a direct result of an assessment of a program level outcome. State PLO statement, enhancement and reason for choosing this enhancement. If none, write “NONE”. Give the percentage of Student Level Outcome statements assessed to date. Run report entitled “CIS SLOAC work” and scroll to the bottom of the report for counts. Then calculate #(Reflections & Analysis + #Archived from ECMS) /#SLO statement times 100. This percentage may be over 100% or 0%. All courses and programs are to be assessed before the Comprehensive Program Review in Spring 2014. State an enhancement that was enacted this year as a direct result of an assessment of a student learning outcome. State course, SLO statement, enhancement and reason for choosing this enhancement. If none, write “NONE”. Assess the impact of external or internal funding trends upon the program and/or its ability to serve its students. If you don’t work with Budget, please ask your Division Dean to give you the information. June 27, 2016 9 De Anza College IV.B Enrollment Trends Annual Program Review Update- The following are possible results to enrollment, students, the college and the community if the program funding was significantly reduced or eliminated: DeAnza is the only college in the area that has been approved to teach State apprenticeship courses. Loss: possible elimination of apprenticeship program to the student/employee as well as a qualified program to the community and loss of jobs. Spring 2013 Assess the impact of external or internal funding changes upon the program’s enrollment and/or its ability to serve its students. If you don’t work with Enrollment Trends, please ask your Division Dean to give you the information. The MCNC program has relationships with major companies, such as Northrop Grumman, Tesla, and Loral as well as many small business owners (which include minority and women owners) in the Bay Area. The program trains new and existing students/employees in the manufacturing field. Loss: Lost career opportunities to DeAnza college students as well as a loss to minority business owners in the local community. As of the Fall 2012 quarter, DMG/Mori Seiki, Gosiger Inc. (Okuma and Nomura equipment providers) and Haas Automation currently has donated, entrusted or consigned over $1.4 million dollars of equipment, classroom curriculum and scholarships to DeAnza College. Loss: Students, some already receiving financial aid, lose the opportunity to continue their education from the elimination of scholarships. DeAnza College would lose community partners that have helped the college save an enormous amount of dollars in new equipment through donations, consignments and entrustments. The list could go on and on. The bottom line is there would be limited opportunities for students, many in the targeted population we try so hard to help, to gain skills so they may become employable and contributing members of the community. It is our responsibility at DeAnza College to help all the students in the community, not just the students going to four year colleges. Although it is our department goal to help all students achieve their highest educational level, a vocational and employable skill June 27, 2016 10 De Anza College Annual Program Review Update- Spring 2013 is very important in the lives of many students. V. A.1 -Faculty Position Needed V. A.2 Justification for Faculty/Staff Positions: Growth V. A.3 Staff Position Needed Advance Technology Manufacturing Program -Based on our advisory input, an additional full time instructor position would increase the level of instruction in currently developed high tech classes such as automated touch probes, carbide cutting tool technology, high speed machining and rapidly changing cad/cam software. Our SLO and assessment data has shown that our program is achieving our goals training students to become desirable employees in the community. But, with the DMG/Mori Seki Educational Partnership and the Gosiger Inc. partnership in its first stage (Advanced Manufacturing), the need for new SLO and assessment work will increase dramatically. At this time full time FTEF is only 37%. An additional full time instructor would increase the overall quality, success rate and retention of the program. The obvious being more student opportunities to gain higher wage jobs. None V. A.4 Equipment Request Over $1000.00 V. A.5 Equipment Title and Description, Quantity Two 14” Engine Lathes (instructional equipment). The new lathes would replace current Lathes that are now over 35 years old. The new lathes would have a life expectancy of 25 years and come with a 2 year warranty…No extended warranty would be required. The equipment would not require new or renovated infrastructure due to the fact that the current infrastructure is already in place supporting the existing machines. The equipment would be used by every entry level student entering the program and has a life expectancy of 25 years. The loss of the current equipment would reduce the amount of future students trained as well as effect “hands on training”, which ultimately turns into employment opportunities. This type of V. A.6 Equipment Justification A drop down menu will allow you to choose: Replace due to Vacancy, Growth, None Needed Unless Vacancy If there is a request for one or more new faculty state the SLO/PLO assessment data, reflection, and enhancement that supports this need. A drop down menu will allow you to choose: Replace due to Vacancy, Growth, None Needed Unless Vacancy Only make request for staff if relevant to your department only. Division staff request should be in the Dean’s summary. A drop down menu will allow you to choose: Under $1,000 or Over $1,000 or no equipment requested Description should identify if the item(s) are new or replacement(s), furniture/fixtures, instructional equipment, technology related, expected life of item, recommended warrantees etc. Did this request emanate from a SLOAC or PLOAC process? Does this item require new or renovated infrastructure (eg wireless access, hardwire access, electric, water or heat sources . . . ) Who will use this equipment? What would the impact be on the program with or without the equipment? What is the life expectancy of the current equipment? How does the request promote the college mission or strategic goals? Etc. June 27, 2016 11 De Anza College V. A.7 Facility Request Annual Program Review Update- training is what makes the Manufacturing and CNC program one of the best in the country. None as of this writing. The MCNC facility was renovated in 2004. With the donation of equipment in the future, need could change in the coming years. Spring 2013 Name type of facility or infrastructure items needed. Renovation vs new. Identify associated structures needed to support the facility e.g. furniture, heat lamps, lighting, unique items above and beyond what is normally included in a similar facility V. A.8 Facility Justification None as of this writing. The MCNC facility was renovated in 2004. With the donation of equipment in the future, need could change in the coming years. Who will use this facility? What would the impact be on the program with or without the facility? What is the life expectancy of the current facility? How does the request promote the college mission or strategic goals? Etc. V.B.1 Budget Augmentation How much? Who/what could be supported if this additional funding was awarded? What would the impact be on the program with or without the funds? How does the request promote the college mission or strategic goals? Submitted by: In our department funding is tied in to assessments. So much of our program is “hands on” work, which ties into “hands on” assessments. Funding pays for small equipment, supplies, improved curriculum. The MCNC program excels in “real life” lab experience. More funding leads to higher skills, which leads to higher wage job opportunities. Our CTE goal is putting people to work. With the addition of our new educational partners, DMG/Mori Seki and Gosiger ($1.4 million in equipment in donations and consignments) an additional $5000 added to our B budget would allow the MCNC department to begin to use the equipment to its full potential. This is a small amount compared to our new educational partners commitment. These extra funds would also show our commitment to our partners, our advisory committee, the community and the future employment of our students. All instructors in the MCNC department use the staff development funds every year. These funds allow us to learn new assessment options. It may not be a specific assessment that leads us in this direction, but how we can we improve assessments to align the student’s needs to gain employment. Additional resources allow the program to make major improvements. You will have the ability to reassess based on improved curriculum, advanced training equipment and additional instructor involvement. Mike Appio appiomike@deanza.edu x8283 Last Updated: 5/6/2013 Give date of latest update (Set next box to YES when done and V.B.2 Staff Development Needs V.B.3 Future plans If you do not deal with the B budget directly, you can use the comment: “please refer to the Dean’s summary”. What assessment led to this request? What would the impact be on the program with or without the funds? How does the request promote the college mission or strategic goals? How do you plan to reassess the outcomes of receiving each of the additional resources requested above? APRU writer’s name, email address, phone ext. June 27, 2016 12 De Anza College Annual Program Review Update- Spring 2013 ready for Dean review). June 27, 2016 13