Layered Manufacturing of Thin-Walled Parts Sara McMains, Jordan Smith, Jianlin Wang, Carlo Séquin

advertisement

Layered Manufacturing

of Thin-Walled Parts

Sara McMains, Jordan Smith,

Jianlin Wang, Carlo Séquin

UC Berkeley

Is Layered Manufacturing

really Rapid Prototyping?

2.5”, 15hrs

3.5”, 20hrs

3.0”, 25 hrs

• How can we speed up these manufacturing

technologies?

Raster Scan Technologies

•

•

•

•

Example: 3D Printing

Speed of roller limits the process

Build time = z-height

Speed up: pack build volume in xy with many parts

Vector Scan Technologies

• Example: FDM (Fused Deposition Modeling)

• Build time = volume scanned (material used)

• Our Goal: create a sturdy part that is visually equivalent

but uses less material, so that it builds faster

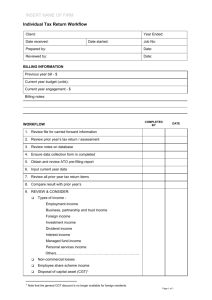

Building Solid Parts with QuickSlice

QuickSlice

3D B-Rep

STL

Slicer

SSL

Support

Roads

• Software interface to Stratasys 1650

FDM Machine

• Input: STL boundary representation

• Slices model into z-layer contours (SSL)

• Builds support structure

• Builds roads (nozzle fill path) (SML)

SML

FDM

QuickSlice Fast Build

3D B-Rep

STL

QuickSlice

Slicer

SSL

SML

Support

• Builds a semi-hollow

version of the solid

• n solid offset rings

• Center filled with a loose

crosshatch pattern

Fast

Roads

FDM

Fast Build Limitations

z

• Structurally conservative

• Only applied to slice

layers whose center area

is completely covered by

slices above and below it

• Gradually sloping

surfaces prevent its

application

• Worst case example

Can Approach Be More Aggressive?

3D B-Rep

Automated Process?

SML

FDM

• Our Goal:

– Create an automated process

– Input: the boundary representation of a desired solid geometry

– Output: a sturdy, physical part that is visually equivalent

while using less material

– Benefits: faster build times and material conservation

• Our Assets:

– QuickSlice software as a black box

– Specifically the loose fill crosshatched roads option

Idea #1: 3D Offset Pipeline

3D B-Rep

Polyhedron

Offset

STL

Quick

Slice

Assume we have true 3D offset surface at

the desired distance inward

• Solid-fill the volume between the

input and the offset surfaces

• Crosshatch-fill the volume within

the offset surface

Unfortunately, the 3D offset is

difficult to implement robustly!

SML

FDM

z

Idea #2: Approximate 3D Offset

3D B-Rep

QuickSlice

Slices

Slicer

Slicer

SSL

Support

Roads

SML

FDM

• Key ideas:

– Offsetting is much simpler in 2D than in 3D

– The manufacturing process eventually represents the part as a

stack in z of layers of 2D contours

• Start: slice polyhedron into desired set of 2D contours

• End: input SSL to QuickSlice to build support and roads

2D Contour Offset

3D B-Rep

Slices

Slicer

Contour

Offset

Offsets

QuickSlice

SML

FDM

S S R

SSL

• Data: layers of 2D contours

• Offset the 2D contours inward by a specified

distance = n layer thicknesses

• Near vertical walls, this is the correct 3D offset

• Approximation degrades as the walls approach

horizontal

2½D Polyhedron Offset

3D B-Rep

Slices

Slicer

Contour

Offset

Offsets

2½D

CSG

QuickSlice

SML

FDM

S S R

SSL

• Data: layers of 2D contours and offsets

• Adjust the loose fill areas in regions where

the vertical coverage above or below is

less than n layers thick

– Perform 2D boolean (CSG) combinations of

the contours and offsets of the ith layer with

the n layers above and below it

– We use OpenGL for the 2D booleans

Regularized Boolean Operations

•

•

•

•

Unregularized: op { , , - }

Regularized: op* { *, *, -* }

A op* B = Closure( Interior( A op B ) )

If A & B are 2D areas and C = A op* B then

C is a non-degenerate 2D area or

A B

AB

A * B

1-Layer Thick 2½D Offset

A Offset Si

B Si Si 1 Si Si 1

C Si Offset Si 1 Offset Si 1

Shell A B C

z

1-Layer Thick 2½D Offset

A Offset Si

B Si Si 1 Si Si 1

C Si Offset Si 1 Offset Si 1

Shell A B C

z

1-Layer Thick 2½D Offset

A Offset Si

B Si Si 1 Si Si 1

C Si Offset Si 1 Offset Si 1

Shell A B C

z

n-Layer Thick 2½D Offset

A Offset Si

n

n

B' Si U Si k 1 Si k U Si k 1 Si k

k 1

k 1

z

n

n

C ' Si U Offset Si k U Offset Si k

k 1

k 1

Shell A B'C'

n-Layer Thick 2½D Offset

A Offset Si

n

n

B' Si U Si k 1 Si k U Si k 1 Si k

k 1

k 1

z

n

n

C ' Si U Offset Si k U Offset Si k

k 1

k 1

Shell A B'C'

n-Layer Thick 2½D Offset

A Offset Si

n

n

B' Si U Si k 1 Si k U Si k 1 Si k

k 1

k 1

z

n

n

C ' Si U Offset Si k U Offset Si k

k 1

k 1

Shell A B'C'

Results: the Bolt Part

• QuickSlice Fast Build • 2½D Offset Method

– Time: 504 min (8:24)

– Filament used: 22.1 m

– Time: 232 min (3:52)

– Filament used: 7.6 m

QuickSlice took 2.71 times as long and

used 2.9 times as much filament

Conclusion

• We have implemented a robust 2D contour

offsetting program.

• We have conservatively approximated the 3D

polyhedron offset using 2D contour slices, 2D

offsets, and 2½D boolean operations.

• We have demonstrated a novel approach to

speeding up FDM manufacturing.

– Our approach decomposes the desired geometry into a

thin sturdy outer shell with a loosely filled center

volume.

– Our approach saves time and material as compared to

the built-in QuickSlice solution.

Thanks to our Sponsors

• NSF

– CyberCut

– CADRE:

• MOSIS++: A Distributed Manufacturing Resource

(EIA-9905140)

• Ford Motor Co.

2D Contour Offset Implementation

Input

Offset 0.1

Offset 0.2

• Difficulties arise from global interactions

• Robust approach based on Voronoi diagram

– Generalization of the approach described by

M. Held 1991

Voronoi Diagram of a Contour

• Input sites are both Vertices and

directed Edge Segments

• VD divides the plane into zones

s.t. every point in a zone is

closest to the corresponding

input site than to any other site

• Vertices of VD have an

associated signed distance

• VD is a signed distance function

Voronoi Mountain

z

z=0

• Create a height

• Offsetting by n

field by raising the

is the same as

vertices of VD in z

slicing the

by their signed

mountain with

distance

the plane z = n

Offset Slicing

z-monotone parabolic VD

edges

for each unvisited VD edge

if VD edge z = n

Crawl VD CCW

around peak

CW around each VD

face

Dragon Curve Example

Input

Voronoi Diagram

Offset