Composite Structures

advertisement

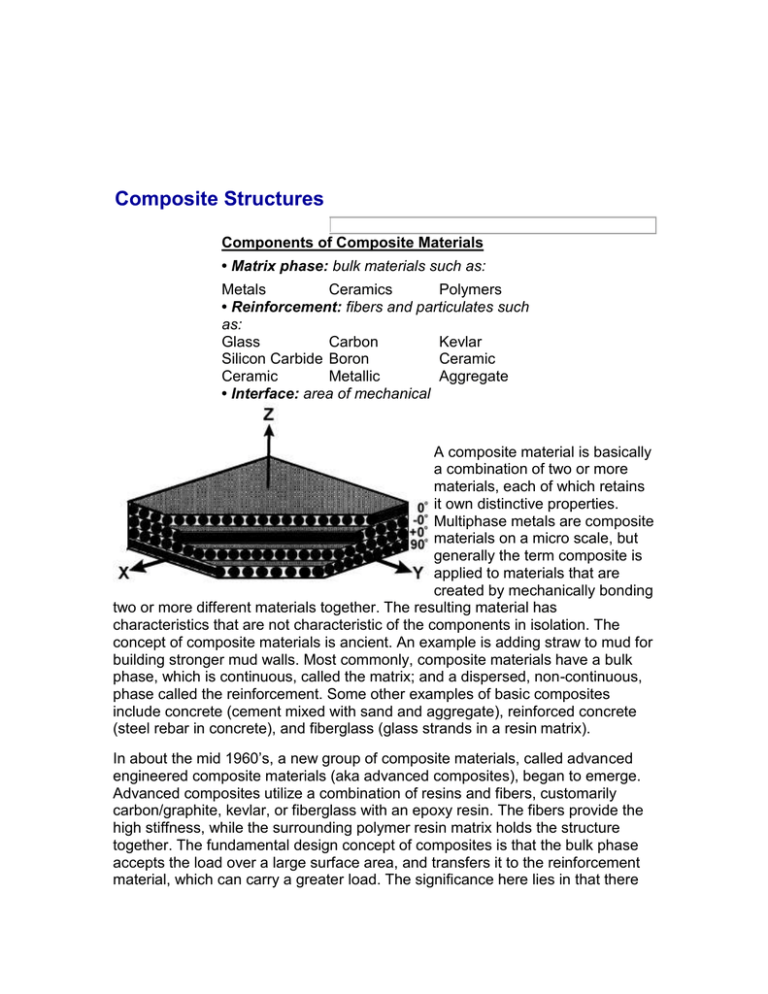

Composite Structures Components of Composite Materials • Matrix phase: bulk materials such as: Metals Ceramics Polymers • Reinforcement: fibers and particulates such as: Glass Carbon Kevlar Silicon Carbide Boron Ceramic Ceramic Metallic Aggregate • Interface: area of mechanical A composite material is basically a combination of two or more materials, each of which retains it own distinctive properties. Multiphase metals are composite materials on a micro scale, but generally the term composite is applied to materials that are created by mechanically bonding two or more different materials together. The resulting material has characteristics that are not characteristic of the components in isolation. The concept of composite materials is ancient. An example is adding straw to mud for building stronger mud walls. Most commonly, composite materials have a bulk phase, which is continuous, called the matrix; and a dispersed, non-continuous, phase called the reinforcement. Some other examples of basic composites include concrete (cement mixed with sand and aggregate), reinforced concrete (steel rebar in concrete), and fiberglass (glass strands in a resin matrix). In about the mid 1960’s, a new group of composite materials, called advanced engineered composite materials (aka advanced composites), began to emerge. Advanced composites utilize a combination of resins and fibers, customarily carbon/graphite, kevlar, or fiberglass with an epoxy resin. The fibers provide the high stiffness, while the surrounding polymer resin matrix holds the structure together. The fundamental design concept of composites is that the bulk phase accepts the load over a large surface area, and transfers it to the reinforcement material, which can carry a greater load. The significance here lies in that there are numerous matrix materials and as many fiber types, which can be combined in countless ways to produce just the desired properties. These materials were first developed for use in the aerospace industry because for certain application they have a higher stiffness to weight or strength-to-weight ratio than metals. This means metal parts can be replaced with lighter weight parts manufactured from advanced composites. Generally, carbon-epoxy composites are two thirds the weight of aluminum, and two and a half times as stiff. Composites are resistant to fatigue damage and harsh environments, and are repairable. Composites meeting the criteria of having mechanical bonding can also be produced on a micro scale. For example, when tungsten carbide powder is mixed with cobalt powder, and then pressed and sintered together, the tungsten carbide retains its identity. The resulting material has a soft cobalt matrix with tough tungsten carbide particles inside. This material is used to produce carbide drill bits and is called a metal-matrix composite. A metal matrix composite is a type of metal that is reinforced with another Composites A composite is commonly defined as a combination of two or more distinct materials, each of which retains its own distinctive properties, to create a new material with properties that cannot be achieved by any of the components acting alone. Using this definition, it can be determined that a wide range of engineering materials fall into this category. For example, concrete is a composite because it is a mixture of Portland cement and aggregate. Fiberglass sheet is a composite since it is made of glass fibers imbedded in a polymer. Composite materials are said to have two phases. The reinforcing phase is the fibers, sheets, or particles that are embedded in the matrix phase. The reinforcing material and the matrix material can be metal, ceramic, or polymer. Typically, reinforcing materials are strong with low densities while the matrix is usually a ductile, or tough, material. Some of the common classifications of composites are: Reinforced plastics Metal-matrix composites Ceramic-matrix composites Sandwich structures Concrete Composite materials can take many forms but they can be separated into three categories based on the strengthening mechanism. These categories are dispersion strengthened, particle reinforced and fiber reinforced. Dispersion strengthened composites have a fine distribution of secondary particles in the matrix of the material. These particles impede the mechanisms that allow a material to deform. (These mechanisms include dislocation movement and slip, which will be discussed later). Many metal-matrix composites would fall into the dispersion strengthened composite category. Particle reinforced composites have a large volume fraction of particle dispersed in the matrix and the load is shared by the particles and the matrix. Most commercial ceramics and many filled polymers are particle-reinforced composites. In fiber-reinforced composites, the fiber is the primary load-bearing component. Fiberglass and carbon fiber composites are examples of fiber-reinforced composites. If the composite is designed and fabricated correctly, it combines the strength of the reinforcement with the toughness of the matrix to achieve a combination of desirable properties not available in any single conventional material.