2009_6_june_barkashar_EMC.ppt

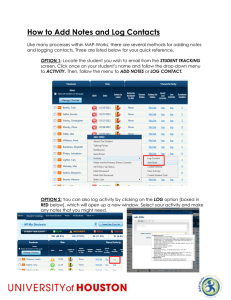

advertisement

High Doping Effects on In-situ and Ex-situ Ohmic Contacts to n-InGaAs Ashish Baraskar*, Mark A. Wistey, Vibhor Jain, Uttam Singisetti, Greg Burek, Brian J. Thibeault, Arthur C. Gossard and Mark J. W. Rodwell ECE and Materials Departments, University of California, Santa Barbara Yong J. Lee Intel Corporation, Technology Manufacturing Group, Santa Clara, CA 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 1 Outline • Motivation – Low resistance contacts for high speed HBTs – Approach • Experimental details – Contact formation – Fabrication of Transmission Line Model structures • Results – Doping characteristics – Effect of doping on contact resistivity – Effect of annealing • Conclusion 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 2 Outline • Motivation – Low resistance contacts for high speed HBTs – Approach • Experimental details – Contact formation – Fabrication of Transmission Line Model structures • Results – Doping characteristics – Effect of doping on contact resistivity – Effect of annealing • Conclusion 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 3 Device Bandwidth Scaling Laws for HBT To double device bandwidth: • Cut transit time 2x: – Reduce thickness 2:1 ☺ – Capacitance increases 2:1 ☹ • Cut RC delay 2x – Scale contact resistivities by 4:1 We Wbc Tb Tc 1 in RC 2f HBT: Heterojunction Bipolar Transistor f max f 8 Rbb Ccb eff Uttam Singisetti, DRC 2007 *M.J.W. Rodwell, IEEE Trans. Electron. Dev., 2001 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 4 InP Bipolar Transistor Scaling Roadmap Emitter: 512 16 256 8 128 4 64 2 32 1 width (nm) access ρ, (m2) Base: 300 20 175 10 120 5 60 2.5 30 1.25 contact width (nm) contact ρ (m2) ft: fmax: 370 490 520 850 730 1300 1000 2000 1400 2800 GHz GHz - Contact resistance serious barrier to THz technology Less than 2 Ω-µm2 contact resistivity required for simultaneous THz ft and fmax* *M.J.W. Rodwell, CSICS 2008 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 5 Approach To achieve low resistance, stable ohmic contacts • Higher number of active carriers - Reduced depletion width - Enhanced tunneling across metal-semiconductor interface • Better surface preparation techniques - Ex-situ contacts: treatment with UV-O3, HCl etch - In-situ contacts: no air exposure before metal deposition • Use of refractory metal for thermal stability 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 6 Outline • Motivation – Low resistance contacts for high speed HBTs and FETs – Approach • Experimental details – Contact formation – Fabrication of Transmission Line Model structures • Results – Doping characteristics – Effect of doping on contact resistivity – Effect of annealing • Conclusion 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 7 Epilayer Growth Semiconductor epilayer growth by Solid Source Molecular Beam Epitaxy (SS-MBE)– n-InGaAs/InAlAs - Semi insulating InP (100) substrate - Unintentionally doped InAlAs buffer - Electron concentration determined by Hall measurements 100 nm In0.53Ga0.47As: Si (n-type) 150 nm In0.52Al0.48As: NID buffer Semi-insulating InP Substrate 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 8 Two Types of Contacts Investigated In-situ contacts: Mo - Samples transferred under vacuum for contact metal deposition - no air exposure Ex-situ contacts: Ti/Ti0.1W0.9 - exposed to air - surface treatment before contact metal deposition Contact metal 100 nm In0.53Ga0.47As: Si (n-type) 150 nm In0.52Al0.48As: NID buffer Semi-insulating InP Substrate 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 9 In-situ contacts In-situ Molybdenum (Mo) deposition - E-beam chamber connected to MBE chamber Why Mo? - Refractory metal (melting point ~ 2623 C) - Work function ~ 4.6 (± 0.15) eV, close to the conduction band edge of InGaAs - Easy to deposit by e-beam technique - Easy to process and integrate in HBT process flow 20 nm in-situ Mo 100 nm In0.53Ga0.47As: Si (n-type) 150 nm In0.52Al0.48As: NID buffer Semi-insulating InP Substrate 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 10 Ex-situ contacts Ex-situ Ti/Ti0.1W0.9 contacts on InGaAs • Surface preparation - Oxidized with UV-ozone for 10 min - Dilute HCl (1:10) etch and DI rinse for 1 min each • Immediate transfer to sputter unit for contact metal deposition • Ti: Oxygen gettering property, forms good ohmic contacts* *G. Stareev, H. Künzel, and G. Dortmann, J. Appl. Phys., 74, 7344 (1993). 100 nm ex-situ Ti0.1W0.9 in-situ 5 nm ex-situ Ti 100 nm In0.53Ga0.47As: Si (n-type) ex-situ 150 nm In0.52Al0.48As: NID buffer Semi-insulating InP Substrate 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 11 TLM (Transmission Line Model) fabrication • E-beam deposition of Ti, Au and Ni layers • Samples processed into TLM structures by photolithography and liftoff • Mo and Ti/TiW dry etched in SF6/Ar with Ni as etch mask, isolated by wet etch 50 nm ex-situ Ni 500 nm ex-situ Au 20 nm ex-situ Ti Mo or Ti/TiW 100 nm In0.53Ga0.47As: Si (n-type) 150 nm In0.52Al0.48As: NID buffer Semi-insulating InP Substrate 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 12 Resistance Measurement • Resistance measured by Agilent 4155C semiconductor parameter analyzer • TLM pad spacing varied from 0.6-26 µm; verified from scanning electron microscope • TLM Width ~ 10 µm 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 13 Error Analysis 3.5 3 Resistance () • Error due to extrapolation* – 4-point probe resistance measurements on Agilent 4155C – For the smallest TLM gap, Rc is 40% of total measured resistance • Metal Resistance – Minimized using thick metal stack – Minimized using small contact widths – Correction included in data • Overlap Resistance – Higher for small contact widths 2.5 2 dd 1.5 dR dRc 1 0.5 0 0 1 2 3 4 5 Gap Spacing (m) 6 *Haw-Jye Ueng, IEEE TED 2001 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 14 Outline • Motivation – Low resistance contacts for high speed HBTs and FETs – Approach • Experimental details – Contact formation – Fabrication of Transmission Line Model structures • Results – Doping characteristics – Effect of doping on contact resistivity – Effect of annealing • Conclusion 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 15 Results: Doping Characteristics -3 Active Carriers (x 10 cm ) 20 19 -3 Active carriers (cm ) 10 10 10 19 Tsub : 440 oC 18 10 18 10 19 -3 10 Total Si atoms (cm ) n saturates at high dopant concentration 2009 Electronic Materials Conference 20 7.5 [Si]: 1.5 x1020 cm-3 7 6.5 6 5.5 5 4.5 400 410 420 430 Substrate Temperature, T sub o 440 ( C) Enhanced n for colder growths -hypothesis: As-rich surface drives Si onto group-III sites June 24-26, 2009 – University Park, PA Ashish Baraskar 16 Results: Contact Resistivity Metal Contact Active Carriers (cm-3) ρc (Ω-µm2) In-situ Mo 6 x1019 1.1±0.6 In-situ Mo 4.2 x1019 2.0±1.1 Ex-situ Ti/Ti0.1W0.9 4.2 x1019 2.1±1.2 • Mo contacts: in-situ deposition; clean interface • Ti: oxygen gettering property 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 17 -3 4 active carriers 12 10 Tsub: 440 oC 3 8 in-situ Mo ex-situ Ti/Ti W 6 0.1 2 0.9 4 1 2 0 2 4 6 8 10 12 19 -3 14 19 14 0 Active Carriers (x10 cm ) 5 16 2 Contact Resistivity (-m ) Results: Effect of doping-I 0 Total Si atoms (x10 cm ) • Contact resistivity ( c) ↓ with ↑ in electron concentration 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 18 Results: Effect of doping-II c Contact Resistivity (log ) 100 10 Tunneling 1 C exp N d Thermionic Emission c ~ constant* * Data suggests tunneling. 1 -10 1 10 -10 -10 2 10 3 10 -1/2 -3/2 [N ] , cm -10 4 10 d High active carrier concentration is the key to low resistance contacts * Physics of Semiconductor Devices, SM Sze 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 19 2 Contact Resistivity (-m ) Results: Thermal Stability Contacts annealed under N2 flow for 60 secs • Mo contacts stable to at least 400 C • Ti/Ti0.1W0.9 contacts degrade on annealing* 3 2.5 ex-situ Ti/Ti W 0.1 0.9 2 in-situ Mo 1.5 0 100 200 300 Anneal Temperature (C) 400 *T. Nittono, H. Ito, O. Nakajima, and T. Ishibashi, Jpn. J. Appl. Phys., Part 1 27, 1718 (1988). 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 20 Conclusion • Extreme Si doping improves contact resistance • In-situ Mo and ex-situ Ti/Ti0.1W0.9 give low contact resistance - Mo contacts are thermally stable - Ti/Ti0.1W0.9 contacts degrade • ρc ~ (1.1 ± 0.6) Ω-µm2 for in-situ Mo contacts - less than 2 Ω-µm2 required for simultaneous THz ft and fmax Contacts suitable for THz transistors 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 21 Thank You ! Questions? Acknowledgements ONR, DARPA-TFAST, DARPA-FLARE 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 22 Extra Slides 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 23 Correction for Metal Resistance in 4-Point Test Structure W Rmetal ( sheet contact )1 / 2 / W sheet L / W L ( sheet contact )1 / 2 / W sheet L / W Rmetal / 3 From hand analysis & finite element simulation Rmetal / 2 Error term (-Rmetal/3) from metal resistance Effect changes measured c by ~40% (@1.3 -m2) All data presented corrects for this effect 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 24 5 19 Doping density (x10 )cm -3 Doping Vs As flux 4 3 Tsub: 440 C 2 2 2009 Electronic Materials Conference 4 6 8 10 12 -6 As flux (x10 ) torr June 24-26, 2009 – University Park, PA 14 Ashish Baraskar 25 Active Carrier, Mobility Vs Total Si 2200 2000 Active Carrier 4 1800 3 1600 1400 2 1200 1 Mobility 0 0 2009 Electronic Materials Conference 5 10 Total Si atoms (x1019cm-3) June 24-26, 2009 – University Park, PA Mobility (cm2/Vs) Active Carriers (x1019 cm-3) 5 1000 800 15 Ashish Baraskar 26 Strain Effects [Si]=1.5 x1020 cm-3, n=6 x1019 cm-3 (asub – aepi)/asub = 5.1 x10-4 Van de Walle, C. G., Phys. Rev. B 39, 3 (1989) 1871 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 27 Random and Offset Error in 4155C 0.6647 • Random Error in resistance measurement ~ 0.5 m • Offset Error < 5 m* Resistance () 0.6646 0.6645 0.6644 0.6643 0.6642 0 5 10 15 20 25 Current (mA) *4155C datasheet 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 28 Accuracy Limits • Error Calculations – dR = 50 mΩ (Safe estimate) – dW = 1 µm – dGap = 20 nm • Error in ρc ~ 40% at 1.1 Ω-µm2 2009 Electronic Materials Conference June 24-26, 2009 – University Park, PA Ashish Baraskar 29