2007_PCSI_rodwell_slides.ppt

advertisement

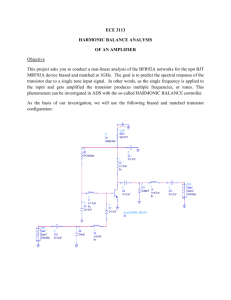

PCSI Conference, January 15, 2008, Santa Fe THz & nm Transistor Electronics: It's All About The Interfaces. M. Rodwell, Art Gossard University of California, Santa Barbara Collaborators (III-V MOS) A. Gossard, S. Stemmer, C. Van de Walle University of California Santa Barbara C. Palmstrøm, University of Minnesota P. Asbeck, A. Kummel, Y. Taur, University of California San Diego M. Fischetti University of Massachusetts Amherst J. Harris, P. McIntyre, Stanford University rodwell@ece.ucsb.edu 805-893-3244, 805-893-5705 fax TeraHertz and nanoMeter Electron Devices How do we make very fast electron devices ? ...by scaling What are the limits to scaling ? attainable contact resistivities, attainable thermal resistivities attainable contact stabilities and for FETs, attainable capacitance densities How can the materials growth community help ? work on interfaces (contacts and gate dielectrics) ! Guidance of utility of other device structures / features nanowire pillar devices access resistances & capacitances relevance and irrelevance of mobility THz & nm Semiconductor Device Design... ... is scaling Frequency Limits and Scaling Laws of (most) Electron Devices PIN photodiode Rtop thickness C area / thickness Rtop contact / area Rbottom Rbottom 1 / stripe length I max, space-charge-limit area / thickness 2 power length T log length width To double bandwidth, reduce thicknesses 2:1 reduce width 4:1, keep constant length current density has increased 4:1 resistance capacitance transit time device bandwidth Rtop Rbottom applies to almost all semiconductor devices: transistors: BJTs & HBTs, MOSFETS & HEMTs, Schottky diodes, photodiodes, photo mixers, RTDs, ... high current density, low resistivity contacts, epitaxial & lithographic scaling FETs only: high ereo/D dielectrics THz semiconductor devices Why aren't semiconductor lasers R/C/ limited ? +V (DC) metal P+ P- high er I optical mode AC output field NN+ metal -V (DC) dielectric waveguide mode confines AC field away from resistive bulk and contact regions. AC signal is not coupled through electrical contacts dielectric mode confinement is harder at lower frequencies Bipolar Transistor Design Bipolar Transistor Design is Simple We b T 2 Dn 2 b Tb c Tc 2v sat Rex contact /Ae We Wbc contact Rbb sheet 12 Le 6 Le Acontacts emitter Ccb eAc /Tc I c, Kirk vsat Ae (Vce,operating Vce,punch-through) / T 2 c P T LE Le 1 ln We Wbc Tc length LE HBT scaling laws Goal: double transistor bandwidth when used in any circuit → keep constant all resistances, voltages, currents → reduce 2:1 all capacitances and all transport delays b T 2 b 2 Dn Tb / v c Tc 2v We Tb Wbc Tc → thin base ~1.414:1 → thin collector 2:1 Ccb Ac /Tc → reduce junction areas 4:1 Rex c /Ae → reduce emitter contact resistivity 4:1 I c, Kirk Ae / Tc2 (current remains constant, as desired ) emitter length LE need to reduce junction areas 4:1 Le P T ln K InP LE We K InP LE reduce widths 2:1 & reduce length 2:1 → doubles T reducing widths 4:1, keep constant length→ small T increase ✓ P Rbb sWe 12 Le sWbc 6 Le c Acontacts → reduce base contact resistivity 4:1 reduce widths 2:1 & reduce length 2:1 → constant Rbb ✓ reducing widths 4:1, keep constant length → reduced Rbb ✓✓ Linewidths scale as the inverse square of bandwidth because thermal constraints dominate. Bipolar Transistor Scaling Laws Changes required to double transistor bandwidth: parameter collector depletion layer thickness base thickness emitter junction width collector junction width emitter contact resistance current density base contact resistivity change decrease 2:1 decrease 1.414:1 decrease 4:1 decrease 4:1 decrease 4:1 increase 4:1 decrease 4:1 Linewidths scale as the inverse square of bandwidth because thermal constraints dominate. Status of Bipolar Transistors : September 2007 200 GHz 300 GHz 400 GHz 500 GHz 600 GHz popular metrics : f or f max alone f f max 800 Teledyne 250 nm 700 UIUC DHBT NTT f max (GHz) 600 UIUC SHBT 600nm 400 UCSB DHBT NGST 300 Pohang 350 nm 200 HRL IBM SiGe 100 Vitesse Updated Sept. 2007 0 0 100 200 300 400 500 ft (GHz) 600 f f max (1 f 1 f max ) 1 ETHZ/SFU 250 nm 500 ( f f max ) / 2 700 800 much better metrics : power amplifiers : PAE, associated gain, mW/ m low noise amplifiers : Fmin , associated gain, digital : f clock , hence (Ccb V / I c ), ( Rex I c / V ), ( Rbb I c / V ), (τb τc ) 150 nm thick collector 256 nm Generation InP DHBT 40 dB H mA/m2 10 30 U 21 20 fmax = 780 GHz 10 10 10 10 11 10 S11 12 11 10 2 = 560 GHz 15 10 5 10 10 11 10 0 12 10 1 2 V Hz 260 280 300 freq. (GHz) 200 GHz master-slave latch design 30 H 320 21 30 U 2 240 4 40 mA/m -20 220 3 ce 60 nm thick collector from one HBT S21 -15 5 0 0 9 10 dB S21, S11, S22 (dB) S22 -10 4 0 -5 3 20 f = 560 GHz 5 2 21 mA/m dB 4.7 dB Gain at 306 GHz. 340 GHz, 70 mW amplifier design 10 max 1 V U f 0 12 10 ce 10 10 10 9 10 H 20 4 0 Hz 70 nm thick collector 30 6 2 f = 424 GHz 0 9 10 8 20 10 fmax = 218 GHz 20 10 f = 660 GHz t Z. Griffith, E. Lind, J. Hacker, M. Jones 0 9 10 10 10 11 10 Hz 10 12 0 0 1 2 V ce 3 InP Bipolar Transistor Scaling Roadmap industry university university appears →industry 2007-8 feasible maybe emitter 512 16 256 8 128 4 64 2 32 nm width 1 m2 access base 300 20 175 10 120 5 60 2.5 30 nm contact width, 1.25 m2 contact collector 150 4.5 4.9 106 9 4 75 18 3.3 53 36 2.75 37.5 nm thick, 72 mA/m2 current density 2-2.5 V, breakdown 520 850 430 240 730 1300 660 330 1000 2000 1000 480 1400 GHz 2800 GHz 1400 GHz 660 GHz f fmax power amplifiers digital 2:1 divider 370 490 245 150 How Can Material Scientists Help ? To build a 5-THz bipolar Transistor... ...we need 0.25 -m2 Ohmic contacts, & these must be stable at 300 mA/m2. ...Can you help ? Ohmic Contacts Ex-Situ Ohmic Contacts are a Mess textbook contact with surface oxide with metal diffusion Surface contaminated by semiconductor oxides On InGaAs surface: Indium and Gallium Oxides, elemental As Metals Interdiffuse with Semiconductor TiPtAu contacts: Ti diffusion. Pt contacts: reaction. Pd contacts: reaction Interface is degraded → poor conductivity Interface is badly-controlled→ hard to understand→ hard to improve Our HBT Base Contacts Today Use Pd or Pt to Penetrate Oxides TEM : Lysczek, Robinson, & Mohney, Penn State Sample: Urteaga, RSC Pt Reacted region InGaAs Pt Contact after 4hr 260C Anneal Au Wafer first cleaned in reducing Pd & Pt react with III-V semiconductor Penetrate surface oxide Pt Reacted region InGaAs Provide ~5 -m2 resistivity (InGaAs base, 8*1019/cm3) reaction depth is a problem for HBT base Pt/Au Contact after 4hr 260C Anneal Chor, E.F.; Zhang, D.; Gong, H.; Chong, W.K.; Ong, S.Y. Electrical characterization, metallurgical investigation, and thermal stability studies of (Pd, Ti, Au)-based ohmic contacts. Journal of Applied Physics, vol.87, (no.5), AIP, 1 March 2000. p.2437-44. Improvements in HBT Emitter Access Resistance U. Singisetti A. Crook S. Bank E. Lind 125 nm generation requires 5 - μm2 emitter resistivities 65 nm generation requires 1-2 - μm2 Recent Results ErAs/Mb MBE in-situ Mo MBE in-situ TiPdAu ex-situ TiW ex-situ J(mA/um^2) Degeneracy contributes 1 - μm2 10 2 10 1 10 0 10 1.5 - μm2 0.6 - μm2 0.5 - μm2 0.7 - μm2 20 nm emitter-base depletion layer contributes 1 - μm2 resistance Te=0 nm Fermi-Dirac -1 10 nm steps Boltzmann 10 -2 10 -3 -0.3 Equivalent series resistance approximation -0.2 -0.1 V - be 0 0.1 0.2 E fn ( x) x J qn( x) Te=100 nm In-situ ErAs-InGaAs Contacts Epitaxially formed, no surface defects, no Fermi level pinning (?) In-situ, no surface oxides, coherent interface, continuous As sublattice J.D. Zimmerman et al., J. Vac. Sci. Technol. B, 2005 Thermodynamically stable ErAs/InAs Fermi level should be above conduction band 1 InAlAs/InGaAs Approximate Schottky barrier potential III Er As D. O. Klenov, Appl. Phys. Lett., 2005 Results nevertheless disappointing: 1.5 - μm2 S.R. Bank, NAMBE , 2006 Low-Resistance Refractory Contacts to N-InGaAs Results initially by luck: control samples for ErAs experiments Mo contacts: deposition by MBE immediately after InGaAs growth TiW contacts: sputter deposition after UV-Ozone & 14.8-normality ammonia soak Both give ~ 1 -m2 resistitivity in-situ Mo contact ex-situ TiW contact Coherent Epitaxial Metal Semiconductor Contacts ? Chris Palmstrom suggests materials such as Fe3Ga, CoGa, NiAl It might be possible to grow these with low interfacial densities on InGaAs or InAs. Key question: what resistivity would we expect for a zero-defect, zero-barrier metal-semiconductor interface ? If we introduce a small difference in Fermi Level between metal and semiconductor, what current do we compute from integration of N(E) v(E)F(E)T(E) ? Shape as Substitute for Low-Resistance Contacts: SiGe HBTs wide emitter contact: low resistance narrow emitter junction: scaling (low Rbb/Ae) P base thick extrinsic base : low resistance thin intrinsic base: low transit time wide base contacts: low resistance narrow collector junction: low capacitance SiO2 N+ subcollector These are planar approximations to radial contacts: → reduced access resistance N- SiO2 extrinsic emitter extrinsic base 2 bulk 2 r ln L W 2 Rcontact c Lr Rbulk extrinsic base N+ subcollector should help less with small devices: ...widths scale faster than thicknesses→ trench fringing capacitance dielectric trench conducts heat badly Field-Effect Transistors Simple FET Scaling Goal double transistor bandwidth when used in any circuit → reduce 2:1 all capacitances and all transport delays → keep constant all resistances, voltages, currents All lengths, widths, thicknesses reduced 2:1 S/D contact resistivity reduced 4:1 C gs ~ eWg Lg / Tox C gs, f ~ C gd ~ eWg Csb ~ Cdb ~ eWg Lc / Tsub If Tox cannot scale with gate length, Cparasitic / Cgs increases, gm / Wg does not increase hence Cparasitic /gm does not scale ~ Lg / v g m ~ C gs / ~ (eLgWg / Tox ) / Gds ~ Cd ch / ~ eWg / If Tox cannot scale with gate length, Gds/gm increases Well-Known: Si FETs no longer Scale Well EOT is not scaling as 1/Lg (ITRS roadmap copied from Larry Larson's files) High-K gate dielectrics: often significant SiO2 interlayer, can limit EOT scaling S/D access resistance also a challenge: about 1 -m2 required for 20 nm Because gate equivalent thickness is not scaling, present devices scale badly output conductance is degrading with scaling other capacitances are not scaling in proportion to Cgs hence are starting to dominate high frequency performance How Can Materials Scientists Help ? High K-dielectrics for Si CMOS are still extremely important Self-aligned (Salicide-like) contacts of very low resistivity are needed ...for 2 mA/micron operation at 700 mV gate overdrive, we want ~300 Ohm-micron lateral access resistivity → about 0.7 Ohm-micron^2 resistivity in a 25 nm wide contact Why consider III-V (InGaAs/InP) CMOS ? Low access resistance: 1 -m2 , 10 -m Light electron→ high electron velocity (thermal or Fermi injection) → increased Id / Wg at a given oxide thickness (?) → decreased Cgs /gm at a given gate length Cox Challenge: Low density of states Cdos q 2 m* 2 3.4 F/cm2 @ 1 nm EOT Challenge: filling of low-mobility satellite valleys limits ns to ~ 8*1012 /cm2 limits Id / Wg Cdos ~3 F/cm2 ballistic case limits ns to ~ 6*1012 /cm2 limits Id / Wg limits gm /Wg Challenge: light electron limits vertical scaling ~1.5-2.5 nm minimum mean electron depth III-V MOS: What might be accomplished Drive current simulationideal (ballistic) assumptions r Composition Optimization for Highest Ballistic Current Taur & Asbeck Groups, UCSD; Fischetti Group: U-Mass: IEDM2007 I_ballistic (mA/um) 7 50% InGaAs 50% InP 60% InGaAs 40% InP 40% InGaAs 60% InP 100% InGaAs 100% InP 6 5 4 3 2 implant isolated 1 0 0 0.2 0.4 VG (V) 0.6 0.8 1 22 nmInGaAs: gate length, nm thick InGaAs / InP channel • More higher 5 injection velocity, lower overall mass 3-4 mA /m intrinsic Cgs ~350 fF/mm --- comparable to fringing and stray capacitances sical CMOS Research Center er well sub-well barrier P+ InGaAs Trade-offs between DOS and injection velocity: • More higher overall mass,silicon lower injection velocity underInP: similar assumptions, channels show N+ N+ S/D Contact Process Flow For III-V MOSFETs selective-area S/D regrowth er er er er er InGaAs well er well er well er well InP well InP well InP well InP well barrier (starting material) barrier barrier CBE in-situ etch barrier CBE in-situ selective-area regrowth electroplate S/D metal non-selective-area S/D regrowth er er er er er er er InGaAs well InP well well InP well well InP well well InP well well InP well barrier barrier barrier barrier barrier (starting material) recess etch nonselective regrowth in-situ S/D metal er planarize er etch er strip planarization material III-V MOSFETs Can Provide Very Low S/D Access Resistance Objective : I d /Wg ~ 5 mA/ m @ (Vgs Vth ) 0.7 V transcondu ctance g m / Wg 7 mS/ m 14 - m source resistance will reduce g m and I d by 10%. With 50 nm wide contacts, this requires c 0.7 - m 2 L S/D 50 nm Lg sidewall metal gate T ox source contact N+ regrowth gate dielectric drain contact N+ regrowth quantum well barrier undoped substrate P + substrate Tw undoped substrate Modern III - V HEMTs have ~ 10 : 1 larger (~ 100 - m) source resistance ... because of the poor extrinsic source access region. Improving FETs by Developing Other Materials Other materials may offer high mobilities but... ID Id increasing VGS VDS Vgs Vth I D coxWg vinjection(Vgs Vth V ) for (Vgs Vth ) / V 1 where V vinjectionLg / → mobilities above ~ 1000 cm2/V-s of little benefit at 22 nm Lg increased injection velocities are of value... ...but not at sacrifice in density of states Nanopillar and Nanowire Devices Nanopillar devices might have improved 2-D electrostatics ... but only if wire diameter is ~10 nm or less Access resistances are serious issue Capacitances to source-drain pad regions a serious concern III-V Nanowires FETs still must address defect density dielectric-semiconductor interface III-V nanopillar devices experience same DOS, confinement challenges as planar III-V devices Conclusion THz & nm Transistor Electronics is all about the interfaces Bipolar Transistors: P and N ohmic contacts with very low resistivity stability at high current density FETs gate dielectrics contact resistance density of states