GRAMM International Future Energy Challenge ‘07 Versamachine

advertisement

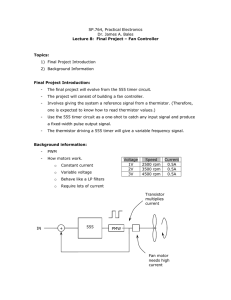

GRAMM International Future Energy Challenge ‘07 Versamachine Geoff Sanders, Richard Tan, Ankit Tripathi, Maung Myat, and Marc Hesse Overview Purpose Specifications System Description System Layout/Breakdown Labor Distribution Future Schedule to meet Marketability/Impacts and Sustainability Challenges Risks and Contingencies Questions/Suggestions and Comments Purpose Electric machine (motor): Works both as a starter (motoring) and an alternator (generator) Target: Electric Car, Hybrid Electric Car Reasons: IFEC ’07 challenge Save Space Decrease Cost Increase Efficiency Specifications Must provide 30 Nm of Torque startup. Must motor up to 3000 rpm in 3-5 seconds Must generate 1 KW of power Must be at least 75% efficient Must use NEMA frame 56, which is less than 7 inches in diameter http://www.leeson.com/ System Description A two pole induction machine (motor) Inverter/Rectifier Motor Drivers Gate Drivers (MOSFET DRIVER) Micro-controller (TI / Freescale) User Interface (using a CAN, RS 232 cable, PC Master) RF/Bluetooth Sensors (flux, torque, Hall, temperature, etc) Power Supply System Layout http://www.freescale.com/webapp/sps/site/overview.jsp?nodeId=02nQXGrrlPglzQMszY Induction Machine (Motor) Squirrel cage induction machine with Variable Frequency (V/f) Control Will work on the principles of 1. Flux weakening/strengthening 2. Pole changing 3. Frequency Change General Torque-Speed Characteristics Torque-Speed curve change from starting point (30Nm) to 750 rpm Torque-Speed curve change from 8 pole (750 rpm) to 4 pole (1500 rpm) Torque-Speed curve change from 4 pole – 1500 rpm to 2250 rpm Torque-Speed curve change from 4 pole – 2250 rpm to 3000 rpm Generalized frequency and speed operation of motor Frequency-time Diagram Speed-time Diagram BLOCK DIAGRAM Converter (Inverter/Rectifier) Converter must fulfill two functions: 1) Inverter operation during starting and motoring up to 3000rpm 2) Rectifier operation during generating mode Inverter PWM Inverter 1) 2) 3) 4) Operates during both motoring and generating modes Converts DC supply voltage to 3 phase AC Provides excitation current to stator windings Additional specifications of the Inverter Input dc voltage: VDC = 200V Frequency range: 10-200 Hz Current at low frequency of 15 Hz: Iline = 30 Apeak Output voltage as high as possible for given input voltage Rectifier Rectifier Operates only during generating Converts AC current to DC in order to charge battery Additional specification of the rectifier Output voltage: VDC = 200V @ 10 ADC maximum or at least deliver 1 kW to the battery at 200V with efficiency of 75% Gate/Motor Drivers Provide fast change in current to drive the gates of all IGBT/MOSFET switches in the converter Sensors, Switches & Power Supply Sensors Operational sensors Hall effect Temperature Position encoders Testing Torque transducer Flux meter Universal Dynamometer Switches winding switches Pole changing N reduction Power Supply 200 V DC Motor Driving Power Converter Motor Current Voltage Sense Current Voltage Sense Receiver DSP Or MicroController ADC Memory Encoder Hall Effect Sensor BLOCK DIAGRAM DSP/Micro-Controller 3 Primary functions Control switching of PWM inverter IGBT/MOSFET switches Control winding switching For pole changing To reduce windings by half during 4 pole operation Interact with user interface to produce desired operation User Interface PC Master Software Serial port connection Later use RF/Bluetooth http://www.freescale.com/files/product/doc/AN1948.pdf PC Master Support Freescale 56F80x 56F82x 56F85x Possibly supported by: MC68HC08 (MC68HC908MR32) MC68HC512 MPC500 PC Master Features Control the motor Start-up/shut-down Speed control Read/change variables Scope slower variables Record fast variables Stimulate variables Send application commands with parameters Display help items (block diagrams, characteristics) Remote control of application through the internet PC Master Windows http://www.freescale.com/files/product/doc/AN1948.pdf Other parts Voltage regulators Resistors, capacitors, and heat sinks Voltage shifters RAM/ROM ADC/DAC RS232 serial port UART Clocks Task Distribution Maung/Richard Part research and ordering Design inverter/rectifier Implement sensor circuits Circuit schematics and PCB design Ankit/Geoff Motor design finalization and ordering User interface/system controller Marc/Geoff User’s Manual Micro-controller coding Technical manual compilation All Documentation Test/debug Wire-wrap prototyping GANTT CHART Budget Category Item Induction Motor Motor/Generator Custom Rotor Fabrication Stator Re-winding Power MOSFETs Motor Controller Gate Drive Board Aluminum Heat Sink Pole Changing Switches Micro-controller and Support System Controller Wireless Communication Various Sensors Flux Meter DC/AC Measurement Switch Testing and Measuring Equipment External Power Plug-in Torque Transducer Torque Sensor Cable TRD-S Position Encoder Other PCB fabrication Voltage regulator/resistors/caps Total Unit Cost $250 $1,000 $500 $20 $20 $50 $5 $500 $200 $100 $380 $40 $30 $1,290 $95 $81.50 $66 $200 Quantity 2 1 1 6 1 1 6 1 1 1 1 1 1 1 1 1 3 1 Total Cost $500 $1,000 $500 $120 $20 $50 $30 $500 $200 $100 $380 $40 $30 $1,290 $95 $82 $198 $200 $5,335 Marketability Almost all motor-vehicle manufacturers in the world can use it as it would Increases overall efficiency of vehicle Decreases overall cost Take up less space Target Manufacturing cost of $100 Possible Patent Challenges, Risks, and Contingencies Challenges This has never been done effectively! What makes us think we will succeed where many have failed? Risks We could quite possibly fail to meet the IFEC specifications with our first (capstone) design. We may be unable to make the machine automatically shift speeds and windings Challenges, Risks, and Contingencies Contingencies For expo we will have a motor controlled with our controller that will run, although it may not meet the requirements dictated by IFEC. If this occurs a permanent magnet rotor will be designed and used in place of the squirrel cage rotor in order to increase torque and efficiency This is beyond the scope of capstone Will be able to run each characteristic for testing using user interface to set frequency and manually switch windings Questions / Suggestions http://www.smartquestion.com/images/sq_image.jpg