Blimpage Critical Design Review

advertisement

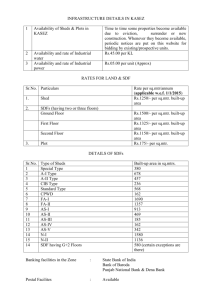

Blimpage Critical Blimpage Team: Daniel McCabe Design Review Nguyen Trinh Joseph Brannan David Wolpoff Philip Grippi System Overview • Modular general-purpose drone controller • Navigation, collision-detection, general motor interfaces, data collection • Zero-impact on system performance – Lightweight, independently powered What is the Blimpage • Composed of six main modules: – – – – – – General-purpose microcontroller network Motor / servo controller Position and heading monitoring Collision-detection / alarm Data collection Off-module communication Functional Block Diagram The Micros MSP 430 F1232 Micro Controllers Key Features: Ultra Low Power: 300 μA (Active) 0.7 μA (Standby) C-Programming Interface Master Functions • • • • • • Arbitrates data transfers on i2c bus Prioritize Data Transfers Passes data among subsystems Handle user-input objectives Coordinate startups and shutdowns Bleating Master State Machine • And Now Something COMPLETELY different. 90 80 70 60 50 40 30 20 10 0 East West North 1st 2nd 3rd 4th Qtr Qtr Qtr Qtr Master State Machine. Take 2 • Init – Initialize all slaves. • Query – Check who has data – Prioritize data • Idle – Handle ‘master’ tasks. • Xfer – Carry out all bus transactions in priority order. Command Set • • • • • Initialization: – From Master: “Are you alive and what is your target type?” – From Slave: “I am target type TARGET.” Query Data: – From Master: “Do you have data?” – From slave: “I have data for TARGET, of priority DATA” Transfer Data: – From Master: “Here is DATA from TARGET” – From slave: “Her is DATA for TARGET” Objective Update: – From Master: “New objective from TARGET is DATA” – From slave: “New objective for TARGET is DATA” Global Abort: – From Master: “halt immediatly” – From Slave: “They sky has fallen! Tell everyone to halt” • • • • • Global Abort: – From Master: “halt immediatly” – From Slave: “They sky has fallen! Tell everyone to halt” Local Abort: – From Slave: “I'm dead, go on without me” Block Transfer: – From Master: “I have DATA words from TARGET” – From slave: “I have DATA words for TARGET” – Master then reads DATA words from slave and writes them to TARGET. Debug Code: – From slave: “Process debug info DATA” Global Reset: – From Master: “Reset yourself, and restart operations.” Modified START: SDA 2 ic STOP: Protocol SDA SCK SCK STT STT ADDRESS CYCLE: i2c Functionality • Fully compatible with standard i2c devices • Added START pin for micro-controllers • 7-bit address size • 8-bit data size • 16-bit word size: for large block transfers Position and Heading Intro • Detects position from digital compassHMR3100 • Detects heading from HMR3100 and two accelerometers-ADXL3100 • Sends direction instruction to Motor Controller Module via I2C bus • Receives collision direction information via I2C bus from Collision Detection Module Position/Heading Block Diagram HMR3100 Pos/Heading uC Master uC - ADXL311 - || || ------------------------------------------------I2C BUS ------------------------------------------------|| || Motor uC Collision uC Digital Compass HMR3100 • • • • • • • 5 degree Heading Accuracy, 0.5 degree Resolution 2-axis Capability Uses 3.3 V DC Single Supply Operation Uses 9600 N.8.1 communication for outputting binary data Delivers output binary data to UART of Positon/Heading uC UART binary data converts into decimal data for position’s degree With output data of ADXL311, sends direction instruction to motor controllers module via I2C bus HMR3100 Time Diagram Continuous Mode: 2 Hz heading queries at 9600 baud rate Calibration Mode: Accelerometer ADXL311 • • • • • • • Dual-axis accelerometer Uses 5-V single-supply operation with 0.4 mA typical consumption Uses Internal Low Pass Filter with bandwidth of 10 Hz Based on blimp’s average acceleration of 5 (cm/s)/s, 50 mV (VPP) variation of output voltage from ADXL311 Put the variation of output voltage through an external LPF (MAX7490) of 2 Hz Then scale the variation of output voltage 7 times bigger from TLV2370 Op-amp Then put the amplified variation output voltage into the ADC10 in Pos/Heading uC ADXL3100 and Logic Block Diagram ADXL311 MAX7490 --- TLV2370 ------ LP Filter Pos/Heading uC ----- ADC10 ADXL311 and HMR3100 Schematic Motor Control Intro • Motor module uC receives direction instruction over I2C bus from Position and Heading Module • 4 uC logic level outputs are optically isolated from H-Bridges – control 2 motors’ behavior • uC logic level PWM signal is optically isolated from Servo • Two fans operate in forward or reverse • Servo controls position of fans (up or straight) • 3 V battery powers motors and servo Motor Control Block Diagram Motor uC -------------------------| | x2 H-Bridge Motor x4 optical | | Drivers isolators | | ----- ---| ----- <------- ----- ----- | | | PWM -------- signal optical isolator ^ | Micro Servo | 3 V Battery ----- || <---| ----------------------| Motor Control Schematic (A High - B Low) Reverse (A Low - B High) Forward (Both Low or Both High) Stop uC MTR header P3.4-7 L MTR CNTRL B P3.7 L MTR CNTRL A P3.6 R MTR CNTRL B P3.5 R MTR CNTRL A P3.4 R_MTR_CNTRL_B R_MTR_CNTRL_A L_MTR_CNTRL_A J26 HEADER 4 Servo CNTRL header P2.4 uC_GND 1 uC GND J27 HEADER 1 L_MTR_CNTRL_B 1 SERVO CNTRL P2.4 J28 HEADER 1 uC GND header uC_SERVO_CNTRL 1 2 3 4 J29 Q1 MOSFET_I_EP_DGS Q2 MOSFET_I_EP_DGS Date: Document Number 1 Wednesday, September 29, 2004 Rev 2 Sheet 9 of 10 MTR BATT header HEADER 2 4 1 1 4 R_MTR_B_BRIDGE R19 ??? R MOTOR Q6 MOSFET_EN_DGS Q8 MOSFET_EN_DGS R26 1 50 1035 0 1 1/20W /2 0W R27 3 2 2 U12 PC357N 3 R_MTR_A_BRIDGE 3 2 2 Motor Control Board Si ze A 4 1 1 4 3 Ti tle R25 1500 1/20W 1035 1/20W R24 U11 PC357N 10uF U14 SERVO_DIODE1 R22 R23 1 50 1035 0 1 1/20W /2 0W C20 R_MTR_DIODE2 Q7 MOSFET_EN_DGS 1 2 J30 1 2 MOTOR_SRVO_CNTRL 3 Servo header R_MTR_B_OPTO Q5 MOSFET_EN_DGS R_MTR_A_OPTO L MOTOR U10 PC357N R_MTR_DIODE1 R18 ??? L_MTR_B_BRIDGE U13 U9 PC357N L_MTR_DIODE2 L_MTR_A_BRIDGE 1 4 3 10uF L_MTR_B_OPTO L_MTR_A_OPTO L_MTR_DIODE1 R20 R21 1500 1/20W 1035 1/20W C19 L_ MTR 2 Q4 MOSFET_I_EP_DGS R_MTR Q3 MOSFET_I_EP_DGS U8 PC357N MOTOR_GND MOTOR_VCC R28 1 03 5 1 /2 R29 0W 1 50 0 1 /2 0W HEADER 3 Motor Control State Machine Collision Detection Intro • Collision module uC cycles through 6 channels on Mux/Demux using binary addressing • Vcc enable signal multiplexed to 6 Voltage Regulators which power 6 distance sensors (limits power consumption) • Distance sensor outputs de-multiplexed into LPF • LPF output sampled by uC’s ADC10 • Collision status register and priority flag updated • Collision direction information passed over I2C bus to positioning and heading module • 5 V regulated voltage powers module components | Collision Detection Block Diagram | -------------------------------- | Mux/Demux >---| ---Vcc | 6x Voltage Regulators --< <-------| -< | <-------| | ^ | ^^ | | Channel select -------------------| | >---- -- 6x Collision Sensors power output LP Filter Collision uC Slave Collision Detection Schematic U19 1 C32 2 OUT CAP POL 3 NC 4 GND NC4 + Opto uC J37header J36 uC A0 uC A1 uC A2 SENSE 1 2 3 4 1 2 OPTO_V5 OPTO_GND U20 IN NC7 NC6 SHDN 8 7 6 5 C26 CAP NP 1 C34 2 OUT CAP POL 3 NC 4 GND NC4 + LT1121-3.3 R34 10k U18 IN NC7 NC6 SHDN 8 7 6 5 C28 CAP NP + LT1121-3.3 R35 10k HEADER J38 2 1 IN NC7 NC6 SHDN + OPTO_15K_CLK C33 1 CAP 2POLOUT 3 NC 4 GND NC4 D1 HEADER 1 IN NC7 NC6 SHDN 8 7 6 5 C27 CAP NP + 1 C35 2 OUT CAP POL 3 NC 4 GND NC4 U23 IN NC7 NC6 SHDN 8 7 6 5 C29 CAP NP + 1 C37 2 OUT CAP POL 3 NC 4 GND NC4 LT1121-3.3 Opto Sensor header LT1121-3.3 IN NC7 NC6 SHDN LT1121-3.3 R39 10k R38 10k R37 3.3V Zener J32 10k OPTO_VCC1 OPTO_VCC2 OPTO_VCC3 OPTO_VCC4 OPTO_VCC5 OPTO_VCC6 2nd Order LPF Filter 2 2 4 6 8 10 12 14 1 3 5 7 9 11 13 U17 LPA LPB BPA BPB NA/HPA NB/HPB INVA INVB SA SB SHDN COM GND EXTCLK VDD CLK 16 15 14 13 12 11 10 9 HEADER 7X2 U15 MUX/DEMUX MAX7490_QSOP R30 10K R31 10K C21 0.1uF C23 0.1uF OPTO_INVA O PTO _S 5B O PTO _S 6B O PTO _S 4B C22 0.1uF 1 2 3 4 5 6 7 8 C30 CAP NP U21 R33 10k OPTO_LPA OPTO_BPA OPTO_HPA 8 7 6 5 LT1121-3.3 R36 10k U22 HEADER 4 1 C36 2 OUT CAP POL 3 NC 4 GND NC4 C24 0.1uF R32 10K OPTO_S2B OPTO_S1B 1 2 VDD 3 DB 4 RS 5 S8B 6 S7B 7 S6B 8 S5B OPTO_S3B 9 S4B 10 S3B 11 S2B 12 S1B 13 GND 14 WR NC DA VSS S8A S7A S6A S5A S4A S3A S2A S1A EN A0 A1 A2 28 27 26 25 24 23 22 21 20 19 18 17 16 15 ADG527AKR_28L_SOIC OPTO_DA OPTO_RX1 OPTO_RX2 OPTO_RX3 OPTO_RX4 OPTO_RX5 OPTO_RX6 8 7 6 5 C31 CAP NP Collision Detection State Machine Module State Machine Communications • Enables communication with “outside” world. • RS232 protocol, via MAX3233. • Reads data from Master and outputs it to host PC for interpretation. • Reads data from host and outputs it to Master. • Enables debugging, etc. Data Acquisition • Servo Motorized ‘message’ deployment • Delivers messages discreetly and accurately. • Camera scrapped for blimp due to weight constraints. • (Time Permitting) JamCam camera will be deployed on R/C Car – RS232 communication – Documented protocol • (Time Permitting) Audio/Temperature/Humidity Sensors Parts List • Motor Control – – – – – • Collision Detection – – – – – • 1 ADG527A Analog Devices Multiplexer 1 MAX7490 Maxim Dual Universal Switched Capacitor Filter 6 LT1121-3.3 Linear Technology Micropower Low Dropout Regulators with Shutdown 6 GP2D12 Sharpe General Purpose Type Distance Measuring Sensors 1 Diodes Incorporated Surface Mount 3.3V Zener Diode Positioning and Heading – – • 4 Zetex 20V N-Channel MOSFETs 4 Zetex 20V P-Channel MOSFETs 5 NEC High Isolation Voltage SOP Photocouplers 2 small DC fan motors 1 4.7 g Cirrus Micro Servo 1 HMR3100 Honeywell Digital Compass Solution 1 ADXL311 Analog Devices Low Cost, Ultra-compact +-2g Dual Axis Accelerometer 1 MAX7490 Maxim Dual Universal Switched Capacitor Filter Parts List 2 • Master – 6 MSP430F1232 Microcontrollers – 1 Clock in a Box – 1 TPS61100 Switching boost converter • Communal – Various Resistors – Various Capacitors – Various Inductors • • Assorted PCB’s Blimp Costs (The Big Stuff) • • • • • • • • • Microcontrollers: $40.00 x 3 revisions = $120.00 Compass: $100.00 Infrared Rangefinders: $60.00 PCB’s $80 x 3 revisions = $240.00 Blimp $100.00 Programming tool: $200.00 Assorted DigiKey purchases: $300.00 Total Costs: $1120.00 Sanity: Priceless (but absent) ROI • Projected Development Cost: $1200.00 • Projected Production Cost at Volume: $500.00 • Projected Cost to consumer: $5000.00 (including support) • Projected Sales: 10,000 units. • ROI: $45,000,000 Updated Schedule Division of Labor • Master / Slave system (i2c) – Dave, Dan • Communication Module – Dave, Phil • Motor Control, Collision Detection – Joe • Position / Heading – Nguyen • Data Collection Module – Phil, Dan Division of Labor • Group Tasks – Documentation – PCB Population – Systems Integration – Review and Testing Milestone 1 • Airborne Blimp • Final Testing – Collision – Motor • Basic functionality – Pos/Head – Comms – Data Acq. Milestone 2 • Significant Blimp Maneuverability • Basic testing on R/C Car • All modules completed and in testing • Basic user interface (for destination data) Expo • All systems fully implemented and tested • Documentation Complete – User’s Manual – Technical Manual • Happy Jack