Campus Lighting Retrofits University of Illinois at Urbana-Champaign in conjunction with ICECF

advertisement

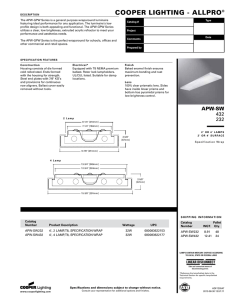

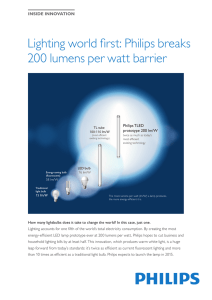

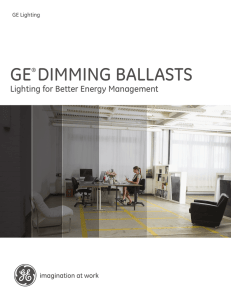

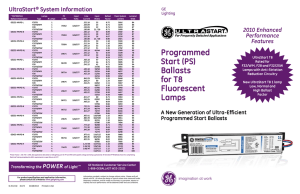

Campus Lighting Retrofits University of Illinois at Urbana-Champaign in conjunction with ICECF Eva Sweeney, P.E., LC, LEED© AP ISTC Sustainability Series Tuesday, December 2, 2008 December 2, 2008 UIUC Sustainability Goals • Energy reduction policy – 10% in 3 years • Signatory to American College and University Presidents Climate Commitment • Required to develop plan to reach carbon neutrality • New construction must be LEED Silver Certified at a minimum. • Business Instructional Facility • Lincoln Hall Renovation • Huff Hall Addition • NCSA Petascale Computing • Illinois Fire Service Institute • Several aspects of sustainability in Campus Strategic Plan • Need for comprehensive sustainability policy 12/2/2008 Urbana Campus Energy Costs FY 2003: FY 2004: FY 2005: FY 2006: FY2007: FY2008: FY2009? 12/2/2008 $26,612,000 $35,684,000 $52,282,000 $70,778,000 $58,830,000 $78,449,000 (+34%) (+47%) (+35%) (-17%) (+33%) Big Ten Energy Usage, 2007 kwh/GSF 30.00 kwh per GSF 25.00 20.00 15.00 10.00 5.00 0.00 wa Io io Oh e at t S n Illi ois e sin at t n S o is c nn e W P e an du g r i Pu ich M Institution 12/2/2008 a te ian ta d S n I an g i ich M Other Motivating Factors • • • • • • • 12/2/2008 Large number of existing facilities--700 locations Utility fund shortfalls $400M deferred maintenance backlog Need for an “across the board” fix Need “boots on the ground” quickly Limited staff resources Cost! 12/2/2008 Why Lighting? • • • • • • Easy and Non-invasive Upgrades increase quality and productivity Highly visible to building occupants Improved reliability & maintainability 2-5 year payback Low-hanging fruit Environmental Impact 12/2/2008 Illinois Clean Energy Community Foundation • http://www.illinoiscleanenergy.org • Four projects currently at UIUC • • • • 12/2/2008 Biomass (Miscanthus) Power Plant ($825K) Wind Turbine ($2.0M) Campus Lighting Retrofits ($1.18M) Business Instructional Facility ($75K) ICECF Energy Efficient Lighting Upgrade Grant Program • • • • • 12/2/2008 Incentive based on demand reduction (60¢/watt) Applicable to new or retrofit fixtures Fluorescent, HID, LED exit signs, controls Must apply & be pre-approved Reimbursement after project completion DCEO Public Sector Electric Efficiency Program • http://www.illinoisenergy.org • Incentives based on Prescriptive methods • Many specific upgrades & replacements • High-Performance T8: $7.00/lamp • Custom incentive option available (7¢/kWH) • Must apply & be pre-approved • Reimbursement after project completion 12/2/2008 UIUC Campus Lighting Retrofit data • • • • • • 12/2/2008 44 buildings representing ~7M sq.ft. Highest energy users Linear fluorescent T12 to High-Performance T8 Estimated total cost $4.2 million Project budget $2.8 million ICECF commitment $1.18 million UIUC Campus Lighting Retrofit data • • • • 12/2/2008 80,233 light fixtures 2.9 MW reduction ~$900,000 annual cost savings (12 hr/day) 12.8 million kWh saved per year 12/2/2008 Building Audit Spreadsheet 12/2/2008 Technical Considerations • Lamp: lumens, color, life, warranty • Ballast: input watts, ballast factor, instant start vs. rapid start • “High Performance” T8 system ≥ 90 LPW • Luminaire: Lens, Reflector, Environment • 4-lamp to 2-lamp reflector kits save 75% • Controls 12/2/2008 Other Lighting Upgrade Programs • • • • • New construction / LEED Remodeling CFL replacement as routine maintenance LED Exit signs (DCEO) Targeted applications & individual projects • Gymnasiums • Pools / Ice Rink • Warehouses Lighting Upgrades: A Guide for Facility Managers (Damon Wood, 2004) 12/2/2008 Typical Efficacy for Various Light Sources 12/2/2008 Color Temperature 12/2/2008 Color Spectrum - Sunlight 12/2/2008 Color Spectrum 12/2/2008 Color Spectrum 12/2/2008 Fluorescent Lamp Data Lamp Manufacturer Philips T12 "Cool White" Part # F34/CW/RS/EW/ALTO Philips Universal (standard T8) Philips Plus (long life) Philips Advantage Philips Energy Advantage Philips Energy Advantage Sylvania Octron F32T8/TL835/ALTO F32T8/TL835/PLUS/ALTO F32T8/ADV835/ALTO F32T8/ADV835/XEW/LL/ALTO 25 F32T8/ADV835/EW/LL/ALTO 30 FO32/835 XPS ECO 12/2/2008 Initial Mean Life @ Lumens Lumens Watts 3hr/start CRI 2650 2300 34 20000 62 2950 2950 3100 2400 2850 3100 2800 2800 2950 2280 2700 2945 32 32 32 25 30 32 20,000 30,000 30,000 24,000 24,000 30,000 85 85 85 85 85 85 Lamp Lumen Maintenance 12/2/2008 Ballast Data 12/2/2008 Execution Method • • • • • • 12/2/2008 No A/E needed In-house audits & inventories Direct materials purchase--no contractor markup Labor-only contract hire (specialty firms) Multiple crews, one per building Staff electricians where practical Side Benefits • • • • • • • Improved quality of light (CRI) Eliminate magnetic ballast flicker Improved lumen maintenance (quantity) Occupants report very positive response Remove PCB-containing and high-mercury materials Less trash and waste than new fixture purchase Lamp/ballast warranty & reduced maintenance needs Lessons Learned (so far…) • • • • • • 12/2/2008 Consider sensitive areas & need for shift work Contact department staff prior to start date Have a recycling plan before you start! Identify a secure lay-down area for materials Labor costs on per-fixture basis Keep room-by-room “as built” records Triple Bottom Line 12/2/2008 Discussion 12/2/2008 Thank you! Eva Sweeney, P.E., LC, LEED© AP UIUC Facilities & Services Engineering Division eva@illinois.edu (217) 333-2271 http://www.fs.uiuc.edu/ http://www.energymanagement.uiuc.edu/ 11/18/2008