Lecture 39

advertisement

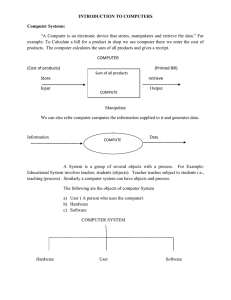

Lecture #39: Magnetic memory storage • Last lecture: – Dynamic Ram – E2 memory • This lecture: – Future memory technologies – Magnetic memory devices – Hard drives, tape drives, Optical disks 12/3/2004 EE 42 fall 2004 lecture 39 1 Future memory technologies • Memory speed, cost and density are among the chief bottlenecks on compute power. • Increasing CPU clock rates have only resulted in small increases in speed of operation due to the memory system and mass storage (disk) I/O bottleneck. • A significant amount of research effort is directed to improving memory technology 12/3/2004 EE 42 fall 2004 lecture 39 2 Advanced memory technologies • Ferroelectric Random Access Memory (FRAMs) • Magnetoresistive Random Access Memories (MRAMs) – Tunneling Magnetic Junction RAM (TMJ-RAM): • Experimental Memories – Quantum-Mechanical Switch Memories – Single Electron Memory 12/3/2004 EE 42 fall 2004 lecture 39 3 FRAM 12/3/2004 EE 42 fall 2004 lecture 39 4 Ferroelectric material 12/3/2004 EE 42 fall 2004 lecture 39 5 TMJ-Ram • Tunneling Magnetic Junction RAM (TMJ-RAM): – Speed of SRAM, density of DRAM, nonvolatile (no refresh) – “Spintronics” (electron spin affects transport) – Same technology used in the read heads of high-density disk-drives: Giant magnetoresistive effect 12/3/2004 EE 42 fall 2004 lecture 39 6 Tunneling Magnetic Junction 12/3/2004 EE 42 fall 2004 lecture 39 7 Mass Storage • For storage of larger amounts of information, magnetic film storage dominates • Information is stored in the form of magnetic domains in a Ferromagnetic film, written or read by a moving head 12/3/2004 EE 42 fall 2004 lecture 39 8 Magnetic domains • Ferromagnetic materials have a quantum interaction which makes adjacent atoms line up their magnetic field in the same direction N N N N N N N N N N N N N S S S S S S S S S S S S S 12/3/2004 EE 42 fall 2004 lecture 39 9 Magnetic interactions • On a larger scale, magnets feel a force to line up in opposing directions, reducing the total magnetic field. • For example, if you try to hold two magnets next to each other, there will be a strong force which will rotate them to the configuration: 12/3/2004 N S S N EE 42 fall 2004 lecture 39 10 Magnetic domains • If you look microscopically at a magnetic material, it forms domains, or areas where the magnetic poles are aligned, adjacent to regions where the magnetization is in the opposite direction. • In a thin film, the domains look like this: 12/3/2004 EE 42 fall 2004 lecture 39 11 Moving magnetic domains • Magnetic domains don’t move easily at room temperature, but they can be changed by applying magnetic fields. • If most of the domains in a material are aligned in one direction, we call it a permanent magnet. • The core of an inductor or a transformer is made of a ferromagnetic material where the domains line up easily, and then randomize again when the external field is turned off 12/3/2004 EE 42 fall 2004 lecture 39 12 Writing to magnetic media • Magnetic storage material is comprised of a thin film of ferromagnetic material which is relatively magnetically hard. • A small electromagnet is used to create domains oriented in a particular direction 12/3/2004 EE 42 fall 2004 lecture 39 13 Reading magnetic material • Conventional read heads for magnetic media work just like the secondary winding of a transformer. • Instead of a primary winding changing the magnetic field through a coil, and thus changing the voltage, the magnetic media is moved next to the read coil. • This produces a voltage across the read coil which can be amplified and translated as data 12/3/2004 EE 42 fall 2004 lecture 39 14 Transformer + + Transformer V1 V2 - - 12/3/2004 EE 42 fall 2004 lecture 39 V1 N1 V2 N 2 15 Storage density for DRAM vs DISK 9 v. 22 Mb/si 45% 40% 35% 30% 25% 20% 15% 470 v. 3000 Mb/si 10% 5% 0.2 v. 1.7 Mb/si 0% 1974 1980 1986 1992 1998 source: New York Times, 2/23/98, page C3, “Makers of disk drives crowd even more data into even smaller spaces” 12/3/2004 EE 42 fall 2004 lecture 39 16 SRAM vs. DRAM vs. Disk – Access latencies: • DRAM ~10X slower than SRAM – Successive bytes 4x faster than first byte for DRAM • Disk ~100,000X slower than DRAM – First byte is ~100,000X slower than successive bytes on disk 12/3/2004 EE 42 fall 2004 lecture 39 17 Nano-layered Disk Heads • Recent large improvement in Disk capacity comes from “Giant Magneto-Resistive effect” (GMR) read heads Coil for writing 12/3/2004 EE 42 fall 2004 lecture 39 18 Typical Numbers of a Magnetic Disk Track Sector • Rotational Latency: – Most disks rotate at 3,600 to 15,000 RPM – Approximately 16 ms to 4 ms per revolution, respectively – An average latency to the desired information is halfway around the disk: 8 ms at 3600 RPM, 2 ms at 15,000 RPM Cylinder Head Platter • Transfer Time is a function of : – – – – – Transfer size (usually a sector): 1 KB / sector Rotation speed: 3600 RPM to 10000 RPM Recording density: bits per inch on a track Diameter typical diameter ranges from 2.5 to 5.25 in Typical values: 2 to 80 MB per second 12/3/2004 EE 42 fall 2004 lecture 39 19 Disk Device Terminology Arm Head Inner Outer Sector Track Track Platter Actuator • Several platters, with information recorded magnetically on both surfaces (usually) • Bits recorded in tracks, which in turn divided into sectors (e.g., 512 Bytes) • Actuator moves head (end of arm,1/surface) over track (“seek”), select surface, wait for sector rotate under head, then read or write – “Cylinder”: all tracks under heads 12/3/2004 EE 42 fall 2004 lecture 39 20 Photo of Disk Head, Arm, Actuator Spindle Arm Head Actuator Platters (12) 12/3/2004 EE 42 fall 2004 lecture 39 21 Disk Device Performance Outer Track Inner Sector Head Arm Controller Spindle Track Platter Actuator • Disk Latency = Seek Time + Rotation Time + Transfer Time + Controller Overhead • Seek Time? depends no. tracks move arm, seek speed of disk • Rotation Time? depends on speed disk rotates, how far sector is from head • Transfer Time? depends on data rate (bandwidth) of disk (bit density), size of request 12/3/2004 EE 42 fall 2004 lecture 39 22 Disk Device Performance • Average distance sector from head? • 1/2 time of a rotation –7200 Revolutions Per Minute 120 Rev/sec –1 revolution = 1/120 sec 8.33 milliseconds –1/2 rotation (revolution) 4.16 ms • Average no. tracks move arm? –Sum all possible seek distances from all possible tracks / # possible • Assumes average seek distance is random –Disk industry standard benchmark 12/3/2004 EE 42 fall 2004 lecture 39 23 Devices: Magnetic Disks • Purpose: Track Sector – Long-term, nonvolatile storage – Large, inexpensive, slow level in the storage hierarchy • Characteristics: Cylinder – Seek Time (~8 ms avg) • • • 7200 RPM = 120 RPS => 8 ms per rev ave rot. latency = 4 ms 128 sectors per track => 0.25 ms per sector 1 KB per sector => 16 MB / s Transfer rate – – 10-30 MByte/sec Blocks • Capacity – – Gigabytes Quadruples every 3 years (aerodynamics) 12/3/2004 Head positional latency rotational latency Platter Response time = Queue + Controller + Seek + Rot + Xfer EE 42 fall 2004 lecture 39 Service time 24 Areal Density 1973 1979 1989 1997 2000 2004 Areal Density 1.7 1000000 7.7 100000 63 3090 10000 17100 1000 130000 Areal Density Year 100 10 1 1970 1980 1990 2000 2010 Year –Bits per unit area changed slope from 30%/yr to 60%/yr about 1991 12/3/2004 EE 42 fall 2004 lecture 39 25 Technology Trends Disk Capacity now doubles every 12 months; before 1990 every 36 motnhs • Today: Processing Power Doubles Every 18 months • Today: Memory Size Doubles Every 18-24 months(4X/3yr) The I/O GAP • Today: Disk Capacity Doubles Every 12-18 months • Disk Positioning Rate (Seek + Rotate) Doubles Every Ten Years! 12/3/2004 EE 42 fall 2004 lecture 39 26