Earth Pressure on Retaining Walls: Limited Space Analysis

advertisement

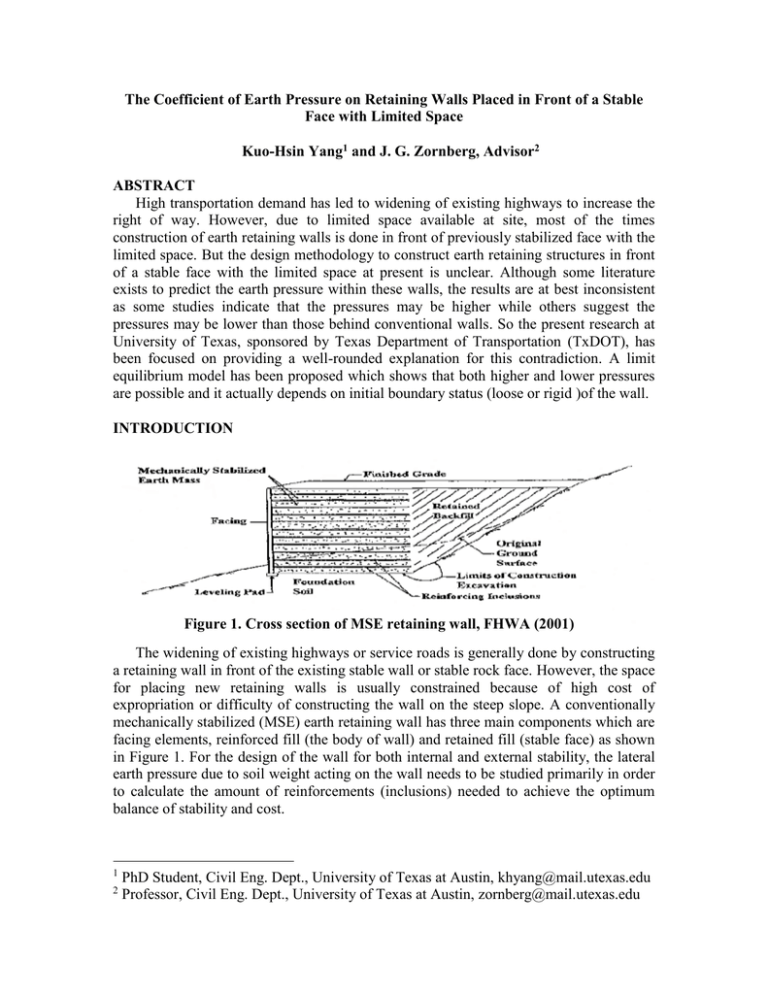

The Coefficient of Earth Pressure on Retaining Walls Placed in Front of a Stable Face with Limited Space Kuo-Hsin Yang1 and J. G. Zornberg, Advisor2 ABSTRACT High transportation demand has led to widening of existing highways to increase the right of way. However, due to limited space available at site, most of the times construction of earth retaining walls is done in front of previously stabilized face with the limited space. But the design methodology to construct earth retaining structures in front of a stable face with the limited space at present is unclear. Although some literature exists to predict the earth pressure within these walls, the results are at best inconsistent as some studies indicate that the pressures may be higher while others suggest the pressures may be lower than those behind conventional walls. So the present research at University of Texas, sponsored by Texas Department of Transportation (TxDOT), has been focused on providing a well-rounded explanation for this contradiction. A limit equilibrium model has been proposed which shows that both higher and lower pressures are possible and it actually depends on initial boundary status (loose or rigid )of the wall. INTRODUCTION Figure 1. Cross section of MSE retaining wall, FHWA (2001) The widening of existing highways or service roads is generally done by constructing a retaining wall in front of the existing stable wall or stable rock face. However, the space for placing new retaining walls is usually constrained because of high cost of expropriation or difficulty of constructing the wall on the steep slope. A conventionally mechanically stabilized (MSE) earth retaining wall has three main components which are facing elements, reinforced fill (the body of wall) and retained fill (stable face) as shown in Figure 1. For the design of the wall for both internal and external stability, the lateral earth pressure due to soil weight acting on the wall needs to be studied primarily in order to calculate the amount of reinforcements (inclusions) needed to achieve the optimum balance of stability and cost. 1 2 PhD Student, Civil Eng. Dept., University of Texas at Austin, khyang@mail.utexas.edu Professor, Civil Eng. Dept., University of Texas at Austin, zornberg@mail.utexas.edu For the conventional walls with sufficient backfill space as to fully develop the linear failure surface, Rankine theory accurately predicts the earth pressure. The instrumentation records from full-scale retaining walls have indicated that earth pressures and failure surface predicted by Rankine active earth pressure theory represent the test observations. However, for the case of walls with constrained space where the linear failure surface is not fully developed, Rankine’s theory is inappropriate to calculate the earth pressures. Leshchinsky (2003) and Lawson (2005) performed a series of limit equilibrium and finite different analyses on MSE walls with limited space for the backfill. They concluded that the earth pressures increased with the increase in the wall width to length ratio, L/H, and reached maximum value equal to the coefficient of active earth pressure, Ka, for the given soil which was same as width wide enough to fully develop the linear failure surface. As opposed to this, Frydman (1987) proclaimed that the earth pressures in the walls with limited spaces were larger than predicted by Rankine active earth pressure theory. It is worthy to mention that the earth pressure varies with not only L/H but also the location of interest. For example, the earth pressure at wall face, along the failure surface, and at interface between wall and stable face are all different. It should be very careful and clear when try to compare the earth pressure in different papers. To solve this conflict the best approach would be to carry out field measurements of test sections. So attempts were made by Turner (2005) to measure the displacement data of the wall with limited space but no force and earth pressure data was computed. Ryan (2003) conducted the laboratory testing using centrifuge on MSE-shoring composite walls and, once again, stains were focused rather than stress distributions. In next section, a limit equilibrium model, based on the design guideline (FHWA, 2001),was proposed to account for in this study to provide a well-rounded explanation for current contradiction. LIMIT EQUILIBRIUM MODEL Fig2. Hodograph of Force Equilibrium The proposed limit equilibrium model is based on the static approach, which leads to lower bound solution. The 2-D hodograph with the geometry of a bilinear failure surface is shown in the Fig. 2. P is the stabilizing force, W is the wall weight, R is the resistant force along the failure surface, Pb is the reaction force from stable face to the backside of the wall, L, H is the width and height of the wall, H’ is the intact length between stable face and the backside of the wall, θ is the angle between failure surface and horizontal ground, is the soil friction angle, and δ is the interface friction angle varied with the different types of stable faces. The reaction force, Pb, from the stable face acting on the backside of the wall was computed using equation 1: Pb= 0.5 Kb γ H’2 (1) The coefficient of backside reaction pressure, Kb was computed using following assumptions. Kb was assumed equal to the coefficient of Rankine’s active earth pressure, Ka, if the wall had a loose boundary like a yielding face or wrap-round face that allowed development of enough deformation to reach active state, used extensible materials like geosynthetics or polymers as the reinforcements, the working stresses in the wall were near the failure stresses. On the other hand, Kb was assumed equal to the coefficient of atrest earth pressure, Ko, if the wall had a rigid boundary like an unyielding face that did not develop any deformation due to the soil earth pressure, used inextensible materials like metallic strip as the reinforcements, soil mass was anchored or wall was under working stress conditions far away from failure stress conditions. Knowing Pb for a given wall with L/H, two unknown, P and R, can be found by assigning a series of θ and solving the equations of horizontal and vertical force balance. Then, the coefficient of earth pressure at wall face, K, can be obtained from the maximum P in each case of given L/H. RESULTS AND ANALYSIS Ko Rigid Boundary 0.5 0.4 Ka Loose Initial Boundary 0.3 0.2 Steel (Kb=Ko) 2 K =P/0.5γ H (Coefficent of Earth Pressure at Front Face of the Wall ) 0.6 Concrete (Kb=Ko) Soil (Kb=Ko) 0.1 Steel (Kb=Ka) Concrete (Kb=Ka) Soil (Kb=Ka) (Lawson 2005) 0 0.1 0.2 0.3 0.4 0.5 0.6 L/H Figure 3. Coefficient of Lateral Earth Pressure Varying with the Width and Height Ratio under Two Different Boundaries Conditions An earth retaining wall with backfill friction angle of 30o is simulated. The values of coefficient of earth pressure at the wall face, K obtained for various L/H are as shown in Figure 3. The comparison was also made with three materials commonly used as a stable facing, i.e. steel, concrete and soil, to observe the effect of δ on the K. Further, the values predicted by Lawson’s model were plotted for comparison. For loose initial boundary condition, the coefficient of earth pressure increased with increasing L/H, and reached the maximum value, Ka, when the width was wide enough for Rankine’s active failure surface to develop fully( it is so the case of conventional wall without limited space). The proposed model showed the same trend as predicted by Lawson’s model but magnitudes were lower for a given L/H. The stable face made of soil material having highest δ showed the lowest K at the same L/H. This was attributed to the friction at interface between wall and stable face which provided upward vertical shear resistance and caused reduction in the vertical and lateral stress in soil. For the rigid initial boundary condition, K decreased with the increase in L/H, and, once again, reached the minimum value of Ka when the linear failure surface can be developed through out the entire soil mass. In general, although the trends in two initial conditions are opposite, they both converge to the Ka when the effect of boundary no longer exists. DISCUSSION AND CONCLUSIONS A limit equilibrium model has been proposed to account for the earth pressure acting on the retaining wall with the limited space built in front of the already existing stable facing. The model predicts the earth pressure accounting for two opposite trends. The pressures higher and lower than Rankine’s active earth pressure are relied on the interpretation of the initial loose or rigid boundary status. Future research is geared toward using centrifuge test data to verify the proposed model and compare with already existing models. The stress-deformation analyses by finite element method (FEM) would be studied to predict accurately the phenomenon of actual deformations and stiffness in wall system and how they may affect the stress distribution in soil. The ultimate objective of this research is to develop design guidelines for such composite walls. REFERENCE Elias, Victor, Christopher, Barry R, and Berg, Ryan R. (2001), "Mechanically Stabilized Earth Walls and Reinforced Soil Slopes Design and Construction Guidelines," Report No. FHWA-NHI00-043, National Highway Institute, Federal Highway Administration, Washington, D.C., March. Frydman, Sam and Keissar, Israel (1987), "Earth pressure on retaining walls near rock faces," Journal of Geotechnical Engineering, ASCE, Vol. 113, No. 6, June, pp. 586-599. Lawson, C. R., and Yee, T. W. (2005), "Reinforced soil retaining walls with constrained reinforced fill zones," Proceedings, Geo-Frontiers 2005, ASCE Geo-Institute Conference. Leshchinsky, Dov, and Hu, Yuhui (2003), "Design implications of limited reinforced zone space in SRW's," Proceedings of the 17th GRI Conference on Hot Topics in Turner, John P. and Jensen, Wayne G. (2005). "Landslide stabilization using soil nail and mechanically stabilized earth walls: case study”, Journal of Geotechnical and Geoenvironmental Engineering, ASCE, Vol. 131, No. 2, Feb., pp. 141-150. Woodruff, Ryan (2003), "Centrifuge modeling of MSE-shoring composite walls," Thesis submitted to the faculty of the Graduate School of the University of Colorado in partial fulfillment of the requirements for the Master of Science degree, Department of Civil Engineering, Boulder.