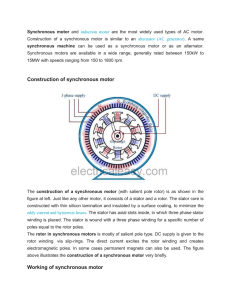

Hysteresis Motors • Stator • Rotor – same as for induction

advertisement

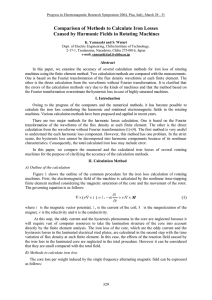

Hysteresis Motors • Stator – same as for induction motor • Rotor Smooth cylinder Principle of Operation Stator Flux establishes these magnetic poles Rotor poles “induced” by Stator Flux Spin the stator poles with the rotor blocked Rotor poles follow the rotating flux, but lag behind by angle δh Stator poles moving CCW Spin the stator poles with the rotor blocked If the rotor is released, it will accelerate to synchronous speed Hysteresis Power Loss, Ph Ph kh f r B n max where fr = frequency of flux reversal in the rotor (Hz) Bmax = maximum value of flux density in the air gap (T) Ph = heat-power loss due to hysteresis (W) kh = constant Mechanical Power developed 1 s Pmech Ph s n Ph kh f Bmax Th nr n 1 s kh f Bmax 5252 s nr ns (1 s ) f r sf s Mechanical Power Developed (cont) n 5252kh f s Bmax Th ns 120 f s ns P n 5252kh Bmax Independent of frequency Th and speed! 120 P Hysteresis Motor at Synchronous Speed No load and negligible rotational losses Induced rotor magnets remain locked with the rotating poles produced by the stator Hysteresis Motor at Synchronous Speed Apply a step increase in shaft load. The rotor slows down and the induced rotor magnets lag the rotating poles of the stator by an angle δmag . The rotor returns to synchronous speed at the new torque angle. Hysteresis Motor at Synchronous Speed Tmag sin( mag ) Tmagmax occurs @ mag 90 If shaft load causes δmag>90°, the rotor pulls out if synchronism, the magnet torque drops to zero, and the machine develops hysteresis torque. This torque is not sufficient to carry the load. Torque-Speed Characteristic Constant Hysteresis Torque allows the motor to synchronize any load it can accelerate “Normal” Operating Range