4010Exclusively/Workbook/DryLabCornSyrupViscosity/Dry lab corn syrup viscosity.docx

advertisement

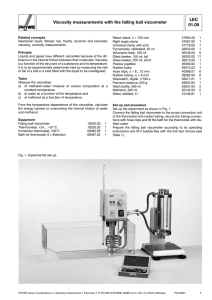

Dry lab corn syrup viscosity Sadly, we did not do much with cone-and-plate viscosity this year. You can read about it in the HowTo guide for our lovely, reliable Wells-Brookfield viscometer (http://macro.lsu.edu/howto/WELBROOK.DOC). The device is simplicity itself: a shallow metal cone rotates at a steady speed (given in rotations per minute, or RPM) above a flat metal plate. A fluid situated in the gap provides viscous drag. The torque required to rotate the cone at a certain rate is measured and displayed as a digital signal from 0 to 100. To convert this to viscosity, one multiplies by what the instrument manual calls the RANGE parameter. Here are some results on corn syrup: RPM 6 3 1.5 0.6 0.3 1. 2. 3. 4. 5. 6. 7. ShearRate Range Trial 1 Trial 2 Trial 3 Trial 4 Trial 5 45 51.4 59.4 59.1 64.6 64.5 61.9 22.5 102.8 36.2 36 31.6 31.8 33.9 11.25 205.6 19.8 19.7 15.2 14.7 14.75 4.5 514 8.3 6.9 9.5 4.9 7.4 2.25 1028 4.3 3.6 3.5 3.4 3.7 You are to determine the apparent viscosity by multiplying the average of the five trials into the range parameter. Also compute the standard deviation (function STDEV in Excel is one way to do this). Plot the apparent viscosity (and error bars) against shear rate. What is the zero-shear-rate viscosity and its uncertainty? Repeat the exercise after adding an offset of 3 units to your average (this simulates a malfunction in the instrument—e.g., offset error). Does the fluid seem to be Newtonian? Would you have reached the same conclusion if you did not know about the offset error? So….the is very s accounte can be d when the You wou non-New An Origi If you go add 3 un that the This enh non-New offset er