Manufacturing, Service Operations and Logistics from Prof. Goldsman’s lecture notes

advertisement

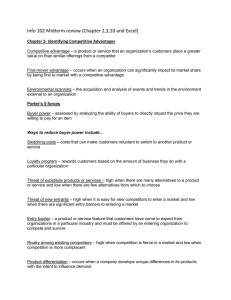

Manufacturing, Service Operations and Logistics from Prof. Goldsman’s lecture notes Outline Manufacturing and Service Terminologies Product/Process Matrix Vocabulary List Manufacturing Service Setup, setup cost Lot or batch size Product mix Capacity Custom process/project Jobshop Batch flow/batch process Line flow/flowshop/flowline/mass production Continuous flow Product/process matrix Capital intensive, labor intensive Manufacturing versus Service Manufacturing: makes things Physical goods: books, cellphones, pipes, bricks, cars, … Service: makes intangible items Education, lawyers and other professionals, repairs, hotels, entertainment, … Created, delivered, and consumed at once << capital investments compared to manufacturing Why Service Matters? Growing sector Newer, hence more opportunities for IEs Environmental concerns turning manufacturing into service Buy transportation, not a car! Product/Process Matrix PRODUCT MIX PROCESS PATTERN One of a kind or few Very jumbled flow; process segments loosely linked PROJECT JOB Low Vol. many products Worker motivation; balance; maintaining enough flexibility LINE FLOW Stay on the diagonal! Bidding; delivery; product design, flexibility Challenges for management Scheduling; materials handling; shifting bottlenecks BATCH FLOW Line flow Challenges for Mangement Very high Vol. Std product (commodity) SHOP Jumbled flow; but a dominant flow exists Cont, automated, rigid flow; process segments tightly linked Higher Vol. several major products Quality (product diff’n); flex in output vol. CONTINUOUS FLOW Price Capital expenses for big chunk capacity; technological changes; material mgt; vertical integration Note That… During the lifecycle of a product (Product Life Cycle), the process strategy may change Computers? Many real process don’t fit so neatly into these categories It’s just a guidelines! Supply Chain Management “Consist of all stages involved, directly or indirectly, in fulfilling a customer request. The supply chain not only includes the manufacturer and suppliers, but also transporters, warehouses, retailers and customer themselves” – Chopra and Meindl Suppliers’ Suppliers Assembler Suppliers Logistics Providers Distributors Customer Supply Chain Management Physical Product SCM Information Money The Traditional Supply Chain Suppliers Manufacturers Information Flows Goods Flow Wholesale Distributors Retailers Customers Today’s Supply Chain Wholesale Distributors Retailers Manufacturers Supplier Exchanges Customers Logistics Exchanges Virtual Manufacturers Contract Manufacturers Logistics Providers Information Flows Goods Flow Customer Exchanges Four Categories of SCM*) PLAN SOURCE DELIVER MAKE *) Michael Hugo Plan-Source-Make-Deliver Plan • Demand Forecasting • Product Pricing • Inventory Management Source • Procurement • Credit and Collections Make Deliver • Product Design • Productions Scheduling • Facility Management • Order Management • Delivery Scheduling • • • • • • Delivery Performance Inventory Reduction Fulfillment Cycle Time Forecast Accuracy Overall Productivity Lower Supply-Chain Costs • Fill Rates • Improved Capacity Realization Benefit of SCM Increase Competitiveness Customer Results: Increased ROI Planning Cycle Time Operating Expenses (Overtime) Customer Service Throughput revenues ROI assets Inventory Order LT Production LT expenses Key Drivers Key drivers to the SCM process are: – Shorter life cycles – Reduced costs – Improved customer service Supply Chain Solutions Covers ROI impact scheduling manufacturing planning scheduling move master planning strategic business planning transportation planning distribution planning Program Binusian 2012 months demand management days hours demand fulfillment weeks store sell strategic year + buy make tactical operational 17 SCM: Manufacturing Perspective P R O D U C T C O M P L E X I T Y Special machine building Make -to-order production Assembly production / Assemble -to- order Production by lots Period -based production /takted flow production Process manufacturing Mass production PRODUCT STABILITY