CHAPTER 6 HEAT TRANSFER IN CHANNEL FLOW 6.1 Introduction

advertisement

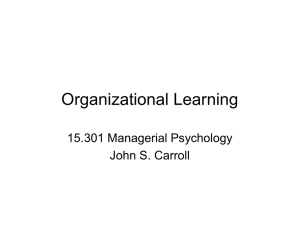

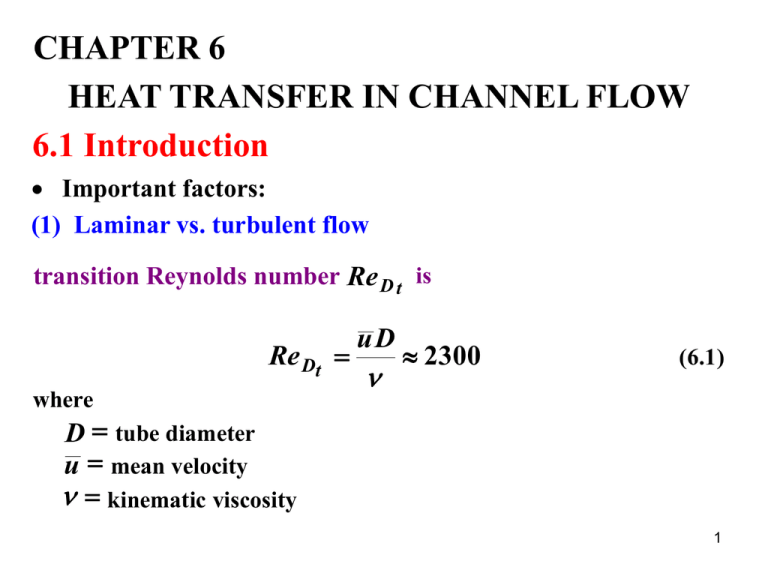

CHAPTER 6 HEAT TRANSFER IN CHANNEL FLOW 6.1 Introduction Important factors: (1) Laminar vs. turbulent flow transition Reynolds number Re D t is Re Dt where uD 2300 (6.1) D tube diameter u mean velocity kinematic viscosity 1 (2) Entrance vs. fully developed region Based on velocity and temperature distribution: two regions: (i) Entrance region (ii) Fully developed region (3) Surface boundary conditions Two common thermal boundary conditions: (i) Uniform surface temperature (ii) Uniform surface heat flux (4) Objective Depends on the thermal boundary condition: (i) Uniform surface temperature. Determine: axial variation of (1) Mean fluid temperature (2) Heat transfer coefficient (3) Surface heat flux 2 (ii) Uniform surface flux. Determine axial variation of: (1) Mean fluid temperature (2) Heat transfer coefficient (3) Surface temperature 6.2 Hydrodynamic and Thermal Regions: General Features Uniform inlet velocity Vi and temperature Ti • Developing boundary velocity and thermal boundary layers • Two regions: r (1) Entrance region (2) Fully developed region V i 6.2.1 Velocity Field (1) Entrance Region (Developing Flow, 0 x Lh ) x uc u L h f d F 6 3 • Hydrodynamic entrance region Length Lh : hydrodynamic entrance length Streamlines are not parallel ( v r 0) Core velocity uc uc ( x ) (increasing or decreasing with x?) Pressure p p( x ) , ( dp / dx 0 ) D / 2 r V i x uc L h (2) Fully Developed Flow Region u f d F 6 x > Lh : fully developed flow Streamlines are parallel ( v r 0) For 2-D, constant r : u / x 0 4 6.2.2 Temperature Field Entrance Region (Developing Temperature, 0 x Lt ): r Thermal entrance region Tc Ts Length Lt : Thermal entrance length Vi Core temperature Tc is uniform (Tc Ti ) Ti t D / 2 T x t Ts f d Lt F 6 (2) Fully Developed Temperature Region x Lt fully developed temperature T T ( r , x ) or T / x 0 Dimensionless temperature is invariant with x ( / x 0 ) 5 6.3 Hydrodynamic and Thermal Entrance Lengths Lh and Lt are determined by: (1) Scale analysis (2) Analytic or numerical methods 6.3.1 Scale Analysis (1) Hydrodynamic Entrance Length Lh Scaling of external flow: 1 x Re x r (4.16) V i Apply (4.16) to flow in tube: at x Lh , D D Lh 1 Re L h x uc u L h f d F 6 (a) 6 Express Re L in terms Re D h Re Lh (b) into (a) u Lh u D Lh L Re D h v v D D Lh / D Re D (2) Thermal Entrance Length Lt 1/ 2 ~1 (6.2) Scale for u: u ~u (all Prandtl numbers) Scale of t : For external flow t ~ LRe L-1/2 Pr -1/2 (4.24) Apply (4.24) for flow in tube: L Lt , t D - D ~ L t Ret 1/2 Pr - 1/2 7 (a) Express Re L in terms Re D t Re Lt u Lt u D Lt Lt Re D v v D D (b) (b) into (a) 1/2 Lt / D Re D Pr ~1 Lt ~ Pr Lh (6.3) (6.4) 6.3.2 Analytic/Numerical Solutions: Laminar Flow (1) Hydrodynamic Entrance Length Lh Lh C h Re D De (6.5) 8 De = equivalent diameter 4Af De P A f = flow area Table 6.1 Entrance length coefficients and Uniform surface flux Uniform surface temperature 0.056 0.043 0.033 0.090 0.066 0.041 2 0.085 0.057 0.049 4 0.075 0.042 0.054 0.011 0.012 0.008 Geometry a b a Compare with scaling: b 1/ 2 C t [1] Ct Ch P = perimeter C h = coefficient Table 6.1 Lh / D Re D Ch a ~1 (6.2) b Rewrite (6.5) Lh / D Re D 1/2 C h 1/2 (a) 9 Example: Rectangular channel, a / b 2, , Table 6.1 gives C h 0.085 Substitute into (a) 1/ 2 Lh / D Re D 0.085 1/ 2 0.29 (b) (2) Thermal Entrance Length Lt Lt Ct PrReD De (6.6) C t is given in Table 6.1 Compare with scaling 1/2 Lt / D Re D Pr ~1 (6.3) Rewrite (6.6): 10 1/2 Lt / D Re D Pr C t1/2 (b) Example: Rectangular channel, a / b 2, , Table 6.1 gives C t 0.049 gives 1/2 Lt / D Re D Pr 0.049 1/ 2 (c) 0.22 Turbulent flow: Experimental results: Lh and Lt are shorter than in laminar flow Rule of thumb : Ln 10 60 D (6.7a) Ln 40 100 D (6.7b) 11 6.4 Channels with Uniform Surface Heat Flux q s L W h e n s u r f a c e h e a t f l u x i s u n i f o r m S u r f a c e t e m p e r a t u r e i s v a r i a b l e Tm x Tm( x) Section length L qs Inlet temperature: Tmi Tm (0) Surface flux q s F 6 Determine: (1) Total heat transfer (2) Mean temperature variation Tm ( x ) (3) Surface temperature variation Ts ( x ) 12 Total heat: q s q s As q s P x (6.8) As = surface area P = perimeter Conservation of energy: Assumptions: (1) Steady state (2) No energy generation (3) Negligible changes in kinetic and potential energy (4) No axial conduction q s qs P x mc p [Tm ( x ) - Tmi ] or m = mass flow rate Tm ( x ) Tmi q s P + x mc p (6.9) 13 c p = specific heat ( 6 . 9 ) a p p l i e s t o a n y r e g i o n a n d a n y f l o w ( l a m i n a r , t u r b u l e n t o r m i x e d ) U s e h e a t t r a n s f e r a n a l y s i s t o d e t e r m i n e T ( x ) s u r f a c e t e m p e r a t u r e s Newton’s law of cooling qs h( x )Ts ( x ) - Tm ( x ) Solve for Ts ( x ) qs Ts ( x ) Tm ( x ) + h( x ) Use (6.9) to eliminate Tm ( x ) 14 Ts ( x ) Tm i Px 1 + q s + c h ( x ) m p (6.10) T ( x ) h x ( ) i s n e e d e d i n ( 6 . 1 0 ) t o d e t e r m i n e s T o d e t e r m i n eh ( x ) : ( 1 ) L a m i n a r o r t u r b u l e n t f l o w ? ( 2 ) E n t r a n c e o r f u l l y d e v e l o p e d r e g i o n ? Example 6.2: Maximum Surface Temperature Water flows through tube Mean velocity = 0.2 m/s Tmi 20 C o 15 q s L Tmo = 80 o C D = 0.5 cm T m Uniform surface heat flux = 0.6 W/cm2 x D T (x ) m 0 Fully developed flow at outlet q s T x ) s( Nusselt number for laminar fully developed flow NuD hD 4.364 k (A) Determine the maximum surface temperature (1) Observations Uniform surface flux Ts Ts ( x ), maximum at the outlet 16 Laminar or turbulent flow? Check Is outlet fully developed? Check Re D Lh and Lt Uniform Nusselt number (h is constant) Length of tube section is unknown (2) Problem Definition (i) Determine L T s (L) (3) Solution Plan (ii) Determine (i) Apply conservation of energy (ii) Compute Re D (iii) Calculate Lh and Lt (iv) Apply uniform flux analysis ( v ) If applicable use (A) to determine h 17 (4) Plan Execution (i) Assumptions Steady state Constant properties Axisymmetric flow Uniform surface heat flux Negligible changes in kinetic and potential energy Negligible axial conduction Negligible dissipation (ii) Analysis Conservation of energy: p DLq"s mc p (Tmo - Tmi ) 18 (a) c p = specific heat, J/kg-oC D = tube diameter = 0.5 cm = 0.005 m L = tube length, m m = mass flow rate, kg/s Tmi = mean temperature at the inlet = 20oC Tmo = mean temperature at the outlet = 80oC q s = surface heat flux = 0.6 W/cm2 = 6000 W/m2 From (a) Conservation of mass: mc p (Tmo - Tmi ) L= p Dq (b) m (p / 4) D 2 r u (c) s where 19 u = mean flow velocity = 0.2 m/s r = density, kg/m3 Surface temperature: Apply (6.10) Ts ( x ) Tm i Px 1 + qs + mc p h( x ) (6.10) h = local heat transfer coefficient, W/m2-oC P = tube perimeter, m Ts ( x ) = local surface temperature, oC x = distance from inlet of heated section, m Perimeter P: P=pD (d) Maximum surface temperature: set x = L in (6.10) 20 Ts ( L) Tm i PL 1 + q s + mc p h( L) Determine h(L): Is flow laminar or turbulent? Compute Re D (e) Re D uD (f) Properties Tm Tmi + Tmo Tm = 2 (g) ( 20 + 80)(o C) 50o C T = 2 For water: c p = 4182 J/kg-oC k = 0.6405 W/m-oC 21 Pr = 3.57 = 0.553710 m2/s 3 r = 988 kg/m -6 Use (g) Re D 0.2(m/s)0.005(m) -6 0.5537 10 (m /s) Compute Lh and 2 1806 , laminar flow Lt using (6.5) and (6.6) Lh C h Re D De Lt C t PrRe D De C h = 0.056 (Table 6.1) C t = 0.043 (Table 6.1) (6.5) (6.6) 22 Lh = 0.056 0.005 (m) 1806 = 0.506 m Lt = 0.043 0.005 (m) 1806 3.57 = 1.386 m ? L a n d L I s s m a l l e r o r l a r g e r t h a nL t h Compute L using (b). Use (c) to compute m m = 988(kg/m3) 0.2(m/s)p (0.005)2(m2)/4 = 0.00388kg/s Substitute into (b) L= 0.00388(kg/s) 4182(J/kg- o C)(80 - 20)( o C) 2 4 2 2 = 10.33 m 0.005(m) 0.6 (W/cm )10 (cm /m ) L L L a n d i s l a r g e r t h a n b o t h . t h F l o w i s f u l l y d e v e l o p e d a t t h e o u t l e t 23 Equation (A) is applicable NuD hD = 4.364 k (A) (iii) Computations. Apply (A) 0.6405(W/m- o C) h(L) = 4.364 = 559 W/m2-oC 0.005(m) Use (e) 2 Ts (L) 20 C + 6000(W/m ) o + o 2 o 0.00388(kg/s)4182(J/kg- C) 559(W/m - C) π 0.005(m)10.43(m) 1 Ts ( L) 90.7o C (iv) Checking. Dimensional check: Quantitative checks: (1) Alternate approach: apply Newton’s law at outlet 24 q s h ( L )T s ( L ) - T mo (i) solve for T s (L) T s ( L) Tmo 2 4 2 2 q s 0.6(W/cm ) 10 (cm /m ) = 90.7oC + = 80 (oC) + h 559(W/m 2 - o C) (2) Compare value of h with Table 1.1 Limiting check: For Tmi Tmo , L = 0. Set Tmi Tmo in (b) gives L = 0. (3) Comments. In laminar flow local h depends on local flow condition: entrance vs. fully developed Check Re D to determine: (i) If flow is laminar or turbulent (ii) Entrance or fully developed 25 6.5 Channels with Uniform Surface Temperature When surface temperature is uniform, surface heat flux is variable Surface temperature: Ts Ts Inlet temperature: Tmi Tm (0) Section length: L m (2) Total heat q s dx dqs Determine (1) Mean temperature variation Tm ( x ) Tm ( x ) x Tmi dTm Tm + dx dx Tm dx Fig. 6.4 26 (3) Surface flux variation qs ( x ) Analysis Apply conservation of energy to element dx Assumptions (1) Steady state (2) No energy generation (3) Negligible changes in kinetic and potential energy (4) No axial conduction dqs m c p dTm (a) Newton's law: dqs h( x )Ts - Tm ( x )Pdx 27 Combine (a) and (b) dTm P h( x )dx Ts - Tm ( x ) m c p (c) Integrate from x = 0 ( Tm Tm (0) Tmi ) to x ( Tm Tm ( x ) ) Tm ( x ) - Ts P ln T T m cp mi s x 0 h( x )dx Must determine h(x). Introduce h 1 h x x 0 h( x )dx (6.12) (6.12) into (6.11) 28 Tm ( x ) Ts + (Tmi Ph - Ts ) exp[x] mcp (6.13) (6.13) applies to any region and any flow (laminar, turbulent or mixed) To determine h(x): (1) Is flow laminar or turbulent flow? (2) Entrance or fully developed region? Total heat: Apply conservation of energy: q s m c p [Tm ( x ) - Tmi ] 29 Surface flux: Apply Newton’s law: qs( x ) h( x )[Ts - Tm ( x )] (6.15) Properties: At mean of inlet and outlet temperatures Example 6.3: Required Tube Length • Air flows through tube • Uniform surface temperature, Ts 130o C r Ts • Mean velocity = 2 m/s, • Tmi 35 C o • D = 1.0 cm u 0 Ts D x u L 30 • Nusselt number for laminar fully developed flow hD NuD 3.657 k (A) Determine: tube length to raise temperature to Tmo 105o C (1) Observations • Laminar or turbulent flow? Check Re D • Uniform surface temperature • Uniform Nusselt number (h is constant) for fully developed laminar flow • Length of tube is unknown 31 (2) Problem Definition. Determine tube length needed to raise temperature to specified level (3) Solution Plan. Use uniform surface temperature analysis Compute Re D . Laminar or turbulent? (4) Plan Execution (i) Assumptions Steady state Fully developed flow Constant properties 32 • Uniform surface temperature • Negligible changes in kinetic and potential energy • Negligible axial conduction • Negligible dissipation (ii) Analysis Tm ( x ) Ts + (Tmi - Ts ) exp[- Ph x] mcp (6.13) c p = specific heat, J/kg- o C h = average h, W/m 2 - o C m = flow rate, kg/s P = perimeter, m 33 Tm(x) = mean temperature at x,o C Tmi = mean inlet temperature = 35 o C Ts = surface temperature = 130 o C x = distance from inlet, m Apply (a) at the outlet (x = L), solve for L Ts - Tmi L ln P h Ts - Tmo m cp (a) Tmo = outlet temperature = 105 o C Properties: at Tm Tm = Tmi + Tmo 2 (b) 34 P=pD (c) D2 m p ru 4 (d) D = inside tube diameter = 1 cm = 0.01 m u = mean flow velocity = 2 m/s r = density, kg/m3 For fully developed laminar flow hD NuD 3.657 k (e) h = heat transfer coefficient, W/m 2 - o C k = thermal conductivity of air, W/m - o C 35 k h h 3.657 , for laminar fully developed D Compute: Reynolds number uD Re D (f) (g) Use (b) o Tm = ( 35 + 105)( C) 70 o C Properties: c p = 1008.7 J/kg - o C 2 k 0.02922 W/m- o C Pr 0.707 19.9 10 -6 m 2 /s r 11.0287 kg/m 3 36 Use (f) Re D 2(m/s)0.01(m) 1005 , flow is laminar -6 2 19.9 10 (m /s) (iii) Computations P = p 0.01(m) = 0.03142 m (0.01)2 (m 2 ) m p 1.0287(kg/m 3 )2(m/s) 0.0001616 kg/s 4 o 0.02922(W / m C) = 10.69 W/m 2 - o C = 3.657 h 0.01(m) Substitute into (a) 0.0001616(kg/s)1008.7(J/kg -o C ) (130 - 35)(o C) = 0.65 m L ln 2 o o 0.03142(m)10.69(W/m - C) (130 - 105)( C) 37 (iv) Checking. Dimensional check (i) L 0 for Tmo Tmi . Set Tmo Tmi in (a) gives L 0 (ii) L for Tmo Ts . Set Tmo Ts in (a) gives L = Quantitative checks: (i) Approximate check: (h) Energy added at the surface = Energy gained by air Energy added at surface hp DL(Ts - Tm ) (i) Energy gained by air = mc p (Tmo - Tmi ) (j) (j) and (k) into (i), solve for L L m c p (Tmo - Tmi ) (k) h pD(Ts - Tm ) 38 L 0.0001616(kg/s)1008.7(J/kg- o C)(105 - 35)( o C) 10.69(W/m - C)π (0.01)(m)(130 - 70)( C) 2 o o = 0.57 m (ii) Value of h is low compared with Table 1.1. Review solution. Deviation from Table 1.1 are expected (5) Comments. This problem is simplified by two conditions: fully developed and laminar flow 39 6.6 Determination of Heat Transfer Coefficient h( x ) and Nusselt Number Nu D r qs Two Methods: ro (1) Scale analysis 0 (2) Analytic or numerical solutions Tm 6.6.1 Scale Analysis Ts Fig. 6.5 Fourier’s law and Newton’s law T ( ro , x ) -k r h Tm - Ts (6.16) 40 Scales: r ~ t (a) T ( ro , x ) Tm - T s ~ t r (b) (a) and (b) into (6.16) k h~ Tm - Ts t Tm - Ts or h~ k t (6.17) 41 Nusselt number: hD NuD k (6.17) into the above NuD ~ D t (6.18) Entrance region: t D , NuD 1 Special case: fully developed region t ( x) ~ D (6.18) gives NuD ~ 1 (fully developed) (6.19) 42 t in the entrance region: For all Pr t ~ x Pr -1 / 2 Re -x 1 / 2 (4.24) (4.24) into (6.18) D 1/ 2 1/ 2 Nu D ~ Pr Re x x (c) Express in terms of Re D ux uD x x Re x Re D D D (d) into (c) (d) 1/2 D NuD ~ x Pr 1/2Re1/2 x (6.20a) 43 or NuD PrRe x/D 1/ 2 ~1 (6.20b) 44 6.6.2 Basic Considerations for the Analytical Determination of Heat Flux, Heat Transfer Coefficient and Nusselt Number (1) Fourier’s law and Newton’s law T x , ro qs - k r Define dimensionless variables T - Ts , x/D Re D Pr Ti - Ts v x vx vr , vr u u , , (a) r R ro Re D uD (6.21) 45 (6.21) into (a) k 0( ,1) qs( ) Ts - Ti ro R (6.22) Newton’s law q"s h Tm - Ts (6.23) Combine (6.22) and (6.23) k (Ts - Ti ) ( ,1) k 1 ( ,1) h( ) ro (Tm - Ts ) R ro m ( ) R (6.24) Dimensionless mean temperature m : Tm - Ts m Ti - Ts (6.25) 46 Nusselt number: h( ) D h( )2ro Nu( ) k k (6.26) (6.24) into (6.26) - 2 ( ,1) Nu( ) m ( ) R (6.27) Determine: q s ( ), h( ) and: Nu( ) Find ( , R ) . Apply energy equation (2) The Energy Equation Assumptions • Steady state 47 • Laminar flow • Axisymmetric • Negligible gravity • Negligible dissipation • Negligible changes in kinetic and potential energy • Constant properties 1 T T T T T rc p v r + + vz k r + 2 z r r r r z 2 (2.24) Replace z by x, express in dimensionless form 4 1 vx + 2 Re D Pr v r R + R R R R ( Re D Pr )2 2 2 (6.28) 48 Pe Re D Pr , Peclet number (2.29) • Third term: radial conduction • Fourth term: axial conduction • Neglect axial conduction for: Pe PrReD 100 (6.30) Simplify (6.28) v x 4 + 2 Re D Pr v r R R R R R (6.31) (3) Mean (Bulk) Temperature Tm Need a reference local temperature. Use Tm ( x ) 49 mc pTm where m 0 ro 0 ro r c p v xT 2prdr (a) r v x 2prdr (b) (b) into (a), assume constant properties ro v x T r dr Tm 0 r 0 v x rdr (6.32a) o In dimensionless form: Tm - Ts m Ti - Ts 1 0 1 v x RdR 0 v x RdR (6.32b) 50 6.7 Heat Transfer Coefficient in the Fully Developed Temperature Region 6.7.1 Definition of Fully Developed Temperature Profile Fully developed temperature: Ts ( x ) - T ( r , x ) Ts ( x ) - Tm ( x ) Let x / d 0.05Re D Pr (6.33) Definition: For fully developed temperature is independent of x 51 Therefore (r ) (6.34) 0 x (6.35) From (6.34) (6.33) and (6.35): Ts ( x ) - T ( r , x ) 0 x x Ts ( x ) - Tm ( x ) (6.36a) Expand and use (6.33) dTs T dTs dTm - (r ) 0 dx x dx dx (6.36b) 52 6.7.2 Heat Transfer coefficient and Nusselt number T ( ro , x ) -k r h Tm - Ts (6.16) Use(6.33) to form T ( ro , x ) / r , substitute into (6.16) do ro h -k dr (6.37) Conclusion: The heat transfer coefficient in the fully developed region is constant regardless of boundary condition 53 Nusselt number: hD d ( ro ) NuD -D h dr (6.38) Entrance region scaling result: NuD ~ 1 (fully developed) (6.19) Scaling of fully developed region: scale for T ( ro , x ) / r T ( ro , x ) Ts - Tm ~ r D Substitute into (6.16) k h~ D (6.39) 54 (6.39) into (6.38) NuD ~ 1 (fully developed) (6.40) 6.7.3 Fully Developed Region for Tubes at Uniform Surface flux r • Uniform flux • Determine • Ts ( x ) • h Newton’s law: u 0 qs T D x qs Fig. 6.6 qs h Ts ( x ) - Tm ( x ) (a) 55 Ts ( x ) and Tm ( x ) are unknown q s and h are constant (a) gives: Ts ( x ) - Tm ( x ) Differentiate (b) (c) into (6.36b) Combine (c) and (d) constant (b) dTs dTm dx dx (c) T dTs x dx (d) T dTs dTm (for constant q ) s x dx dx (6.41) 56 To determine h form (6.16) : Determine: T ( r , r ), Tm ( x ) and Ts ( x ) Conservation of energy for dx dTm qsPdx + mc pTm mc p Tm + dx dx Simplify dTm q s P dx mc p (6.42) = constant qs (6.42) into (6.41) T dTs dTm q s P = constant = x dx dx mc p (6.43) m dTm Tm + dx dx Tm ( x ) dx Fig. 6.7 57 Conclusion: T ( x , r ), Tm ( x ) and Ts ( x ) are linear with x Integrate(6.43) qsP Tm ( x ) x + C1 mc p (e) Tm (0) Tmi (f) C 1 = constant Boundary condition: Apply (e) to (f) C1 Tmi (e) becomes Tm ( x ) Tmi qsP + x mc p (6.44) 58 Determine T ( r , x ) and Ts ( x ) Apply energy equation (2.23) in the fully developed region Assumptions • Negligible axial conduction • Negligible dissipation • Fully developed, v r 0 r c pv x T k T r x r r r (6.45) r2 v x 2u 1 - 2 r o (6.46) 59 However m p ro2 r u P 2p ro equation (g) becomes 4qs r 2 k T r 1 - 2 ro ro r r r Boundary conditions: Integrate (6.47) (6.47) T (0, x ) 0 r (6.48a) T ( ro , x ) k qs r (6.48b) 4 r 2 r 3 T qs - 2 kr + f x ro 2 4ro r (h) 60 f ( x ) = “constant” of integration Boundary condition (6.48a) f ( x) 0 (h) becomes T 4qs r r 3 - 2 r kro 2 4ro Integrate 4qs T (r , x ) kro r 2 r4 - 2 + g( x ) 4 4ro (6.49) g ( x ) = “constant” of integration Boundary condition (6.48b) is satisfied Use solution to Tm ( x ) to determine g ( x ) 61 Substitute(6.46) and (6.49) into (6.32a) 7 roqs Tm ( x ) + g( x ) 24 k (6.50) Two equations for Tm ( x ) : (6.44) and (6.50). Equating g( x ) Tmi 7 roqs Pqs + x 24 k mc p (6.51) (6.51) into (6.49) T ( r , x ) Tmi 4qs + kro r 2 r 3 7 roqs Pqs + x (6.52) 2 mc p 4 16ro 24 k Surface temperature Ts ( x ) : set r ro in (6.52) 62 Ts ( x ) Tmi 11 roqs Pqs + + x 24 k mc p (6.53) T ( r , x ), Tm ( x ) and Ts ( x ) are determined (6.44), (6.52) and (6.53) into (6.33) 24 1 (r ) 1 11 ro2 2 r 4 24 Pq s 7 x+ x r - 2 + 11 4ro 11 mc p (6.54) Differentiate(6.54) and use (6.38) 48 NuD 4.364 , laminar fully developed 11 (6.55) 63 Comments: • (6.55) applies to: • Laminar flow in tubes • Fully developed velocity and temperature • Uniform surface heat flux • Nusselt number is independent of Reynolds and Prandtl numbers • Scaling result: Nu D ~ 1 (6.40) 64 6.7.4 Fully Developed Region for Tubes at Uniform Surface Temperature • Fully developed • Uniform surface temperature Ts Determine: Nu D and h Assumptions: • Neglect axial conduction • Neglect dissipation • Fully developed: v r 0 Energy equation (2.24): T k T r c pv x r x r r r (6.45) 65 Boundary conditions: T (0, x ) 0 r T ( ro , x ) Ts Axial velocity r2 v x 2u 1 - 2 ro (6.56a) (6.56b) (6.46) Eliminate T / x in equation (6.45). Use (6.36a) Ts ( x ) - T ( r , x ) 0 x x Ts ( x ) - Tm ( x ) (6.36a) 66 for Ts ( x ) Ts, (6.36a) gives T Ts - T ( r , x ) dTm x Ts - Tm ( x ) dx (6.57) (6.46) and (6.57) into (6.45) r 2 Ts - T ( r , x ) dTm k T r c p u 1 - 2 r ro Ts - Tm ( x ) dx r r r (6.58) Result: Solution to (6.58) by infinite power series: NuD 3.657 (6.59) 67 6.7.5 Nusselt Number for Laminar Fully Developed Velocity and Temperature in Channels of Various Cross Sections • Analytical and numerical solutions • Results for two classes of boundary conditions: (1)Uniform surface flux (2)Uniform surface temperature • Nusselt number is based on the equivalent diameter De 4 Af (6.60) P • Results: Table 6.2 68 69 • Compare with scaling NuD ~ 1 (fully developed) (6.40) Example 6.4: Maximum Surface Temperature in an Air Duct qs • 4 cm 4 cm square duct • Uniform heat flux = 590 W/m 2 Tmo • Heating air from 40 o C to 120o C u • Tmi u = 0.32 m/s L • No entrance effects (fully developed) 70 Determine: Maximum surface temperature (1) Observations • Uniform surface flux • Variable Surface temperature, Ts ( x ) , maximum at outlet • Compute the Reynolds number • Velocity and temperature are fully developed • The heat transfer coefficient is uniform for fully developed flow • Duct length is unknown • The fluid is air 71 (2) Problem Definition (i) Find the required length (ii) Determine surface temperature at outlet (3) Solution Plan (i) Apply conservation of energy (ii) Compute the Reynolds (iii) Apply constant surface solution (iv) Use Table 6.2 for h (4) Plan Execution (i) Assumptions • Steady state 72 • Constant properties • Uniform surface flux • Negligible changes in kinetic and potential energy • Negligible axial conduction • Negligible dissipation (ii) Analysis Conservation of energy P Lqs m c p (Tmo - Tmi ) (a) c p = specific heat, J/kg- o C L = channel length, m m = mass flow rate, kg/s 73 P = perimeter, m q s = surface heat flux = 590 W/m 2 Tmi 40 o C Tmo 120 o C Solve (a) for L L mc p (Tmo - Tmi ) (b) P q Find m and P m r S 2u (c) P 4S (d) S = duct side = 0.04 m u = mean flow velocity = 0.32 m/s 74 r = density, kg/m 3 (c) and (d) into (b) L r S u c p (Tmo - Tmi ) (e) 4 q Surface temperature: Use solution (6.10) Ts ( x ) Tmi Px 1 + + qs m c h ( x ) p (f) h( x ) = local heat transfer coefficient, W/m 2 - o C Ts ( x ) = local surface temperature,o C x = distance from inlet, m 75 Maximum surface temperature at x = L Ts ( L) Tmi 4L 1 + + qs r S u c h ( L ) p (g) Determine h(L): Compute the Reynolds number Re De u De (h) De = equivalent diameter, m = kinematic viscosity, m 2 /s 2 A S De = 4 = 4 =S P 4S (i) 76 (i) into (h) Re De uS (j) Properties: At Tm Tm = Tmi + Tmo 2 Tm (k) (40 + 120)( o C) o 80 C = 2 Properties: c p = 1009.5 J/kg- o C k = 0.02991 W/m - o C Pr = 0.706 77 = 20.92 10 - 6 m2/s r = 0.9996 kg/m3 (j) gives Re De 0.32(m/s)0.04(m) 611.9 , -6 2 20.92 10 (m /s) laminar flow (6.55) and Table 6.2 Nu De hh h De k = 3.608 k h 3.608 De (l) (m) 78 (iii) Computations. Use (e) 3 o o 0.9996(kg/m ) 0.04(m)0.32(m/s) 1009.5(J/kg- C)(120 - 40)( C) L 0.4378 m 2 (4) 590(W/m ) Use (m) 0.02991(W/m - o C) h(L) = h = 3.608 = 2.7 W/m 2 - o C 0.04(m) Substitute into (g) Ts ( L) 40( o C ) + 590( W/m 2 4(0.4378)(m) 1 ) 0.9996(kg/m 3 ) 0.04(m)0.32 (m/s) 1009.5(J/kg - o C) + 2.7(W/m 2 - o C) 79 Ts (L) = 338.5 o C (iv) Checking. Dimensional check: Quantitative checks: (1) Alternate approach to determining : Newton’s law at outlet qs h [Ts ( L) - Tmo ] (n) Ts (L) Solve for 2 s 590(W/m ) q o o Ts (L) = Tmo 120 ( C) + 338.5 C = 2 o 2.7(W/m - C) h (2) Compare h with Table 1.1 Limiting check: L =0 for Tmo Tmi . Set Tmo Tmi into (e) gives L = 0 80 (5) Comments (i) Maximum surface temperature is determined by the heat transfer coefficient at outlet (ii) Compute the Reynolds number to establish if the flow is laminar or turbulent and if it is developing or fully developed 81 6.8 Thermal Entrance Region: Laminar Flow Through Tubes 6.8.1 Uniform Surface Temperature: Graetz Solution • Laminar flow through tube r Ts • Velocity is fully developed • Temperature is developing u • No axial conduction (Pe > 100) • Uniform surface temperature Ts T Ti 0 x t Fig.6.8 Velocity: vr 0 (3.1) 82 1 dp 2 vz ( r - ro2 ) 4 d z (3.12) Rewrite (3.1) vz 21 - R 2 u (3.1) and (6.61) into (6.31) v*z 1 1 2 1- R R 2 R R R Boundary conditions: (6.61) (6.62) ( ,0) 0 R ( ,1) 0 (0, R) 1 83 Solution summary: Assume a product solutions ( , R) X ( )R (R) (a) (a) into (6.62), separating variables dX n + 22n X n 0 d (b) d 2Rn 1 dRn 2 2 2 + + ( 1 R ) R n n 0 2 2 R dR dR (c) • n = eigenvalues obtained from the boundary conditions • Solution X n ( ) to (b) is exponential • Solution Rn (R) to (c) is not available in terms of simple tabulated functions 84 Solutions to (b) and (c) into (a) ( , R) C nRn ( R) exp(-22n ) (6.64) n0 C n = constant Surface flux: k 0( ,1) qs( ) Ts - Ti ro R (6.22) (6.64) gives dRn (1) ( ,1) Cn exp(-22n ) R dRn n0 Define C n dRn (1) Gn 2 dR (d) (e) 85 (e) into (6.22) 2k qs ( ) - Ts - Ti Gn exp(-22n ) ro n0 (6.65) Local Nusselt number: is given by - 2 ( ,1) Nu( ) m ( ) R (6.27) (d) gives ( ,1) / R Mean temperature m ( ): (6.61) and (6.64) into (6.32b), integrate by parts and use(e) m 8 Gn 2 n0 n exp(-22n ) (6.66) 86 (d), (e) and (6.66) into (6.27) Nu Gn exp(-2n ) n0 2 2 2 n0 Gn (6.87) exp(-22n ) n Average Nusselt number: For length x h ( ) D Nu( ) k Two methods for determining h ( ) : (f) (1) Integrate local h( ) to obtain h ( ) (2) Use (6.13) 87 Tm ( x ) Ts + (Ti - Ts ) exp [- Ph x] mcp (6.13) Solve for h Tm ( x ) - Ts ln h Px Ti - Ts mcp (g) (g) into (f), use m r u p D 2 / 4 P p D and definitions of , Re D and m in (6.21) and (6.25) 1 Nu( ) - ln m ( ) 4 (6.68) • Need n and G n to compute q s ( ), m ( ), Nu( ) and Nu( ) • Table 6.3 gives n and G n • (6.67) and (6.68) are plotted in Fig. 6.9 as Nu( ) and Nu88( ) 89 Average Nu Nusselt number Local Nu x/D ReD Pr Local and average Nusselt number for tube at uniform surface temepratu re [4] Fig. 6.9 90 Comments (1) Nu D and NuD decrease with distance from entrance (2) At any location Nu D NuD (3) Asymptotic value (at 0.05 ) for Nu D and Nu D is 3.657. Same result of fully develop analysis Nu( ) 3.657 (6.69) (4) Properties at Tmi + Tmo Tm 2 (6.70) (5) Solution by trial and error if Tmo is to be determined 91 Example 6.5: Hot Water Heater • Fully developed velocity in tube • Developing temperature • Uniform inlet temperature Ti 25 o C • Diameter = 1.5 cm r • Length = 80 cm • Flow rate = 0.002 kg/s • Heat water to 75 o C Determine: Surface temperature u Ts Ti 0 x t (1) Observations • Uniform surface temperature 92 • Compute Reynolds number: Laminar or turbulent flow? • Compute Lh and Lt : Can they be neglected? (2) Problem Definition (i) Determine Ts (ii) Determine h (3) Solution Plan (i) Apply uniform surface temperature results (ii) Compute the Reynolds number: Establish if problem is entrance or fully developed (iii) Use appropriate results for Nusselt number (4) Plan Execution (i) Assumptions • Steady state 93 • Constant properties • Uniform surface temperature • Negligible changes in kinetic and potential energy • Negligible axial conduction • Negligible dissipation (ii) Analysis Uniform surface temperature Tm ( x ) T s + (Tmi - T s ) exp[- Ph x] mcp h = average heat transfer coefficient, W/m 2 - o C m = flow rate 0.002 kg/s (6.13) 94 Tmi mean inlet temperature 25o C Tmo mean outlet temperature 75 o C Apply (6.13) at outlet (x = L) and solve for Ts Ts 1 Tmi - Tm ( L) exp( Ph L / mc p ) 1 - exp( Ph L / mc p ) Properties: at Tm (a) Tm = Tmi + Tmo 2 Perimeter P P=pD D = diameter = 1.5 cm = 0.015 m 95 Determine h : Compute the Reynolds Re D u uD 4m (e) r p D2 Properties: at Tm c p = 4182 J/kg-oC o ( 20 + 80 )( C) Tm = 50 o C 2 k = 0.6405 W/m-oC Pr = 3.57 = 0.553710-6 m2/s 96 r = 988 kg/m3 Use (e) u 4(0.002)(kg/s) 988(kg/m )p (0.015) (m ) 3 2 2 0.01146 m/s Use (d) gives Re D 0.01146(m/s)0.015(m) -6 0.5537 10 (m /s) 2 310.5 , laminar flow Determine Lh and Lt Lh Ch Re D D Lt C t PrRe D D (6.5) (6.6) 97 C h= 0.056 (Table 6.1) C t = 0.033 (Table 6.1) (6.5) and (6.6) Lh = 0.056 0.015 (m) 310.5 = 0.26 m Lt = 0.033 0.015 (m) 310.5 3.57 = 0.55 m • Lh and Lt are not negligible, tube length L = 0.8 m • Use Graetz solution Fig. 6.9 or Table 6.4 Compute x/D Re D Pr (f) 98 Nusselt number Nu gives h k h Nu D (g) (iii) Computation. Evaluating at x = L 0.8(m)/).015(m) 0.0481 310.5 3.57 At 0.481 Fig. 6.9 gives Nu 4.6 Substitute into (g) 0.6405(W/m- o C) h 4.6 196.4W/m 2 - o C 0.015(m) 99 Equation (a) gives Ts Compute the exponent of the exponential in (a) Ph L p (0.015)(m)( 196.4(W/m 2 -o C)0.8(m) 0.88524 o mc p 0.002(kg/s)4182(J/kg- C) Substitute into (a) 1 Ts 25( o C) - 75( o C)exp(0.88524) 110.1o C 1 - exp(0.88524) (iv) Checking. Dimensional check: Limiting checks: (i) For Tmi T (L) (no heating) Ts should be equal to Tmi . Set Tmi T (L) in (a) gives Ts Tmi 100 (ii) If L = 0, Ts should be infinite. Set in L = 0 (a) gives Ts Quantitative checks: (i) Approximate check: Energy added at the surface = Energy gained by water (h) Let Tm = average water temperature in tube Energy added at surface = hp DL(Ts - Tm ) (i) Energy gained by water = mc p (Tmo - Tmi ) (j) (j) and (k) into (i), solve for Ts 101 Ts Tm + m c p (Tmo - Tmi ) (k) h p DL (k) gives Ts 50( C) + o 0.002(kg/s)4182(J/kg-o C)(75 - 25)(o C) 196.4(W/m2 -o C)p (0.0155(m)(0.8)(m) 106.5o C (ii) Compare computed h with Table 1.1 (5) Comments • Small error is due to reading Fig. 6.9 • Fully developed temperature model: Nu D = 3.657, gives h 156.3W/m 2 - o C 102 6.8.2 Uniform Surface Heat Flux • Repeat Graetz entrance problem with uniform surface heat • Fully developed inlet velocity • Laminar flow through tube • Temperature is developing • No axial conduction (Pe > 100) r Energy equation: Same as for Graetz problem u T Ti 0 x qs D t qs Fig. 6.10 103 1 1 2 1- R R 2 R R R (6.62) Boundary conditions: ( ,0) )0 R ( ,1) qsro R k (Ti - Ts ) ( 0, R ) 1 (6.71a) (6.71b) (6.71c) Analytic solutions: Based on separation of variables (1) Local Nusselt number 104 hx 11 1 Nu( ) An exp(-2 n ) k 48 2 n 1 -1 2 (6.72) 2 Table 6.6 lists eigenvalues n and constant An (2) Average Nusselt number hx 11 Nu( ) k 48 2 -1 1 1 - exp(-2 n ) An 2 2 n 1 2 n (6.73) Limiting case: Fully developed: Set (6.72) or (6.73) -1 11 Nu( ) 4.364 48 Same as fully developed result (6.55). (6.74) 105 Graphical results: Fig. 6.11 106 Average Nu Nusselt number Local Nu x/D ReD Pr Fig. 6.11 Local and average Nusselt number for tube at uniform surface heat flux [4] 107