Farm Notes July 2012 CLOSING DATE NEARS FOR MARYLAND FALL- SEEDED FORAGE

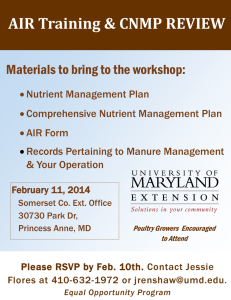

advertisement

Farm Notes July 2012 In This Issue …….. Closing Date For MD Fall Seeded Forage ........................ 1 July Is Ice Cream Month .................................................. 2 Meetings For Proposed Changes To Nutrient Management Regulations ....................................................................... 2 Women In Dairy 2012 Conference ................................... 3 FSA Future Payments ....................................................... 3 Weed Management in Double-Crop Soybeans ................. 4 Adapt Your Feeding Strategies For Summer Conditions.. 4 Lameness’ Domino Effect ................................................ 7 New Website Offers Farm Safety Resources.................... 8 Poisonous Pasture Weeds ................................................. 9 Reading This Article Could Save Your Life ................... 10 Smaller Year-Ending Soybean Stocks Expected ............ 11 Summer Ventilation: Fan Efficiency & Maintenance ..... 11 USDA Gearing Up To Conduct 2012 Census ................ 12 Using Plant Analysis To Diagnose Problems ................. 13 What To Expect From Foliar Fertilizer Programs .......... 14 Dates To Remember ....................................................... 15 CLOSING DATE NEARS FOR MARYLAND FALLSEEDED FORAGE The deadline for farmers to obtain crop insurance on fallseeded forage acreage is July 31, 2012. Current policyholders also have until July 31 to make any changes to existing contracts. The forage seeding policy covers newly seeded acreage of alfalfa and forage mixtures containing at least 50 percent alfalfa, clover, birdsfoot trefoil, or any other locally recognized and approved forage legume species (by weight) planted by August 31, 2012, for (Allegany & Garrett Counties) and September 10, 2012, for (Baltimore, Carroll, Cecil, Frederick, Harford, Howard, Montgomery & Washington Counties). A grower may secure up to $275 worth of coverage per acre under the plan. Coverage under this particular policy ends the earliest of: total destruction of the crop, initial harvest, commencement of grazing and/or final adjustment of a loss or abandonment of the crop. If there is an adequate stand, the acreage may then be insured for second and subsequent years under a separate forage production policy. Growers are strongly urged to contact a local crop insurance agent as soon as possible for premium quotes and other details. For a list of crop insurance agents, farmers may contact their local USDA Farm Service Agency office or log on to the following Risk Management Agency web site: http://www3.rma.usda.gov/tools/agents/ Source: 1 JULY IS ICE CREAM MONTH National Ice Cream Month is held in each year in July in the United States. Ronald Reagan designated July as National Ice Cream Month in 1984. He also named the third Sunday in July as National Ice Cream Day. Reagan recognized the popularity of ice cream in the United States (90% of the nation's population consumes ice cream) and stated that these two events should be observed with "appropriate ceremonies and activities." Source: Wikipedia PUBLIC MEETINGS PLANNED ON MARYLAND’S PROPOSED CHANGES TO NUTRIENT MANAGEMENT REGULATIONS The Maryland Department of Agriculture (MDA) will host a series of public meetings across the state to provide information to farmers, environmental interests, local governments and other stakeholders on proposed changes to Maryland’s Nutrient Management Regulations and offer an opportunity for public comment. The draft regulations are scheduled for publication in the Maryland Register on June 29, 2012. To read the proposed regulations online visit the Maryland Register or MDA’s website. The proposed regulations were submitted to the Joint Committee on Administrative, Executive and Legislative Review (AELR) on May 22 of this year following months of discussions with stakeholder groups and input from Governor Martin O’Malley’s Baystat Scientific Panel. They are designed to achieve consistency in the way all sources of nutrients are managed and help Maryland meet nitrogen and phosphorus reduction goals spelled out in its Watershed Implementation Plan (WIP) to protect and restore the Chesapeake Bay. MDA will hold public meetings in four locations around the state in July. All meetings will be held from 7:00 p.m. to 9:00 p.m. For more information, contact the Nutrient Management Program at 410-841-5959. North Central Maryland Tuesday, July 10, 2012 Harford Community College Amoss Center 401 Thomas Run Road Bel Air, MD 21015 Western Maryland Wednesday, July 18, 2012 Washington County Agricultural Education Center 7313 Sharpsburg Place Boonsboro, MD 21733 Eastern Shore Monday, July 23, 2012 Talbot Community Center 10028 Ocean Gateway Easton, MD 21601 Southern Maryland Wednesday, July 25, 2012 Calvert County Fairgrounds 140 Calvert Fair Drive Prince Frederick, MD 20610 Comments may be sent to Jo Mercer, Ed.D., Program Manager, MDA’s Nutrient Management Program, Maryland Department of Agriculture, 50 Harry S. Truman Parkway, Annapolis, MD 21401, or email jo.mercer@maryland.gov, or fax to (410) 841-5950. Comments will be accepted through August 13, 2012. Source: MDA 2 WOMEN IN DAIRY 2012 CONFERENCE November 7, 2012 Best Western Premier Central Hotel and Convention Center 800 East Park Drive, Harrisburg, PA Hours: 9 a.m. to 4 p.m. About the conference: "Women in Dairy 2012" is a conference that promises to inspire, inform, and motivate you! Whether you’re a dairy owner, manager, employee, or an agribusiness professional, you'll enjoy this opportunity to network with other women in dairy at a day created just for you. Re-visit this site for more information coming soon: http://www.das.psu.edu/dairy-alliance/education/womenin-dairy Source: Penn State Extension Dairy Team FSA - OVER THE COUNTER CHANNEL (OTCnet) – FUTURE PAYMENTS FSA was told to inform all producers about this new process. We do not yet know when this will take effect, but it could be as early as September 30, 2012. Over the Counter Channel (OTCnet) FSA/CCC is moving toward OTCnet, an electronic method for processing customer check payments. When a check is submitted for payment either in person or through the mail, the check will be converted into an Electronic Funds Transfer (EFT). The funds will be debited from the producer’s account, usually within 24 hours of receipt. Please see the U.S. Department of Treasury legal notices posted in the Service Center or visit the following U.S. Department of Treasury Internet site for detailed information. http://fms.treas.gov/otcnet/legal.html What is OTCnet? OTCnet is a Web-based online application process for converting paper checks presented to FSA into electronic debits to the producer’s bank account. It presents many benefits, such as reducing lost/misplaced checks and paper handling. This improves customer relations, speeds the check clearing process, and reduces the potential for human error. How will your check be handled? The check will be scanned into the system and voided. The customer will not receive the check back from FSA. FSA will hold checks for up to 14 calendar days to ensure that the item was successfully processed, and then FSA will shred the check. How quickly will funds be transferred from your account? The transfer of funds from your account could occur within 24 hours. Therefore, you should be sure that you have sufficient funds in your account to process the transaction. If you do not have sufficient funds, we may initiate the transaction again. 3 How will this transaction appear on your account statement? The transfer of funds will be reflected on your account statement. The transaction may be recorded in a different place on your statement than where your checks normally appear, such as under “other withdrawals” or “other transactions”. What are your rights if there is a problem with the transaction? You have protections under Federal law for an unauthorized electronic fund transfer from your account. You should contact your financial institution immediately if you believe that the transaction reported on your account statement was not properly authorized or is otherwise incorrect. Source: FSA WEED MANAGEMENT IN DOUBLE-CROP SOYBEANS With the barley and wheat crops coming off earlier than normal this year, double-crop soybean planting should be as popular as ever. Weeds are generally less of a problem in double-crop soybean because of the delayed planting date. This results in fewer weeds emerging, but when they are present, the combination of weed competition and potential dry weather can greatly impact yield potential. A weed-free start is one of the most critical aspects of weed management in double-crop soybean. One of the biggest weed concerns is managing glyphosate-resistant marestail or horseweed. Some of these populations may also be ALS-resistant. Marestail that are cut off during small grain harvest will recover, branch out, and probably be even more difficult to control. In full season soybeans, we have been strongly advocating the use of 2, 4-DLVE in the burndown program. However, most growers are not willing to wait the necessary 7 days after 2, 4-D application in doublecrop. So, what are the options? • • • • • • • • For glyphosate susceptible marestail, apply glyphosate at 1.5 lb ae/A (44 fl oz of Roundup PowerMax, 48 fl oz or Touchdown Total or Durango DMA or 64 fl oz of a 3 lb ae/gal product). Include 1 pt per acre 2, 4-DLVE in the burndown and wait 7 days to plant. Add 1 oz of Sharpen (or equivalent rates of Optill or Verdict) to glyphosate. Add FirstRate (or Authority First or Sonic) or a chlorimuron containing product (Authority XL, Canopy, Envive, Synchrony, Valor XLT, etc.) to improve control if the population is not ALS-resistant. Use Ignite or Liberty at 29 to 36 fl oz in the burndown application. This is fairly good on marestail, but not that effective on some other weeds such as large annual grasses and Canada thistle. You can tankmix with other herbicides to improve performance and provide residual control (Sharpen, metribuzin, etc.) Plant a LibertyLink soybean and apply Ignite or Liberty POST as needed. Plant a Roundup Ready soybean and apply glyphosate POST if marestail is not a problem. For growers interested in non GMO soybeans, a number of POST herbicides are still available, but many of the broadleaf products have some potential for soybean injury and they are not effective for control of marestail. Source: Bill Curran and Dwight Lingenfelter, Weed Science, PNST Extension ADAPT YOUR FEEDING STRATEGIES FOR SUMMER CONDITIONS In addition to cooling, shade, and ventilation, strategic adjustments to diet formulation and feeding management can help cows to better cope with extreme weather conditions. 4 Until recently, heat stress for dairy cows was thought to begin at a temperature humidity index (THI) of 72. However, research using modern cows with greater milk production has determined that heat stress can begin at a THI of 68. Summer season negatively affects dairy cow performance in Pennsylvania as temperature and humidity rise. The main effects associated with summer conditions in dairy cows are a notable drop in milk and fat yield along with increased health and fertility problems. These can obviously have considerable impact in profitability, so we all must make adjustments to management and feeding practices to get through this challenging period. Hot, humid summer conditions cause bunk problems such as mold and fermentation that affect feed quality. Molds grow more readily in hot, wet weather, while feeds exposed to these conditions will undergo fermentation and heat in the feed bunk. Spoiled and heated feed is a real problem as it is not acceptable for dairy cows. Even heifers will back off from this type of feed if it is fed to them the following day after being refused by the cows. The intensity of heat stress can be measured by the temperature humidity index (THI), which combines the effects of temperature and humidity. Until recently, heat stress for dairy cows was thought to begin at a THI of 72. However, research using modern cows with greater milk production has determined that heat stress can begin at a THI of 68. At this level body temperature reaches 101.3°F and respiration rate is 60 breaths per minute; milk losses and reproductive losses also occur at this threshold. To diminish the effects of heat stress, cows decrease feed dry matter consumption, drink more water, and attempt to evaporate water from lungs and skin. Heat stressed cows eat less to avoid excess of heat from digestion, which is even more critical if the diet digestibility is low. When a cow's dry matter intake (DMI) decreases, the amount of nutrients available to support high milk yield is limited. In addition, energy expenses to maintenance are increased mainly due to efforts to stay cool, such as increased panting activity. If cows are refusing food, they have a greater chance of increased sorting for smaller particle size that can in turn increase the risk of sub-acute ruminal acidosis. Increased respiration rates increases the amount of carbon dioxide lost from the blood and bicarbonate excreted in urine, so less bicarbonate goes to saliva. Heat stressed cows also have less chewing activity and fewer ruminal movements due to less feed/forage intake. Hence, the buffering capacity of the rumen is reduced and they become prone to develop ruminal acidosis. Increased sweating makes the cow lose electrolytes, mainly potassium and sodium that are important for the overall animal cation-anion balance. In addition to cooling, shade, and ventilation considerations that are very important, strategic adjustments to diet formulation and feeding management can have a significant importance in allowing cows to better cope with extreme weather conditions. Strategies should be considered according to specific farm conditions, and some of these are: Adjust nutrient concentration Adjust nutrient concentration in the diet to help account for the drop in DMI, thereby keeping the same amount of nutrients in less feed. Special considerations to neutral detergent fiber (NDF), protein, potassium, and sodium are needed. Because forages produce greater heat of fermentation and have less energy than grain, decreasing forage to concentrate ratio can help to reduce NDF and the load of heat from digestion while increasing energy density of the diet. However, if NDF levels are already close to NRC recommendations, a decrease in fiber can risk leading to acidosis problems. The use of high quality forages and more digestible fiber in those forages 5 could play a key role in this as it improves diet digestibility and lessens the heat impact. Additives that improve fiber digestibility, such as yeast culture, can also be helpful. Increased protein concentration is important to maintain high milk yield with low DMI; however, keeping the amount of protein supplied in balance with the cow’s needs is essential to controlling diet costs and limiting nutrient losses in manure. Reducing rumen degradable protein and balancing for amino acids can be particularly helpful in diets for cows under heat stress. It is important to check that potassium and sodium concentrations are at least at 1.5 and 0.5% of ration dry matter respectively to facilitate electrolyte equilibrium and restore minerals lost due to increased respiration and perspiration. Adjust ration magnesium levels accordingly (0.35 to 0.40%). Feeding buffers such as sodium bicarbonate or sodium bentonite might help to prevent rumen pH drop and problems related to acidosis, including milk fat depression. Including or increasing inert fats can help to maintain energy intake when DMI is depressed by heat. In addition, fats produce less heat than fiber or starch when they are digested. Adjust feeding frequency Adjusting feeding frequency so cows are fed more than once a day could contribute to maintaining the freshness offered. Attention should be given to the feed quality in order to observe molds or feed heating and to cleaning the bunk more frequently. Feed animals several hours before or after the daily THI peak. Early morning and late afternoon feeding can avoid the coincidence of peak THI with the peak of digestion heat, which often occurs some four hours after feeding. Provide ample water Allow for ample drinking water. Water is a very important nutrient to produce milk, it becomes the most critical during heat stress as cows use it to refresh. Cows should have free and easy access to drink fresh and clean water; watering units have to be working well, without leaks and they have to be cleaned often to avoid algae or other contaminants. Providing more water space per cow can be beneficial in the summer months. Manage the environment It has to be kept in mind that environmental management can have a great impact on alleviating heat stress. Fans and sprinklers are effective tools to keep cows cool; adequate cow density, ventilation, and shade should also be provided to avoid heat stress. Summer conditions can be tough on high producing dairy cows, but adequate feeding practices can help to mitigate the effects of heat and humidity on cows’ well-being and performance. Source: By Elmer Edgardo Corea, professor, University of El Salvador and visiting Fulbright Scholar; Dr. Jud Heinrichs, professor, Penn State Department of Dairy and Animal Science, and Coleen Jones, Penn State Extension Dairy Team 6 LAMENESS' DOMINO EFFECT Research shows how lameness can contribute to reproductive problems that drain profits. As I visit dairy farms across Pennsylvania in my role as a Penn State Dairy Extension Team member, two dairy cow health related problems persist on many of the farms, lameness and delayed pregnancies due to various reproductive issues. According to an eXtension article updated on January 27, 2011, studies completed in the state of New York have shown lameness to cost $90 per cow/year on average. Interestingly, the review of an article written by John F. Smith (1999), Extension Dairy Specialist, New Mexico State University, suggests that a delay in pregnancy of 30 days may result in a loss of $90 per cow/year, based on a loss of $3.00 per cow per day for open cows beyond 90 days post calving. Can lameness ($90 per cow/year) add to reproductive problems ($90 per cow/year) in dairy herds we are working with, resulting in a multiplying effect on loss to profitability? In the proceedings of the 2011 Dairy Cattle Reproduction Council’s annual meeting, Dr. Jeffrey Defrain, Dr. Michael Socha, and Dr. Dana Tomlinson, Zinpro Inc., present a review of several research articles that provides an answer to this question. Here are some of the major conclusions they cited from studies conducted on this topic: Lucey et al. (1986) found that lameness was associated with a longer interval between calving and first service breedings. The largest increase (17 and 30 days) occurred in cows with either sole or white line lesions that were occurring in early lactation. The study also found that conception rates were lower in lame cows (31%) compared to other healthy cows (40%). More recent work by Hedandez et al. (2005) found lameness increased the time period from calving to conception 3 times greater than the estimates initially reported by Lucey et al (1986). Speicher et al. (1997) examined data for cows scoring 3 or higher on the 5 point dairy cow locomotion scoring system. These cows were 2.8 times more likely to have increased days to first service, 15.6 times more likely to have increased days open and 9.0 times more likely to have increased services per conception. These cows were also 8.4 times more likely to be culled from the herd. Hernandez et al. (2000) found cows with abscesses/sole ulcers were open 63 days longer than healthy cows exhibiting no lameness issues. Melandez et al. (2003) showed that cows clinically lame due to a claw disorder in the first 30 days post calving had a 58.9 % decrease in first service conception rate and an increase in the incidence of ovarian cysts. With these studies in mind, it is apparent that dairy producers should deal promptly with dairy cow lameness, not only because of the economic losses due directly to lameness issues, but also because of the economic losses due indirectly to lameness as it relates to increased days open and other reproduction factors. Information about lameness can be found at http://www.healthyhooves.com/pdffiles/dr%20shearer.pdf. Source: By Gary Hennip, Extension educator, Penn State Extension Dairy Team 7 NEW WEBSITE OFFERS FARM SAFETY RESOURCES A new farm-related educational resource has been added to a national website that offers everyone from beginning farmers to veteran growers answers to hundreds of farm-related safety and health questions, in an easy-to-navigate format featuring information offered from a consortium of 74 land-grant universities, including Ohio State University. The website (http://www.extension.org/farm_safety_and_health) offers answers and tips on farm safety and health issues ranging from grain bin entrapments to safe beef cattle handling, said Dee Jepsen, Ohio State University Extension's state safety leader. "This online resource will serve many groups, including educators, injury outreach specialists and farm workers, with valuable information that can be accessed anytime," she said. "And in an agricultural community where business is done all day, every day, there is never a down time for safety and health information." eXtension (which is pronounced E-extension) is a national internet-based educational network and partnership of 74 universities that provides online access to objective, research-based information and education, Jepsen said. The new section is called Community of Practice, Farm and Ranch eXtension for Safety and Health, or FReSH. "Agriculture is a dangerous industry," she said. "This on-line resource is now available to serve hard-working men, women and families with up-to-date safety and health materials to protect the most valuable assets: the farm workers. "Besides providing answers to frequently asked farm safety questions, this site also contains relevant articles on a variety of safety and health topics, and a calendar of farm safety events." Some of the articles that appear on the site include: • • • • • • Safety recommendations when baling and handling big round bales. Confined-space hazards and gas monitoring of manure pit gases. Beef cattle handling safety. ATV safety. Hearing loss and protection for agricultural producers. Grain bin entrapments from flowing grains. "We are nearing our peak season for the frequency and severity of farm-related injuries," Jepsen said. "This is great timing for eXtension to support the upcoming summer season with an ounce of prevention." Support for the farm safety and health content on the website comes from a team of educators, including Linda Fetzer, Dennis Murphy and Aaron Yoder of Pennsylvania State University; Richard Brozowski, University of Maine; Karen Funkenbusch, University of Missouri; Jepsen, Ohio State; Carol Jones, Oklahoma State University; Michael Pate, Utah State University; Charles Schwab, Iowa State University; and John Myers, Centers for Disease Control and Prevention. Source: Ohio State University Extension, June 9, 2012 8 POISONOUS PASTURE WEEDS As hot and dryer weather arrive in Pennsylvania, poisonous plants in pastures become a greater concern. Slow growth of pasture grasses can easily result in overgrazing, which means that grazing animals might not have sufficient forage intake and start eating some less desirable plant species. Grazing animals will very rarely eat poisonous weeds if there are other options. Keeping pastures growing rapidly and knowing which species to be most concerned about will help in minimizing the risk of poisonous pasture plants. Table 1. Selected poisonous plants of the Northeast (adapted from Fishel, 2000; Hardin, 1973; and Hill and Folland, 1986; and Wolfgang, Penn State) Common Bouncing bet Buttercups Cherry, black Hemlock, poison Jimsonweed Locust, black Milkweeds Nightshade species Pigweed species Problems/symptoms Leaves and stem – delayed for several days; depression, vomiting, abdominal pain, diarrhea Leaves and stem especially in flower. Dried hay loses toxicity - anorexia, salivation, weakness, convulsions, breathing difficulty, death Leaves (wilted leaves are worse), stems, bark and fruit - anxiety, staggering, breathing difficulty, dilated pupils, bloat, death All plant parts - nervousness, salivation, vomiting, diarrhea, weakness, paralysis, trembling, dilation of pupils convulsions, and coma, death Entire plant (seeds are most toxic) - Thirst, mood swings, convulsions, coma, death Leaves (especially wilted), seeds, and inner bark - causes weakness, depression, anorexia, vomiting and diarrhea Entire plant - depression, muscle tremors, spasms, bloat, difficult breathing Vegetation, unripe fruit - loss of appetite, salivation, weakness, trembling, paralysis Foliage (worse in drought) - kidney disease, weakness, edema, rapid respiration Pokeweed Entire plant, especially roots – gastrointestinal cramps, weakened pulse, respiration, salivation Snakeroot, white Leaves and stem - constipation, loss of appetite, salivation, rapid respiration. Toxin passes through milk (milksickness) Flowers and leaves – photosensitivity which leads to redness of muzzle, around eyes, and around white hair St. Johnswort Toxic ingredient — toxicity dosage Saponin – amount equivalent to 3% animal dry weight) will kill within 4 hrs. Protoanemonin - toxicity reported to vary with species, age, and habitat, Generally 1-3% of body weight necessary. Cyanogenic glycosides - Less than 0.25 lb leaves (fresh wt.) can be toxic to 100 lb animal. Leaves from several small to mid-sized branches are sufficient to kill an adult animal. Coniine and others (pyridine alkaloids) - 0.5 to 4% (fresh wt,) equivalent of cattle wt, is toxic. In horses, 0.25% of body weight. Solanaceous alkaloids – 0.06 to 0.09% (dry wt.) equivalent of animal body wt, is toxic. Phytotoxin robin, glycoside robitinm - bark extract and powder in amount equivalent to 0.04 - 0.1% of animal wt. toxic to horses, Cattle 10-times more tolerant. Glycosides and galitoxin - 0.3 to 0.6% of body weight. Solanine - toxic at 42 mg/kg (LD50). 0.1 to 0.3% of body weight. Nitrates nitrate oxalates, unknown - 0.5 to 1% of diet. Sheep, hogs, and young calves most susceptible. Phytolacctinm - 10 or more berries can result in toxicity to humans, Unknown for livestock, but perhaps 100-200 berries/1000 lb. Trophine alkaloid - varies from 1 to 2% of animal body wt, after 2 weeks. Toxin cumulative. Hypercin - uncertain 9 Key points about weed forage quality and poisonous plants: • • • • • • Some weeds have excellent nutritive quality. Weeds in the vegetative stage of development usually are more nutritious than more mature weeds. Regardless of weed quality, livestock may avoid grazing certain plants because of taste, smell, or toxicity. Some plants contain potentially poisonous substances that may be toxic to livestock if consumed – properly identify potential problem weeds and consult with a veterinarian if necessary. A productive pasture is important to reduce the potential incidence of toxic weed exposure to livestock. Remember to soil test and maintain the proper lime and fertility levels. If possible, routinely mow or spray to manage weed problems within and around pasture area Source: Marvin Hall, Dwight Lingenfelter and Bill Curran, PSU Extension Forage and Weed Specialists READING THIS ARTICLE COULD SAVE YOUR LIFE The recent tragic death of three Pennsylvanians at a Maryland manure storage should act as a reminder of the risks associated with all manure storages. Injuries and fatalities are commonly associated with confined space manure storages that are enclosed, such as beneath animal quarters, or belowground reception and pump out pits. However, these deaths occurred at a non-enclosed earthen dairy manure storage that was open to the atmosphere. For many of us these open-air storages are not thought of as confined spaces. It is important to realize that these storages still meet the definition of a confined space in terms of occupational safety and health. This is because the areas are not designed for normal worker/human occupation and often do not have means of egress. In a common storage situation, once you cross beyond the fence you are entering a confined space. In the case of open-air manure storage pits and ponds there are many hazards to consider. Every manure storage is different. Footing near storages can be hazardous. Steep and slippery slopes that can make getting out of manure storages difficult or impossible. Localized layers of hazardous gases can exist above manure surfaces, especially on hot, humid days with little to no breeze. Increased rate of gas release may occur due to movement, agitation, removal, or addition of manure. This may mean that someone who is ‘treading’ in manure may not have sufficient oxygen to breathe. Finally, response time for adequate emergency actions can be slow due site isolation and remoteness. Agricultural safety guidelines are admittedly crude in comparison to industrial standards. Dennis Murphy, Davis Hill (both with the Penn State Ag Safety program), Mike Aucoin, Department of Agriculture, and I have put together the following list of safety guidelines to follow. 1. Make sure everyone that needs to be near manure storage structures understand the hazards that exist, including the effects that the various gases have on them. 2. Make sure the open air manure storage has a fence installed around the perimeter and access gates are locked to keep unauthorized personnel from entering the area. 3. The open air storage should have manure drowning hazard signs and no trespassing signs on all sides of the storage. 4. If you must go into the fenced area of the open manure storage, wearing a safety harness with life line attached to a safely located solid object or anchor will enhance your chances of rescue. 10 5. Never work alone. The second person’s role is to summon help in an emergency and assist with rescue without entering the storage (more than 50% of confined space deaths occur to rescuers!). 6. Rescue equipment, such as flotation devices and lifelines, should be attached to every manure pump. 7. Move slowly around manure storages as the ground can be slippery or uneven and may cause a person to trip or stumble. There should be no horseplay near the open manure pit or pumping equipment. 8. Always act as if manure depths are deep. Unlike water, you cannot see into manure to judge the bottom surface. 9. Bystanders and non-essential workers should stay away from pump out or other accessible areas. 10. Explosive gas may be lurking near where agitation or pumping is occurring. No smoking, open flames or sparks should be allowed. If equipment malfunctions during agitating or pumping of the manure, shut all equipment off and remove it from the storage before servicing or repairing. 11. If you feel unsure or uncomfortable with what you are getting ready to do near the open manure pit, step back, contact someone and review the situation before proceeding. 12. Be prepared to call 911 if an emergency happens. Being prepared means accurately describing the incident, number of victims, and giving specific directions to the site of the emergency. Further information on manure storage safety can be found at http://www.agsafety.psu.edu/ Source: Rob Meinen, Department of Animal Science, PNST SMALLER YEAR-ENDING SOYBEAN STOCKS EXPECTED Implications The projections of small year-ending domestic stocks for corn and soybeans now put additional importance on the size of the 2012 harvest. The Grain Stocks and Acreage reports to be released on June 29 will provide a chance to re-evaluate the stocks and production situation, but the main focus will continue to be on yield prospects. On-going stressful weather in substantial portions of the corn and soybean growing areas and declining crop condition ratings are cause for concern, but the markets continue to reflect very high yield expectations. Unless the weather pattern in central and eastern growing areas changes, prices may have to start reflecting more production risk. Source: Darrel Good, Department of Agricultural and Consumer Economics, University of Illinois SUMMER VENTILATION: FAN EFFICIENCY AND MAINTENANCE Poor maintenance can reduce efficiency of ventilation systems by as much as 40 percent. The ventilation system of your dairy consumes about 21% to 24% of the energy used on the dairy. This does not mean that you should shut off the fans for the summer, but it does mean you should be looking at the efficiency of those fans. Fan efficiency is commonly measured as cubic feet per minute (cfm) of air per watt (W) of electricity consumed to give a cfm/W number. Fan efficiency is affected by several factors including blade design, housing design, and motor efficiency. Therefore it can be said that “not all fans are created equal” and you often “get what you pay for”. 11 If you are looking to buy new fans make sure you take a look at the efficiency rating of the fans as you compare. Typically larger fan will have better efficiency than smaller fans. If installing fans in a tunnel ventilation system, look for fans with a minimum efficiency rating of 20 cfm/W at 0.05-inches static pressure. Efficiency ratings for circulation fans are also available. However, it is given as a Thrust Efficiency Ratio in terms of pounds of force per kilowatt of power (lbf/kW). Once again, larger fans tend to have a better efficiency. When shopping for circulation fans you should be looking for fans with a minimum rating of 21 lbf/kW. Possibly the best thing you can do to improve the efficiency of your ventilation system is to simply maintain your fans. Poor maintenance —mostly lack of cleaning — can reduce efficiency by as much as 40%! What this means is the electric bill stays the same, but less air is moving in the barn. Those squeaking bearings, flopping belts, and dirty blades and shutters are really just robbing your power. Accumulation of as little as 1/8 inch of dirt on the fan blades can significantly reduce fan performance. Monthly fan maintenance and cleaning would be best, but at a minimum it should be done before start-up and twice during the summer. To keep cows happy, healthy, and productive requires ventilation. In the summer this means lots of air to help in cow cooling, which leads to lots of fans. Making sure you choose well built and efficient fans and then regularly maintaining those fans goes a long way in helping to keep energy costs in check on the dairy. For more about managing ventilation in your dairy barn, view the video at: http://www.das.psu.edu/dairyalliance/education/technology Source: By John Tyson, Agricultural Engineer, Penn State Extension Dairy Team USDA GEARING UP TO CONDUCT 2012 CENSUS OF AGRICULTURE:NATIONAL AGRICULTURAL CLASSIFICATION SURVEY IS AN IMPORTANT STEP TOWARD A COMPLETE COUNT Surveys are now arriving in mailboxes around the nation to help identify all active farms in the United States. The National Agricultural Classification Survey (NACS), which asks landowners whether or not they are farming and for basic farm information, is one of the most important early steps used to determine who should receive a 2012 Census of Agriculture report form. NACS’s Census and Survey Director, Renee Picanso says “The Census is the leading source of facts about American agriculture and the only source of agricultural statistics that is comparable for each county in the nation. Farm organizations, businesses, government decision-makers, commodity market analysts, news media, researchers and others use Census data to inform their work.” NACS is required by law as part of the U.S. Census of Agriculture. By this same law, all information reported by individuals is kept confidential. NASS will mail the 2012 Census of Agriculture later this year and data will be collected into early 2013. “The NACS survey is the first step in getting a complete count, so we ask everyone who receives a survey to complete and return it,” said Picanso. “The Census is a valuable way for producers and rural America to show their strength – in numbers.” The 2012 Census of Agriculture is your voice, your future, your responsibility. For more information about NACS, the Census of Agriculture, or to add your name to the Census mail list, visit http://www.agcensus.usda.gov. Source: NASS/USDA 12 USING PLANT ANALYSIS TO DIAGNOSE NUTRIENT DEFICIENCY PROBLEMS Plant analysis is a valuable tool for monitoring crop nutrition and diagnosing suspected plant nutrient deficiency problems. There are two ways to use plant analysis. The first method is to compare the analysis of the plant tissue with standard tables of interpretive values. Since the table values are for specific plant parts sampled at a specific stage of growth, it is critical that sampling guidelines be strictly followed. The following table provides general sampling guidelines for common agronomic crops. Information on sampling other crops and plant analysis interpretation levels are available on the Penn State Agricultural Analytical Services Lab web site at: http://www.aasl.psu.edu/plant_tissue_prog.html Sampling Guidelines for Plant Analysis Crop Sampling Time Plant Part Corn Silking Earleaf Corn 12-18” tall Whole plant Forage legumes Bud to 10% bloom Top 1/3 of plant Small grains Just prior to heading Uppermost leaves Soybeans Prior to or early flowering Uppermost full leaves Forage grasses 3-4 weeks between cuttings Top of the plant Remember that book values are only available for the few specific stages of growth such as those given in the table above. For annual crops the recommended sampling times are often not for the stage of growth when the problem is observed and usually they are too late to take corrective action. For perennial crops corrective action can often be taken during the next season or next cutting. A final problem with this method is that there are many environmental and cultural factors that can influence the level of a nutrient in plant tissue. Thus, book values are only ball-park estimates of sufficiency for nutrients and actual sufficiency levels can vary significantly depending on the specific conditions. For using plant analysis to diagnose visible nutrient deficiency problems, the best approach is to take comparative samples. With this method two samples are taken for analysis. One sample is taken from the problem area and the second sample is taken from a nearby area that is as near to identical to the problem area as possible but is showing normal growth. This method can be used at any stage of growth and it eliminates the confounding effects of most of the cultural and environmental factors. When using this method the two samples must be taken at the same time and the same plant part must be sampled. Usually the newest fully developed leaves or stems are the best plant part to sample for this method. If the problem is nutritional, comparison of the nutrient levels in the two samples usually gives a direct indication of the problem. Regardless of the method used, it is important to use all available information to interpret the plant analysis for diagnosing a nutrient deficiency. Look carefully at the symptoms on the plants, note any patterns in the field, consider the timing of the appearance of the problem. Keep in mind that not all nutrient deficiencies in plants are the result of nutrient deficiencies in the soil. Soil tests and plant analysis are often complementary. They can confirm each other, but they can also indicate when the cause of the problem is something other than a soil deficiency of the nutrient. If the soil test level is adequate but the plants are deficient, this indicates that some 13 other factor is limiting the plants ability to take up the available nutrients. Some areas to consider include: possible interactions with other cultural practices such as tillage or pesticides; pest injury such as root worm feeding; differences in varieties or hybrids; or soil physical conditions such as compaction. If used properly plant analysis can be a very useful tool for diagnosing plant nutritional problems and suggesting solutions to these problems. Source: Doug Beegle, Soil Fertility, PNST Extension WHAT TO EXPECT FROM FOLIAR FERTILIZER PROGRAMS Strong commodity prices have encouraged producers to look for ways to increase their yields even if it is only for a few bushels. Retail businesses have of wide array of available foliar fertilizers for producers to try to get those few bushels. Before using a foliar program one should review university research summaries and ask if the concept is sound. University research has not shown a consistent response to foliar fertilizers. There have been sites that have seen a yield response and some that have seen a yield loss. For most sites there has been no yield change (Ohio data has not shown a yield gain or loss). When a yield response has been seen, researchers were often unable to explain why it worked at one site and not others. Soybeans have been more responsive than corn. Universities generally do not recommend foliar programs since the research results have been inconsistent, unrepeatable and unpredictable. There are limitations to a foliar program. Crop leaves are made for photosynthesis and not nutrient absorption. A foliar has to be absorbed by the leaf before it dries by entering stomata openings or passing through the cuticle – neither one an easy process. Because of this limitation, it is highly unlikely that a plant would have the ability to absorb large amounts of any given nutrient. Thus a foliar program would be impractical to correct major deficiencies for the macronutrients (N, P, K, Ca, Mg, or S). However, a savvy marketing program often adds a small amount of N or S to a foliar for visual impact (causes the leaves to look greener giving the impression one is getting a benefit from the foliar, but generally no increase in yield). If too much N has been added tissue burn may occur. If a soil is truly not able to provide roots a micronutrient, foliar application may be a viable option since the crop only needs a very small amount. This critical amount would have to enter the leaf through the same restricted pathways as mentioned above. However, available micronutrients should easily be provided to roots in fields where the soil has the optimum pH range, has adequate organic matter, has proper soil moisture, and has followed a balanced nutrient program based on soil tests. University research is one tool a producer has to select production practices. There are many new foliar programs and products available each year that universities’ have not evaluated. If a producer selects one of these programs, they should leave at least one strip that does not receive the foliar program for a yield check to confirm potential benefits. Producers should be suspicious of programs that recommend foliar products based on plant analysis. There have been instances where a company pulls tissue from a field for analysis and then recommends a producer to apply certain foliar products based on that analysis, regardless of crop condition or growth stage. No university research supports this type of nutrient recommendation. Plant analysis is a diagnostic tool and not a fertilizer recommendation program. Nutrient sufficiency levels were not established or correlated to make a fertilizer recommendation, but to evaluate a crop at a specific stage of development. Tissue analysis is an interpretive 14 tool, not an absolute yes or no answer tool. When properly used as a diagnostic tool, plant tissue should be collected from a normal area and the area of concern along with a soil sample for analysis from the two areas. Source: Ed Lentz, Extension Educator, Ohio State University Extension, Findlay, OH (From the Ohio State University Extension, CORN Newsletter, 2012–18) DATES TO REMEMBER July 7 Ayrshire Show-Frederick, MD July 7 Holstein Show-Hagerstown, MD July 16 Holstein Show-Central, MD (evening) July 16 Holstein Show-Queen Anne’s 4-H Park, MD July 17 Holstein Show-Deep Creek, MD (evening) July 19 Au Natural! Non-Chemical Weed Control-6 to 8 pm, UMD Equine Rotational Grazing Demo Site, 4241 Folly Quarter Road, Ellicott City, MD Contact: jenreyn@umd.edu July 19 Holstein Show-Frederick, MD (evening) July 21 Jersey Show-Frederick, MD July 25–27 Mid Atlantic Dairy Grazing Conference & Organic Dairy Field Day-Washington College Gibson Center, 300 Washington Avenue, Chestertown, MD 21620 Contact: jdouthit@umd.edu or 410-778-1661 August 3 & 4 Brown Swiss Show-Frederick, MD August 9 Organic Vegetable Growers Twilight Meeting-5 to 8:30 pm, Upper Marlboro Research & Education Center, 2005 Largo Road, Upper Marlboro, MD 20774 Contact: 301-6278440 August 14-16 Ag Progress Days-Contact: http://agsci.psu.edu/apd August 30 Ayrshire Show-MD State Fair, Timonium, MD August 30 Holstein Futurity-MD State Fair, Timonium, MD August 30 Jersey Show-MD State Fair, Timonium, MD August 30 Milking Shorthorn Show-MD State Fair, Timonium, MD August 30 Red & White Show-MD State Fair, Timonium, MD August 31 Brown Swiss Show-MD State Fair, Timonium, MD August 31 Holstein Show-MD State Fair, Timonium, MD 15 August 31 Guernsey Show-MD State Fair, Timonium, MD September 8 2012 Horse Pasture Management Seminar-9 to 3 pm, UMD Equine Rotational Grazing Demo Site, 4241 Folly Quarter Road, Ellicott City, MD Contact: jenreyn@umd.edu Visit our web site at http://carroll.umd.edu For more event listings visit http://www.agnr.umd.edu/AGNRCalendar/ Yours for better farming from your Carroll County Agriculture Extension Educators, Michael R. Bell Extension Agent Agriculture & Natural Resources mbell@umd.edu Bryan R. Butler, Sr. Extension Agent Commercial Horticulture/ Mid-MD Tree Fruit bbutlers@umd.edu Steve Allgeier Extension Educator Home Horticulture/ Master Gardener Coordinator hortman@umd.edu If you would like to be removed from our mailing list, please call: 410-386-2760 or 1-888-326-9645. If you have a disability that requires special assistance for your participation in a program please contact the Carroll County Extension Office at 410-386-2760, Fax: 410-876-0132, two weeks prior to the program. The information given herein is supplied with the understanding that no discrimination is intended and no endorsement by University of Maryland Extension is implied. 16