ETSI SR 002 787 V1.1.1

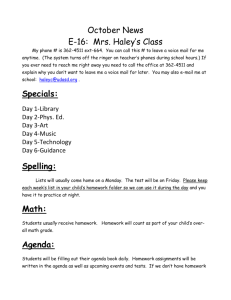

advertisement