,:i;x, ";;;; ; :#ffi ;1 " * *, *,.t :if

advertisement

";;;;

;:#ffi;1

"**,*,.t:if,:i;x,

;:,i::!,

:#,:,;:t"

i ;x:f,::

:3:,f

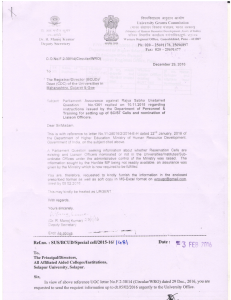

CuAV/HZSM-Sfor METHANE CONVERSIONTO LIQUID HYDROCARBONS

Nor Aishah Saidina Aminr

Didi Dwi Anggoro'?

lFaculry of Chemical& Natural ResourcesEnEineerins,UnivetsitiTeknologiMalatsia'

81310Studai, Johor, Malqsia

Universit, of DiponeSorc,Semamng50239,Indonesia

'zDepartnentof ChemicalEngineennS,

Abstract

of naturalgas,and in particular'the

The dhectconversion

to usefuiproduclshasbeen

principalcomponena.

methane,

inlenseiystudiedover the pastdecadesZSM-s zeolitehas

been known to be a suitable catalyst for olefln

olisomerizadon,but i! is not resistantto high temperatur$.

lnlhis work, HZSM-s was modified with copper and

lungsLenlo developa highly active and heal resisLanL

ofCu

Theperfomlances

oxidatjve-acidca!alysL.

biluncrional

modified W/HZSM-5 were comparedwith MSM-5 for the

oxida[ion of methane to liquid hydrocarbons The

chamcterizationresultsrevealedthatthe additionof tungsten

ro HZSM-s zeolite imFoved its themlal stabilitv. Response

SurfaceMethodology (RSM) was enployed to detemine

the optimum metha.neconvenion and C5' selectivity.

Numerical results indicated the optimum methane

conversionof 29.4 7owith the correspondingCi* selectivity

at 12.3vol.%ofOr,203.9mvminof

of57.27,wereachieved

total feed flow rate,and % W dopedof 3.2 wt%. The

optimumC5*seleclivity ol 70.2 qow^s andneAat 7.6 \ol.Ea

oi or, 208.9nJ/rnin of total feed flow mte, and 3.2 wt.7oof

w content with the correspondingmetharc conversion of

26.'7%. By means of variance analysis and additional

experiments,the adequacyof this model was confumed.

Keywords

T\rngsten;CoPPer;HZSM-5i Liquid

Methaneconversion;

Hyalrocarbons

Introduction

Crudeoil is a non-renewableresourceand cannotbe solely

relied as lhe feedstock or energy souce in firture New

natural gas deposits are being continuously discovered;

hence,naturalgasis a new potentialresource.Methane' the

largest component of natural gas, can be conv€rted to

valuable liquid fuels or other imPortant chemical

intermediates,In general,thereare two routesfor converting

methaneto gasoline:indirectly or/and direcdy. The indirect

route is a two-step process whereby natuml gas is fust

convertedinto synthesisgas (a rnixture of hydrogen and

carbonmonoxide),and then into gasolinerange.Tbe direct

route is the one step prccessin which the natural gasreacts

ISBN:983-2643-15-5

with oxygen (or another oxidiziog species)10 give the

desiredproductdirectly.

Zeolitesareuniquematerials.Unlike othercatalysts,zeolites

possess active sites on intracrystalline sudace

crystallo$apbicatly.For eachpafiicular zeolite stluctule the

acidity per active site reached a maximum value at a

pafiicular StAl ratio, which will determine the acidic

strengthof the zeolite. Emst andWeitkamp [l] reportedthe

prcsenceof stong acid sites in the zeolite catalyst was

detrimeotalfor ihe selectiveoxidation of methaneto higher

hyahoca$ons;otherwise oxidized products, CO" (carbon

monoxide and carbon dioxide) predominate.When the

acidity is reducedby exchangingthe zeolitewith alkali melal

cations, the selectiviry to higher hydrocarbonsis slighdy

enhanced. Han et al. {21 demonstrat€dthe successful

productionof higher hydrocarbonsfmm methaneoxidation

using ZSM-5 zeolite catalystloadedwith metal oxides.The

metal oxideswith sufficiendy high dehydrogentionand low

olefin oxidation activities reduce the acidity of ZSM_5

resultingin higherhydncarbonsproduction.

The incorDorationof two different metals could deate

mateiats ;i$ well-defined or new €atalytic and acidic

properties.One recent study has r€vealedthai acidic and

catalytic properties of these materials dependedon the

locationandsuroundings of ths metalions [3]. De Lucaset

al. t4-61discoveredthat the introductionof Cu (II) ions by an

ion-exchangemethodcould remarkablyincreasethe activity

of Mo[IZSM-5 for methanearcmatizationandimprovedits

stability to some extent. Mo species is the most acttve

conponent for methanenon-oxidalivearomatizationso far,

but its activity andstability n€€dto be improved.

Molybdenumsupportedon H-ZSM-s, is activeandselective

for benzenefornation from methaneI7-9l Il was clearly

established that at high temperaturc molybdenum in

Mo/HZSM-5 was reducedand formed MorC species[10].

Further, during the activation process of Mo/HzsM-s.

silesin

molybdenumspeciesmigratedlowads exchangeable

that

generally

reported

the zeolite framework uo,lll. It is

active

moiybdenum

on

the activation of methaneoccurred

speciesfonning ethyleneas the primary intermediatebefore

beirg convertedinto benzene.By usingpuremethanefeed,it

was found that methaneconversionand iates of benzene

formaliondrasLically

decreaedto. a few hou-rsowing !o

107'.l

Pruuedin$ oJktcn^iohat Co"ferene On Chenial uA Bioptucds Eh9i"eenbs

27' - 2q Aug6t 2003. UniwBiti Malattit Sabah,Kota Kaabai

signjficantcokeformation.To reducecoke fo(nation, some

preliminaryeffortshavebeenmadetoadd sele€tedoxidative

reagentssuchasoxygenandcarbondioxide (10% or higher)

to the methanegasfeed, but the sromatic productfomation

was completely inhibiied on Mo/HZSM-5 catalyst as

previouslyIl2, l3l.

reported

On |he basisof the chemi€alsimilaritigs betweenMoO3and

WOr it seemsreasonableto expect a paralelism in their

cahlytic properties. Ding et al. Il4l reported the

non'oxidativemethanereaction over WHZSM-s Droduced

C:-C,: hydrocarbons.

Undermndirionof ?00oC,a;d a flow

rate of methane+ argon at 12.5 cmlmin, the Cr-CI,

hydrocarboDs

selectivitywas 70-80%.However,methane

conversion

wassmall,between2%znd3%.

Tungstenand Mo are under the samegoup in the periodic

table of the elements (VI B), and hence the chemicat

propertiesof oxides or ca$ides of W and Mo are similar.

Therefore,the structuraland catslytic resemblancebetween

W andMo-HZSM-5is expecte-d.

Xionget al. [5,16] studied

the incoryorationof metalsZn, Mg, Mn, La, andZr inio rhe

W IZSM-s caralysi.The WHZSM-s basedcatalysrwas

suitablefor reactiontemperaturesas high as 800oCto obtain

a much higher methaneconvercionand yields of arorDatic

hydrocarbon without loss of W component n5l. They

confimed that the intensity and concentrarionof Bdnsted

acid sites have affected the catalyst activity for ethylene

selectivity and the rat€ of aromatizationof ethylene [161.

The incorpomtion of Mg?* and Zn2* into the W IZSM-s

, resulted in the elimination of a large potion of strong

Brdnstedacid sites,but new mediumstrengthBrdnstedacid

sites emerged.The medium strength Brdnsted acid sites

enhancedthe benzene selertivity and suppressedcoke

formation,thusFolonging the lifetirne of the catalysr.

.Cu loadedZSM-5 catalyst via acidic ion exchangemethod

hasbeenidenlinedto be Lhepotenlialcaraiysrfor conversion

of methaneto liquid fireh [17,18]. However, rh€ infiared

study of meral loaded ZSM-5 catalysr indicated that the

catalysisarenot resistantto high temperatures.

At 800"Code

studyhasindi€atedthat metal loadedZSM-5 did not exhibir

vibrationbandsat 3610 cm' and 3660 cm-'. but ZSM-5

showeda weakvibradonband at 3666 cmr (ascribedto OH

groups on non-framework Al species) [18]. The result

suggestedthatthe frameworkandnon-frameworkaluminum

werc either exhactedto acidic solution or becamesilanol

defectform when calcinedat 800"C and madethe catalysts

ResponseSurface Methodology (RSM) is a method to

determinethe optimum condirion of a process. RSM has

similarity with regressionanalysis. In rcgressionanalysis,

empirical maihernatical model are derived from the

experim€ntaldata. RSM is a set of techdiquedesignedto

1078

find the optimum value of the r€sponseand the influencing

factors.

In this paper HZSM-s was modified with tungsten and

copp'ff and.the catalyst p€rformance was tested for the

oxidationofmethaneto liquid hydrocarbons(C5). The roles

of W and Cu, the Bronstedacid sites,and catalytic a€rivity

will be studiedby meansof hydrogen-TPR,anmonia-TPD,

FIIR, nitogen adsorption(NA) andmethaneoxidation.The

optimization of the direct conversion of merhaneusing

3.0Cu loaded WZSM-s catalyst was studied ro obtain

maximum methane convercion and C5+ selectivity by

utilizing experimentaldesigr andempiricatmodeling.

Exp€riment

Cstalyst Preparation

ZSM-5 zeolite with a Sior/Alrq mob ra{io of 30 was

supplied from Zeolyst Intemational Co. Lrd, Nethe ards.

The surfac€ area of the zeolite was 400 m%. Cu (3%

weight)-IzsM-5 catalysrwas preparedby impregnatinEa

certain amountof the HZSM-s zeolite carrier with €oDDer

nilraLe

solution. Thecoppernitratesolurion a" pr"pur"aby

"

dissolving coppff nitsate hyalrare (Cu(NOrr.3HrO)

in

deionized water and adding a small amounrof HZSO4to

rcgulatethe pH valueof the solution to 2-3. The sample(10

ml of solution per gram zeolite) was dried in an oven ar

120"C for two hours and then calcined at 50Ot for four

hou's.

The 3.0 wt.% ofcu loadedWAIZSM-s waspreparedby Ii$i

imprcgnatinga certainamountof the IIZSM-5 zeolitecanier

with a calculatedamount of tungstenhydmte in aqueous

solutions. The tungstenhydrate solurion nas preparedby

dissolving

ammonium

tungsten

hyalmre

((NH1)6.Wrr.Oao.HrO)

in deionizedwater andaddinga small

amountof H2SOaio rcgulatethe pH valueof the sotutionto

2-3, followed by drying at 120"Cfor two houls andcatcining

at 4O0.c for four houN,andsubsequentlyimpregnatingwith

a calculated amount of H2SOa acidified copper nitate

aqu€ous

solution(pH=2-3). Finally,rhesamplewasclriedaL

120'C for two houF. and calcined aL500"C in air for five

Characterizatlon and Cstalyst T€sting

The catalystswerc charactedzedby XRD, hydrogen"TpR,

ammonia-TPD, FTIR and nitrogen adsorption. The

peformance of the caralysrs was tested for methane

conv€mionto liquid hydrocarbons(LHC) via a single step

reaction in a fixed-bed micro reactor-Gc combination

systemund€rreaclioncondjlionat aunospherjc

pressure

and

800f. The fed g i wlrs composedol methane(99.9%

pu.ity) and oxygen, An on-line cas Ckomarogaphy

e.quippedwith TCD and Porapat-N column was utilized io

analyzefiegas.Theliquidproductswereanalyzed

usingGC

FID andEP-l capillarycolumn.

ISBNr983-2643-15-5

p

ol td.rnatio4ot CoiJ.anc? On Ch.akol aad 3iop44$ EnBk4nne

Prcc..dilss

' "27*

- 2a' Aulu"i 2o0J u^i!.Aii Malarsia sdbah Kota Kkobalu

*',

+1,"

bonsselectivitywere

andC5' hydrocarMeganeconversion

(2)' respeclivelv'

and

l)

t

basedon equaLions

aat-Julared.

l

moleofcHq {ir)- moleofcH4 (dr)

CJt4conv=-noteof CH4 ;;

mole of CH4(n) - mole of CH4lod)

00%

(l)

(2)

*tooso

From Figurc I (Pareto Chart)' the most significant

arecleartvthe% volofOr lXr) andils quadrahc

oarameLers

(X:xt.

ot loial tlow ot teedgasesfir)

The quadratic

;|fect

(Xr) are significant hrt less

W

quadratic

%

wt

of

of

aral

imponant. The % $l of W and loLalflow of fe€d gases

% wt of

u.tuully upp.* low, a" well as lhe interactions

W-totd flow (XrXr) and % wt of W-% vol of Oz (XrXJ'

The intemction of % vol of O?- total flow of feed (XrXr)

was insignificant

Optlmisation of C5+Selectivity by RegressionAnalysis

H']O'

wtrerei = CO, COz,CzHr.CrHa.CrH6,CrH6,Ci, and

Resultsand Discussions

Optimizallonot MerbaneConversionby Regressioo

AnelYsis

yielded$e

surfacemelhodology

ofresponse

TheaoDlication

lollowine regre.sionequalion. which is an empirical

relationshipbetweenCi selectivity and the test variable in

codedunit givenin Eq. (4).

Y = 67.0195+ 32.0514xr + 8 1699x, + 0 5304x3-0 0833

x,'?

xt'z

ri 4).4-s.1106

xrx3- o.oo

- o.s3s6

x,x - o.qoog

(4)

"

xr'?

o.oo12

The applicationof responsesurfaaemethodologyProduced

ttre foiiowing regressionequation, which is an empirical

relationship between methane conversion and the test

variablein codedunit givenin Fa (3).

x1- 0 0500

+ 9.5251xr + 4.4146x, + 0.1-549

Y = -28.5459'7

xlx,- 0.0042xrxr - 0.0003x.,xi- 1.275lxtz'O l7l3 x2''

(3)

o.odo3x3'?

of thefitringof the modelcanbe checkedby

Theeoodness

Table I showslhe Analysir of Variance

."u"ot

";r..lu.

to mehane

model that corresPonds

for

$e

{ANOVAJ

convenion. The valu€ol coeffrcienlR'= 0940 indicares

thatonly 6% of total vanationis not explainedby tbe model'

The vahe of F is comparedto the tabie value &pr.N.Fa)'

which is the upper 100o PercentPoint of the F distribution,

with p.l and N-p degreesof freedom.respectively The

o[ lhe fined modelfrom Eq. (3) is lelled using

adeouacv

stad; F.- SinceF value at 10.4633exceededthe table vatue

a high

F€0.0r,= 7 9761. lhe FisherF test demonsEared

model.

regtessions

significance

for thefired

Tablet.ANOVAIoTft? methMcconv?tsion

Sun of

D€gree Mean

Squlre

s.s.

4J0.508

S.S-Enor

27.430

S.S.Tolal 457.918

9

F

F0.0r

Rl

Erld Earimab1tu3.1@v'rua)

Figure1-Parctocha of stfuda izedeffectsofmethane

con|ersion

Table 2 showsthe Analysis of Variance(ANOVA) for the

model that exptainsthe responseof the C5+selectivity. The

Analysisof Variance(ANOVA) for the modelexPlainsthe

of lhe Ci seleclivity. The co€mcientR'= 0.95

response

indicat€sihat only 5% of total variation is not exPlainedby

ihe model. The value of F is comparedto the table value

Fer,N*d , which is the upper 100 d percentpoint of rlle F

diitribution, with p-l and N-p. degees of fteedom'

respectively.Sincethe valueF = I 1.5647exceededthe table

value Rr.6rr) = .9761,the FisherF testalsodemonsaaEdits

high significancefor rhefitted regressionsmodel

'7_9161 0.94

47.834 10.4632

4.572

l5

ISBNr983-2643-15-5

1079

Praceedias oI tat.natiatul ConJerctueOn Chenical and Biaprues Euinee.ihe

2f -2q Ausust2003 , U^ive6ni Molottio Sdban,Kota Kihdba\

Table4 - The RONand conposition of liq idfuels ot)et

3.OCuloaded3.2w ,zSM-5 catalyst

Table2- ANOVAfoT the Cs- selectilrit,

Degre€

Sumof

F

Sqllare

s.s.

4866.406

S.S.Enor 280.532

F0.01 R,

l l .5 6 4

540.7t2 '72 7.9761 0.95

9

6

46.755

S.S.Toral 5146.938 l 5

Composition of Liquid Fuels

Gasolinerange(Cs-ro)

82.8

cr i range

18.2

Compositlon of Gasollne range

Vo

n-Paraffins

9.0

Iso-Paraffins

22.O

Olefins

52.O

r'7.o

The resultsin Table 3 pertainto the catalytic reactiontestat

the oplimized reaction condition when comparedwith the

modelingresult. The experimentalvaluesarc 27Eoar]d69Eo

for Clla conversionand Cs* selectivity, respectively. The

rcsults in Table 3 ako indicatedthat to achievea high Cr+

selectivity tbe percentageof 02 in the feed gas is very

critical; otherwise the oligomerizatiod activity will be

suppressed.Me€nwhile the % error betweenthe predrcted

and experim€ntal results for CH4 conve$ion tuid Cr'

The djscrcpancies

selectiviry

are8% and2 %. respectively.

betweenthe predictedand experimentalrcsults are probably

dueto ihe characteristicof the catalysb which havenot been

takeninto accountby the statisticalmodel. Nevenheless,the

differences are within the acceptablelimit. ftom these

rcsults,it is verified that the statisticalmodelis usefulfor the

prediclionofCr+selecliviryandCHaconversion.

accurale

TabLe3 - Cowaison betweenpredictedand obsened

o,

dop€d

(%

( %)

CH4

Ci

3.2

3.2

12.3

7.6

Totd

flow of

feed

Pred.

Obs.

%

Ermr

RON

86.1

Characterization of 3.0Cu8.2WHZSM-5 Catalyst

The isothem adsor?tionof 3.0Cu,/3.2WZSM-5-Frcshand

3.0Cu,/3.2WlzSM-5-Used,as shown in Figur€ 2 as an

example,is a combinationof typesI andIV. The p.esenceof

hysteresisloop was associatedwiahcapillary condensation,

where in the caseof zeolite, it indicated the fornation of

mesoporcs. The profile for 3.0Cu/3.2WZSM-5-Us€d

indicatedenlargementof somemicroporesresultingin mol€

mesoporesbeing fomed.

The ammonia-TPDspectraof the catalystprovided useful

information aboutthe intensity and the concenaationof lhe

acid sites on the catalystssurfaceas tabulatedin Table 5.

The concentrationof tbe sudace acid siies (acidity) of the

ZSM-s and 3.0CuB.2WHZSM-5-Fresh zeolite were the

same. The acidity of 3.0Cu/3.2WIZSM-5-Used was

undetected(- 0) becausethe aluminium in the ftamework

was Fobably €xtracted.after reactionat 752t for a period

of five hours.

20.].9 29.4% 27.0% 8.O%

208.9

702%

69.0% 2.0%

NoterPred.= predicted;Obs.= observed

The composition of liquid fuels and RON over

3.0CuB.2WZSM-5 catalyst is shown in Table 4. The

ResearchOcIaneNumber (RON) was estimated[9] !o be

86.1. The gasolinecompositionhas a low n-paratrin and

high aromaticscontent,at 9% and 177,, rc,spertivelywhile

(hemajority is olefins at 527, asindicatedin Table 4.

Table5 - Total volure, pore dishbhtion and aciditJ ol the

catalysts

Catalysts

Av. PoreDiam.

(a)

Acidity

(moYkg)

HZSM-5

24.3

0.87

3.0Cu/3.2W,{ZSM-

26.1

0.87

45.2

0

5 - Fresh

3.0Cur3.2WIZSM5 - Used

1080

ISBN:981-2643-15.5

ProceeAkssof IntebatioBL Confercnc.Oi Chenical atu Biapruess Ensineenns

2l - 2y AtBBt 2003 , Unive6iti Malayia Sabah,Kota Kinobalu

250'C

3.0Cu/3.2WHZSM-5-Fresh

430.C

3.0W6.0Cu/HZSM-i

l.0Cu,3.2W/HZSM-5-Used

200

300

400

500

T/"C

Figure 3 - Antnonia TPD spectraof samples

Figure 2 - 'Ihe diaeramsisothcrmadsorptionof catalrsts

Figure 3 depictslbe ammonia-TPDspectraof the HZSM-s

and modified HZSM-s with loading ofw and Cu. For ihe

HZSM-s, the amnonia-TPD pealGappearedat - 23?'C and

- 430'C, wbich may be ascrib€dto the desorptionof two

kinds of ammoniaspeciesadsorbedon weit acid (mostly

Lewis acid) sites and strong acid (mostly Br6nsted acid)

sites.respectively

1201.

Theadditionof3.2% W and3.0%Cu to HZSM-sledto rhe

reducedintensiiy ofthe high temperarure(- 430'C) peakand

a srnall downshift of its position as revealedin Figure 3.

This is similar to the results found by previousresearchers

of Mg'?+andZn2"into the

i15,161,wherethe incorporation

WHZSM-s host catalyst resulted in the elimination of

strong surfaceBrdnstedacid si.es. For the 3.0%Cu/3.2W

HZSM-s-Used,

the ammonia-TPDpeaksdisappeared

at 237"C and - 430"C. This indicatedthat after rcacrion, the

acidsitesof the3.07,Cu6.2WrZSM-5hadweakened.

Cu and W ioadedHZSM-s samplesshowedihar in the OH

stretchingvibration thfee IR bandsat = 3610 cm_r,due to

bridgeSi-OH (Al) acidic goups, at = 3660 cm'r due to

non-framework

A1sites,or octahe&al,andar 3740cm'r,

a$ributedto terminalSi-OHnon-acidicgroups[21].

ISBN:981-2643-15-5

Futher reactionwilh methaneand oxygenal 753oCfor five

hoursresulledin the disappearance

of lhe bandar = J.6t0

cm' for 3.0cu./3.2w,fi2sM-5-used

sample. This is

Fobably due to the extracrionof aluminum in tle zeolitic

frameworkinto the non-fiameworkor due (r the deposition

of carbonaceous

rcsidues. The deposilionof the coke led ro

catalystdeactivationafter five hoursof reaction.

The H?-TPR profiles of

3.0W/3.0Cu/IIZSM-5,

3.0Cu/3.2WIIZSM-5 for ftesh and used samples are

depictedin Figure 4. As observed,all the curves conrain

severalpeaksin the temperaturerangeof 200-900"C. The

TPR pattemsof both catatystsexhibitedrwo peik with rhe

maximumat E800oCwhich could be due to rhereducrionof

W species.The reducibiliry of ihis type of catalystdecreased

as the strength of the intemction bet$,eenthe merat oxide

speciesandthe suface of ihe supportincreased

The observed hy&ogen-TPR peak at

for

3.0Cu./3.2w/HZSM-5-fteshcould be due to the-400"C

reducrionof

Cu'?*species. The spectrademonstrateal

the existenceof a

single reduction peak of Cu'+ ro Cuo at 420"C. However,

allerreactional800"Clhep€akdisappeared.

Oncrrrrrrcstmg

feature of Figure 4 is lhe HxTpR specra of

3.0CuB.2WHZSM-5-usedwhich indicaleda peakar 340'C

Gigure 4). This small pea-kmay be attributedto lhe

reduclionof Cu'* ro Cur'. Nevertheless,

lhe peakof W' ' did

not changebeforeandafter thereaction. TheTPRprofile for

tungstenrevealedthat the additionof rungstenhadincreased

1 08 1

Prcrc.dkss of tnkrnat;aaoJaohJp@c. On I h?nical aut sibpta pt: Lnpn..rino

27' - 29' Aus& 2@J , Uniec^ri Matdvia satah Ko@kifubal:u

the thermalstabiliry of the catalyst,as theW componenrwas

notlostby sublimation

afterreactionat 753oC.

3.0Cu/3.2W^IZSM-5-Used

3.0Cu/3.2WlzsM-s-Fresh

liquid fuets. rhe advantases of

y1i9l

l.*

- !9 HZSM-s

3.0CuB.2W

included higher crystalliniry, highe;

amounrof Brttnsredacid sites and medium strength of

Brdnsted acid sites. T?R analysis indicated that ii;

resjsLance

of HZSM-5 rowardstempemture

wasenhanced

bv

loadjngW andthehighreacLion

(?sJoC)did noi

remperarure

Iead to lhe loss of W componentby subtimarjon.

3.0Cu6.2WHZSM-5 catatysi is a potential catalysq

becauseunderoptimum conditionshigh methaneconversion

(2?%)andC5*selecriviry

(69%)wereobrained.

Acknowledgement

(D.D.Argrarelultyacknowledges

OneofrheauLhors

rle

^.

rnanclat

supportreceivedin the form o[ a researchgranl

(Project Nor 02-02-06-0101) and (project No:

09-02-06-005?-SR005/09-07)

fiom rheMinistry of Science,

Techrology andEnvironment,Malaysia.

References

370'C

S. Emst,J, Weirkamp,Inc.Inarisio, M. Frias,J.M.

Benrgen (Ed.), HydrocarbonsSourceof Energy,

craham& Trotman,London,1989,p.461.

[2] S, Han,D.J. Mafienak,R.E. patermo,J.A. pearson,D.E.

walsh,JournatofCatalysis148(1994)134.

lll

3.0w/3.0Cu7HZSM-5

300

't00

500

900

T/'C

,

Figurc 4 - Htbogen-TpR spectraof samples

Conclusions

The direcr conversionof merhanewff optjmjzedover

Cu-wZSM-5 calatysL

using SLarsofl

Stadsli;a version6.0

soflwarc. The three independentvariabtesjnvolved in rhe

optimisationa.e %wt. of W doped, %vol. of Or, and total

flow of f€ed gases. The parelo chart indicaied thar the

variablewith $e largesteffect was % vol. of O, (X, andits

quadrariceffecL(XrXr. This ;s fo[owed by ftow tolal of

feedgases(X,). % wt. of W dopedtxr) and itl quadmlic

effects(X3& andXrXr). The interacrionsbetweenany rwo

of rhe independent

variablescan be neglecred.From the

RSM resulrs lhe opdmal melhane conversion, Cj.

selectivity, and Cr* yield of 29.4%, '70.2qo,and 20.6%,

respectivelywereobtained.The adequacyof this modelwas

confirmed by means of vadance analysis and additional

Frcm the chamcterizationsrudies,the 3.OCu/3.ZW,4IZSM_5

had more potenrial to catalyze the methane oxidarion

1082

[3] V. Pafiul€scu,C. Anastasescu,

C. Constaniin,

B.L. Su.

Catal.Today,Anicles in press2852 (2002) I .

[4] A. de Lucas,J.L. Vatverde,p. Canizares,L. Rodriguez,

Appl.Catal.A 172(1998)165.

[5] A. de Lucas,J.L. Vatvede,p. Canizares,I..

Rodriguez,

Appl.Catat.A 184(1999)143.

p. Sanchez,

[6] A- de Lucae.J.L. Vatverde.L. Rodriguez,

M.T.carcia.lMot.Carat.

A t7l (200t)tq5.

L7l Y. Shu.Y. Xu. S.T.Wong,L. Wang.X. Cuo,J. Calat.

i70(1997)rL

[8] J.H. Lunsford,M.p. Rosynek,D. Wang,Stud.Surf. Sci.

Catal.tu (r997\25t.

[9] R.Ohnishi,

S.Liu,e Dung.L wang.M tchikawa,

J.

caral.t82 (1999)92.

ll0l D. Wang,J.H. Lunsford,M.p. Rosynek,J. Caral.169

(t99',7

) 347.

[11] R.W,BorryIII, E.C.Lu, y. Ho Kin, E. rglesia,Srud.

surf. sci. catal. 119(1998)403.

[12]Wang,L., Tao,L., Xi€. M., Xu, c., Huang,J., andX!,

Y.. Catal.Letr 2l (1993)35.

[13]Wang,D., Lunsford,J. H., andRosynek,

M. p.,J. Catal.

169(t991 ) 34j .

[14]W. Ding,c.D. MeitznerD.O.Marter,E.Iglesia,Jphy.

Chem.105(2001)3928.

ISBN:983-2643-15-5

P@.ninet

oflntltl,atioial co'fe@ce On Cheniel a"d Eiopt@es E situcnnq

2T -2y Ausut 2N3,lJnteebtti Malatsiosal,att, Kota Kitubtlu

Il5l Z.T. Xiong,L.L. Chen,H.B. Zhang,r.L. Z]jng,C.D.

Lir, C^t^|.Lefr.14(2OOl)227.

for publicariotr

in

tl8l N A S Amin,D D Anggoro.accepr€d

Joumalof Naturalcas Chemistry,

SciencePress,2. .

116l Z.T. Xiong,H.B. Zhang,G.D. Lin, J.L. Zng, Catal.

Lett.14 (2001)233.

c, Jambre.N, Deur-SiftarProsrenik

M

u9l Protic-Lovasic

V. FueI,1990,69:525@3

UniversitiTeknologr

071 D.D.Anggoro,MasterThesis,

Malaysia.Malaysia,1998

[20] G.L. Woolery, G.H. Kuehl, H.C. Tin*en, A.W.

Chester,

J.C.Vartuli,Zeolites19(I9n)288.

[21]N A S Amin,D D Anggoro,underreviewby Joumatof

Mol€cularCatalysis,2003.

ISBN:983-2643-15.5

1083