by Electrosynthesis of Benzoic Acid from Chlorobenzene Fixation

advertisement

Electrosynthesisof BenzoicAcid from Chlorobenzeneby

CarbonDioxideFixationMethod

Suliman, Norhuda

AbdulNlanaf.

MohdAfis , Normala

AishahAbdulJalil'. Hartini

-----tluilf,iETlyati

Hairomr,[4ohdRazifHarunrandsugengTriwahyono'z

rFacultyof Chemic€land

Engineering,

NaturalResources

ScienceStudies,

'lbnu SinaInslituleforFundamenlal

a1310UTIVI

Skudai,Johor,[4alaysia

lJniversiliTeknologilvlalaysia,

my

'Corespondingauthotemailadd€ss: aishah@ftkksa.utm.

Abstract

by usinga simpleelectrolysissystemvia

methodof chlorobenzenes

An alternativedechlorination

Electrolysis

of chlorcbenzene

was carriedout

developed.

carbondioxidefixationtechniquehas been

platinum

Reaction

in an N,Nanode

and

a

cathode.

with

an

aluminium

cell

fitted

in a one-compartment

bromide(TPAB)at ooc,

(DMF)solutioncontainingO.1Mof tet€propylammonium

dimethylformamide

100 Ncc/minof CO, flow rate and 120 m/,/cm'of currentdensitywas found to be the optimum

yieldot benzoicacid.Thisconditions

wasthen

whichgaveT2o/a

of thiselechocafuoxylation,

conditions

in oder to convertit to theircorresponding

appliedto l,2iichlorobenzeneand 1,3-dichlorobenzene

benzoicacids.

chlofobenzene,benzoicacid, c€rbon dioxide,fxalon

Keywol.dsj Electfosynthesis,

lntloduction

is the simplestaromaticchloride,and formsthe framewofk of highlytoxico€anic

Chlorobenzene

polychlorobiphenyls

(PCBs),dioxinsand furans[1].Such componentswhichare

chloridessuch as

and

producedin a broad range of industrialprocessesare hazardousdue to their carcinogenic

compoundssuchas

mutagenicactivity.Thereare variousmethodsfor eliminalionof organochlorine

by biologicaltreatmentl2l, steamreforming[3], catalyticreactions[4], and incinerationHowever,

and couldalso produce

expensive,

ttiesemethodsrequirelongerrcactiontime and hightemperature,

another

is incomplete

moretoxicmaterialssuchas dioxinsandfuransif the combustion

[5].Therefore,

in oder to overcometheseproblems.

techniqueis necessary

alternative

reductionwhich is expectedto offer an

One of the promisingmethodsis by eleckochemical

is

safe, clean,cheapand easy to control

This

technique

of dechlorination.

effectiveconsequence

organics

halidescan be simplyreducedby

In

many

cases,

as

a

reagent

since it use electron

[6].

studieson the fast and efficient

and ambientpressure.Furthermore,

at roomtemperature

electrolysis

of PCB

may contributeto a new technologyfor the safe detoxification

of chlorobenzene

electrolysis

and dioxinswith lowenergyconsumption

[7]. However,eventhis techniqueis efficientand desirable

wastewhichcontainschlorine

of electrochemical

amongthe otherireatmentmethods,finalpurification

ions, precipitantor complexesstill is a problem.Therefore,hereinwe repod anotheraltemative

by usingcarbondioxidefixationmethod Benzojc

of chlorobenzene

dechlodnation

electrcchemically

processof electrochemical

waste but could

produced

the

disposal

is

not

only

simplify

acid that was

for examplein preparingcompoundsbearingsubstituents

alsooffersa greatnumberof advantages,

(F, CN, CO, R, co, and OR) that are not compatiblewith the preparationof organometallic

compounds

[8].

Matedalsand Methods

Materials

and 1,3-dichlo1,2-dichlorobenzene

werechlorobenzene,

usedin this experiment

The substaates

(D[4A),

(THF),

N-methyl-2-pyrdimethylacetamide

tetrahydrofuran

solvents

were

whilethe

robenzene

(DMF) Supportingelectrolytes

rolidinone(Nl\4P),acetonitrile(N/eCN)and N,N-dimethyl-formamide

perchlorate(TEAP),tetraethylammonium

bromide

used in this study were tetraethylammonium

from FlukaChemikaand

(TEAB)andtetrapropylammonium

bromide(TPAB).Theywercall purchased

usedas received.

cell equippedwith a magneticstirrerand a

was car ed out in a one-compartment

Electrolysis

(2 x 2 cm'), aluminiumbar anodeand a

platinum

plate

cathode

with

a

serumcap.The cellwas fltted

out

in

a

DlllF

soluton {10m1)containing01lvl of

path

was

carried

The

electrolysis

for CO2.

tube

was used as a model

and tolueneas a standardmaterial.Chlorobenzene

TPAB. chlorobenzene

substrateand five parameterswere studied in order to obtain the optimumconditionsof this

currentdensityand typeof anodematerials,

The paEmetercweretemperature,

electrocarboxylation.

solvents and supportingelectrolytes.Progress of the reaction was analyzed by FID gas

(AgilentTechnologies)

withHP-5column

chromatograph

Resulisand Discussion

stirringrcactionwithoutcurrentpassedgaveonly20%

Blanktest resultshowsthat conventional

and no benzoicacidwas producedat all. Therefore,in ordefto enhance

of chlorobenzene

conversion

and yield of benzoicacid,firstlythe effectof currentdensityon

the conversionof chlorobenzene

was carriedout at 0'C with magnesiumanodeand

was studied.Electrolysis

electrccarboxylation

platinumcathodeunderfour differentvaluesof currentdensity,whichwere 30, 60, 120 an"d180

at 120 mA'/cm'gave

mA,/cm2.

As shownin Figure1, after2 F/molof currentpassed,the electrolysis

(10%) Therefore,

yield

(60%)

acid

and

maximum

of

benzoic

of

c-hlorobenzene

highest

conversion

the

120mA,/cm'asthe optimumcurrentdensityin thiseletrocarboxylation.

we considered

^40

;

6

;60

Co.ve6ronof chlorobenzene

.9

e40

20

1m

60

90

curent densily(mAJcm'z)

onelectroc€rborylalion

ofchlorobenzene

Figure1i Effectof€urenldensity

Next,the efiectof typeof anodematerialswas studiedand the resultis shownin Table1. All data

was achievedwhenzincwas useas an

of chlorobenzene

weretakenat 3 F/mol.Completeconversion

atall. Theconversion

becamelowerwhenmagnesium,

anode:howeverno benzoicacidwas Droduced

yield

up to 3-9dloAnd it was

benzoic

acid

was

increased

of

copperand carbonwere used,but the

whichgave 3570,

in

material

this

electrocarboxylation

was

optimum

anode

the

foundthat aluminium

of aluminaum

higher

electrical

conductivity

maybe

due

to

the

yield

acid.

This

is

of

benzoic

the highest

comparedto othermaterials.On the otherhand,zinc metaldid not pedormwell in this non-aqueous

solventto producebenzoicacid sincemay be it relatedto what was reportedby lto that zinc show

highertendencyin producingcarbonmonoxide,oxylateand glyoxylatein the similarsystem[9]. The

effectof typeof cathodematedalswas alsostudiedby replacingthe platinumcathodewithcarbonand

as a cathodecomparedto

stainlesssteel.However,bothof them did not show betterperformance

platinumin thiselectrocarboxylation.

of chlorcbenzene

Table1: Effectof lvpeof anodematerialon elecirccarboxylalion

Typeof anodematerial

(%)

Convercion

YieldofBenzoicacid(%)

Zr

t\,49

100

45

77

40

49

9

35

3

7

Cu

c

(2 mmoD,

(anode)[,]-Pt(cathode),0.1[4

0'C, 120mAJcm',

Chloobenzene

TEAP-DMF,

Toluene(2 mmol)

werecarried

the electrolyses

of thiselectrocarboxylation,

In orderto findthe optimumtemperature

whichwereOoC,roomtempe€tureand 70dC.As shownin Figure2,

out at threedifferentlemperatures

and the highestof benzoicacid (35%).

at 0'C gave77Voconversionof chlorobenzene

electrolysis

(24"c)

seem

do

not

appropriate

in this system.While,the

at

room

temperature

Howevef,the rcaction

was carriedout at 70"C,but this tempe€ture

conversion

was increasedup to 93%whenelectrolysis

tempe€ture

to benzoicacid.We can seethat increasing

chlorobenzene

was notsuitablein converting

will favorthe decreasingof benzoicacid. Lowertemperaturemay increasethe solubilityof carbon

whichis classifiedas an aproticsolventand this may enhancethe

dioxidein dimethylfomamide,

undersuchcondition[8].Therefore,aimingto a simpleand mild

stabilityof the reductionintermediate

in thiselectrocarboxylation.

OoCas the optimumtemperature

we considered

conditionof electrolysis,

100

9

.q

:6 0

640

I

az o

40

80

Temperature

CC)

of chlorobenzene.

Figure2: Effectoftempefalureon eleclroc€rboxylation

(anode)Al-Pl(calhode),

0.1M TEAP-DIMF

Currenlpassed: 3 F/mol,

( 2 mmoD,

Toluene(2 mmol)

chlorobenzene

120m,rJcmz,

The effectof solventwas alsostudiedin orderto enhancethe yieldof benzoicacid.As tabulated

in Table2, the sequenceof the optimumsolventsis DN4F> NMP> [4eCN> DMA> THF. DMFgave

comparedto othersolventsaftet2 Flmol of currentwas

the highestyield of carboxylicacid (18o/o)

This is may

passed.Thus,DVIFis considered

to be the optimumsolventfor thiselectrccarboxylation.

be due to its highestamountof dielectricconstantamongthe othersolvents.DMSOalso is a good

solventfor manyinorganicsaltsand organiccompoundss nce it has the highestamountof dielectric

constant,howe;er, ii not appropriatein this reactiondue to it freezingpoint is at 20'C. While'

in acetonhile or lesspolarsolvents,wouldincreasedthe voltagedue to the precipitation

electrolysis

on the surfaceof the electrodeduringthe reaction

of chlorobenzene

Table2: Effectof tvpeof solventon eleclfocarboxylation

Yieldof Benzoicacid(%)

eJ

TetEhydrofu|an

CIHF)

(DI\,lA)

Dimethylacetamide

(NMP)

pyrrolidone

N-methyl-2

Acetonitrile(l\,4eCN)

(D[4F)

N,N-dimethylfomamide

0

0

23

7

76

18

n. iz mmoD

t"n

is also an imporlantparameterin this electroNext,the effectof typesof supportingelectrolytes

used in the expeimentsweretetraethylAs shownin Table3, supportingelectrolytes

carboxylation.

bromideAccording

bromideand tetrapropylammonium

tekaethylammonium

ammoiiumperchlorate,

of suppofting

the

effectiveness

the

sequence

of

at

2

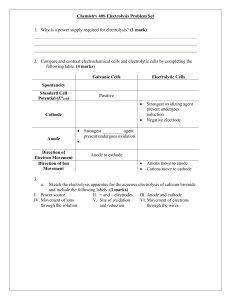

F/mol,

to the resuitwhich were all taken

rateconstant

>

will

decrease

the

>

in

size

of

cation

The

increasing

TPAB

TEAB.

are

TEAP

electrolytes

of elecfontransferfromelectrodeto subskate[10].This is the reasonbehindthe smallestyield(8%)

bromideat 2 F/molcomparedto the tetraalkylammonium

of benzoicacid by tetrapropylammonium

ion benefits

rateconstantof the tetraprcpylammonium

smaller

ionsof TEAPand TEAB.However,the

termination

later

through

time

and

causing-a

yield

increases

benzoic

acid

the

of

when

the electrolysis

TPABis the onlysalts

electrolyte

of currentpassed.Table3 showsthat comparedto othersupporting

the highest

the currentpassedto 14 F/moland eventuallygave61olo,

that couldcontinueconducting

yieldof benzoac

acid.

on electfocarboxylalio.

of chlorcbenzene

eleclrclyte

Table3: Effectot lypeof supporting

(SE)

Electrolyte

Typeof Supporting

perchlorate

(TEAP)

Tetraethylammonium

bromide(TEAB)

Tetraethylammonium

bromide{TBAP)

Tetrapropylammonium

bromide(TBAP)"

Tetrapropylammonium

Conversion Yieldof Benzoic

76

83

90

18

10

I

61

(2 mmol)Toluene(2 rnnro)

(anode)Al'Pt(calhode),

o.1M SE Ol\4F,

O"c,120 rnA/cm',chlorcbenzene

pa$ed.

14

F/molofcurrenl

" Dalawastakenat

in DMF solutioncontaining

Therefore,we consideredthat electrolysisat OoCand 120 mAJcm'z

bromidewithaluminiumanodeand platinumcathodeas the optimumconditions

tetfapropylammonium

Finally,we stud;edthe flowrateof carbondioxideand the resultis shown

in thiselectrocarboxylation.

did not get

of chlorobenzene

in Table4. Aftef 3 F/molof currentpassed,we foundthatthe conversion

that the

Howevef,

it

was

observed

to

190

Ncc/min

was

raised

up

eventhe flow rate

higherthat 62010

yield of benzoicacidwas increasedwith the increasingof flow rate.By allowingthe currcntto pass

wereincreasedupto 78%and 890/0,

until6 F/molfor 1OOand 190 Ncc/min,we foundthatconversions

for 100 Ncc/minof flow rate at the same condition'the yieldof benzoic

Nevertheless,

respectively.

we considered

that 100

to maximum(72%)but notfor the 190Ncc/minTherefore,

aci; abo increased

Ncc/minas the optimumflow rate in this system and next this conditionwas appliedto 1'2benzoicacid.Howevef,may be due to the

in oder to convertit to its corresponding

dichlorobenzene

benzoicacid

was

70% but no corresponding

sterichindrancethe conversionof l,2iichlorobenzene

was prcducedat all.

ofchlorobenzene

Table4: Effectof CO,nowtateon eleclrccarborylation

Flowrateof CO,

{Ncc/min)

30

80

100

100150

200

190-

Conversion

('/"J

Yieldof Benzoic

acid(%)

26

60

54

78

20

62

89

3

16

72

18

11

(2 mmol),

(anode)M'P(cathode),

0'C, 120mtucm',Chlorobenzene

0.1w|TEAP-DMF,

i

passed

(2

run

uriil

6

F/mol

of

cunenl

was

mmol).

Electrolvsis

To uene

e and the resultis showsin Figure3. In this

ichlorobenzen

Theabovefeactionalsoappliedto 1,3_d

acidor 3was achievedbutthe peakof isophthalic

case.completeconveEionof 1,3-dichlorcbenzene

yield

acid and

Figure

the

of

benzoic

3,

acid could not be traced. As shown in

chlorobenzoic

However,

the

1

lorobenzene.

of

conversion

of

,3-dich

was increasedwiththe increasing

chlorobenzene

yield

passed,

the

was

F/mol

of

current

then

20%

at

6

yield

was

only

of benzoicacid

maximum

and finallythe currentwasterminatedafter9 F/molof currentpasseddueto the increasing

decreased

ofvoltaoe.

_e.*

Q-" ry"""iO

m

8zo

.e 60

€bo

E!,o

i30

"zo

't0

of 1,3-dichlotobenzene.

Figute3: Electtocarboxylation

:3 F/mol,

(anode)Al-P(cathode),

Curenlpassed

01MTEAPDIVF,

(2

(

2

mmol),

Toluene

mmo

120mA,/cm?.

Chlorcbenzene

)

The prcposed reaction mechanism of this dlectrocarboxylationof chlorobenzeneis shows ,n

Figure4. The reactionstarted at anode where aluminiumwas oxidizedto give Al"'cation and donated

th;ee electrons. While at cathode, cO2 received an electron to form anion radical' cor' lhen,

chlorobenzenereceived one electron to form benzene radical, Af and releasingchloine atom' ClThe remainingelectrcnwas receivedby this benzeneradicalto form benzeneanion,Ai Anion radical

of CO, reactedwith benzene anion, Aa to give carboxylatedanion IArcOO ] which, finally pfotonated

by solventto give benzoicacid.

-

A t + A t3*

+ 3e

Cathode: C Or+ e-+ C Or-'

O'.'- Qo - c '.

: cot' .

overar

O" rf- ry"oo"

of chlorobenzene

of electrocarboxylation

Figure4: Theproposedreactionmechanism

Conclusion

by usinga simpleelectrolysis

methodof chlorobenzenes

dechlorination

an alternative

ln conclusion.

Benzoicacidthatwas producednot

systemvia carbondioxidefixationtechniquehasbeendeveloped.

onlysimplifiedthe wastekeatmentof harmfulcompoundsbut alsocouldbe consideredin conveding

thosecompoundsto usefulproductssuchas carboxylicacidsthal havemanyusesespeciallyin the

fieldof phafmaceuticalAcknowledgemenis

for financialsupportsundera Fundamental

TeknologiIVlalaysia

Ourgratitudegoesto Universiti

Foundation

for their

ResearchGrant(No.75048).We wouldalsoliketo thankthe HitachiScholarship

Grant

Instruments

forthe GasChrcmatography

supportespecially

References

\ r3

Chenistry(2005)581.38-45

1. A.A.lsse,M.G.Ferlinand A. Gennaro,Journalof Electroanalytical

(2oo3)

2. P. Cognet,R.H.Leite,A.M. Wilhelmand H. Delmas,Joumalof AppliedElectrcchenistry

33:693.

(2000)26:217126

B: Envircnmental

AppredCatalysis

N. Cout6andJ. T. Richardson,

(2001)111.21-27

Pollution

T. Dombek,E. Dolan,J. Schultzand D. Klarup,Envircnmental

(1999)74:60

Technology

anc!

Biotechnology

Chemical

Journalof

5. lvl.A.KeaneandG. Tayoularis,

Electrochemisw

lsse,

and

V.

Monliel,

A.A.

Sanchez-Sanchez

6. A. Gennaro, M. Carlos,

(2004) 6, 627-631.

Connunications.

Chenbtry (2004)

N. Hoshi,K. Sasaki,S. Hashimoto,and Y. Hori,Journalof Electroanalytical

568:267--271.

V. Montiel,D.A. Tryk, A. Aldaz and A Fujishima,Pure Appl Chen

8. c.M. Sanchez-Sanchez,

(2001)73, 12, 1917-1927

.

L K. ltoandS. lkeda, Bull. Chen. Soc. Japan(1987t60:2517

and a Guide"lvl.Dekkero'

'10.M. l\I- Baizerand H. Lund"OrganicElectrochemistry:

An Introduction

(1991).

NewYork,USA,