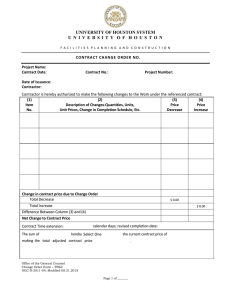

HOUSTON COMMUNITY SYSTEM, HOUSTON, TX Project No. 20150720-41 KATY CAMPUS REROOFING

advertisement