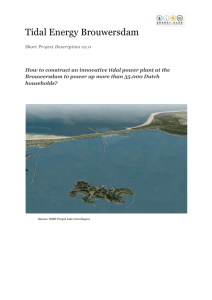

2.5 Tidal power plants (TPP) 2.5.1 Introduction

advertisement