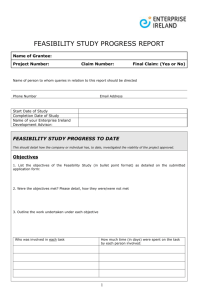

PROJECT PROPOSAL & FEASIBILITY STUDY NaturaFill: Fuel for Thought Team 13

advertisement