Anisotropic constitutive equation for friction

advertisement

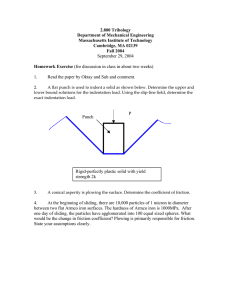

Journal of Applied Mechanics Vol.11, pp.271-282 (August 2008) JSCE Anisotropic constitutive equation for friction with transition from static to kinetic friction and vice versa K. Hashiguchi* and S. Ozaki** * Member Dr . of Eng. andDr. of Agr., Prof, Dept.Civiland Environ.Eng., Collegeof Technology,DaiichiUniversity, (Kokubu-Chuo1-10-2,Kirishima-shi,Kagoshima-ken899-4395,Japan) **Dr. of Agr.,AssistantProfessor,Facultyof Engineering,Divisionof SystemsResarch, YokohamaNationalUniversity(Tokiwadai79-5,Hodogaya-ku,Yokohama240-8501,Japan) Highfrictioncoefficientis firstobservedwhen a slidingbetweenbodiescommences,which is calledthe staticfriction. Then,the frictioncoefficientdecreasesapproachingthe lowest stationaryvalue, which is calledthe kineticfriction. Thereafter,if the slidingstops for a whileand then it startsagain,the frictioncoefficientrecoversand a similarbehavioras that in the firstslidingis reproduced.In this articlethe subloading-friction model1)witha smooth elastic-plasticslidingtransition(Hashiguchi,2005) is extendedso as to describethe reduction from the staticto kineticfrictionand the recoveryof the staticfriction.The reductionis formulatedas the plasticsofteningdue to the separationsof the adhesionsof surfaceasperities inducedby the slidingand the recoveryis formulatedas the viscoplastichardeningdue to the reconstructions of the adhesionsof surfaceasperitiesduringthe elapseof timeundera quite high actualcontactpressurebetween edges of asperities.Further,the anisotropyof frictionis describedby incorporatingthe rotationandthe orthotropyof sliding-yieldsurface. Key Words: anisotropy; constitutive equation; friction; elastoplasticity;hardening/softening; subloadingsurfacemodel;viscoplastkity. 1. Introduction Descriptionof the frictionphenomenonby a constitutiveequation has been attainedfirst as a rigid-plasticity2),3). Further,it has beenextendedto an elastoplasticity4)-17) in whichthe penaltyconcept, i.e. the elastic springsbetweencontact surfacesis incorporatedand the isotropichardeningis taken into accountso as to describethe test results18) exhibitingthe smooth contacttractionvs. slidingdisplacementcurve reachingthe static-friction.However, the interiorof the sliding-yieldsurfacehas been assumedto be an elasticdomainand thus the plasticslidingvelocitydue to the rate of traction insidethe sliding-yieldsurfaceis not described.Therefore,the accumulationof plasticslidingdue to the cyclicloadingof contact traction within the sliding-yieldsurface cannot be describedby these models. They could be calledthe conventional frictionmodelin accordancewiththe classificationof plasticconstitutivemodelsby Drucker19). On the other hand, the firstauthor of the presentarticlehas proposedthe subloadingsurfacemodel20) 21)within the frameworkof unconventionalplasticity , which is capable of describingthe plasticstrainrate by the rate of stressinside •\ 271•\ the yield surface.Based on the conceptof subloadingsurface,the authors proposed the subloading-frictionmodel1),22) which describesthe smoothtransitionfrom the elasticto plasticslidingstate and the accumulationof slidingdisplacementduringa cyclicloading of tangentialcontacttraction.Besides,in this model the reduction of frictioncoefficientwiththe increaseof normalcontacttraction observedin experiments15),23),24) is formulatedby incoiporating the nonlinearsliding-yieldsurface,whilethe decreasehas not been taken into accountin Coulombsliding-yieldsurface,which has beenadoptedwidelyin constitutivemodelsfor frictionso far. It is widelyknownthat when bodiesat rest beginto slideto each other,a high frictioncoefficientappearsfirst, whichis called the staticfriction, and then it decreasesapproachinga stationary value, called the kineticfriction. However,this process has not beenformulatedpertinentlyso far, althoughthe increaseof friction coefficientup to the peak has been described as the isotropic hardening,i.e. the expansionof sliding-yieldsurfaceas described above. Further,it has been foundthat if the slidingceasesfor a while and then it starts again, the frictioncoefficientrecoversand the similarbehavioras that in the initialslidingis reproduce25)-35). The recoveryhas been formulatedby equations includingthe time elapsedafterthe stop of sliding26),28),30),31),33),35). However,the inclusionof time itselfleadsto the loss of objectivityin constitutive equationsas known from the fact that the evaluationof elapsed time variesdependingon the judgmentof time when the sliding stops,which is accompaniedwith the arbitrarinessespeciallyfor the statevaryingslidingvelocityin low Generallyspeaking, the variationof materialpropertycannot be describedpertinently by the elapsefroma particulartimebuthas to be describedby state of internalvariableswithoutthe inclusionof timeitself The reductionof frictioncoefficientfrom the staticto kinetic frictionand the recoveryof frictioncoefficientmentionedabove are to be the fundamentalcharacteristicsin frictionphenomenon, which havebeen recognizedwidelyfor a longtime. Differenceof the staticand kineticfrictionsoften reachesup to severalten percents.Therefore,the formulationof the transitionfromthe staticto kineticfrictionand vice versa are of importancefor the development of mechanicaldesignin the field of engineering.However, the rationalformulationhas notbeenattainedso far. The differenceof frictioncoefficientsis observedin the mutuallyoppositeslidingdirections.It couldbe describedby the rotation of sliding-yieldsurface,whilstthe anisotropyof soilshas been describedby the rotationof yield surface36)-38). Further,the difference of the rangeof frictioncoefficientsis observedinthe different slidingdirections.It could be describedby conceptof orthotropy of sliding-yieldsurface14). In this article,the subloading-friction model1)is extendedso as to describethe reductionof frictioncoefficientfromthe staticto kinetic frictionas the plasticsofteningdue to the slidingand the recoveryof frictioncoefficientas the viscoplastichardeningdue to the creep phenomenoninduced with the elapse of time under a high contactpressurebetweenedgesof surfaceasperities.It is further extendedso as todescribethe anisotropyby incorporatingthe rotationand the orthotropyof sliding-yieldsurface. (2) n is the and •Z and of unit outward-normal denote I is the the and second-order Kronecker's Vn vector scalar identity delta ƒÂij is the normal the =1 component for at the tensor contact tensor having i=j , ƒÂij of the sliding surface, products, the components =0 velocity, (•E) respectively, for i •‚ j . i.e. (3) where the sign of Vn is selected to be plus when the counter body approaches to the relevant body. Fig. 1. Contact traction f and sliding velocity v. Further, it is assumed that V is additively decomposed the elastic sliding velocity Ve into and the plastic sliding velocity Vp , i.e. (4) with (5) (6) (7) 2. Formulation of the constitutiveequation for friction The subloading-friction mode1)is extendedbelow so as to describethe static-kinetic friction transition,i.e. the transitionfrom staticand kineticfriction,and vice versa. where Ves respectively, and Vpn are the elastic plastic part, of Vn . The contact traction f acting on the body is decomposed into the normal part, i.e. normal-traction 2.1 Decompositionof slidingvelocity The slidingvelocity V is definedas the relativevelocityof the counterbody and is additivelydecomposedinto the normal and the part, i.e. tangential traction ft fn and the tangential as follows: (8) part Vn and the tangentialpart Vt as follows(seeFig. 1): (9) (1) where whilst n is identical to the normalized i.e. •\ 272•\ direction vectors of fn , (10) describing anisotropy due to the rotation around the null traction point without the normal component of contact surface, while it is and fn is the normalpart of the contacttraction f , i.e. assumed thatitdoesnotevolve leading to I = 0 , andthusitholds (11) that (18) where the sign of body is compressed tions of the velocity fn is selected by the tangential are I-n•Zn•‚t•Zt counter contact not to be body. traction necessary plus when Here, note and the identical (t•ßft/•aft•a) in the the that relevant the tangential in (19) direc- The anisotropy sliding general and three-dimensional be- Now, let the hypo-elastic far elastic relation, small compared sliding whilst with velocity the the be given elastic plastic sliding sliding by velocity by the translation of of friction such it is phenomenon of the sliding-yield is de- surface. Then, it holds that is usually in the that the anisotropy scribed by the rotation the following velocity is described yield surface but the anisotropy of frictional materials as soils is described by the rotation36)-38). Therefore, assumed havior. of metals friction (20) phenomenon. (12) where lin and component, which are it are respectively, related to the the noimal component of t , (•‹) denoting material-time and derivative where s is an arbitrary rate, based on (•E) Therefore, tangential the corotational denoted by (21) the f =0 (13) with what follows, In surface sliding where the skew-symmetric tensor ƒ¶ is the spin describing normal based rotation of the contact surface. an and at are the elastic contact surface. not an absolute tive velocity can be in the normal On the velocity between adopted objectivity. moduli to the It follows and other hand, of a point two points Eq. the sliding on the body on the constitutive from the tangential contact relation (12) as directions velocity surface it is since and traction the interior but of traction by Eq. shape space, of that i.e. the slid- the inside (17) and that plastic surface. be renamed as the swface. on the concept of subloading suiface20),21), we in- the shape and spect to relathus it has sliding-subloading the current surface, contact traction which point f always and passes keeps a similar orientation to the normal sliding-yield surface with re- is the = const origin . of Then, the contact traction space, sliding-subloading i.e. surface f =0 fulfills for the fol- it lowing geometrical i) lines characteristics. the that All connecting ing-subloading the (15) an arbitrary surface normal called where the second-order tensor Ce described degree-one. similar domain is to v but the surface, that elastic (21) the through contact of the of contact assume Eq. the troduce rigid-body keeps by the rate surface sliding-yield Then, we a purely whilst function surface is induced let the quantity, to the origin is not velocity Therefore, (14) respect = const. scalar homogeneous sliding-yield for ƒÀ ing-yield which is derived from Euler's the orientation as follows: positive and sliding-yield the point its surface similarity-center, inside conjugate join which at is the point a unique the slidinside point, origin of the is the fictitious contact elastic contact traction space in the present model. modulus tensor given by ii) All ratios necting (16) face of two to •\ 273•\ an sizes Let responds ratio, 0 < R < 1 to the con- sliding-subloading conjugate points inside The coincides sur- line-element identical. size of the sliding-yield denoted to the null the line-element the normal ratio with con- is the slid- called ratio the of the surfaces. of the of the noimal ing-yield are which ratio arbitrary inside conjugate of these the an arbitrary surface similarity-ratio, that (17) where F is the isotropichardening/softeningfunctiondenoting the variationof the size of sliding-yieldsurface. ti is the vector of two ing-yield of points that necting 2.2 Normal sliding-yieldand sliding-subloadingsurfaces Assumethe followingisotropicsliding-yieldsurfacewith the isotropichardening/softening,which describes the sliding-yield condition. length surface by R traction subsliding sliding-subloading be (0 •… R •… state ( f state = 0) (0 < f called surface the 1) , where as the most < F to normal slid- R = 0 cor- elastic ), and R state, =1 to the normalsliding-yieldstate in whichthe contacttractionlieson the normal sliding-yieldsurface( f = F ). Therefore,the normal sliding-yieldratio R playsthe role of three-dimensional measure of the degree of approachto the normal sliding-yieldstate.Then, the sliding-subloading surfaceis describedby (22) The material-timederivativeof Eq. (22) leadsto (23) where (24) Here, note rial-time by that the derivative direct to the substituting a•E(ƒ¶a) = 0 formation Eq. for of tional transformation corotational an the (13) arbitrary into is for the peraturein general.The first and the second terms in Eq. (25) stand for the deteriorationsand the formations,respectively,of the adhesionsbetween surfaceasperities.On the other hand, so far these phenomenahave been describedby separateformulations for the softeningdue to the slidingdisplacementand the hardening due to the timeelapsedafterthe stopof sliding.Here,the inclusion of the time itselfin constitutiveequationS26),28),30),31),33),35) is not allowed violatingthe objectivitysincethe evaluationof elapsedtime from the stop of slidingdependson the subjectivityas knownfrom the statevaryingslidingvelocityin low level. mate- is verified a . The noting direct derivative verified the Eq.(23), vector material-time derivative of derivative the materialconstantsinfluencingthe recoveringrateof F dueto the elapseof time, whilethey wouldbe functionsof absolutetem- to trans- the general corota- scalar func- tion39). 2.3 Evolution rules normal It could 1 ) If the the of the sliding-yield be stated sliding from function experiments commences, maximal minimal hardening and the ratio value of stationary the that friction static-fiction value of coefficient and reaches then it reduces kinetic-friction. Fig. 2. Function U(R) for the evolution rule of the normal sliding-yieldratio R . first to the Physically, this It is observed in experiments that the tangential traction inphenomenon tions of bodies could the to is ing-yield and caused by friction Physically, the the between elapsed edges time of could of with initial after phenomenon the recovery the creep Taking is reproduced the due be the adhesions of under a quite high surface asperities. elapse the of time. to be caused ing-yield surface and it does not increase any more when it reaches rule of the normal sliding-yield ratio as follows: (26) where U(R) is a monotonicallydecreasingfunctionof R fulfillingthe followingconditions(Fig 2). (27) it be hardening assumed due to Letthe function U satisfyingEq. (27) be simplygivenby account of these facts, let the function F evolution rule be postulated (28) of the isotropic as follows: where u lead is the to the analytical material constant. integration sliding up •ß •aVp•adt where Fs creasing slid- pressure (25) tively. k the normal phenomenon. hardening/softening minimum approaching asperities contact let it increases gradually time of sufficient by the viscoplastic thereafter the normal sliding-yield surface. Then, we assume the evolution with surface Then, slid- behavior interpreted the is caused normal the coefficient, sliding an elapse that to the sliding. of fiction gradually as the creases almost elastically with the plastic sliding when it is zero but contact assumed of softening separa- between it be contraction recovers this let the reduction behavior reconstructions during that after coefficient the static the by the asperities Then, i.e. the plastic ceases identical to be caused surface sliding40). the by of the surface, 2 ) If the sliding friction interpreted adhesions due reduction be and values and rate Fk of m of F (Fs •† F are due F •† Fk) for the static the material to the plastic are and the kinetic constants sliding, maximum frictions, influencing and and and respecthe de- n are of under Ro as follows: Eq. R (26) with Eq. for the accumulated the initial (28) can plastic condition up - uo0 : R = (29) On the other hand, the following function has been used widely so •\ 274•\ far. 2.5 (30) However,an analyticalintegrationcannot be obtainedfrom Eq. formulated (26) with Eq. (30) and thus Eq. (30) is inconvenientto formulate the return-mappingmethod attractingthe contacttraction to the subloading suliace41). 2.4 Relationshipsof contact traction rate and slidingvelocity The substitutionof Eqs. (25) and (26) into Eq. (23) gives riseto the consistencyconditionfor the sliding-subloading surface: Loading The in the loading 2. It holds this proportionality factor , is derived Eq. (32) into Eq. (31), of (plastic sliding) (elastic v =v process process sliding) e leading it holds it should The Vp •‚ process 0 . Vp to N•ECe•Ev= = 0 . Further, N•ECe•Eve= be- N•Ef in that in hand, the that modulus negative other and be noted plastic and is the proportionality facts: that unloading while 0 (Eq. takes (36)). both signs hardening/softening that the definite >>‚•p in relaxation does lowing inequality be tensor not of positive materials. contact general plastic factorƒÉ mc •† mP noting positive N•ECe•EN (33) Substituting equation (43) (32) is a positive constitutive (42) 3. 0) for the is given in this section. (41) (31) Assumethatthe directionof plasticslidingvelocityis tangentialto the contactplane and outward-nonnalto the curvegenerated by the intersectionof sliding-yieldsurfaceand the constantnormal tractionplane fn = const. , leadingto the tangentialassociated (> criterion in the foregoing First, note the following cause where ƒÉ loading 1. It is required that in the flow rule,i.e. criterion elastic and and On thus it Ce holds postulating proceed the modulus that that infinitely, let the the fol- assumed. as follows: (44) (34) Then, in the unloadingprocess Vp = 0 the followinginequalitieshold dependingon the sign of the plasticmodulusmP , i.e. the hardening,perfectly-plasticand softeningstatesfrom Eqs. and thus (35) (34) and (41)-(44). where (36) (37) SubstitutingEqs. (4) and (35) into Eq. (31),the slidingvelocityis givenby (45) Therefore, the in which The locity, positive denoted proportionality by the symbol •È factor in terms , is given from of the Eqs. sliding (38) (38) sliding ve- tive in (39) of ƒÉ is not the unloading and an of ƒÉ but rion is given in the perfectly-plastic is induced, loading as the sign can unloading be done or negative. unloading process softening proceeds On process. Thus, processes by that of •È. the other the cannot from if the hand, •È distinction be judged Therefore, the the state, plastic is negabetween by loading the a sign crite- as follows: The traction rate is derived from Eqs. (4), (15), (32) and (46) (39) as follows: (40) where < > an arbitrary is the scalar McCauley's variable bracket, i.e. <s> = (s+ •b s •b)/2 or (47) for s . in lieu of Eq. (44). •\ 275•\ (56) 3. Specific sliding-yield surfaces It can be stated from experiments that the friction coefficient decreases with the increase of contact pressure15),23),24),42).There- (57) fore, the normal sliding-yield surface cannot be described appropriately by the Coulomb sliding-yield surface in which the tangential contact traction and the normal contact traction are linearly re- where lated to each other using the angle of external friction and the ad- (58) hesion. In what follows, the sliding-yield surface with thenonlinear relation of tangential contact traction and normal contact trac- Further,it holdsfromEqs. (16) and (55)-(57)that tion is assumed below, by which the reduction of friction coefficient with the increase of normal contact traction is described. The closed normal sliding-yield and the sliding-subloading surfaces can be described (59) by putting (48) (60) as follows: (49) where (50) M is the material constant denoting the traction ratio (=ft/fn) at the maximum point of ft . The simple examples of the function g(X) in the sliding-yield function in Eq. (48) are as follows: (61) (62) (51) (52) (63) (53) (54) (64) All the sets of Eqs. (17) and (48) with Eqs. (51)-(54) exhibit the closed surfaces passing through the points fn = 0 and fn = F at ft = 0 . Eq. (51) and (52) are based on the original Cam-clay yield surface43)and the modified Cam-clay yield surfaces44),respectively, for soils. Eq. (53) exhibits the tear-shaped surface1)45),46)which is reversed from the surface of Eq. (51) on the axis of normal contact traction. Eq. (54) exhibits the parabola1). It holds for Eq. (48) that The substitutionof Eqs. (16) and (59)-(64) into Eqs. (38) and (40) leadsto the slidingvelocityvs. contacttractionrate and its inverserelationare givenas follows: (55) (65) •\ 276•\ (76) The substitutionof Eqs.(16) and (72)-(76) into Eqs.(38) and (40) leads to the slidingvelocityvs. contactfractionrate and its inverserelationare givenas follows: (66) (77) On the other hand, the normal sliding-yield and the sliding-subloading surfaces for the circular cone of the Coulomb fric- tion condition is given by putting (67) as follows: (68) where ƒÊ is the in the identical friction form coefficient with and Eq.(25) the evolution rule is given as follows: (69) ƒÊs and ƒÊk and the cients, are minimum frictions, respectively. function of f of ƒÊ and i.e. f(f,ƒÀ) surfaces shape constants and thus static in in degree-zero, sliding-subloading conical material the friction Eq.(67) and in Eq.(68) expand/contact designating and the kinetic is normal the maximum, increase/decrease anisotropy site sliding directions can be described by the aforementioned and surfaces to orthotropic The difference of fiction coefficients in the mutually oppo- homogeneous sliding-yield with the 4. Extension coeffi- are open (78) having rota- tional anisotropy. However, the difference of the range of friction a coefficients in the different sliding directions cannot be described by the rotational anisotropy. In order to extend so as to describe it, R. let the concept of orthotropy be further incorporated below. It holds for Eq.(68) that (70) (71) Further,it holds fromEqs.(16) and (57) that (72) (73) (74) (75) Fig. 3. Surface asperity model suggesting and the orthotropic anisotropy. the rotational The simple surface asperity model is illustrated in order to obtain an insight into the anisotropy in Fig.3. Here, the directions •\ 277•\ M1 in the inclinationof surfaceasperitieswould lead to the rotational anisotropy,and the anisotropicshapes and intervalsof surfaceasperitiesto the orthotropicanisotropy.Now, choosingthe bases el and e*2in the directionsof the maximumand the minimumprincipal directionsof anisotropy,respectively,and letting e*3coincide with n so as to make the right-handcoordinatesystem (e*1,e*2,), it canbe writtenas (79) while the spin ƒ¶ of the base (e*1, e*2, e*3) is described as (80) Eq.(79) is rewritten by (85) where as follows: (86) (81) In Fig. 4 the section of the sliding-yield surface with the rotational and the orthotropic anisotropy is depicted in the coordinate system with the bases (e*1,e*2). Invokingthe orthotropicanisotropyproposedby Mroz and Stupkiewicz(1994),let Eq. (48) with Eq. (49) taken accountof the rotationalanisotropybe extendedas follows: The subscript i takes 1 or 2 and is not summedeven when it is repeated It holds fromEqs. (16) and (85) that (87) (82) (83) where (84) , and M2 are the material constants standing for the values of M in the maximum and the minimum principal directions of ani- sotropy, respectively. (88) (89) (90) Fig. 4. Sliding-yield surface with the rotational and the orthotropic anisotropy. Thepartialderivativesfor Eq. (82) are givenas ―278― (91) (94) Eq. (67) with Eq. (68) for Coulombfrictionconditionwith the rotationalanisotropyis extendedto the orthotropicanisotropy as follows: (95) (96) (92) where The substitutionof Eqs. (16) and (88)-(92) into Eqs. (38) and (40) leads to the slidingvelocityvs. contacttractionrate and its inverserelationare givenas follows: (97) C1 and C2 are the materialconstants.The partialderivativesfor Eq. (95) are givenas follows: (93) (98) Further,it holds fromEqs. (16) and (98) that (99) (100) ―279― (101) (102) (105) (103) The substitutionof Eqs. (16) and (99)-(103)into Eqs. (38) and (40) leads to the slidingvelocityvs. contacttractionrate and its inverserelationare givenas follows: The calculationfor slidingwiththe orthotropicanisotropyhas to be performedinthe coordinatesystemwiththe principalaxesof orthotropy,i.e. (e*1,e*2,n). 5. Linear slidingphenomenon We examinebelow the basic responseof the presentfriction modelby the numericalexperimentsand the comparisonwithtest data for the linearslidingphenomenon(Fig.1) without a normal slidingvelocityleadingto (106) The traction rate vs. sliding velocityrelation for Eq. (82) with Eq. (83) under the condition(106) is given from Eqs. (40), (90)-(92) by (104) (107) while it holds that fn=const. ― 280― The tractionrate for Eq. (95) with Eq. (96) is given from Eqs. (40) and(101)-(107) by locity. This advantage is of importance especially for the analysis of cyclic friction phenomena in which a loading and an unloading are repeated 6. The difference of friction coefficients in the mutually opposite sliding directions and the difference of the range of frictioncoefficients in the different sliding directions are described by the rotational and the orthotropic anisotropy, i.e. the rotation and the orthotropy of sliding-yield surface. The constitutive equation of friction formulated in this article would be applicable widely to friction phenomena between solids. It will be extended so as to be applicable to rubber-like material exhibiting a large nonlinear elastic behavior in thefuture. References while mp and mc aregivenby Eq. (70) and(71). (108) 6. Concluding remarks The constitutive model for friction is formulated by extending the subloading friction model1) so as to describe the isotropic hardening/softening of sliding-yieldsurface in this article.Fundamental features of this model are as follows: 1. The process for the rising of friction coefficient up to the static-friction and the subsequent reduction to the kinetic-friction is formulated in the unified way as the isotropicsoftening process due to the plastic sliding based on the concept of subloading surface describing the smooth elastic-plastic transition, although only the rising process has been discussed and it has beendescribed as the isotropic hardening process in the pastmodels4)-12), 14),17) . 2. The process for the recovery from the kinetic-to static-friction is formulated as the isotropic hardening due to the creep deformations of surface asperities, while it has been formulated by the irrational equation involving the elapsed time after the stop of sliding so far. 3. The smooth elastic-plastic transition is depicted and the cyclic sliding behavior can be described by incorporating the concept of the sliding-subloading locity due to therate ing-yield surface surface in which the plastic sliding ve- of contact traction inside the normal slid- isdescribed exhibiting the smooth tic-plastic transition. It is inevitable for the prediction elasof the loosing of screws, bolts and piles, the smooth stress/strain distribution at contact surface and the increase of traction with slip in wheel rotation on a solid surface for instance. 4. The reductionof frictioncoefficientwith the increaseof normal contacttractionis describedby incorporatingthe nonlinearsliding-yieldcondition. 5.A judgmentwhetheror notthe slidingyield conditionis fulfilled is not requiredin the loadingcriterionfor the plasticslidingve- •\ 281•\ 1) Hashiguchi,K., Ozaki,S. and Okayasu,T. (2005): Unconventionalfrictiontheorybasedon the subloadingsurfaceconcept, Int.J. SolidsStruct.,42, 1705-1727. 2) Seguchi,Y., Shindo,A., Tomita,Y. and Sunohara,M. (1974): Slidingrule of friction in plastic forming of metal, Compt. Meth Nonlinear Mech, Universityof Texas at Austin, pp. 683-692. 3) Fredriksson,B. (1976): Finite element solution of surface nonlinearitiesin structuralmechanicswith specialemphasisto contactand fracturemechanicsproblems,Comput.Struct.,6, 281-290. 4) Michalowski,R and Mroz, Z. (1978): Associated and non-associatedslidingrules in contact frictionproblems,Archiv.Mech, 30, 259-276. 5) Oden,J.T.and Pires,E.B.(1983a): Algorithmsand numerical resultsfor finiteelement approximationsof contactproblems with non-classicalfrictionlaws,Computerand Structures,19, 137-147. 6) Oden, J.T. and Pires, E.B. (1983b): Nonlocaland nonlinear frictionlaws and variationalprinciplesfor contactproblemsin elasticity,J. Appl.Mech.(ASME),50, 67-76. 7) Curnier,A. (1984): A theory of friction,Int.J. SolidsStruct., 20, 637-647. 8) Cheng,J.-H. and Kikuchi,N. (1985): An incrementalconstitutive relationof uniaxialcontactfrictionfor large deformation analysis,J. Appl.Mech.(ASME),52, 639-648. 9) Oden,J.T.and Martines,J.A.C(1986): Modelsand computational methods for dynamic friction phenomena, Comput. Meth.Appl.Mech.Eng.,52, 527-634. 10) Kikuchi,N. and Oden, J.T.(1988): Contactproblemin elasticity: A study of variationalinequalitiesand finite element methods,SIAM,Philadelphia. 11) Wriggers,P., Vu Van,T., and Stein,E. (1990): Finiteelement formulationof large deformationimpact-contactproblems withfriction,Comput.Struct.,37, 319-331. 12) Peric, D. and Owen, R.J. (1992): Computationalmodel for 3-D contact problems with friction based on the penalty method,Int.J. Numer.Meth.Eng.,35, 1289-1309. 13) Anand,L. (1993): A constitutivemodel for interfacefriction, ComputationalMechanics,12,197-213. 14) Mroz, Z. and Stupkiewicz,S. (1998): Constitutivemodel of adhesiveand ploughing frictionin metal-formingprocesses, Int.J. Mech.Sci.,40, 281-303. 15) Gearing,B.P.,Moon,H.S.and Anand,L. (2001): A plasticity modelfor interfacefriction:applicationto sheetmetalforming, Int.J. Plasticity,17,237-271. 16) Laulsen, T.A. (2001): Computationalcontact and impact mechanics: Fundamentals of modeling internationalphenomenain nonlinearfinite elementanalysis.Springer. 17) Wriggers,P. (2003): ComputationalContact Mechanics,J. Wiley,Chichester. 18) Courtney-Pratt,J.S. and Eisner,E. (1957): The effect of a tangentialforceon the contactmetallicbodies,Proc.Roy.Soc., Ser.A, 238, 529-550. 19) Drucker, D.C. (1988): Conventionaland unconventional plasticresponseand representation, Appl.Mech.Rev.(ASME), 41, 151-167. 20) Hashiguchi,K. (1980): Constitutiveequationsof elastoplastic materials with elastic-plastictransition.,J. Appl. Mech. (ASME),47, 266-272. 21) Hashiguchi, K. (1989): Subloading surface model in unconventionalplasticity,Int.J. SolidsStruct.,25, 917-945. 22) Ozaki, S., Hashiguchi, K., Okayasu, T. and Chen, D.H. (2007): Finite element analysis of particle assembly-water coupledfrictionalcontactproblem,Comput.Model.Eng. Sci., 18(2), 101-119,2007. 23) Bay, N. and Wanheim,T. (1976): Real area of contactand friction stresses at high pressure sliding contact, Wear, 38, 201-209. 24) Dunkin,J.E. and Kim, D.E. (1996): Measurementof static frictioncoefficientbetweenflat surfaces,Wear,193, 186-192. 25) Dokos, S.J. (1946): Sliding frictionunder extremepressure ., Tram.ASME,68, A148-156. -I 26) Rabinowicz,E. (1951): The natureof the staticand kinetic coefficientsof friction,J. Appl.Phys.,22, 1373-1379. 27) Rabinowicz,E. (1958): The intrinsicvariablesaffectingthe stick-slipprocess,Proc. Phys.Soc.,71, 668-675. 28) Howe, P.G., Benson, D.P. and Puddington, I.E. (1955): London-Vander Waals' attractiveforces between glass surface,Can. J. Chem.,33, 1375-1383. 29) Derjaguin,B.V., Push,V.E. and Tolstoi,D.M. (1957): A theory of stick-slippingof solids,Proc. Conf. Lubr. and Wear, Inst.Mech.Eng.,London,pp. 257-268. 30) Brockley, C.A. and Davis, H.R (1968): The time-dependenceof staticfriction,J. Lubr. Tech.(ASME),90, 35-41. 31) Kato,S., Sato,N. and Matsubayashi,T. (1972): Some considerationson characteristics of staticfrictionof machinetool sideway,J. Lubr.Tech.(ASME),94, 234-247. 32) Richardson,R.S.H.and Noll, H. (1976): Surfacefrictionundertime-dependentloads, Wear,37, 87-101. 33) Horowitz,F. and Ruina,A. (1989): Slippatternsin a spatially homogeneous fault model, J. Geophysical Research, 94, 10279-10298. 34) Ferrero,J.F. and Barrau,J.J. (1997): Studyof dry frictionunder small displacementsand near-zeroslidingvelocity,Wear, 209, 322-327 35) Bureau,L., Baumberger,T, Caroli,C. and Ronsin, O.(2001): Low-velocityfrictionbetweenmacroscopicsolids,C.R Acad Sci.Paris, SeriesIV,Differentface of Tribology,2, 699-707. 36) Sekiguchi,H. and Ohta,H.(1977): Inducedanisotropyand its time dependence in clays, ConstitutiveEquations of Soils (Proc.Spec.Session9, 9thICSFME),Tokyo,pp.229-238. 37) Hashiguchi,K. and Chen,Z.-P (1998): Elastoplasticconstitutive equationsof soilswiththe subloadingsurfaceand the rotational hardening,Int. J. Numer. Anal. Meth. Geomech.,22, 197-227. 38) Hashiguchi,K. (2001): Descriptionof inherent/inducedanisotropy of soils: Rotationalhardeningrule with objectivity, Soils& Foundations,Vol.41,No.6, 139-145. 39) Hashiguchi,K. (2007): General corotationalrate tensor and replacementof material-timederivativeto corotationalderivative of yield function,Comput.Model.Eng Sci.,17(1), 55-62, 2007. 40) Bowden,F.P. and Tabor,D. (1958): TheFriction and Lubricationof Solids,ClarendonPress. 41) Hashiguchi, K. (2008): Basic Formulation of Retum-MappingMethodfor SubloadingSurfaceModel,Annual ResearchReportof DaiichiUniv.,20, 135-148. 42) Stupliewicz,S. and Mroz, Z. (2003): Phenomenological model of real contact area evolutionwith account for bulk plastic deformationin metal forming,Int.J. Plasticity,19, 323-344. 43) Schofield,A.N. and Wroth, C.P. (1968): Critical State Soil Mechanics,London,McGraw-Hill. 44) Roscoe,K.H. and Burland,J.B. (1968): On the generalized stress-strainbehaviourof 'wet' clay, EngineeringPlasticity, CambridgeUniv. Press,pp.535-608. 45) Hashiguchi,K. (1972): On the yieldingof frictionalplastic body-hardening rule, Proc.27th annual meeting JSCE,pp. 105-108. 46) Hashiguchi,K. (1985): Macrometricapproaches-staticintrinsicallytime-independent, ConstitutiveLaws of Soils(Proc. DiscussionSession 1Aof 11thICSMFE),San Francisco,pp. 25-56. (Received:April 14,2008) •\ 282•\