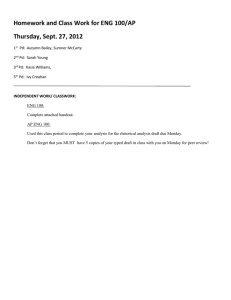

[Company Name] [Company Group, Division, Location] Document Title: Quality Records

advertisement

![[Company Name] [Company Group, Division, Location] Document Title: Quality Records](http://s2.studylib.net/store/data/014681688_1-fc8d1d16a0c0df321f74d243180475c1-768x994.png)

[Company Name] [Company Group, Division, Location] Document Title: Quality Records Document Number: Document Filename: [Document Number] [Document Filename] CONTROLLED COPY/ MASTER COPY STAMP HERE OTHER STAMP HERE Revision Level DRAFT 1.00 Revision Date DD/MM/YY DD/MM/YY DCO/ECO Number YY-00000 YY-00000 Description of Revision Draft Initial Release COMPANY PROPRIETARY AND CONFIDENTIAL Revision Author Author Name Author Name [Company Name] [Company Group, Division, Location] Quality Records [Document Number] Rev x.xx DD/MM/YY Table of Contents 1.0 Purpose ........................................................................................................................................................ 2 2.0 Scope ........................................................................................................................................................... 2 3.0 Definitions ................................................................................................................................................... 2 3.1 Design History File (DHF) ................................................................................................................ 2 3.2 Device History Record (DHR) .......................................................................................................... 2 3.3 Device Master Record (DMR) .......................................................................................................... 2 3.4 Controlled Copy ................................................................................................................................ 2 3.5 Controlled Document ........................................................................................................................ 2 3.6 Uncontrolled Copy ............................................................................................................................ 2 3.7 Quality Records................................................................................................................................. 2 4.0 Responsibilities ............................................................................................................................................ 2 4.1 Quality Assurance ............................................................................................................................. 2 4.2 Document Control ............................................................................................................................. 2 4.3 Departmental Manager ...................................................................................................................... 3 4.4 [Company Name] Employees ............................................................................................................ 3 5.0 References and Applicable documents ........................................................................................................ 3 6.0 Procedure ..................................................................................................................................................... 3 6.1 Quality Record Requirements ........................................................................................................... 3 6.2 Approval/Control/Retention .............................................................................................................. 3 6.3 Document Users ................................................................................................................................ 4 6.4 [Company Name] Device Master Record Requirements................................................................... 4 6.5 [Company Name] Device History Record Requirements .................................................................. 4 6.6 [Company Name] Design History File Record Requirements ........................................................... 4 Table of Figures Table 1. Document Matrix Legend .......................................................................................................... 5 Table 2. Document Matrix ....................................................................................................................... 5 [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 1 of 7 [Company Name] [Company Group, Division, Location] Quality Records [Document Number] Rev x.xx DD/MM/YY 1.0 Purpose To ensure that all quality records pertinent to the quality system and products are maintained and managed effectively, and to provide objective evidence of quality system implementation. 2.0 Scope This procedure applies to all quality records for the operation of the quality system at all facilities of [Company Name]. 3.0 Definitions 4.0 3.1 Design History File (DHF) A compilation of documents that describes the design history of a finished device. 3.2 Device History Record (DHR) A compilation of documents containing the production history of a finished device. 3.3 Device Master Record (DMR) A compilation of documents containing the procedures and specifications for a finished device. 3.4 Controlled Copy A controlled copy is an exact copy of the original controlled document that must be maintained for uniformity, process control, and tracking. It has limited and specific distribution, and the front page is marked in red with "Controlled Copy". Document Control must issue any controlled copies. 3.5 Controlled Document A controlled document is the original document that must be maintained for uniformity, process control, and tracking. There is one original for each document, instruction, procedure, standard, or form. It may be maintained on paper, or as an electronic file. The master copy of any document is the electronic file available for viewing on the network. Document Control maintains controlled documents. 3.6 Uncontrolled Copy Any copy of a document that is not controlled is an uncontrolled copy. An uncontrolled copy may be used for informational purposes only. These documents may not be used for operation of the quality system, manufacture of product, for accept / reject decisions on product or processes and operation of quality related processes. 3.7 Quality Records Records that demonstrate conformance to required and adequate operation of the quality system herein referred to as documents. Responsibilities 4.1 Quality Assurance Decides which documents are quality records. Quality Assurance ensures that all documents meet applicable standards. 4.2 Document Control Maintains the "master copy" showing approvals and latest revision of documents that are maintained by Document Control. Maintain a current list of released documents on the network. [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 2 of 7 [Company Name] [Company Group, Division, Location] Quality Records [Document Number] Rev x.xx DD/MM/YY Notify Quality Assurance of any document(s) that is added to or removed from the Quality System that is considered a quality record. 4.3 Departmental Manager Notify Quality Assurance of any document or report that would be considered a quality record. 4.4 [Company Name] Employees Identify obsolete versions of documents; Recommend changes to documents; Prevent unauthorized copying or amendment of documents; Not to obtain or use documents other than [Company Name] documents. 5.0 References and Applicable documents Document Retention, Storage and Disposition Engineering/Production Document Release and Change Control Design History File 6.0 Procedure The majority of all documents are uploaded to computer databases (BAAN and O:\Solidworks) through electronic procedures for storage, filing, and archiving. The use of computerized storage ensures legibility, retrievability and a suitable environment that minimizes damage and deterioration. Where paper documents are utilized, the issuing department is responsible for the establishment and maintenance of suitable procedures. Quality records shall be made available for evaluation for an agreed period to a customer when agreed contractually. 6.1 Quality Record Requirements All documents must be legible. All paper documents that require information to be filled out must be completed in blue or black ink. NO PENCIL is permitted. NO RED or colored ink other than mentioned above may be used. If a mistake is made on a paper document, the mistake shall be crossed out with a single line, dated and initialed. 6.2 Approval/Control/Retention A list of quality records is identified in the document matrix. Documents not appearing or referred to on this list are not quality records and are not governed by this procedure. Incorporation of external quality related standards into the quality system requires written approval by the Quality Assurance Manager. The document matrix indicates the Controller of the document/data. This person/department manager is responsible for approval and updating documents and records. Document control will notify affected departments of document and records changes. Retention period requirements of documents are based on business and regulatory requirements. [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 3 of 7 [Company Name] [Company Group, Division, Location] 6.3 Quality Records [Document Number] Rev x.xx DD/MM/YY Document Users Documents must not be changed without the controllers consent. Users cannot deface, amend, destroy, add or delete information to documents. Document users are required to destroy or return obsolete versions of paper documents once revised. 6.4 [Company Name] Device Master Record Requirements [Company Name] will maintain a device master record for each device manufactured with the following contents: (Refer to document matrix) 6.5 [Company Name] Device History Record Requirements [Company Name] will maintain a device history record for each device manufactured with the following contents: (Refer to document matrix) 6.6 [Company Name] Design History File Record Requirements [Company Name] will maintain a design history file record for each device manufactured with the following contents: (Refer to Design History File) [Document Filename] COMPANY PROPRIETARY AND CONFIDENTIAL Page 4 of 7 [Company Name] [Company Group, Division, Location] Table 1. Quality Records [Document Number] Rev x.xx DD/MM/YY Document Matrix Legend Abbreviation ADMN DC DPML ENG HR MANF ME MTN PM PURC QA QA MGR QS Table 2. Meaning Administration Document Control Departmental Engineering Human Resources Manufacturing Manufacturing Engineering Maintenance Program Management Purchasing Quality Assurance Quality Assurance Manager Quality Systems Document Matrix Document Name Approved Supplier List Archival Records: Admin/Document Control Artwork Maintained By PURC ADMN/DC Controlled By QA ADMN/DC Part of DMR DC ME or ENG * Audit Checklist Audit Summary Reports Calibration Procedures QA QA QA QA QA QA * Calibration Record QA QA MANF QA ME QA QA DC QA ENG Contracts/ Modifications Controlled Environment Monitor Log Corrective Action Notice Customer Complaint Form ADMN MANF ADMN ME QA QA QA QA Daily Receiving Log Daily Shipping Log Document Approval Record Drawings PURC PURC DC DC PURC PURC DC ME or ENG Engineering Change Order DC ME, ENG, PM or QA QA ME Cleanroom Cleaning Checklist Complaint Analysis Form Complaint Log Component Specifications External Audit Records Hepa Air Velocity Measurement [Document Filename] QA MGR MANF Part of DHR * * * COMPANY PROPRIETARY AND CONFIDENTIAL Retention Period (Minimum) 3 years Permanently Product Life + 2 years Continuing 2 years Product Life + 2 years Product Life + 2 years 5 years Product Life + 2 years Permanently Product Life + 2 years Permanently 5 years 2 years Product Life + 2 years 5 years 5 years 5 years Product Life + 2 years Product Life + 2 years 5 years 5 years Page 5 of 7 [Company Name] [Company Group, Division, Location] Document Name Quality Records [Document Number] Rev x.xx DD/MM/YY Maintained By Controlled By Log Incoming Inspection Report QA Inprocess Inspection Log Inspection Procedures Part of DHR Retention Period (Minimum) QA * QA QA * DC QA QA QA MGR DC QA QA ENG QSM DC QSM ME * DC ME * QA QA Product Life + 2 years Product Life + 2 years Product Life + 2 years 5 years Continuing Product Life + 2 years 2 years Product Life + 2 years Product Life + 2 years 5 years QA DC QA DC * Material Review Report QA QA * MDR Event Report Log MDR Reports QA QA QA QA Medical Device Report Analysis Form Medical Device Report Event Form Mold, Fixture, Jig Certification Record Non-Product Specific Work Instructions Order Entry Form Organizational Charts QA QA QA QA QA ME DPML DPML Continuing Product Life + 2 years Product Life + 2 years 5 years Product Life + 2 years Product Life + 2 years Product Life + 2 years Lifetime of Tool + 2 years Per Department ADMN HR ADMN HR 5 years Continuing Parts List/BOM DC ENG or ME Preventive Maintenance Workorder Process Specification ME ME DC ENG * Process Validation Records QA QA * Product Release Verification QA QA * Product Description DC PM * Product Manuals/Labeling DC ENG * Internal Audit Records Internal Auditor List (ISO) Lab Notebooks Management Review Reports Manufacturing Procedures Manufacturing Process Procedure/Specifications Marketed Product Correction and Removal Form Master Calibration List Material Disposition Sheet [Document Filename] Part of DMR * * * * COMPANY PROPRIETARY AND CONFIDENTIAL * Product Life + 2 years 2 years Product Life + 2 years Product Life + 2 years Product Life + 2 years Product Life + 2 years Product Life + 2 Page 6 of 7 [Company Name] [Company Group, Division, Location] Document Name Quality Records [Document Number] Rev x.xx DD/MM/YY Maintained By Controlled By Part of DMR Product Requirements Document(Functional Specs) Product Travelers DC PM * QA ME * Product Tree DC ENG * Project Management Plans DC PM PURC PURC DC QA ADMN QA PURC PURC QA MGR QA ADMN QA QA DC QA ENG or ME * QA MGR ENG DC QA ENG ME or ENG * DC ME or ENG * Stock Purge Request PURC PURC Supplier Evaluation Technical Report QA MGR PM QA PM Temporary Calibration Extensions QA QA Test Procedure DC ME * Test Specification DC ME or ENG * ADMN ADMN PURC QA ADMN ADMN QA QA QA ME QA QA Purchase Orders Purchase Requisition Quality Manual Quality Trend Reports Quotation Form Returned Material Authorization Request Returned Product Form Schematic Scrap Report Software Problem Report Software Release Source Code Training Exemption Training Record Vendor Authorization Request Vendor History Form Vendor Notification Report Workmanship Standard [Document Filename] Part of DHR * * * COMPANY PROPRIETARY AND CONFIDENTIAL Retention Period (Minimum) years Product Life + 2 years Product Life + 2 years Product Life + 2 years Product Life + 2 years 7years, 7 years Continuing 2 years 5 years 5 years 5 years Product Life + 2 years 2 years 5 years Product Life + 2 years Product Life + 2 years Product Life + 2 years 2 years Product Life + 2 years Lifetime of Equipment + 1 year Product Life + 2 years Product Life + 2 years Permanently Permanently 3 years Product Life + 2 years 5 years Product Life + 2 years Page 7 of 7