The Fifth Dimension: The Supplier & OEM Interface Steve Walukas Vice President

advertisement

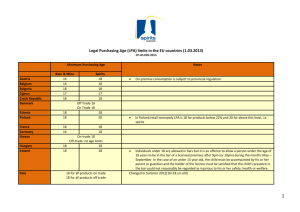

The Fifth Dimension: The Supplier & OEM Interface Steve Walukas Vice President Corporate Quality DaimlerChrysler Corporation 1 The Fifth Dimension The Supplier & OEM Interface ¾ ¾ ¾ ¾ DaimlerChrysler Overview The Chrysler Group Results The Chrysler Group’s Product Offensive Internal and External Interface 2 DaimlerChrysler Overview THE AUTOMOTIVE BUSINESS AND AUTOMOBILE-RELATED SERVICES ACCOUNT FOR 99% OF DAIMLERCHRYSLER'S REVENUES 3 DaimlerChrysler’s Strategy is Based on Four Strategic Pillars Global Presence Strong Brand Portfolio Innovation & Technology Leadership Broad Product Range 4 Extensive Research Capabilities Permanent staff 1,600 scientists plus 1,000 doctoral/diploma candidates/junior staff 5 Disciplined Product Development Processes Product Product Strategy Strategy Development System Chrysler Development System Customer Trends IDEATION Competition Design Ideas PPDC BUSINESS CASE Continuous Continuous Improvement Improvement V1 Mid-Cycle Freshening Renewal Technology Management Concept Development Design Execution Launch Technology Trends Fuel Prices Identify Establish Program Potential Vision Alternatives Program Transition Economic Environment I H1 H2 Confirm Product/ Process Design G1 G2 Optimize Product/ Process Design EF Verify Product/ Process Design D1 D2 Validate Product/ Process & Verify Facilities C Validate Vehicle/ Facilities & Launch Ramp-up B A Regulatory Trends Product Strategy Team Product Executive Committee • Regulatory Changes (PEC) • Quality Improvement (Monthly Review) • Cost Reduction (Bi-weekly Component Teams) Product Innovation Team 6 Worldwide Manufacturing Locations 7 Global Retail Locations Market Performance Center (MPC) Joint Venture Independent Distributor 8 The Chrysler Group’s Transformation By Leveraging our Global Enterprise, The Chrysler Group’s New Generation of Vehicles Shares the Ultimate in: • Innovation • Quality • Styling • Environment • Value • Safety 9 2004 Calendar Year Product Offensive Crossfire Roadster Town & Country PT Cruiser Convertible SRT-6 Roadster 300C Grand Cherokee Durango SRT-6 Coupe 2005 2004 NOV DEC JAN FEB MAR APR MAY JUNE JULY AUG 1st 2nd 3rd SEP OCT NOV DEC JAN 4th Caravan Dakota Wrangler Unlimited SRT-10 Magnum Liberty Diesel Liberty Refresh/ Renegade 10 Product Offensive 2004 – 2007 25 in New vehicles to market 36 months 11 Chrysler Group: Strategic Transformation CHRYSLER GROUP HAS SHOWN SIGNIFICANT PROGRESS REDUCING WARRANTY CONDITIONS AND EXPENSES Warranty C/1000 Goal: Best in Class by 2007 1996 1997 1998 1999 2000 2001 2002 Model Years P:\ P:\SHARED 2003 2004 2005 2006 2007 12 2004 Consumer Reports PT Cruiser Toluca Assembly Plant Chrysler Sebring Sterling Heights Assembly Plant RECOMMENDATION Jeep Liberty Toledo North Assembly Plant Dodge Stratus Sterling Heights Assembly Plant 13 J.D. Power IQS - Results 2004 Chrysler Group Top Quartile Models Dodge Neon Dodge Stratus Coupe Chrysler PT Cruiser Dodge Ram Pickup HD Dodge Caravan/Grand Caravan 14 2004 Harbour Report ¾ Command Performance: Chrysler Group is Most-Improved Automaker in The Harbour Report 2004 ¾ 7.8 % improvement ¾ Set new industry benchmark in transmission productivity ¾ 15 2004 Focus ¾ Emphasis on Warranty Improvements ¾ Launch Management ¾ Prevention of Problems ¾ Speed of Problem Resolution ¾ Durability / Reliability / 3/36 Warranty ¾ Improve Internal and External Collaboration 16 The Extended Enterprise Collaboration Internal Departments Shareholders Design Engineering Manufacturing Procurement & Supply Sales & Marketing Finance NADA Dealer Councils Dealer Advertising Associations Labor UAW(U.S.A.) CAW (Canada) El Sindicato (Mexico) Management Government Agencies EPA NHTSA Dealers DaimlerChrysler Financial Institution Analyst Credit, DaimlerChrysler Bank External Organizations AIAG VDA/ISO JAMA Suppliers Production Parts Tooling & Equipment Service & Parts 17 Importance of Collaboration ¾ We rely on our partners to: • Provide perfect parts and services • Efficiently design & produce parts & services • Proactively look for better standards, methods, parts, products, and services • Continuously strive for improvement • Provide innovative methods and technology • Delight the customers through passionate execution of requirements and customer wants 18 The Fifth Dimension: The Supplier OEM Interface DaimlerChrysler Corporation Scott R. Garberding Vice President Supplier Quality 19 The Suppliers’ role is key within Chrysler Group • 1,300 Top Parent Suppliers • 64,000 purchased production components • $26 Billion annual buy Our performance directly relates to the performance of our supply base. 20 Primary Root Cause for Critical PRISMs 60 51 50 39 40 30 20 11 10 10 8 3 2 0 Inadequate Process Control Method Process Control Method Not Followed Inspection and Testing Design Control Control of Nonconforming Product Handling, Storage, Packaging and Presentation Part Identification and Traceability 21 Primary Root Cause for Critical PRISMs 60 51 50 40 30 75% of all defects are due to Process Non-Conformance 39 20 11 10 10 8 3 2 0 Inadequate Process Control Method Process Control Method Not Followed Inspection and Testing Design Control Control of Nonconforming Product Handling, Storage, Packaging and Presentation Part Identification and Traceability 22 Global Supplier Quality Initiatives Quality Funnel Restructured Process Sign-Off Layered Process Audit Improve Process CDS Quality Gates Best Practices Feedback Forever Requirements Revision Source Package Revision 23 What is a Layered Process Audit (LPA)? ¾LPA is an ongoing system of process checks that verify proper methods, settings, operator craftsmanship, error proofing devices and other inputs are in place to ensure a defect free product. ¾LPA’s assure that defined methods and work instructions are utilized, problem solving solutions are held in place, and all process issues are identified and quickly correctly. 24 How does an LPA Work? PFMEA Control Plan Work Instructions Corrective Actions Continuous Improvement Inputs Technical Memory Prevention Actions Employee Workshops Process Audits Build Technique Error Proofing Machining Attributes •Audits are conducted regularly by all levels of supervision •Non-conformances are immediately addressed 25 LPA - Frequency Plan Plant Manager 1 X Week Area Management 2 X Week Production Supervisor 1 X Shift • Encourages Management Involvement • Encourages Operator Feedback • Establishes Accountability 26 LPA Benefits Reduces •Build variation based on work standardization •End-of-line inspection •Part defects Improves •First time through capability •Morale Facilitates •Operator training •Management/operator interface Reinforces •Safety regulations 27 LPA Success at Kokomo Transmission Plant Repair Inventory vs First Time Capability vs LPA # of LPA Checks / Week KTP Now conducting 6700 Process Layered Audit Checks 100 Repair Inventory FTC 95 90 85 80 75 1800 70 65 0 Process Layered Audits 31-03 34-03 37-03 40-03 43-03 46-03 49-03 52-03 60 21-02 24-02 27-02 30-02 33-02 36-02 39-02 42-02 45-02 48-02 51-02 1-03 4-03 7-03 10-03 13-03 16-03 19-03 22-03 25-03 28-03 18-02 180 First Time Through (%) 5400 55 Weekly 28 Supplier Interface – LPA’s will be mandatory ISO/ TS 16949 ¾ DaimlerChrysler Customer Specific Requirements New section under Internal Audits Effective 7/01/04 for Powertrain & Component Plants suppliers; 1/1/05 for all remaining suppliers ¾Posted on AIAG, IAOB, and QMS web sites ¾Letter mailed to all suppliers DaimlerChrysler Corporation Peter M. Rosenfeld Executive Vice President Procurement & Supply August 6, 2004 A Layered Process Audit ("LPA") is a quality improvement business system involving multiple layers of management. It consists of regularly scheduled reviews of all elements in a manufacturing/ assembly process to ensure that: equipment is being properly maintained; error proofing is working, and; proper craftsmanship and/or build techniques, from standardized work instructions, are being followed. Utilization of LPA will result in more disciplined processes and improve overall quality. Most Chrysler Group Powertrain facilities are already using LPA. I am writing to you because I am asking that all supplier manufacturing facilities providing parts to one or more of Chrysler Group's Powertrain plants deploy LPA. Within the next few weeks, your plant and quality managers will be receiving correspondence which will provide additional information about LPA training. The course work will be conducted at the DaimlerChrysler Technology Center during the next Supplier Training Week scheduled for May 10 through 14. This training will fulfill your company's training requirements and, more importantly, will assist you in immediately implementing this procedure within your facility. At the same time, the Chrysler Group will be moving to make LPA a mandate for suppliers to its powertrain plants in the third quarter of 2004. The Chrysler Group is in the process of finalizing implementation of LPA in all of its powertrain plants. It has proved to be a valuable tool to improve first-time through capability which ensures quality to the customer. The Layered Process Audit is a system to ensure that we build the best quality product together. I appreciate your company's, and your personal, support on this matter. Sincerely, 29 Supplier Interface – LPA Compliance Verification Compliance Form ¾ Summary of training, implementation, and LPA results/ compliance ¾ One form per supplier location to be submitted monthly to SQ Specialist Layered Process Audit Compliance Report Supplier Name: DCX SQ Specialist Report Supplier Code City State/ Prov. Country Month Year Training & Implementation Summary LPA Trained LPA Implemented Countermeasure Comments Countermeasure Comments Staff/ Top Management: Mid-Level Management: Line Supervisors: Audit Sheets Developed LPA System & Infrastructure Established Number/ % of DCX Lines utilizing LPA Monthly Compliance Summary Line / Operation / Number / Name / Description Number of items to be audited Number of items audited LPA 1 LPA 2 LPA 3 LPA 4 LPA 5 LPA 6 LPA 7 LPA 8 LPA 9 DCX TOTAL % of audits accomplished No. of items in compliance %of items in compliance Frequency: Top Management (1/ week) Mid-Level Management Line Supervisors (1/ shift) Error Proofing (1/day) Green Yellow Red In Compliance In Progress Not Started Submitted By: _______________________ Approved By: _______________________ Date Submitted: _____________________ 30 Layered Process Audit Proven successful internally ¾ Expanding Collaboration to our Supply base ¾ Not asking Suppliers to do something we are not ¾ Training available to all Chrysler suppliers ¾ Low investment – significant quality return 31 The Fifth Dimension: The Supplier OEM Interface DaimlerChrysler Corporation Scott R. Garberding Vice President Supplier Quality 32