T I C STANDARD OPERATING PROCEDURE

advertisement

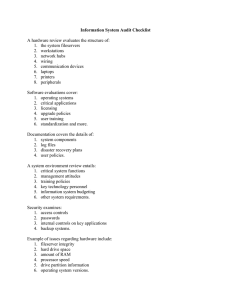

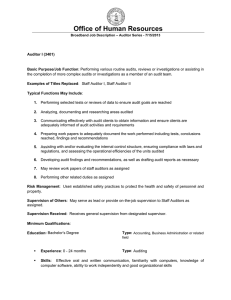

T C I STANDARD OPERATING PROCEDURE TCP.17.01 09/22/00 INTERNAL QUALITY AUDITS Page 1 of 3 - Cari Spears – Management Representative - Celeste Johnson – Office Manager - Dennis Johnson – President ORIGINAL IF GREEN : Prepared by : Approved by 1.0 Document # Revision Date PURPOSE AND SCOPE 1.1 To verify that our Quality System is in compliance with ISO 9002 and that our practices are in compliance with our documented Quality System. 1.2 To ensure the continued capability of all elements of our Quality System. 2.0 DEFINITIONS 2.1 Quality System: Organizational structure, procedures, processes and resources needed to implement and maintain quality management. 2.2 Auditor: An employee who has the qualifications to perform quality audits. 2.3 Lead Auditor: An auditor designated to manage a quality audit. 2.4 Observation: A statement of fact made during an audit and substantiated by objective evidence. 2.5 Objective Evidence: Records or statements of fact, which can be verified. 2.6 Nonconformance: The nonfulfillment of specified requirements. 3.0 PROCEDURE 3.1 AUDITOR QUALIFICATON 3.1.1 Auditor candidates must be employed at TCI for at least 90 days. 3.1.2 Auditor candidates must successfully complete an Auditor Training Course. 3.1.3 Internal Auditor Training is conducted by the Management Representative in accordance with ISO 10011 – Guidelines for Auditing Quality Systems. 3.1.4 Certification from an accredited training body may be provided. If certification was received from past employment, one may be qualified after 90 days with a brief review of TCI auditing practices. 3.1.5 Evidence of Auditor Qualification is maintained in Employee Training Files. 3.2 LEAD AUDITOR – AUDIT PREPARATION 3.2.1 The Management Representative is the Lead Auditor, however this duty may be delegated to an experienced Auditor with management approval. The Lead Auditor has final decisions regarding the conduct of the audit and any observations. 3.2.2 The Lead Auditor is responsible for: A. Preparing and maintaining the Audit Schedule, auditee notification at least one week prior to an audit. B. Preparing the Audit Plan, conducting opening and closing meetings. C. Selecting the Audit Team, ensuring that Auditors are independent of the activity they have been assigned to audit. D. Briefing the Auditors, defining the requirements of each audit assignment and assisting in the preparation of audit checklists as needed. E. Assisting Auditors in preparing the Audit Reports. F. Reporting on Audit Results at Management Review Meetings. T C I STANDARD OPERATING PROCEDURE INTERNAL QUALITY AUDITS ORIGINAL IF GREEN Document # Revision Date TCP.17.01 09/22/00 Page 2 of 3 3.3 OPENING MEETING OBJECTIVES 3.3.1 Introduce the members of the audit team to the auditees and establish communication links with activities being audited. 3.3.2 Review the scope and objectives of the audit and provide a short summary of the methods and procedures to be used to conduct the audit. 3.3.3 Clarify the details of the audit plan and confirm the time and date for the closing meeting and any interim meetings. 3.4 CONDUCTING THE AUDIT 3.4.1 All TCP’s and TCW’s will be audited at least once per year. In addition to annually scheduled audits, the Lead Auditor may select certain activities for follow-up or more frequent auditing as their status and past compliance history changes. 3.4.2 General Housekeeping, work environment, knowledge of the Quality System and Policy, product identification and traceability, document and data control and control of quality records are observed in all audited areas every audit. If not reviewed, the reason must be noted in the comments space on the Audit Report. 3.4.3 The Auditors will collect evidence through interviews, examination of documents and quality records, and observation of activities and conditions in areas of concern. 3.4.4 Information gathered through interviews should be tested or investigated by acquiring the same information from other independent sources, such as physical observation, measurements and records. 3.4.5 All audit observations are documented, even if not originally covered on the checklist. Area management will be constantly informed of findings, there are to be no surprises at the closing meeting. 3.4.6 During the audit, the Lead Auditor may make changes to the Auditors work assignments or the audit plan, if necessary to achieve the audit objectives. 3.5 CLOSING MEETING OBJECTIVES 3.5.1 Present audit observations to auditee management, taking into account their perceived significance. 3.5.2 Present the audit teams conclusions regarding the effectiveness of the quality system in the form of audit reports and quality issue forms. 3.5.3 Findings of nonconformance will be resolved through the Quality Issue process, keeping in mind that corrective actions need to be to a degree appropriate to the magnitude of the problem and commensurate with the risks encountered. NOTE: For internal audit quality issues, the Lead Auditor is authorized to accept or reject corrective actions unless problem solving is required T C I STANDARD OPERATING PROCEDURE INTERNAL QUALITY AUDITS ORIGINAL IF GREEN Document # Revision Date TCP.17.01 09/22/00 Page 3 of 3 3.6 FOLLOW-UP AUDIT ACTIVITIES 4.0 Necessary follow-up activities are determined by the Lead Auditor as corrective actions are submitted for approval. 3.6.2 The Lead Auditor will note required follow-up on the audit schedule and determine an appropriate length of time needed to implement the corrective action and judge it’s effectiveness. 3.6.3 Follow-up activities may be assigned to an auditor or performed by the Lead Auditor. Findings are noted on the original Quality Issue and, if satisfactory, the issue is approved by the Lead Auditor and closed. REFERENCE DOCUMENTS 4.1 4.2 4.3 4.4 4.5 5.0 3.6.1 TCP.14.01 – Corrective and Preventive Actions TCF.14.01 – Quality Issue Form TC.17.SCH – Audit Schedule TCF.17.01 – Audit Plan Form TCF.17.02 – Audit Report Form SAFETY AND ENVIRONMENTAL ISSUES 5.1 As referenced in audited policies, procedures and work instructions. 6.0 REVISION RECORD Description of Change Original Issue Reference QI #IA-001 Date 12-18-98 09-22-00