vii ii iii iv

advertisement

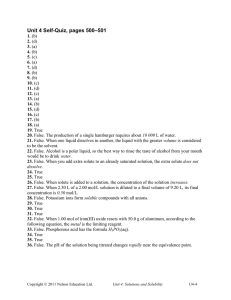

vii TABLE OF CONTENTS CHAPTER 1 2 TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENT iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xi LIST OF FIGURES xiv LIST OF SYMBOLS xx LIST OF APPENDICES xxii INTRODUCTION 1 1.1. Overview 1 1.2 Statement of the Problem 4 1.3 Objectives of the Study 5 1.4 Scope of the Study 6 LITERATURE REVIEW 7 2.1 Introduction 7 2.2 Theory of Thermoluminescence Process 8 2.2.1 Simple Model of Thermoluminescence 8 2.2.2 First-order Kinetics 10 viii 2.2.3 Second-order Kinetics 12 2.2.4 General-order Kinetics 16 2.3 Glow curve Analysis 16 2.3.1 Initial Rise Methods 17 2.3.2 Peak Shape Methods 18 2.3.2.1 Method of Lushchik 19 2.3.2.2 Method of Chen 19 2.3.3 Methods of Various Heating Rates 22 2.3.4 Curve Fitting 23 2.4 Characteristics of Thermoluminescent Dosimetry 3 (TLD) 24 2.4.1 Linearity 24 2.4.2 Energy Response 26 2.4.3 Fading 27 2.4.4 Annealing Procedures 28 2.4.5 Stability and Reproducibility 29 2.4.6 Precision and Accuracy 30 2.5 Glass Formation 31 2.6 Theory of Energy Band Gap 32 2.7 Photoluminescence 33 RESEARCH METHODOLOGY 34 3.1 Introduction 34 3.2 Material for Glass Sample Preparation 34 3.2.1 Borates Glasses 35 3.2.2 Lithium Carbonate 35 3.2.3 Potassium Carbonate 36 3.2.4 Copper 36 3.2.5 Tin Oxide 37 3.3 Powder Mixing 37 3.4 Glass Preparation 38 3.5 Structural Characterization Measurements of Samples 38 ix 3.5.1 X-Ray Diffraction Analysis 39 3.5.2 Field Emission Scanning Electron 4 Microscopy (FE-SEM) 40 3.6 UV-Vis-NIR Measurements 42 3.7 Photoluminescence Measurement 42 3.8 Annealing Precedure 43 3.9 Exposure to Radiation 44 3.9.1 Linear Accelerator Primus MLC 3339 44 3.9.2 X-Ray Machine 45 3.9.3 Cobalt – 60 Gamma-Rays (60Co) 46 3.10 Perspex Sheet 47 3.11 TLD -Reader 4500 48 RESULTS AND DISCUSSION 50 4.1 Introduction 50 4.2 Glass Samples and Composition 50 4.3 Energy Band Gap 53 4.4 Photoluminescence Measurements 56 4.5 FE-SEM Analysis 58 4.6 Effective Atomic Number 58 4.7 TL Response of Undoped Lithium Potassium Borate Glasses 60 4.8 Annealing Procedures 61 4.9 Effect of Heating Rate on TL Response 65 4.10 Borate Glass Glow Curve 68 4.11 Dose-TL Response Relationship 70 4.11.1 TL Response of LKB: Cu Glass Subjected to Photon Irradiation 70 4.11.2 TL Response of LKB: Cu and LKB: Cu with co-doped SnO2 Glass Subjected to Photon Irradiation. 76 4.12 Comparison of TL Response of LKB: Cu and LKB: Cu with co-doped SnO2 Glass. 81 x 4.13 Fading Characteristics Measurement 82 4.14 Optical Bleaching Measurement 86 4.15 Reproducibility 89 4.16 Sensitivity 90 4.17 Minimum Detectable Dose 91 4.18 TL Energy Response Subjected to X-ray Photon Irradiation 92 4.19 Comparison Between Theoretical Calculation of Relative Energy Response and Experimental Results 5 94 4.20 Thermoluminescence Parameters 97 CONCLUSION 102 5.1 Summary 102 5.2 Recommendations and Future Research 106 REFERENCES 107 Appendices A-E 118-135 xi LIST OF TABLES TABLE NO TITLE PAGE 2.1 Annealing procedures applied to lithium borate. 29 4.1 The nominal composition of LKB glass 51 4.2 The nominal composition of LKB: Cu glass 51 4.3 The nominal composition of LKB: Cu co-doped with SnO2 glass 52 4.4 Energy band gap of LKB glass with different Cudoped concentrations. 54 4.5 Energy band gap of LKB: Cu glass co-doped with different SnO2 concentration. 55 4.6 Fraction of elemental composition of LKB: 0.1 Cu mol% glass using FE-SEM 59 4.7 Composition of elemental fraction of LKB: Cu glass co-doped with SnO2 using FE-SEM 60 4.8 Annealing procedures for different types of borate 64 glass. xii 4.9 Dose responses for LKB: 0.1Cu mol% glass 71 subjected to 6 MV photon irradiation. 4.10 Dose responses of LKB: 0.1 Cu mol% glass 72 subjected to10 MV photon irradiation 4.11 Dose response of LKB: 0.1 Cu mol% subjected 73 to12 MV photon irradiation 4.12 Dose response of LKB: 0.1 Cu mol% subjected 73 60 Co gamma-ray irradiation 4.13 Dose response of LKB: 0.1 Cu mol% glass codoped with 0.1 SnO2 mol% subjected to 6 MV photon irradiation . 77 4.14 Dose response of LKB: 0.1 Cu mol% glass codoped with 0.1 SnO2 mol% subjected to 10 MV photon irradiation 78 4.15 Dose response of LKB: 0.1 Cu mol% glass codoped with 0.1 SnO2 mol% subjected to 12 MV photon irradiation 78 4.16 Dose response of LKB: 0.1 Cu mol% glass codoped with 0.1 SnO2 mol% subjected to 60Co gamma irradiation 80 4.17 Fading of LKB: Cu glass and LKB: Cu glass co- 85 doped with SnO2 compared to previous work 4.18 The sensitivity of different TL materials for various photons energy. 91 4.19 Minimum detectable dose for various TL materials. 92 4.20 TL response of LKB: Cu glass and LKB: Cu glass co-doped with SnO2 samples at various photon energies after exposed to absorbed dose of 0.2 m Gy. 93 xiii 4.21 the relative energy response (RER) of LKB: 0.1Cu mol% glass sample determined theoretically and experiment 95 4.22 The relative energy response (RER) of 0.1 SnO2 mol% sample determined theoretically and experiment. 96 4.23 Values of constant c and b depending on τ, δ, or 98 ω for LKB: 0.1Cu mol% glass. . 4.24 Activation energy of samples /eV for LKB: 0.1Cu mol% glass. 99 4.25 Values of c and b depending on τ, δ, or ω for LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol%. 100 4.26 Activation energy of samples /eV for LKB: 0.1 Cu mol% glass co-doped with 0.1SnO2 mol% 100 4.27 Trap frequency factor of samples /s–1 for LKB: 0.1 Cu mol% glass. 101 4.28 Trap frequency factor of samples /s–1 for LKB: 0.1 Cu mol% glass co-doped with 0.1SnO2 mol% 101 xiv LIST OF FIGURES FIGURE NO 2.1 TITLE PAGE Simple two-level model for mechanism of 9 Thermoluminescence 2.2 Energy levels in the forbidden band gap of a 12 solid. 2.3 General TL glow curve, showing also the 21 parameters discussed in the peak shape glow curve analysis methods 2.4 Linearity curve (Oberhofer, 1981) 25 2.5 Energy gap diagram 32 3.1 Electric furnace 38 3.2 XRD instruments used to study the amorphous 39 phase of glasses samples. 3.3 FE-SEM analysis machine 40 3.4 (a) A sputtering machine is used for the gold 41 coating procedure (b) The sample holders 3.5 UV-Vis-NIR spectrophotometer 42 3.6 Photoluminescence spectrophotometer 43 3.7 A furnace (Harshaws) used to anneal TL 44 materials xv 3.8 Linear accelerator primus MLC 3339 (LINAC primus, department of radiotherapy and oncology, hospital sultan ismail, JB). 45 3.9 Industrial x-ray model mG165 46 3.10 60 47 3.11 Perspex sheet used to hold the samples while expose to irradiation 48 3.12 TLD –Reader 4500 49 3.13 Schematic diagram illustrating common features of TLD readers 49 4.1 XRD pattern at room temperature of LKB: 0.1 Cu mol% glass. 52 4.2 XRD patterns for the LKB: 0.1 Cu glass co-doped with 0.1 SnO2 mol%. 53 4.3 Graph (α E )1/2 versus ( E ) for LKB with different Cudoped concentrations. 54 4.4 Graph (α E )1/2 versus ( E ) of LKB: Cu glass codoped with different SnO2 concentration. 55 4.5 PL spectra of LKB with different Cu-doped concentrations excited by 650nm source. 57 4.6 PL spectra of LKB: Cu glass co-doped with different SnO2 concentration excited by 650nm source. 57 4.7 FE-SEM micrographs of LKB: 0.1Cu mol% glass codoped with 0.1SnO2 mol%. 58 4.8 The TL intensity as a function of lithium content 61 4.9 Behavior of TL response and the corresponding standard deviation as a function of the annealing temperature for LKB: Cu glass. 62 4.10 Behavior of the TL response and the corresponding standard deviation as a function of annealing time for LKB: Cu. 62 Co gamma ray source xvi 4.11 Behavior of the TL response and the corresponding standard deviation as a function of the annealing temperature for LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol%. 63 4.12 Behavior of the TL response and the corresponding standard deviation as a function of the annealing temperature for LKB: Cu glass co-doped with SnO2. 64 4.13 Glow curve profile as a function of heating rate for LBK: 0.1 Cu mol% glass. 65 4.14 TL response as a function of heating rate for LKB: 0.1 Cu mol% glass. 66 4.15 Glow Curve as a function of heating rate for LKB: 0.1 Cu mol% glass co-doped with 0.1SnO2 mol%. 67 4.16 TL response as a function of heating rate for LKB: 0.1Cu mol% glass co-dope with 0.1SnO2 mol%. 67 4.17 The glow curves of LKB glass with different Cu concentration. 69 4.18 The glow curves of LKB: Cu glass co-doped with different SnO2 concentration. 69 4.19 TL response of LKB: 0.1Cu mol% glass subjected to 6MV photon irradiation irradiation. 71 4.20 TL response of LKB: 0.1 Cu mol% glass subjected to 10 MV photon irradiation 74 4.21 TL response of LKB: 0.1 Cu mol% glass subjected to 12 MV photon irradiation 74 75 4.22 TL response of LKB: 0.1 Cu mol% glass subjected to 60 Co gamma irradiation 4.23 TL response for 6, 10, 12 MV and 1.25 MeV photon irradiation of LKB: 0.1 Cu mol% glass. 76 4.24 TL response of LKB: 0.1 Cu mol% glass co-doped with 0.1 SnO2 mol% subjected to 6 MV photon irradiation 77 xvii 4.25 TL response of LKB: 0.1 Cu mol% glass co-doped with 0.1 SnO2 mol% subjected to 10 MV photon irradiation 79 4.26 TL response of LKB: 0.1 Cu mol% glass co-doped with 0.1 SnO2 mol% subjected to 12 MV photon irradiation 79 4.27 TL response of LKB: 0.1 Cu mol% with co-doped 0.1 SnO2 mol% subjected to 60Co gamma irradiation. 80 4.28 TL response of LKB: 0.1 Cu mol% glass co-doped with 0.1 SnO2 mol% subjected to 6, 10, 12 MV and 1.25 MeV photon irradiation. 81 4.29 TL response of LKB: 0.1 Cu mol% glass co-doped with 0.1 SnO2 mol% subjected to 6MV photon irradiation. 82 4.30 Fading of LKB: 0.1Cu mol% glass subjected to 6 MV photon irradiation. 83 4.31 Residual signal characteristics of LKB: 0.1Cu mol% glass subjected to 6 MV photon irradiation. 83 4.32 Fading of LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol% of subjected to 6MV photon irradiation for given dose of 1Gy. 84 4.33 Residual signal of LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol% subjected to 6 MV photon irradiation for given dose of 1 Gy. 85 4.34 Optical bleaching of LKB: 0.1mol% Cu glass after exposed to sunlight. . 86 4.35 Optical bleaching of LKB: 0.1Cu mol% glass after exposed to fluorescent lamp. 87 4.36 Optical bleaching of LKB: 0.1Cu mol% glass codoped with 0.1SnO2 mol% after exposed to sunlight. 88 xviii 4.37 Optical bleaching of LKB: 0.1Cu mol% glass codoped with 0.1SnO2 mol% after exposed to fluorescent lamp. 88 4.38 TL response as a function to reproducibility test of LKB: 0.1Cu mol% glass. 89 4.39 TL response as a function to reproducibility test of LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol%. 90 4.40 TL response of LKB: Cu glass and LKB: Cu glass codoped with SnO2 samples versus photon energies after being exposed to absorbed dose of 0.2 m Gy. 94 4.41 The relative energy response as function energy for LKB: 0.1Cu mol % glass. . 96 4.42 The relative energy response as function energy of LKB: 0.1Cu mol% glass co-doped with 0.1 SnO2 mol%. . 97 4.43 The geometrical parameters of LKB: 0.1Cu mol% glass. 98 4.44 The geometrical parameters of LKB: 0.1Cu mol% glass co-doped with 0.1SnO2 mol% 99 xix LIST OF SYMBOLS Be - The binding energy of the electron C - Coulomb D - Absorbed dose Do - Threshold dose E - Trap depth Ef - Fermi level Eg - Forbidden energy Emax - The maximum energy Eγ - Energy of the incident photon Eγ’ - Energy of the scattered photon F - TL system calibration factor Gy - Gray k - Boltzmann’s constant Li - Lithium LiF - Lithium fluoride m - Mass mo - The electron rest-mass n - Number of electrons in a particular trap energy no - The number of trapped electrons at the initial time p - Probability of escaping by the trap RER - Relative Energy Response SE - Photon energy response SnO2 - Tin oxide t - Time Т - Temperature TL - Thermoluminescence xx TLD - Thermoluminescence dosimeters wi - Fraction of that element Z - Atomic number of the atom Zeff, - Effective atomic number σ - Standard deviation τ - Half-life of the phenomenon xxi LIST OF APPENDICES APPENDIX TITLE PAGE A List of publications 115 B Calculation effective atomic number 116 C The Sensitivity of the lithium potassium borate with D Cu-doped 119 Calculation TL kinetic parameter 130