Document 14628941

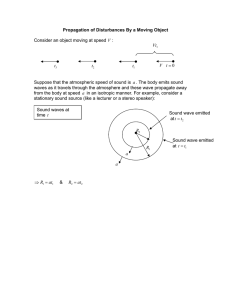

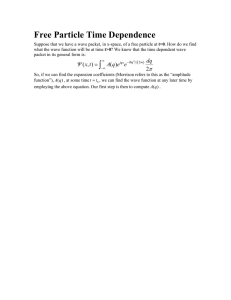

advertisement