The Pilot Design Studio-Classroom Joseph Cataldo The Cooper Union for the

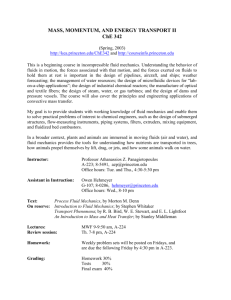

advertisement

The Pilot Design Studio-Classroom Joseph Cataldo The Cooper Union for the Advancement of Science and Art Studio Method Used for Many decades in Architectural and Art Schools Origins The concept of the studio-classroom was originated at Rensselaer Polytechnic Institute Physics Department The studio-classroom model offers lectures plus in-class demonstrations and experiments Benefits ! Lab and classroom are combined. Add -- video, computer projections, interactive software -- and the classroom becomes dynamic, efficient, and engaging, providing a bridge between abstraction and application. ! Next level where the dynamic environment makes the design process central to engineering education. Cooper Union Studio-Classroom •Lectures •Modules •Videos •Demonstrations •Student Classroom Participation Studio-Classroom Model !A series of learning modules was developed to provide access to the practical, theoretical and experimental knowledge of fluids, flows, fields and pertinent analogies. The modules consist of a series of eleven selfcontained sets of material that include: ! Theory ! Design Examples ! Design homework problems ! Design homework projects ! Historical notes ! Experiments and demonstrations ! References Theory !The theory consists of a brief overview of topics that generally make up one chapter in a fluid mechanics text. It is given as a guide to students; not to replace a standard fluid mechanics textbook. Design Examples !The design examples, homework, and projects are important because they show the students how fluid mechanics is used in engineering design. !Homework problems / projects in the modules stress the application of design. III. Design Homework Problem Design the square rod AB shown, σallowable = 20,000 psi, for the cofferdam shown. The shape and the size of the cofferdam is a 10’ cube and is in 8 feet of homogeneous mud media, S.G. = 1.5. Also find what the weight of the cofferdam must be so that it stays in place. A B 8’ 8’ Design Homework Project " 11.25 # 2’ Piezometer Height of Water (ft) 1 7.15 2 7.45 3 7.35 4 7 5 6.5 6 6.25 7 5.75 8 5.25 9 4.75 (a) Why can you use hydrostatics to determine the horizontal force on the gate? (b) Plot the pressure on the gate. (c) Determine the horizontal force on the gate. (d) Plot the hydrostatic pressure on the gate and determine its force on the gate. (e) Why is the force determined in (d) greater than the force determined in (c)? 7.15’ 4.75’ You are asked to check the design for an 11.875’ wide gate, water temperature 57.50F. A series of nine piezometers are drilled in the gate to determine the horizontal force on the gate (number 1 and number 9 are shown). The first piezometer starts .5’ from the bottom of the gate and the rest of the piezometers are spaced .5’ apart. A table of the height of the water in each piezometer is given (measured from the piezometer opening). II. Design Example An engineer must design the support system to hold the pipe junction shown. Determine the reactions to design this system. Take the weight of the junction and the water as 250 lb. (PA) 5 fps 2 fps 45O v v 4 psi 1’ (PA) WT 6 psi 6” 3 psi v v ΣFBODY + ΣFSURFACE = Σ ρvv (v • a) Ry Horizontal Forces π 8 π 1 Rx - (3 × 144 )+ (6 × 144 )cos 45o 4 12 4 2 2 2 π 8 π 1 o 1.94 (10 ) (10 ) − 1.94 2 cos 45 (2 ) 4 12 4 2 ∴ Rx = 97.5 lb. 2 = ( ) Vertical Forces π 1 π 2 (1) (4 × 144 )− (6 × 144)sin45 o 4 4 2 2 Ry – 250 - π 1 2 π 2 1.94 (− 5)(− 5) (1) + 1.94 2 sin 45o (2 ) 4 4 2 ∴ Ry = 862.6 lb. ( v R 10x fps 8” 2 (PA) ) = III. Design Homework Problem Determine the number of bolts necessary to hold the reducing section shown for a flow of 4 cfs. Each bolt is designed to take a compression or tension force of 45 lb. Open to the air 1’ 6” Vacuum 2 psi Design Homework Project For the reducer shown, the total reaction must not exceed 4,000 lb. The pump is places in the system to increase the head. The pump characteristics are given in the table where h is the increase in head across the pump. Assume the water temperature is 500F and the weight of the reducer is 1,000 lb. including the water. Will this pump work in the system? 1’ Pump Characteristics Head (feet) 100 80 60 40 20 Flow Rate (cfs) 0 18 25 30 34 Open to the air Vacuum 2in Hg Pump 2’ 1 R 1 II. Design Example An engineer must design a cable system consisting of 100’ of 1” diameter supporting rods. The structure that the cable is supporting is shown in the figure. Determine the wind force on the system for a maximum wind of 50 mph. Take the wind at 500F. Rods Rods 4’ 10’ Drag = ΣC D ρU 2 A 2 CD = 0.30 Rods (Turbulent) and 1.2 (Rectangle) U = 1.4667(50) = 73.3 ft sec ρAir = .002378 slug ν = 1.8 × 10 − 4 ft 2 sec ft 3 ; Drag Force = Drag Force = 323 lb. 0.3(.002378) (73.3)2 2 (73.3 ) 1 (4 × 10) 100 × + 1.2(.002378) 12 2 2 III. Design Homework Problem A cold water station is in the shape of a half sphere. Determine the force on this 0C. station for a maximum velocity of 40 m sec and take the temperature at 0 40 m/sec 4m Design Homework Project To determine the drag force on a vessel, boundary layer tests were conducted. A pitot tube was used in the test shown. The results of these tests are given in the table. (a) Calculate and plot the boundary layer velocity profile. (b) Estimate the boundary layer thickness. y (in.) h (in.) .02 .3 .035 .7 .044 .8 .06 1.4 .093 1.8 .11 2.6 .138 2.9 h v y vessel .178 3.3 .23 3.9 .27 4.0 .322 4.0 VIDEO CLIPS 10 Different Topics 16 Clips - each about 3 min. VIDEO –FLUID MECHANICS PRINCIPLES DEMONSTRATED (22) Characteristics of Laminar and Turbulent Flow - Concept of viscosity due to shear flow. (11) Flow Visualization - Path Lines - Stream Lines - Time Lines (10) Eulerian and Lagrangian Description in Fluid Mechanics - Pipe flow showing Eulerian and Lagrangian flow (1) Pressure Fields and Fluid Acceleration - Flow through a contracting conduit (1) (1) Pressure Fields and Fluid Acceleration - Use of Euler’s equation, showing rotating disc with manometers (2) (1) Pressure Fields and Fluid Acceleration - Flow withdrawn along a pipe - Stagnation and pitot tubes - Venturi section showing a pressure drop (3) (2) Turbulence - Disorder, Mixing, Vorticity - Momentum transfer - Mixing across streamlines (24) Effects of Fluid Compressibility -Water waves with flow superimposed showing Froude and Mach numbers (22) Characteristics of Laminar and Turbulent flow -Couette flow -Poiseulle flow (31) Vorticity -Vortex meter near boundary layer showing vorticity and a rotating tank showing zero rotation (23) Form, Drag, Lift, and Propulsion -Flow around a rotating cylinder and other shapes (5) Fundamentals of Boundary Layer - Turbulent and laminar boundary layer along a flat plate (7III) Fluid Mechanics of Drag - Boundary layer velocity profile of a channel (7I) Fluid Mechanics of Drag -Flow of air past a sphere and bomb -Sphere and bomb falling in a liquid (23) Form, Drag, Lift, and Propulsion -Flow around curved surfaces -Flow around a disc, sphere -Flow around a cylinder and a roof (24) Effects of Fluid Compressibility - Shock waves on solid bodies RUNNING TIME MIN:SEC MODULE TOPIC Basic Principles 2:14 Kinematics :35 :17 :58 Kinematics 2:09 Conservation of mass 1:26 Conservation of momentum 1:09 1:09 1:02 1:03 1:58 :38 :40 1:27 Equation of Energy, turbulence, and pipe flow Equation of Energy, turbulence, and pipe flow Dimensional Analysis and Similitude Navier Stokes Equations :53 :56 Potential Flow 3:00 Potential Flow 3:36 Boundary layer theory 2:48 Boundary layer theory 1:59 Boundary layer theory :48 1:58 Boundary layer theory :17 2:23 :46 2:56 One-dimensional compressive flow DEMONSTRATIONS •Capillarity •Barometer •Bent tubes manometers •Fluid upthrust •Hydrostatic Container •Dye open channel uniform & nonuniform flow steady & nonsteady flow •Pitot Tube •Jet impact •Reservoir into series pipes •Laminar and turbulent flow •Venturi meter •Source, sink & doublet BENCH SCALE EQUIPMENT •Hydrostatic Bench •2.5m Flow Channel •Impact Jet •Venturi Meter •Hele Shaw •Fluid Friction •Hydrostatic Container •Reservoir Pipes STUDENT CLASS PARTICIPATION •Recite homework 3-4 times a semester weaker student more •Solve a problem after demonstration •Call student to answer questions in class !The students see the most important ideas at least four times $ lecture $ video $ homework $ demonstration Evaluation !Allows the instructor to not lose touch with her/his students' learning process. !Allows students to participate in their own learning process by providing feedback. !Assessment works as a communication tool between faculty and students. Table 2. ASSESSMENT INSTRUMENT ESC 140 FALL 2000 This course has introduced a number of teaching and learning methods for fluid mechanics. We would like to know your reactions to them. Your feedback is important and will help to improve the course in the future. Please reply to this email. Your instructor will get compiled, not individual results. Confidentiality is assured. 1. How effective were the following methods to understand the material covered in class? Use this scale: not effective (1), effective to a limited extent (2) effective to a moderate extent (3), effective to a great extent (4), effective to a very great extent (5), not applicable (N/A) LECTURE 1 2 3 4 5 N/A MODULE 1 2 3 4 5 N/A VIDEOCLIPS 1 2 3 4 5 N/A DEMONSTRATIONS 1 2 3 4 5 N/A TEXTBOOK 2 3 4 5 N/A 1 2. Now please assess the effectiveness of the methods above for each of the topics covered: LECTURE MODULE VIDEOCLIPS DEMOS TEXTBOOK TOPIC 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Fluid phenomena and continuum;stress 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Fluid statics 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Kinematics of flow 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Basic laws; mass;momentum;energy;t hermodynamics laws Dimensional analysis and 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A similitude 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Incompressible viscous flow through pipes 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Potential flow 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Boundary-layer theory 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Navier-Stokes 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A One-dimensional compressible flow 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A Tests 3. How effective were the following parts of the module to understand the material covered in class? from not effective (1), effective to a limited extent (2) effective to a moderate extent (3), effective to a great extent (4), effective to a very great extent (5), not applicable (N/A) THEORY 1 ILLUSTRATION 1 DESIGN HOMEWORK DESIGN PROJECT 1 HISTORY 1 2 2 1 2 2 2 3 3 3 3 3 4 4 4 4 4 5 5 5 5 5 N/A N/A N/A N/A N/A 4. Do you feel competent in the following areas covered in the course? Please rate according to the following scale: not at all (1), to a limited extent (2) to a moderate extent (3) to a great extent (4), to a very great extent (5) Fluid phenomena and continuum;stress Fluid statics Kinematics of flow Basic laws; mass;momentum;energy;th ermodynamics laws Dimensional analysis and similitude Incompressible viscous flow through pipes Potential flow Boundary-layer theory Navier-Stokes One-dimensional compressible flow Tests 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 1 2 3 4 5 N/A 5. Lets focus now on the videoclips. Please explain how they helped you to understand the material and to learn fluid mechanics. Be as detailed and specific as you can. 6. Which of the videoclips was (were) more useful? Which was (were) least useful? Why? 7. Are you generally satisfied with your knowledge of fluid mechanics after taking this course? Please explain. 8. In addition to learning fluid mechanics, have you developed any other skill or ability during this course? 9. What would you do to improve this course? Please feel free to make any suggestions Effectiveness of teaching methods LECTURE MODULE VIDEOCLIPS DEMONSTRATIONS TEXTBOOK NEGATIVE 12.5 25 12.5 6.25 37.5 POSITIVE 87.5 75 87.5 93.75 62.5 ENTHUSIASTIC 75 37.5 37.5 68.75 25 Effectiveness of module parts THEORY ILLUSTRATIONS DESIGN HOMEWORK DESIGN PROJECT HISTORY NEGATIVE 31.25 18.75 18.75 18.75 62.5 POSITIVE 68.75 81.25 81.25 81.25 25 ENTHUSIASTIC 25 43.75 43.75 43.25 6.25 Student self-perception of competence BELOW COMPETENT COMPETENT VERY COMPETENT Fluid phenomena and continuum stress 18.75 81.25 43.25 Fluid statics 6.25 93.75 62.5 Kinematics of flow 0 100 68.75 Basic laws; mass;momentum; energy;thermodynamics laws 6.25 93.75 62.5 Dimensional analysis and similitude 0 100 56.25 Incompressible viscous flow through pipes 6.25 93.75 56.25 Potential flow 18.75 82.25 37.5 Boundary-layer theory 6.25 93.75 37.5 Navier-Stokes 43.75 56.25 18.75 One-dimensional compressible flow 0 87.75 37.5 Tests 0 93.75 62.5 88.75 49.42 AVERAGES 9.6 Conclusions ! The object of this studio classroom was to present fluid mechanics by lecture, demonstrations, videos, design homework and projects, and student participation. ! Almost the whole class felt that the videoclips and demonstrations were effective (over 90%) with approximately an equal amount (87.5%) scoring the lectures positive. ! The students felt confident in almost all the fluid mechanics topics (average of approximately 90%). ! The students gave the module a positive response (75%). ! From the responses in the questionnaire, the studio-classroom was a success. ! From a professor's viewpoint, the new methods made me think more about teaching. Time is spent more efficiently. Equation of Energy, Turbulence and Pipe Flow