Water Treatment Systems and Equipment The Water Approach

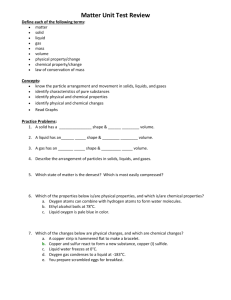

advertisement

Water Treatment for Greenhouses and Nurseries The Water Systems Approach Optional Storage Water Source(s) Systems and Equipment Pressurizing Treatment Blending by Ratus Fischer 828-230-6934 rfischer@fischerecoworks.com Distribution Application Optional Storage Optional Storage University of Florida Workshop 2007 Re-circulation Pros and Cons Before or after Treatment. Optional if incoming line pressure is sufficient Recirculation Collection Discharge Suggested Pond Management Saving Water Initial Investment Saving Fertilizer Operating Costs Zero Runoff Need to Manage Regulation - Proof Risk of Contamination Integral Part of Flood and Gutter systems Low Level Treatment High Level Treatment Irrigation Run-off Contaminated Storage P Roof Drain Site Run-off Silt Pond Pond Clean and contaminated water are separated. Low Volume + highly effective treatment affordable. 1 Common and New Water Treatment Methods (Not including Liquid and Gaseous Oxidizers) Residual effect No Residual effect Ozone Sand Filters Copper Ionization Slow Sand Filtration UV Micro Filtration Membrane Filtration Pressure Pump Skid with VFD (Variable Frequency Drive) Heat Pasteurization Ultra Filtration Nano Filtration R/O Reverse Osmosis Screen and Disk Filters 2 Reverse Osmosis Media Filter Nano Filtration R/O Nano Removes “everything” Removes solids, CaCO3 .001 micron removal .01 micron removal Incl. all pathogens Removes bacteria, most spores, some virus Most plant nutrients pass Operating Pressure Operating pressure 300 PSI typ. 60 PSI + PSI Best for EC reduction Best for Pre-treatment UV, Ozone, Oxidizers, etc. Rejection rate 25–50% Nano Filtration 10 GPM 3 Water Softeners/ Iron Removal Replacing Calcium, Magnesium and Iron with Sodium Chlorine Dioxide Copper Ionization An electric charge is passed between copper bars, releasing copper ions into the water. Automatic control of copper output according to flow and EC is essential Copper Ionization Copper ions act throughout water system 4 Copper Ionization Facts 1 ppm kills pathogens, 2 ppm stops algae. 10ppm ‘overdose’ shows no plant toxicity. Effect on Pythium, Phytophthora and other pathogens documented. Lower cost than most treatments for pathogens Less affected by organic matter in the water than other methods. Copper Ionization 800 GPM Ozone Ozone Facts Very potent oxidizer. Kills pathogens and algae at low concentrations Turns into O2, adding dissolved oxygen to water An electrical arc is used to produce Ozone (O3) on site from atmospheric or bottled Oxygen System costs vary greatly depending on needs, water quality, professionalism of supplier. The Ozone is bubbled through water and dissolved. Organic matter in water depletes ozone. Good filtration and/or other pre-treatments are essential. Typical concentration for disinfection: 10 mg per hour per m³, lower for Bio-film control. Proper design will prevent ozone from escaping and creating human health risk. 5 Fertilizer Mixing and Stock Tanks Ultraviolet Light Disrupts genetic material in cells Low, medium or high pressure mercury vapor lamps Wide spectrum of biocidal Turbidity reduces efficiency; Removal of solids is critical activity Lamps must be kept clean Nothing added to water Fe-chelates may be destroyed Moderate capital and operating cost at low flow rates 6 Heat Pasteurization 195 °F for 2 minutes Rote UV+Ozone 10gpm 3 log Heat Treatment / Pasteurization Reliable elimination of pathogens Best for low volume – high sanitation Can handle certain solids in water Nothing is added to the water Initial investment moderate if heat source available Energy consumption high - best in combination with cheap heat source Needs low of pH (4.5) to prevent scaling of heat exchanger Can deplete dissolved oxygen in water Slow Sand Filtration Medium is colonized by microorganisms Physical and biological activity control Phytophthora, Pythium, Fusarium and others Suitable for low flow applications Typical 2 – 4 gph per sqft of filter area Low energy use, no chemicals added 7 Slow Sand Filtration Facts •Aerobic process, needs oxygen in water. •Water must circulate to keep filter “alive” •Easy to build with common materials •Medium: Carbonate-free sand .2mm •Maintenance: scraping sand surface. •Pre-filtration of dirty water reduces clogging •Often improved plant quality (Suppression) Selected Biofilm and Algae Treatments Ozone .1 ppm ozone eliminates biofilm over time .5ppm suggested for biofilm and algae control Copper Ionization 1 – 2 ppm control biofilm and algae Chlorine Dioxide (such as Selectrocode) .25 ppm control algae and biofilm Water Pre-Treatment Water Pre-Treatment: Nuts and Bolts 1 All water treatment methods require specific water quality to be effective. For Ozone, Copper, Oxidizers (Cl, Peroxide, etc): Reduce solid and dissolved organic matter Lack of appropriate Pre-Treatment is the single most common cause for insufficient or failing treatment. For UV: Reduce solids and light absorbing dissolved matter Most important: Solid and dissolved organic matter absorbs oxidizers, clogs filter membranes, shields UV rays, scales heat exchangers. For Membrane Filters. Reduce solids, org. matter, silicates Pre-treatment can cost as much as the treatment itself, but overall it will reduce investment and operating costs. If anyone sells you water treatment systems without analyzing your water, you are probably wasting money. For Heat treatment: Lower pH to 4.5 For Slow Sand filtration: Remove inorganic and organic solids 8 Water Pre-Treatment: Nuts and Bolts 2 Removing…. Debris, coarse plant matter, sand: Screen filters, cascade filters, settling tanks/ponds Typ. $ 100 – 10.000 Inorganic and organic solids (algae, soil, debris): Media filters (Clearstream©), fast sand filters Typ. $ 3000 – 25,000 Dissolved organic matter (tannins, humic acids): Ultra/nano filtration, aeration in ponds, chemical Aeration BLOWER Blending Unit (Zwart) •Finer bubbles transfer more O2 into water •Saturation depends on temperature: warmer water holds less O2 •Examples: 50ºFÆ11.3 mg/l 82ºFÆ 7.8 mg/l DIFFUSER WATER TANK 9