Laser-based Non-destructive Evaluation and Monitoring John S. Popovics

advertisement

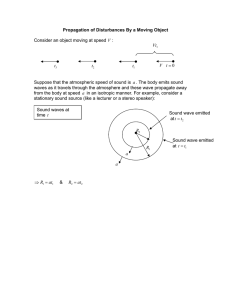

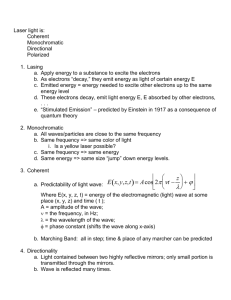

Laser-based Non-destructive Evaluation and Monitoring John S. Popovics Summary Lasers are devices that create a high intensity, directed light beam. The light beam can travel in air or through fiber optic cables. Lasers can be used to generate waves and detect stretching or motion in a solid material without direct contact with the material. Thus lasers are useful in many important engineering applications that require remote non-destructive evaluation (NDE) and sensing such as laser ultrasonics, “smart” structures and vibration sensing. In this lesson, necessary basic concepts about light, lasers, fiber optics and wave propagation are introduced. The basis of wave generation and sensing with lasers is given. Finally specific engineering applications that make use laser-based techniques are described. (I) Introductory Concepts (A) Harmonic motion and wave propagation Many natural phenomena arise from simple harmonic motion. For example, consider a mass hanging vertically from the end of a spring. At first the mass is at rest. If the mass is slightly displaced downward, it will move up and down for some time under the downward action of gravity and the upward restoring action of the spring. A plot of the vertical position of the mass with respect to time shows a general sinusoidal form, and this type of motion is termed “harmonic.” The maximum value gives the “displacement amplitude” of the motion. The frequency of the wave motion () is defined as = 1/T (1) where T is the period of the wave motion. Harmonic motion that has a low value of T therefore has a high value of , and vice versa. T is measured in units of seconds (s), and thus in units of 1/s. Usually the Hertz (Hz) is used as the name for the unit of frequency instead of 1/s, although they have the same meaning. 1.5 T D is place me nt 1 0.5 0 -0.5 -1 phase delay -1.5 0 20 40 60 80 100 Time Harmonic motion shows a general sinusoidal form. The maximum value of the signal gives the “displacement amplitude” of the motion. The period of the wave motion (T) is the time required for the mass to perform an entire round trip of motion. For example, T is the time spacing between two peaks in the plot. If one harmonic signal is slightly delayed behind another identical signal, the time lag is called the “phase delay” or “phase angle” between the two signals. The value of the phase delay ranges between 0 and T. If the phase angle between two signals is either 0 or T, the signals are perfectly aligned and are said to be “in phase.” Propagating waves also cause harmonic motion at a sensed point. Propagating waves are disturbances that travel through a medium with a certain velocity (V). The type of disturbance depends on the type of propagating wave. It is important to understand that no mass is transported by wave itself. Rather, the wave is a passing disturbance that causes motion (or some other disturbance) at a single location in the medium. It is this disturbance at a point, caused by the passing wave, which exhibits harmonic motion. Usually, the resulting motion is described by a combination of individual harmonic motions each with different frequency and amplitude. Audible sound (disturbance of air pressure), ultrasound, RADAR and visible light all exhibit properties of propagating harmonic waves, even though the specific phenomena for each are very different. As an example, consider a piano that is recorded by a nearby microphone. The output of the microphone is electrical voltage that is directly related to the variation in pressure of the air near the front of the microphone. If we play a single key on the left-hand side of the piano keyboard, we hear sound with low pitch. Until the sound dies out, the output of the microphone will look like harmonic wave motion with characteristic values T and . (As a reference, the middle “A” key on the piano has a frequency () of 440 Hz and a period (T) of 2.27x10-3 s.) If we now play a single key on the right-hand side of the keyboard, we hear sound with high pitch. The output of the microphone again looks like harmonic wave motion, but now T is much smaller and therefore much higher. Thus frequency is interpreted as the pitch in the case of audible sound. If we now play a chord on the piano (several keys played together), the microphone output is a complicated signal that does not look like harmonic motion. However, this complicated signal can be broken down into three individual harmonic signals, each with specific values of T and . All harmonic propagating waves obey the fundamental frequency-wavelength relation and exhibit reflection, refraction and interference behaviors. Equation 2 relates the frequency of the wave to the wavelength () in terms of the wave propagation velocity (V) V= (2) Consider again the piano and the microphone. It is known that the velocity of sound waves in air is approximately 330 m/s. If the microphone is 1 m away from the piano, the sound waves will reach the microphone 3.03x10-3 s after the moment that the key (let’s say the middle “A” key) is played. After the wave-front reaches the microphone, the characteristic frequency ( = 440 Hz) of the harmonic wave motion can be determined from the harmonic signal. The wavelength of the resulting sound in air can be computed (using equation 2) to be 0.75 m. It can be seen that has units of length and can be visualized as the distance in space (in this case air) between two points of the same phase of the harmonic wave. Assuming constant wave velocity, is inversely related to . When a propagating wave traveling in a medium impinges on an interface with another medium, wave reflection and refraction occurs. A portion of the incident wave energy will propagate back into the original medium (reflection) while the remaining wave energy will propagate through into the second medium (refraction). Another important property that harmonic waves display is interference. If two identical harmonic waves (same frequency and amplitude) are combined together, the amplitude of the resulting combined wave depends on the alignment (phase delay) of the two individual waves. The amplitude of the combined wave will be maximal if the individual waves are perfectly aligned; this is called constructive interference and the individual waves are “in phase.” If one wave is shifted with respect to the other, the amplitude of the combined wave will be lower than that obtained from constructive interference. In one special case, called destructive interference, the combined signal has zero amplitude. This occurs when one wave signal has a phase delay of T/2 with respect to the other. There are many different types of propagating waves, several of which are classified as “mechanical waves.” These waves propagate a mechanical disturbance in a medium, such as pressure or motion. For example audible sound, ultrasound and vibrations all are mechanical wave phenomena. In fluids and gasses, the mechanical wave propagates a disturbance of pressure. Only this type of disturbance is possible, and this wave is often called an “acoustic” wave. In solid materials, however, more than one mechanical wave mode can exist. In solids, the wave propagates as a disturbance in motion (displacement). The type of the wave is defined by the direction of local particle motion with respect to the direction of wave propagation. “Longitudinal” waves (Lwaves) have particle motion coincident with the propagation direction, while “transverse” waves (T-waves) have particle motion perpendicular to the propagation direction. Lwaves and T-waves propagate throughout a solid. Another type of wave, the Rayleigh surface wave (R-wave), propagates only along the free surface of a solid, and the particle motion is a combination of parallel and perpendicular motions. Each of these wave types travel with different velocity defined by the mechanical properties of the medium through which they propagate. For a given medium, L-waves have the highest velocity and Rwaves the lowest. Mechanical waves exhibit reflection and refraction when they impinge on an interface. The magnitude of the reflection is primarily controlled by the differences in mechanical properties between the two media (for example material stiffness and density.) If the two materials have very different mechanical properties, the amount of reflection will be very high. Thus most mechanical wave energy is reflected at the interface between a solid and air. As a result most sound energy (acoustic wave in air) will reflect back from a distant solid wall (an echo). Similarly, most ultrasonic wave energy traveling in a solid will reflect from an air-filled crack in the solid material. (B) Optics Light is a form of electromagnetic radiation, which behaves as a propagating harmonic wave. All electromagnetic radiation propagates through vacuum with a velocity of approximately 3.0x108 m/s, which is much higher than that for mechanical waves. The constant velocity of electromagnetic waves in vacuum is commonly referred to as “c.” In actual materials such as air, the velocity of propagation is slightly slower, depending on the refractive index of the material. The refractive index of a material is the propagation velocity of electromagnetic waves in vacuum divided by that in the material, and is greater than or equal to 1.0. The refractive index of air at atmospheric pressure is very close to 1.0, so we can assume that the wave velocity air is effectively the same as that in vacuum. Electromagnetic radiation is a disturbance in the electric and magnetic fields, which propagates through a given medium. During propagation, the wave energy is transferred between electric and magnetic fields, which are normally perpendicular to each other and to the direction of propagation. The plane that contains both the direction of the electric field and the direction of wave propagation is called the plane of polarization. Light is unusual in that it can behave both as a wave and also as a collection of discrete packets (photons) of energy. Like ordinary wave propagation, light waves obey the fundamental relation between wavelength () and frequency () (related by the wave velocity c). The full electromagnetic spectrum covers a wide range of frequencies: 104 Hz (long radio waves) to 1021 Hz (high-energy gamma rays). The optical spectrum occupies a small portion of the full spectrum, ranging from 1x1014 Hz (high end of infrared spectrum) to 5 x1015 Hz (low end of ultraviolet spectrum.) Further, visible light occupies a range of frequencies within the optical spectrum, bounded by the infra-red and ultraviolet spectra. In the case of visible light, the frequency of the wave is interpreted as the color of the light. For example, red light has a frequency of 4x1014 Hz while violet light has 8x1014 Hz. Assuming that waves travel with a velocity c, the frequency limits of the visible light spectrum correspond to wavelengths of 700 x10-9 m and 400x10-9 m, respectively. In addition light reflects and refracts at an interface. For light, the nature of reflection and refraction are controlled by the refractive indices of the two materials. Unlike ordinary wave propagation however, photons of light can absorb or emit a finite amount of energy (a quantum). The amount of energy is related to the wave frequency through Planck’s constant (h) E=h (3) where E is the change in energy (typically reported in units of electron volts or eV), and h= 4.14 eV s. Atomic and molecular systems have many discrete energy states in which they can exist. The lowest energy state is termed the “ground state” and the multiple higher energy states are collectively termed “excited states.” Quantum theory states that the energy change associated with transition from the ground state to a specific excited state (E) is associated with a specific frequency, as seen in equation 3. (C) Lasers High amplitude waves that are made up of a single frequency and forced into a highly-directed beam are often needed for engineering applications. This situation is relatively easy to achieve with mechanical waves and some electromagnetic waves such as RADAR. However it is not easy to achieve with visible light using standard technology. The advent of lasers now allows single frequency light amplification and beam confinement. Actually, the word laser is an acronym of Light Amplification by the Stimulated Emission of Radiation. From the previous section, we know that light is emitted when something (for example an electron in an atom) drops from a higher energy state to a lower one and that this change in energy is associated with a specific frequency. If this energy change occurs without any outside influence, it is called “spontaneous emission.” However if we can somehow influence many similar energy drops in a medium at once, we can generate high amplitude light that is made up of primarily one frequency. This is “stimulated emission,” and it can be promoted in a laser medium. For example, imagine that a photon of light energy is passing through a laser medium and then interacts with an atom (electron) that happens to be in a higher energy state. If the original photon has just the right amount of energy, it can induce the atom to reduce to a lower energy. The result is a second identical photon. Since there are now two photons instead of one, the light is amplified. Stimulated emission by itself may not be sufficient for engineering application purposes since the light is not confined, but is emitted in all directions similar to the light emitted by a bulb, and has low intensity. In order to generate a beam of intense light, we Stimulated emission is promoted in a laser medium. In order for this Pumping be to emission stimulated p = (E2-E0)/h effective, we need more atoms (or electrons) to be in a higher energy E1 state than in the ground state, since electrons in the ground state will E0 actually absorb light that is emitted by other energy drops. The excitation process is called “pumping.” Imagine that we pump a medium so that the material is excited from the ground state (E 0) to an excited energy state (E2). This absorption of energy is associated with a specific frequency p (the pumping frequency) by equation 3. Stimulated emission can now occur in the pumped medium in response to incident radiation at another frequency, the “lasing” frequency L, thus lowering the energy of the material to an intermediate state (E1). Since the energy change from the highest energy level to the intermediate is less than that from the ground state to the highest level, the pumping frequency is necessarily greater than the lasing frequency. There are two primary techniques to pump a laser system: the laser medium is illuminated with an intense light source of a given pumping frequency (for example by a discharge tube) or an electrical discharge is passed through a gaseous medium. E2 Lasing L = (E2-E1)/h must amplify the light and confine it to one propagation direction. Suppose that we are able to guide light along one narrow column of a certain length in a laser medium. (For example, we can confine light using the concept of total internal reflection, as described in the following section.) Since this material along that light path can be manipulated to provide stimulated emission (being a laser medium), the light is amplified along the path. If we now add mirrors to each end of the confined light path, the light along that defined path will continue to propagate and progressively amplify as the light travels back and forth along the path. Emitted light rays that travel in other directions simply leak away and have low amplitude. In essence a light “resonator” is set up, and with each pass the internally reflected light stimulates further emission thereby increasing the intensity of the light along that path. If one of the end mirrors allows a portion of the built-up light energy to pass through, then the amplified light will emanate from the end and propagate outward along a confined beam. That is, a laser beam will be generated containing directed light made up of primarily one frequency. (Note that this described resonant cavity scheme is just one of many possible light amplification and confinement schemes.) The described system is capable of generating a laser beam continuously, provided that pumping (see inset above) is continuously applied. Such systems are called continuouswave (CW) lasers, and are important in some engineering applications. In other engineering applications however intermittent laser light is needed, and pulsed laser systems are used to provide laser beams with short duration. There are several different schemes used to obtained laser pulses. Laser light is characterized by the frequency content (or alternatively wavelength content), power, directionality and coherence length of the beam. These characteristics are primarily controlled by the laser system used to generate the light. Lasers have highly controlled beam directionality compared to conventional light sources. A laser beam can be visualized as a cone with an extremely small angle of divergence, typically a few milliradians. Thus the beam is column-like (typically a few millimeters wide) and can propagate long distances through air (several meters) without appreciable signal losses due to beam spreading. Coherence describes how well a light beam maintains classic harmonic form and is an important characteristic for CW lasers. Light is completely incoherent if there is no predictable phase behavior with respect to either space or time. Laser light starts out coherent but soon becomes incoherent as it propagates. The propagation distance within which the light is reasonably coherent is called the coherence length. The coherence length is essentially controlled by the frequency content of the light: the more monochromatic the light, the larger the coherence length. For example, a fairly monochromatic He-Ne laser has a coherence length of the order of 200 mm. Laser, Mode He-Ne, CW CO2, pulsed YAG, CW YAG, pulsed Ruby, pulsed Ga-As, CW Type Wavelength (m) gas 0.633 gas 10.6 solid state 1.06 solid state 1.06 solid state 0.694 semi-conductor 0.815 Application interferometry wave generation interferometry wave generation wave generation fiber optics Laser light characteristics are primarily controlled by the laser system used to generate the light. Lasers (both CW and pulsed) can be classified into the gas, solid state or semiconductor families. Common gas lasers are Helium-Neon (He-Ne) and carbon dioxide (CO2) lasers. Solid state lasers typically use glass or crystal with small amounts of special atoms mixed in to provide a laser medium, such as yttrium aluminum garnet (YAG) and ruby. Diode lasers make use of gallium arsenide (Ga-As) semi-conductor systems. Diode lasers provide low power, less column-like laser beams than those generated by gas and solid state lasers. (D) Optical fibers We now know that a highly column-like light beam can be generated using a laser. As a result, we can control the direction of the light beam and transmit the light over a large distance. However, we cannot transmit the light through physical barriers, such as walls, and we cannot bend the light beam in air to go around obstacles. However, it is possible to transmit light across great distances and around obstacles if we can guide the light along some sort of light “pipe.” Thin transparent glass fibers can be designed to pipe light. More generally, these are called optical fibers. Optical fibers work because they make use of the concept of total internal reflection, which was introduced earlier. If total internal reflection is achieved in a thin fiber, the light can travel along the fiber without losing intensity simply because no light is allowed to leak out to the material outside of the fiber. Optical fiber (core and cladding) is usually made of very pure glass (because it is very transparent) with a typical diameter of about 0.125 mm – about the size of monofilament fishing line. A plastic coating is often added to the outer surface to Optical fibers make use of total internal reflection. If total internal leakage fiber cladding reflection is achieved in a thin fiber, fiber core the light can travel along the fiber without losing intensity simply critical because no light is allowed to “leak” angle out to the material outside of the acceptance fiber. Recall that when light waves angle impinge onto an interface between two different materials, a portion of total internal the energy is reflected and the reflection remaining energy is transmitted through to the second material. The amount of light that is reflected depends on the angle of incidence, i, and the properties (refractive indices) of the two materials. Total internal reflection occurs if t > i and i is greater than the critical angle. Imagine that we have a thin transparent glass fiber (the core) coated with another material (the cladding). In order to satisfy the first requirement for total internal reflection, the refractive index of the cladding material should be lower than that of the core material. The second condition is satisfied if a column-like light source is directed axially along length of the fiber. Typical refractive index values for the core and cladding are 1.5 and 1.485, respectively. Obviously the difference in the refractive indices is small, but it is enough to give a critical angle value of about 81o. In other words, the fiber will transmit the light within an acceptance angle of 18o. ease handling and protect the outer surface from becoming scratched. Mechanically, the fibers are stiff but flexible to some degree. Because a controlled and column-like light source is needed to transmit light through the fiber effectively, low power diode lasers are commonly used. A properly designed clad fiber can transmit light across great distances and around obstacles. Optical fibers can be used to transmit digital data, in the form of light signals, very well. In fact optical fibers are now used in local and long distance telephone systems in place of traditional electrical wires. (E) NDE Destructive tests provide direct and accurate information about the material under inspection. For example, we may be interested in finding the location and extent of cracks or other flaws within the material. We can drill a hole into the material and look for such internal defects. However destructive tests, by their very nature, cannot be carried out at many locations on the structure. Thus, a large part of the structure is not inspected. Nondestructive evaluation (NDE) tests, however, can be carried out at many locations since the tests do not cause any damage. For example, doctors use X-ray images to determine, in a non-destructive fashion, if a bone contains cracks or other damage. In fact the doctors can use many X-ray images of the same bone (say from different directions) since the X-ray itself does no further damage to the bone. However, NDE tests do not provide direct information. Rather, NDE tests provide indirect information, which is then interpreted to assess the condition. For example, an X-ray image directly shows variation in density through the thickness of the inspected material, which may (in some but not all cases) be interpreted to estimate the size and location of cracks (low density) within the bone material (higher density). Ultrasonic waves are also used successfully to detect, locate and characterize defects, such as cracks within solid materials. Reflected wave echoes are used to locate and size the air-filled defects (cracks or voids). However, we need to send and receive mechanical wave energy to use ultrasound effectively in a solid. Embedded or remote sensors can also be used to provide valuable information about a structure or material in a non-destructive manner. (II) Laser Generation of Wave Motion in Solids Lasers can be used to generate mechanical waves in solids, in non-contact fashion. Several physical processes occur when a solid material is illuminated with a laser beam. At low powers, the solid material is locally heated because of absorbed electromagnetic radiation by the material, while at high powers surface material may be vaporized (ablated) and plasma formed as a result. In fact, three regimes for production of mechanical waves in solids using lasers have been identified and are described next. All three regimes use laser light in the near infrared and visible region of the electromagnetic spectrum, but each makes use of different power densities. Pulsed laser sources are usually used. (A) Thermoelastic regime The thermoelastic wave source makes use of lower power densities, usually <107 W/cm2 for metals. All wave modes are generated. The mechanical waves are generated through a thermal mechanism, which makes use of the thermoelastic effect. The thermoelastic effect means that a material will increase in size when heated and contract when cooled. This source generates waves (longitudinal, shear and surface) that propagate in all directions symmetrically about the point of excitation. Within the material, however, the amplitudes of the various wave modes are highly dependent on direction. In general, shear waves and surface waves are most readily generated, although longitudinal waves are also excited. A medium high energy pulsed laser source is appropriate for this application (for example a pulsed ruby laser). (B) Plasma regime When higher power densities are applied to a metallic material, usually >107 W/cm2 for metals, the thermoelastic source is supplemented by the vaporization (ablation) of a layer of the material at the illuminated point. The stress field of the resulting waves is very similar to that owing to the application of a normal point force at the surface. This source generates all wave modes that propagate in all directions symmetrically about the point of excitation, but the generation of longitudinal and Rayleigh surface waves are enhanced. thermoelastic source plasma source laser beam heated area vaporized plasma resulting forces Two different laser-based wave generation mechanisms are possible: the thermoelastic source and the plasma source. Physically, the thermoelastic source results from a rapid local heating at a surface point with subsequent rapid expansions (owing to the thermoelastic effect) followed by a much slower rate of cooling and contraction. The heated area can be visualized as a thin disc extending into the solid material to a depth determined by the heat diffusion characteristics of the material and the duration of the incident laser pulse. The diameter of the heated area is defined by the diameter of the incident laser pulse itself. The mechanical waves (for example ultrasound) are generated from this heated zone by sudden strain, owing to the thermoelastic expansion, acting radially outward from the beam center in the plane of the surface of the material. The plasma source is the thermoelastic source supplemented by the vaporization (ablation) of a layer of the material at the illuminated point. Vaporization occurs when the laser energy is increased. The ablated material forms an ionized gas containing positive ions and electrons (known as plasma) that immediately expands away from the surface of the metal. The resulting momentum pulse from the plasma expansion is transmitted back into the solid, thus enhancing the compression wave generation. As a result of the ablation, a small pit (about 5x10-6 m deep) is formed on the surface of the material; this damage may render the plasma source unsuitable for some applications. High energy pulsed laser sources are appropriate in this application (for example a pulsed YAG laser). (C) Constrained surface regime If the surface of the test material has some sort of coating, the resulting mechanical wave generation by lasers will be affected. Certain coatings act to enhance the mechanical wave generation significantly. The coating acts as a buried wave source at the coating-surface boundary, and the amplitude of all wave modes is enhanced. Coatings such as oil, resin, grease and a transparent constraining layer have been successfully used. The nature of this source most closely resembles that of the plasma source. In fact, the coating layer may be ablated, forming plasma, at higher power densities, although power densities in both regimes may be used. (III) Laser Detection of Wave Motion in Solids Surface motion owing to propagating mechanical waves and vibration in solids can be detected in non-contact fashion using a laser beam. However, the basis of the approach to detect waves (generally called interferometry) is very different than that used to generate mechanical waves in a solid using lasers. Continuous wave laser sources are usually used for interferometry. (A) Interferometry Overview Optical interferometry is a sensitive way to measure surface displacement or motion at all frequencies in a solid. Interferometers are useful because they are noncontact and also provide a flat, broadband response. However, interferometry requires a highly monochromatic (light wave comprised of a single frequency) and directed light source with a reasonably large coherence length. Thus, the use of CW lasers is essential for optical interferometry. Interferometry makes use of the concept of wave interference, described earlier, which is a natural characteristic of harmonic wave motion. Many different interferometry schemes have been developed over the years, but all use laser light reflected from or scattered by the surface of the tested material. Essentially all interferometry schemes can be divided into two types. In the first type, reflected or scattered light is made to interfere with a reference light beam. The phase difference between the two coherent light beams, inferred from the intensity of the combined light beam, gives direct measurement of out-of-plane displacement at the surface. The second type of interferometer detects changes in the frequency of reflected or scattered light. The output is dependent on the out-of-plane motion (velocity) at the surface. Interferometry schemes can be applied using laser beams propagating through air and also laser light propagating in a fiber optic cable. (B) Michelson Interferometry Interferometers of the first type are usually variations of the classic Michelson interferometry scheme. Very small displacements (of the order of the wavelength of the light) such as that caused by passing waves can be detected with this scheme. For this scheme to work effectively however a sufficient amount of light must be reflected back from the sensed surface. In other words, the tested surface should be shiny. Thus, Michelson interferometry may not work for rough surfaces that do not reflect light reference mirror beam splitter laser source moving surface photodetector output The Michelson scheme is the most basic interferometer. A laser beam is passed through a splitter, which divides the light beam and sends it in two different directions. One of the split beams reflects from a stationary reference mirror and is sent back to the splitter. The other beam reflects from the moving surface, and the reflected light is also sent back to the splitter. The two coherent beams are aligned and recombined at the splitter and this light is sent to a light intensity sensor (also called a photodetector). The relative phase difference between the two combined beams at the photodetector depends on the difference between the path lengths of the individual beams. If this path difference is an integral number of wavelengths, the beams interfere constructively and the intensity of the combined beam is at a maximum. If the path difference is an integral number of wavelengths ½, the beams interfere destructively and the intensity of the combined beam is at a minimum. Thus as the measured surface moves toward or away from the splitter, the intensity of the combined beam at the photodetector varies sinusoidally between the maximum and minimum values. effectively. He-Ne lasers are most commonly used with this scheme because of the good properties of the light (monochromatic light with good coherence and small wavelength). (C) Heterodyne Interferometry There are several kinds of the second type of interferometer, with heterodyne interferometry perhaps being the most common. Essentially, the heterodyne approach makes use of Doppler shift phenomenon to measure surface velocity (as opposed to surface displacement with the Michelson scheme) of a material. The well-known Doppler shift phenomenon states that the frequency of a wave (for example laser light) that reflects from a surface will be slightly shifted if, at the moment of reflection, the surface is moving with a specific velocity. If the reflecting surface is moving towards the wave source the frequency will shift upwards, while if moving away the frequency will shift downwards. Like Michelson interferometry, a laser beam is split into a reference beam and test beam and then recombined after reflection from the surface of the test material. Instead of monitoring the relative phase difference in the combined signal however, the frequency is monitored; this process is called “heterodyning.” If the recombined beams have different frequency, intensity fluctuations, known as “beats,” are setup at a specific frequency. The beat frequency is a function of the difference in light frequency of the two beams. In order to simplify the signal processing, the frequency of the reference beam is first slightly shifted a known amount (usually 10x106 Hz to 40x106 Hz increase) before recombining with the test beam. An acousto-optic device, such as a Bragg cell, can be used effectively to shift the frequency of light passing through it. The resulting beat frequency is monitored with a basic frequency tracking procedure. The beat frequency of the combined signal is a result of the known shift of the test signal plus or minus (depending on the direction of surface motion at that moment) that owing to the Doppler phenomenon in the test beam. The frequency tracking procedure gives the instantaneous beat frequency, but is independent of the signal amplitude and often precludes the detection of higher frequency wave motion. This scheme is appropriate for relatively large amplitude surface motions (notably larger than the wavelength of the laser light) and can be applied more readily to rough surfaces since frequency shifts, as opposed to intensity of reflected light, are monitored. As a result, heterodyne interferometry is often used to detect lower frequency, high amplitude wave motion such as that caused by vibration. In fact such a test scheme is commonly referred to as “vibrometry.” CW He-Ne lasers are commonly used in this scheme. (IV) Application of Technology Several engineering applications of the described technology are now presented. (A) Laser-based ultrasonics With the use of lasers, we can generate and detect mechanical wave energy (ultrasound) in a solid material without direct physical contact with that solid. A noncontact sensing technique allows remote and speedy monitoring (for example determination of dimensional properties, presence of defects, monitoring of material composition, etc.) that does not disturb the process under investigation and is not influenced by varying sensor contact and coupling conditions. Furthermore, a non-contact sensing technique allows inspection in environmental conditions that preclude the use of ordinary contact sensors. Laser ultrasonics allow the combination of a mature and effective inspection technique, ultrasonic inspection, with non-contact sensing capability. (1) metals Laser ultrasonics has been successfully used to monitor the quality of steel components during the manufacturing process. The temperature of steel during the hotrolling manufacturing process is approximately 1000o C, so conventional NDE measurements with contact sensors are not possible. However, flaw detection, dimensional sizing and material characterization are possible with laser ultrasonics. For example, consider a laser wave generator acting at a point on the surface of a hot-rolled steel plate and a laser detector sensing the same location on the opposite surface. The presence of planar air-filled in the plate is indicated by a loss of signal between the wave sender (pulsed thermoelastic or plasma source) and receiver (CW interferometer) because of intensive reflection at the defect. A laser system can also be used to determine the dimensions of continuous hot steel elements during the manufacturing process. Finally, Non-contact sensing techniques such as laser ultrasonics allow inspection in environmental conditions (for example high temperature) that preclude the use of ordinary contact sensors. For example, a laser system can be used to determine the dimensions of hot (1000o C) steel tube elements during the manufacturing process. A high energy pulsed laser is used to generate longitudinal waves from a plasma source on the surface of the hot tube. The plasma source is appropriate for this application since the vaporized material is a surface oxide, leaving the base steel material unaffected, so the source is actually a constrained surface ablation source. A laser interferometer is focused at the same point on the surface so to detect motion owing to wave pulses reflected from the back wall of the tube. (see upper inset figure) This configuration simulates ultrasonic pulse echo testing, where the time required for wave echoes to travel through the wall thickness to the far surface and back is monitored. (see lower inset figure) The thickness of the tube is then deduced knowing the longitudinal wave velocity in the metal at the elevated temperature (approximately 4900 m/s). In the signal below is generated by laser ultrasonic system on a hot steel tube. The time delay between two echoes is approximately 4.5x10-6 seconds. Assuming a wave velocity of 4900 m/s, this corresponds to a tube wall thickness of 11 mm. With such a system, tube thickness in the range of 10 to 25 mm can be accurately measured while the tube material is traveling past the sensor configuration at a rate of 2 m/s. The sensors can be as far away as 5 m from the hot material, thus isolating it from the high temperatures. (Images from Scruby and Drain.) laser ultrasonic systems can be used to monitor changing material properties as a function of temperature. The material properties are surmised from the longitudinal wave velocity. For example, the material properties of plutonium-gallium alloy across the temperature range of 40 to 500o C can be measured with a laser system. Such remote measurements were needed because of the high temperature of the metal and also the toxicity of plutonium, which is housed in a sealed container. (2) other materials Laser-based ultrasonic systems are effective in rapidly scanning large areas of panels made of fiber-reinforced composite material. Area scan rates of over 10 m2 per hour are achieved. These types of structures (composite panels) are becoming more common in civilian and military aircraft structures because of their low weight and high strength, but may have complex shapes and contours that make conventional inspection difficult. To assure the structural integrity of the component, it is important to detect the damage in the panels during the manufacture of the material and throughout the life of the aircraft. Recently, laser ultrasonic measurements have been applied to monitor paper Laser based ultrasonic systems are effective in rapidly scanning large areas of panels made of fiber-reinforced composite. Usually, a pulsed CO2 laser is used to generate the waves in the constrained layer mode. This source generates lower frequency waves, which is appropriate for inhomogeneous materials such as fiber composites. An interferometer is used to detect the signals, at a point on either the same side (as illustrated above) or the far side of the panel, thereby simulating conventional ultrasonic testing. A special interferometer is used that can detect signals from non-reflective surfaces. The light beams are scanned across the large specimen using precisely controlled mirrors. Thus the laser does not move at all during the inspection process and the laser system is located up to 1.5 m away from the panel. Variation in panel thickness and the location and depth of damage or defects is determined. Because of the large amount of data generated by the scanning system, images that indicate the location of damage in the panel can be created. In the time-of-flight image shown above, air-filled delaminations within the material are clearly indicated as dark regions. (Image from Thomson and Chimenti) quality during the manufacturing process. The elastic stiffness of paper sheet, along various directions, are important characteristics that should be monitored during the manufacturing process to ensure quality. The measurements can be carried out while the paper is moving; linear scan rates of 400 m per minute have been achieved. A pulsed YAG laser is used to generate waves at a point with a thermoelastic (non-damaging) source, and the resulting waves are detected with a Michelson interferometer using a CW Argon laser. The waves are detected at a point on the same surface of the paper but some known distance away from the point of wave generation. The time required for the wave disturbance to travel the known distance along the surface between sending and receiving points is used to infer elastic stiffness in that direction. (B) “Smart” structures If sensors are embedded within a material or inside of a structure, the internal conditions can be monitored throughout the life of the component. For example, sensors could monitor the stretching or compressing of a component continuously or monitor the existence and propagation of cracks inside the component. The sensors provide a feedback mechanism about the performance internal integrity of the structure, so these types of structures are called “smart” structures. (1) fiber optic sensors Optical fibers may be embedded within or glued onto a structure. After placement the fibers can detect minute variation in structural conditions and thus act as sensors. External conditions such as stretching (strain), pressure or temperature variations induce changes in the phase, intensity or wavelength (frequency) of the light traveling in the optical fiber. By monitoring the changes in the light, variation in the conditions causing the change can be inferred. An added benefit of using optical fiber in large structures is that the light signals can travel great distances inside the optical fiber. Therefore, the laser source need not be near the inspected area, and the data can be collected efficiently at a centralized location. At present, fiber optic sensing technology is used primarily to monitor the amount of stretching or compressing (strain) that occurs inside the material as a result of external loads. However, it can also be used to monitor the progression of cracking inside the material. The principle is based on the assumption that the optical fiber that is firmly embedded in a solid material will itself fracture if a crack propagating in the material interacts with the fiber. As soon as the fiber breaks, the intensity of the light propagating in the cable drops to zero. The most basic sensor is the intensity-type, where the change in the intensity of the light, generated by a diode laser, passing through the optical fiber correlates to the amount of strain applied to the cable. Other types of optical fibers (for example Bragg grating sensors) correlate the applied strain to a shift in the frequency of the light passing through. Interferometry techniques can also be applied using fiber optics, where the phase of light passing through strained optical fiber is compared to that passing through an unstrained (reference) cable. Fiber optic sensors have been incorporated in a range of smart structures, including complicated components such as panels and wingbox structures in aircraft and large structures such as bridges. In the case of aircraft structures, the sensed material is usually fiber-reinforced composites. The optical fiber is incorporated into the fiber lay-up of the composite, thus providing an active and continuous internal strain sensor without disrupting the continuity of the material itself. In bridge structures, optical fibers have been used to monitor strains in concrete girders and also in steel reinforcing bars placed in concrete. Fiber optic sensors have been incorporated into several new structures for the purpose of long term strain monitoring, and the experience to date have been generally favorable. For example, fiber optic cables are embedded in the triple span Schiessbergstrasse bridge in Germany and the double-span Beddington train bridge in Canada to monitor the long term compressive pre-stressing force applied to cables embedded in the concrete bridge girders. In the case of the Canadian bridge, the sensors provided continuous dynamic and static strain monitoring for a period of two years and internal displacement measurements with a precision of 5x10-6 m were achieved. In a recent study, optical fibers were used to monitor strain in steel reinforcing bars placed in concrete beams that were subjected to bending loads. The optical fibers are embedded inside the beams; the fibers are glued to the reinforcing bars before being cast in concrete. Conventional strain gauges were also attached to the bars. As illustrated in the graph above, the fiber optic strain sensors give comparable results to that from conventional externally mounted strain gauges. In the figure, the amount of bending load (moment ratio) is plotted against bending deformation (strain). Fiber optic sensors are more rugged than conventional strain gauges and can provide continuous strain information for long periods of time, possibly throughout the life of the structure. (Image from Ansari) As the performance of fiber optic sensors improves, they will be used on a much larger scale and for a wide range of measurements. For example, new applications of optical fibers have been recently proposed to monitor the condition of bridge components. These new sensors provide information on bridge deck vibration, expansion joint travel, bolt clamp load, cable tension and metal fatigue. These tests would provide a comprehensive monitoring approach to bridges. The performance of these test schemes in actual bridges will be evaluated in the near future. (2) remote vibration or strain monitoring Internal damage in a large structure introduces local stiffness losses, which in turn is manifested in the dynamic response of the structure. Thus, the natural vibration response of a structure (for example the frequency and mode shape of the vibration) is affected by damage within the structure. Thus, monitoring the dynamic response of a large structure can provide clues about the condition of the structure itself. These vibration measurements are usually carried out with the use of sensors mounted directly on the structure. However, the amount of data that can be collected from the structure is restricted because of the limited number of test points and the long-term aggressive environmental conditions to which the sensors are subjected. These problems are remedied by the use of remote, non-contact vibration monitoring with a laser heterodyne interferometer (vibrometer). The velocity of the surface motion, caused by natural vibration (for example that caused by nearby machinery, wind or traffic loading) is monitored. From this response, the natural frequencies of vibration or extent of surface motion at a point can be determined. In some cases, it is important to monitor the extent of surface motion of structures owing to vibration. Scanning laser vibrometers can perform multiple vibration measurements from one test head location, allowing complete inspection of a structure in a relatively short amount of time. A full field vibration image of a large object may be created if enough data is collected. In the inset image, the surface motion data from the side panel of a van during engine operation is collected using a laser vibrometer. Different magnitudes of surface motion are separated by the contour lines superimposed on a photograph of the van. Areas of high surface velocity are marked by “+”. (Image from Scruby and Drain) Laser vibrometers have been used successfully to monitor the cable force in cable-stayed bridge structures. In these structures, cable tension is one of the most important structural parameters. The amount of tension in the cable is directly related to the natural vibration frequency of the cable, analogous to a guitar string. The technique was successfully applied to the Weirton-Stubenville bridge in West Virginia, which has 52 cables in the structure. Vibration in the cables was excited naturally by wind. All cables were monitored from several different vibrometer stations and were inspected within two days. Vibrations were accurately monitored from distances up to 100 m, and the resulting computed cable tensions matched those obtained by conventional methods. The conventional method to monitor cable tension is expensive and time consuming. (V) References State of the art in the applications of fiber optic sensors to cementitious composites. F. Ansari in Cement and Concrete Composites, Volume 19, pages 3-19. 1997. Laser-generated ultrasound: its properties, mechanisms and multifarious applications. S.J. Davies, C. Edward, G.S. Taylor and S.B. Palmer in Journal of Physics D: Applied Physics, Volume 26, pages 329-348. 1993. Understanding Fiber Optics, Third Edition. J. Hecht. Prentice-Hall Inc., Upper Saddle River, NJ. 1993. Laser Ultrasonics – Techniques and Applications. C.B. Scruby and L.E. Drain. Adam Hilger Ltd., Bristol, UK. 1990. Review of Progress in Quantitative Nondestructive Evaluation. Volumes 12 and 17. D.O. Thompson and D.E. Chimenti, editors. American Institute of Physics, Melville, NY. 1999.