The Effects of Diaphragm Components in Resisting Lateral Stability of Precast

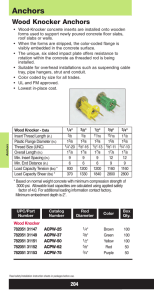

advertisement