C Construc ction Ind

advertisement

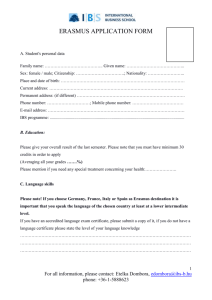

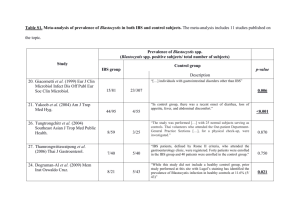

9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I C Construc ction Ind dustry Experiencce of Ind dustralised Build ding M Systeem in Malaysia Moham mad Syazli Fathi, Moh hammad Abedi A and Abdul A Kariim Mirasa Department of Civvil Engineering, UTM Razak School off Engineeringg and Advancced Technolo ogy, UTM In nternational Campus, C Jalaan Semarak, 54100 5 Kuala Lumpur, Maalaysia Corresponding Author’s A Emaiil: syazli@ic.uutm.my Abstractt Government of Malaysia has done various efforts to prom mote the usage of o Industrialisedd Building Systtem e and efffective construuction system compare c to connventional building system. This T (IBS) as an efficient paper reviews the experiencces of Malaysiaan construction n industry in thhe adoption of IIBS from the first f i developmentt. This research h select IBS as a construction ttechnique in wh hich level of establishment until its a manufacturred in a controlled environmeent (on or off site), s transporteed, positioned and a components are assembled innto a structure with minimal additional site works. IBS haave been categgorised to: preccast concrete fram ming, steel form mwork system, steel framing systems, blockk work system and prefabricaated timber framinng system. A coomprehensive review r from varrious sources conducted to define and classiffied IBS in this paper. The finndings of this research illusttrated the timeeline of IBS eestablishment and a development in Malaysia. Keywords: Malaysia, M IBS Roadmap, R Effeective Constru uction System, Industrialised d Building System, Preccast Concrete Framing. F 1. INTRODUC CTION Industtrialised Buildding System (IBS) ( can be viewed as a system, s methood of development, processs, product, approoach, techniquue or industriall philosophy. Government of o Malaysia has h done a lot of effort to prromote the usagee of Industrialiised Building System (IBS)) as an alternaative constructtion method. S Since the first project of IBS inn year 1966, there has nott been one abbsolute definittion on Industtrialised Buildding System (IBS) that could describe the entire buildinng constructionn system. How wever, there are a several deefinitions by reesearchers who studied s into building b constrruction emphasizing on thee concept on off-site consttruction (OSC C) [1], offsite production p (OSP) [2, 3 andd 4], industriaalized and au utomated consstruction [5], off-site manu ufacturing (OSM M), prefabricatted building, pre-assembleed building an nd pre-assemb mbly [6]. Furthhermore, IBS could be more elaborated byy other definitiions such as pre-cast p buildiing, pre-cast construction, nnon-traditionall building, g solutions andd a Modern M Method of Co onstruction industtralised buildiing, modularizzation, innovaative building (MMC C) [7 and 8]. However, H reggardless of all these definitio ons and ideas on IBS, to ennhance the pro oductivity, efficieency and effectiveness of IBS I constructiion projects, the t main strategy and signiificant effort is i to move most of the activiities from coonstruction siite to a moree controlled environment in manufactturing site (desirrably off site). Industrialiseed Building Syystem (IBS) iss not a new ap pproach to thee constructionn industry becaause it has just aggain become feasible f and visible v in Malaaysia as a valu uable solution to improve thhe construction industry mainlly in terms off efficiency, productivity annd effectiveneess. In a largeer view and oppen minded perception, p IBS is further thann implementinng the construuction project through preffabricated metthods. IBS is about the changging of conveentional minddset, enhancinng the capab bility, compettency and vaalue of humaan capital, develooping better cooperation, c teeam working and trust amo ong the partiess in constructiion industry, promoting p intelliigibility, innovvation, transpparency and most m significan ntly the high integrity i that w will eventually y enhance the prroductivity annd efficiency within w the connstruction ind dustry [9]. Mooreover, IBS hhas been iden ntified as a potenttial method to improve overall consttruction perfo ormance in Malaysia M in tterms of quaality, cost effecttiveness, safetty and health,, waste reducction, efficienccy and produuctivity. IBS can be an ap pproach or process implementted within thee constructionn industry resu ulting in less labor-oriented, faster, satisfying the qualitty concern, chhanging of connventional minndset, reengin neering of hum man capital deevelopment, developing d betterr cooperation and a trust, prom moting transparency and inttegrity [10]. There are many m benefits of o Industrialissed Building System S (IBS) as a modern method of co onstruction such as a reduction in constructionn time, less siite materials, better b site maanagement, miinimal wastag ge, cleaner 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I and neater n environnment, controolled quality,, reduction of o labour inteensity, constrruction standaardization, qualitty improvemeent and lower total construcction costs that will eventuually produce better produccts for the partiees such as clieents and conttractors in connstruction ind dustry [9]. It should be nooted that the Malaysian M goverrnment have im mplemented a lot of significant efforts to o bringing the IBS for all prrofessionals in nvolved in the coonstruction industry. One of o these signifficant efforts is i the establisshment of IBS S Roadmap 20 003 -2010 that has h been endoorsed by the Government to be the blu ueprint docum ment for the industrialisatiion of the Malayysian construcction sector. Nevertheless, N t effort to promote the p the usage of IBS aas a valuable alternative a compare to convenntional and labbour intensivee construction method should be more em mphasized by the CIDB of Maalaysia. Conssequently, succcessful IBS projects are Sekisui Hom me (Japan), Living Solutio on (United Kingddom), Open House H (Swedenn) and Wensw wonen (Netherrlands) [11]. This paper includes thee fundamentaal issues on IBS which are the tim meline, definitions and classification. Conssequently, this paper is struuctured into four fo broad parrts. Firstly, thee paper will discuss d the definiitions of indusstralised buildding systems (IBS). ( Second d part of this research r will sset up the estaablishment and development of o IBS timelinee in Malaysia. Thirdly, thiss research willl explore on thhe classification system of IBS S. The final part p of this research will brring up the reesearch concluusion which iss developed in order to enhannce the opporrtunities of coonstruction inndustry for im mplementing the t IBS as a valuable alteernative to enhannce the productivity, effficiency, eff ffectiveness and a quality in order tto be organ nized for internnationalizationn and global coompetitivenesss. 2. DEFINITIO ONS OF INDU USTRALISED BUILDING SYSTEMS (IB BS) IBS iss usually beinng acknowledgged as the term m which repreesents the prefabrication cooncept in the perception p of proofessional parrties with in the t Malaysiann construction n industry whiile as, variouss definitions have h been offereed to IBS by many m researchhers which thiss research willl effort on categorizing thesse definitions.. Industrializeed Building System (IBS) had beco ome a term m to represeent prefabricaation and industtrialization terrminologies inn the Malaysiaan constructio on industry. The T term of IB BS is widely used by the supplyy chain partiees and project stakeholders within the co onstruction inddustry, practittioners, researrchers and the goovernment in Malaysia to signify s industrrialization in construction [6]. [ However,, IBS is ill defined, due that itt is often inteerchangeably with w other terrms such as offsite o and preefabrication [[7]. Consequeently, their definiitions depend greatly on usser’s experiennce, perception ns and undersstanding, whicch may differr from one countrry to other coountry. Neverttheless, it shouuld be noted that lack of a uniform u definnition and unceertainty in the coontext along with w boundaryy of IBS couldd contribute to o the prejudices and misundderstanding reesulting to of IBS implementation w decreaase the efficiency, producctivity and effectiveness e within the co onstruction industtry. Regardless of IBS broaad terms thaat particularly y mentioned in the first part of thiss research (Introoduction), theey have simiilar objectives which is intended i to move most of the activiities from constrruction site to t the manufa facturing site along with manufacturing m g the structurre components for the constrruction of buuildings in a more control environmen nt (preferablyy offsite manuufacturing) raather than constrruct it on sitte (onsite maanufacturing). Consequenttly, IBS is aimed a to enhhance the pro oductivity, efficieency and effeectiveness of IBS construction projects. Different definitions (elevven definition ns) of IBS have been b establishhed by many researchers r as illustrated in Table 1. Table 1-- Variety of IB BS definitions IB BS Definition Author [7] [12] [13] [14] [15] [16] Industrialized Building Sysstem (IBS) is the term to represent the prefabrication n and construction inndustrialization concept in Malaysia. IBS as a constrruction processs and an approacch on manufacttured componennts off or on sitte. IBS as an orgaanizational proccess-continuity of production implying i a steaady flow of dem mand, standardizationn, integration of o the whole pro oduction processs, a high degreee of organization of work and mechhanization to reeplace human laabor. Prefabricated construction thhat involves concrete c forminng, placing, fiinishing and curing hen erecting thee prefabricated components ass part operations awaay from the prooject site and th of a completedd structure. A constructionn system that is i built using pre-fabricated p c components. Thhe manufacturin ng of the componennts is systemaatically done via machine, formworks annd other form ms of mechanical eqquipment. A constructionn technique in which w componeents are manufaactured in a conntrolled environ nment (on or off site)), transported, positioned p and assembled a into a structure withh minimal addittional 2 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I site works IBS can be innterpreted as ann approach or process used in i making consstruction less labororiented and faaster as well as fulfilling qualitty concern. A concept of mass m productionn of quality bu uilding by usingg new building systems and faactory produced buildding componennts. A set of interrrelated elementts that act togetther to enable the designated performance of o the building. Total integrattion of all subbsystem and components c intto overall process fully utillizing industrialized production, p trannsportation and d assembly techhnique. A process, byy which compponents of a building b are coonceived, plannned and fabriccated, transported and erected at sitee. The system in ncludes a balannced combinatioon between softtware c and hardware component. [10] [17] [5] [18] [19] Based on Table T 1, all the t definitionns emphasizess on prefabriication, off-siite production n, off-site manufacturing and mass production of buildinng componen nts as the mainn characteristiic of IBS. Furrthermore, basedd on Table 1, eight e authors have defined IBS as a metthod, concept,, approach andd process. On n the other hand, two authors [15, 17] definned IBS as a product, p systeem and technoology. Conseqquently only one o author [19] has h indicated IBS I as a systeem and also ass a process. Th herefore, from m the Table 1, most of the reesearchers process whicch mostly inccludes the agreedd that IBS iss an integratiion approachh within the construction c produuction of preffabricated com mponents, traansportation of o componennts and at lasst project sitee erection (assem mbly) techniqques. Howeveer, it should be emphasiseed that regarddless of thesee variety of terms, t the purpoose of implem menting IBS inn construction projects is to ground moree effort in chaanging the perception of professsional construuction parties form the construction site to a controlledd environmennt of the manufacturing. As a result, comparing with other eleven e definittions of IBS,, this researcch selects thee valuable definiition of IBS according a to [16] as a construction techn nique in whichh componentss are manufacctured in a controolled environm ment (on or off o site), transpported, positio oned and asseembled into a structure with h minimal additiional site worrks The follow wing part of this t research includes the establishment e t and develop pment of a comprrehensive tim meline on IBS in i Malaysia siince the early 1960’s. 3. ESTABLISH HMENT AND DEVELOPM MENT OF IBS S IN MALAYSSIA IBS in i Malaysia has h been introoduced and implemented in constructioon industry inn order to deeal with a growiing demand of o affordable housing, sollving issues associated with foreign w workers and improving i qualitty, efficiency, effectivenesss and productiivity of consttruction projeccts. Nowadays, IBS has ev volved and impleemented in hyybrid construction projectss to build naational landmaark as signifi ficant valuablee national assetss. From the comprehensivve literature review, estab blishment annd developmeent of IBS have h been illustrrated through the timeline as a shown in Fiigure 1. The Ministry of o Defense Build 2800 Unit of Living Quarters at Lumut Naval Base First Pilot Project P on IBS in Jalan J Pekeliling, Kuala K Lumpu ur 1 9 6 0 1 9 6 6 1 9 6 8 IBS Roadmap 2003-2010 Tam an Tun Sardon n, Penang 1 9 7 8 1 9 7 8 Second Pilot IBS Project in Jalan J Rifle Range, Penang The Idea of IBS in Malaysia Was Created Cons struction Indus stry Master Plan 2006-10 015 MS 1064: Modular Co oordination as G Guideline for Bu uilding Design 1 9 8 0 IBS Roa admap Review 2008-2010 1 9 9 9 IBS Strategic Plan 2 0 0 1 2 0 0 3 Manual for IBS Content Scoring Diterbitkan The Penang State Government Launched Another 1200 Units of Housing 2 0 0 4 2 0 0 6 2 0 0 7 2 0 0 8 2 0 1 0 2 0 1 1 2 0 1 5 IBS Centre Approved by Cabinet on 9 July 2010 Manual for IBS Content Scoring CIS 18 2010: Diterbitkan IBS Road dmap 2011-2015 Figure 1. Establishmeent and develo opment of IBS in Malaysia As shown inn Figure 1, vaarious efforts have been ad dopted since thhe establishm ment of IBS in n Malaysia on thhe early 19600’s. Furtherm more, these effforts have been b reviewedd and improvved for enhaancing the 3 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I efficieency, effectiveeness and succcessful implem mentation of IBS I until 2015. These varioous efforts as illustrated on Figgure 1 will be briefly discusssed on this paart. The usage of o IBS in Maalaysia has beegun since eaarly 1960’s inn a low cost housing scheeme when Minisstry of Housinng and Locall Governmentt of Malaysia visited severral European countries and d evaluate their housing h development proggram [20]. Aft fter their visit in 1964, the government hhad launched first pilot projecct on IBS to speed s up the delivery d time and built affo ordable and quality q housess. Almost, 22.7 acres of land along a Jalan Peekeliling, Kuaala Lumpur was dedicated to t the project comprising of seven block ks with 17storeyy flats (3,000 units of low w-cost flat andd 40 shops lo ot). This projeect was awardded to JV Gaammon & Larsenn and Nielsenn using Danishh System of laarge panel pre-cast concretee wall and plannk slabs. Consequently, the prroject was coompleted withhin 27 monthhs from 1966 6 to 1968 inncluding the ttime engaged d with the constrruction of the RM 2.5 milliion casting yaard at Jalan Daamansara [16,, 20, 21 and 222]. Moreoverr, in 1968, the goovernment of Malaysia launnched a seconnd housing pro oject which was w a six blockk of 17-storey y flats and three blocks of 18-sstorey flats at Jalan Rifle Range, R Penang. The project was w awarded to Hochtief/ Chee C Seng using French Estoitt System [16, 21, 22 and 233]. Precast conccrete is one of o the main IB BS category built b in Malayysia since 19660s. Neverthelless, these buildiings were norrmally associated with pree-fabricated mass m construcction method, low quality buildings, leakagges, abandoneed projects, unnpleasant archhitectural appeearances and other o drawbaccks. Furthermo ore, due to the pooor architectuural design, thhe old pre-fabbricated buildiings have givven the publicc, bad impresssion about precasst concrete. While W as, theree have been quite q a numbeer of cases whhere the use oof IBS had leaad to such drawbbacks such ass, in the casee of Pekelilinng Flats in Kuala K Lumpurr and Taman Tun Sardon,, Gelugor, Penanng. In the casse of Taman Tun Sardon the design was w very basicc and not connsidering the aspect of servicceability such as the need foor wet toilets and a bathrooms [16]. In 1978, thee Penang statee governmentt launched an nother 1200 units u of housinng using preffabrication technoology. Two years y later, thee Ministry of Defense adop pted large prefabricated pannel constructio on system to buiild 2800 unit of o living quartters at Lumut Naval Base [24]. [ In the peeriod of 1980 ttill 1994 theree is a huge gap of decreasing the t IBS utilization towardss developing and a implemennting the IBS. This could be b because of prooblems in thee leakage of IBS I design thhat eventually contributing to poor imagge of IBS buiildings for constrruction industtry. Consequeently, IBS wass not popular in 1980 to 19994. Thereforee, between thee 80’s and 90’s the t use of struuctural steel components c tuurned particullarly in high rise r buildings in Kuala Lum mpur. The usagee of steel struccture gained much m attentionn with the consstruction of 366-storey Dayaabumi complex that was completed in 1984 by Takenaka Corporation of o Japan [16, 21 2 and 22]. IBS becomee more populaar in 1990’s when many Malaysian M inffrastructure annd mega projjects were build especially foor the Commoonwealth Gam mes in 1998. As A a result, in i the boominng period of Malaysian M constrruction industtry during 19994-1997, pre-ccast, steel fram me and other IBS I were usedd as hybrid co onstruction methood to build naational landmaarks such as Bukit B Jalil Sp port Complex, Kuala Lumppur Conventio on Centre, KL Sentral Stationn, KL Tower, Kuala Lumpuur Internationaal Airport, Liightweight Raailway Train (LRT) ( and wers [21 and 22]. 2 Petronnas Twin Tow According too Constructioon Industry Deevelopment Board B (CIDB) [25], based oon the resoluttion which was made m during thhe Colloquium m of Industriallised Construcction System in i 1998, the C CIDB eventuallly formed the IB BS Steering Committee C on 1999 for the effort to brin ng to the foreefront all the IBS related issues in a frameework to prom mote the greateer usage of IBS in the consttruction industtry and to drivve the industry y forward. The IB BS Strategic Plan P in 1999 was publishedd as a result for f establishm ment of this coommittee. Furrthermore, the Coonstruction Inndustry Masteer Plan 2006-22015 (CIMP 2006-2015) 2 haas been publisshed in Decem mber 2006 as meeans to chart the t future direection of the Malaysian M Co onstruction Inddustry. The im mportance and d effort to promoote IBS is hiighlighted undder Strategic Thrust 5: Inn novate througgh R&D to aadopt new co onstruction methoods such as IB BS in the Consstruction Industry Master Pllan 2006-20155 [26 and 27].. These various significantt efforts by thhe governmen nt to promotee the usage oof IBS as a significant s alternnative comparre to the convventional metthod did not made considerable progreess. Thereforee, the IBS Roadm map 2003-20010 was deveeloped and published p to steer the dirrection of IB BS implementtation and promootion activitiees, guide the practitioners p a policy maakers on IBS related issuess in ensuring the global and competitiveness off Malaysian coonstruction plaayers through h the efficient and effective usage of IBS. It should be notted that the foormulated roaddmap is a com mprehensive document that divided the IB BS programm me into a 5M strrategy (five main m focus areas) a that reflects the inp puts needed to t drive the programme which w are Manppower, Materiaals, Managem ment, Monetaryy and Marketiing [16]. I IBS Roadmapp 2003-2010 (First IBS Roadmap) as a significant valuable v alterrnative for co onstruction industtry on the endd of year 20100 did not achieeve the goals of this roadm map. Accordingg to CIDB in Malaysia, only one o KPI (Moonetary) out of o the 5 measurable KPI’s (key perform mance indicatoors) was achieved. The KPI’ss was categorrized to Manppower, Moneetary, Materiaals, Bumiputera Manufactuurers Develop pment and Contrractors or Insttallers Bumipuutera Developpment. Hencee, the new IBS S Roadmap 22011-2015 (Seecond IBS 4 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I Roadm map) is develloped by CIDB under conssultation with the industry players p to chaart the way fo orward for IBS industry. i Alteernatively, Coonstruction Inddustry Develo opment Boardd (CIDB) havve emphasizeed on four policyy objectives which w were quuality, efficienncy, competen ncy and sustaiinability leading to a sustaiinable IBS industtry that will eventually e conntribute to thee competitiven ness of constrruction industtry in Malaysiia [28 and 29]. The T next part of o this researcch will brieflyy discuss on th he classificatioon of Industraalised Building g Systems (IBS). 4. CLASSIFIICATION OF IBS SYSTEM M In Malaysia, M Consstruction Induustry Developpment Board d (CIDB, 20003) has classsified the Ind dustralised Building System (IBS) system into five cateegories which h are: pre-casst concrete frraming, steel formwork system m, steel framiing systems, block b work syystem and preefabricated tim mber framing system. Consequently, this reesearch has cllassified Induustralised Buillding System (IBS) with itts sub system categories with a brief descriiption based on o Table 2. Table 2- Classification n of Industrializzed Building Systems S (IBS) T Type of IBS Sub Systeem Categories Precast Conncrete Wall System Reinforcedd Concrete Building with w Precast Concrete Slab A combinaation of frames with precast cooncrete hollow w core slab or precast planks. p Block Worrk Components Contains of o interlockingg Concrete M Masonry Unitss (CMU), lightweightt concrete blockks and etc. Prefabricated Componentts mber frames, rooof trusses and eetc. Includes tim Precast Conncrete Framing, Panel and Box B Systems Precaast Systeems Concretee Blockk Workk Systeems Prefaabricated Timbber Framingg Systeems Brrief Descriptionns Comprises of precast coolumns, beams,, slabs, 3D co omponents (balconies, staircases, toillets, lift chambeers), permanen nt concrete formwork and a etc. A structuraal framework off the building composed of pree-cast slab and load bearing b wall. The T load beariing walls and slabs are manufacturred off-site and transferred at ssite to be erected. Timberr Form mwork Systems Formwork Componentss (Steel, Plastic andd Aluminum)) Consists off tunnel forms,, beams and coolumns mouldiing forms, permanent steel formworkks, metal decks and etc. Steel Framedd Buildding Systems Steel Frameed Componentss Comprises of steel beam ms and colum mns, portal fram mes, roof trusses and etc. Table 2, shoows that the precast p concreete framed sy ystem which is i fabricated oor manufacturred offsite using machine and formwork is one of the moost popular fo orms of industtrialized buildding system paarticularly in Maalaysia whichh offers advanntages such as a high degreee of flexibility in term oof larger clear distance betweeen columns which w as a ressult the longerr span give big gger open spaace and greateer freedom of designing the flooor areas. Folllowing part of o this researcch will bring down briefly the overall concluded poin nts of this researrch. 4. CONCLU USION This research r selecct the valuablle definition of IBS as a construction technique t in which compo onents are manufactured in a controlled environment (on ( or off sitee), transporteed, positionedd and assemblled into a structuure with minnimal additionnal site workks. Furthermo ore, this studdy proposed aand discussed d the IBS timeliMine in Malayssia since its establishment e t on early 1960s along wiith its developpment toward ds various efforts until 2015. Successful and a effective implementatio on of IBS in Malaysia connstruction ind dustry can offer various beneffits compare to conventionnal in-situ sysstems. Those are: the speeed of construcction, less wastaage of materiaals which meeans cost saviings, reductio on of unskilled workers, faaster and bettter quality controol of construuction, increased site cleaanliness and safety to connstruction proojects. These are very imporrtant aspect inn achieving thee efficient andd effective con nstruction inddustry which w will enhance the t market 5 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I share of constructioon industry, ennhancing the competitive advantages, a prreparing the coonstruction in ndustry for Intenaationalisation and Globalisaation as well as a contributing g to the Malayysian economyy. T governmeent has done a lot of effortts to enhance the The t current coonventional, laabor-intensivee activities to a more m technologgically advancced method off construction n such as by deeveloping the Industrialised d Building System ms (IBS) throough the Consstruction Induustry Develop pment Board (CIDB). ( The ggovernment had h efforts in devveloping the 1st and 2nd IB BS Roadmap to put Malay ysia constructtion industry in producing fast, cost effecttive, high quaality construcction productss and able to o compete with w the globaal construction market. Finallly, the study presented p in thhis paper is a preliminary survey s and is a part of an oongoing researrch, which will eventually attempt a to further fu enhannce the pracctices and im mplementatioon of successsful IBS impleementation aloong with introducing the collaborative tecchnologies in construction industry, partiicularly in the IB BS project deelivery in Maalaysia. Additiionally, it is hoped that thhe results of the main reseearch will hopeffully provide and a form the basis b of a valuuable coordinaation with in thhe Malaysian construction industry. 5. ACKNOWL LEDGMENT The authors a wouldd like to thannk Universiti Teknologi Malaysia M and the Ministry of Higher Education, E Malayysia for sponsoring this reseearch through Research University Grantt No: 01J58. 6. REFERENC CES 1. Pann, W., Gibb, A. A and Daintyy, A. R. J. (20008), “Perspecctives of UK Housebuilders H s on the Use of Offsite Moodern Method of Constructioon,” Construcction Managem ment and Econnomic, 25 (2),, pp. 183-194.. 2. Blissmas, N. and Wakefield, R. R (2009), “D Drivers, Consttraints and thhe Future of O Offsite Manufacture in Ausstralia,” Consttruction Innovvation: Inform mation, Process, Managemennt, 9 (1), pp. 772-83. 3. Blissmas, N. and Wakefield, R. R (2008), “Offsite Manufaacture in Austtralia – Barrieers and Opporrtunities,” Prooceedings of the t Cooperativve Research Centre C (CRC)) for Construcction Innovatiion Third Inteernational Connference, Clieents Driving Innnovation: Beenefiting from Innovation, Gold G Coast, A Australia. 4. Blissmas, N., Paasquire, C. and a Gibb, A. A (2006), “B Benefits Evalluation for O Off-site Produ uction in Connstruction” Coonstruction Management M annd Economicss, 24, pp. 121-130. 5. Waarszawski, A., E. D. (1999), “Industrialized and Autom mated Buildingg Systems: A M Managerial Ap pproach,” E annd F N Spoonn. 6. Gibbb, A. G. F. and a Isack, F. (2003), “Re--engineering Through Pre--Assembly: C Client Expectaations and Drivers” Building Research annd Informationn, 31 (2), pp. 146-60. 7. Kam mar, K. A. M., Hamid, Z. A., A Azman, M. M N. A. and Ahmad, A M. S. S. (2011), “Industrialized d Building Sysstem (IBS): Reevisiting Issuees of Definitioon and Classiffication,” Int. J. Emerg. Sci., 1 (2), pp. 12 20-132. 8. Gooodier, C. Andd Gibb, A. (20007), “Future Opportunitiess for Off-Site in the UK,” JJournal of Con nstruction Management andd Economic, 25 2 (6), pp. 5855-595. 9. Kam mar, K. A. M., M Alshawi, M. M and Hamid, Z. (2009), “Barriers to Inndustrialized B Building Systeem (IBS): Thee Case of Malaysia," Paperr Proceedingss in BuHu 9th h Internationall Postgraduatee Research Conference (IPG GRC), Salfordd, United Kinggdom. 10.Shhaari, S. N. annd Ismail, E. (2003), “Prom moting the Usage Us of Indusstrialized Buillding System (IBS) and Modular Coordiination (MC)) in Malaysiaa,” Constructtion Industry in Engineerrs (Board of Engineer Maalaysia). 11.Ooostra, M. and Joonson, C. C. C (2007), “Beest Practices: Lesson Learnned on Building Concept (eedited by) Kazzi, A. S., Hannus, M., Bouddjabeur, S. annd Malone, A.. (2007),” ‘Open Building Manufacturin ng – Core Conncept and Induustrial Requirrement’, Manuubuild Consorrtium and VTT T Finland Pubblication, Finlaand. 12.Abbd Shukor, A. S., Mohamm mad, M. F. andd Mahbub, R. (2011), “Supp pply Chain Inttegration Challenges in Prooject Procureement in Mallaysia: IBS Contractors C Perspective,” P Management and Innovattion for a Susstainable Builtt Environment, 20 – 23 Junne, Amsterdam m, Netherlandss. 13.Haassim, S., Jaafar, M. S. and Sazalli, S. A. A. H. H (2009), “T The Contractor Perception n Towers Inddustrialized Buuilding System m Risk in Connstruction Pro ojects in Malaaysia,” Americcan Journal of o Applied Sciences, 6 (5), pp. p 937-942. 6 9th Internattional Congresss on Civil Engin neering, May 8--10, 2012 Isfahaan University of Technology (IIUT), Isfahan, Iran I 14.Abbdallah, A. (22007), “Managerial and Economic E Op ptimisation foor Prefabricettd Building Systems,” S Tecchnological annd Economic Development D of Economy, 13 (1), pp. 833-91. 15.Raahman, A. B.. A., and Om mar, W. (2006), “Issues and a Challengee in the Impllementation of o IBS in Maalaysia,” Procceeding of thhe 6th Asia Pacific P Structtural Engineeering and Coonstruction Conference (AS SPEC 2006), Kuala K Lumpuur, Malaysia. Construction 16.CIDB. (2003), “Industraliseed Building Systems S (IBS) S) Roadmap 2003-2010,” 2 n Industry Devvelopment Booard (CIDB), Kuala K Lumpurr, Malaysia. 17.Baadir, Y. F., Kaadir, M. R. A. and Hashim, A. H. (2002),, “Industrialiseed Building S Systems Consttruction in Maalaysia,” Journnal of Architecctural Engineeering, 8 (1), pp p. 19-23. 18.Dietz, A. G. H. (1971), “As Stated S in Jaaffar, S., et al. (2003), Globaal Trends in R Research, Devvelopment andd Constructionn,” Proceedinng of The Intternational Co onference on Industrilised Building Sysstem (IBS 20003), CIDB. 19.Junnid, S. (19886), “Industriilised Buildinng System,” Proceeding of UNESCO O/FEISEAP, Regional Woorkshop. 20.Thhanoon, W. A.. M., Peng, L.. W., Abdul Kadir, K M.R., Jaaafar, M.S. annd Salit, M.S. (2003), “Thee Essential Chaaracteristics of o Industrialissed Building System,” Inteernational Conference on IIndustrialised Building Sysstems, Kuala Lumpur, L pp. 283-294. 2 21.CIDB. (2006), “Industrialised “ d Building Sysstems in Mala aysia,” Constrruction Industtry Development Board (CIIDB), Kuala Lumpur, L Malayysia. 22.CIDB. (2006), “IBS Survey 2005: Surveyy on Malaysiian Architectss Experience in IBS Consttruction,” Connstruction Inddustry Developpment Board (CIDB), ( Kualla Lumpur, Maalaysia. 23.Din, H. (1984), “Industrialiseed Building and a Its Appliccation in Malaaysia,” Proceeeding of Prefa fabrication Buiilding Construuction Seminaar, Kuala Lum mpur, Malaysiaa. 24.Triikha, D. N., and a Ali, A. A. A A. (2004), “Industrializeed Building System S (First ed.),” Univerrsiti Putra Maalaysia Press, Kuala K Lumpur. 25.CIDB. (2005), “Modular Coonstruction inn Constructio on Industry; IBS I Digest,” Construction n Industry Devvelopment Booard (CIDB), Kuala K Lumpurr, Malaysia. 26.CIDB. (2007), “Constructioon Industry Master Plan (CIMP 20006- 2010),” Construction Industry Devvelopment Booard (CIDB), Kuala K Lumpurr, Malaysia. 27.CIDB. (2007), “IBS “ Roadmap ap Review (Finnal Report),” ” IBS Centre, Construction Industry Dev velopment K Lumpurr, Malaysia, (uunpublished). Boaard (CIDB), Kuala “IBS Roaadmap 28.CIDB. (2011),, (2011-2015),” httpp://www.ibsceentre.com.my//ibsweb/indexx.php?option= =com_content& &view=articlee&id=48&Item mid=106 &laang=en [Accessed 30 Octobber 2011]. 29.CIDB. (2011), “Transformattion of Constrruction Industtry through Industrialized In Building System (IBS) Roaadmap (2011-2015)),” htttp://www.pam m.org.my/Libraary/notes/ibs__roadmap_201 11-2015__PA AM_21122010.pdf [Accesssed 30 Octobeer 2011]. 7