Thermally Driven Shape Instabilities of Nb/Cu Multilayer Structures

advertisement

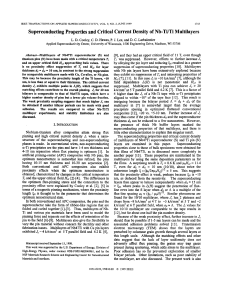

Thermally Driven Shape Instabilities of Nb/Cu Multilayer Structures P. Troche1, J. Hoffmann1, K. Heinemann1, F. Hartung1, G. Schmitz1, H.C. Freyhardt1, D. Rudolph2, J. Thieme2, P. Guttmann2 1 Institut für Metallphysik, Georg-August-Universität Göttingen, Hospitalstraße 3-7, D-37073 Göttingen, Germany 2 Forschungseinrichtung Röntgenphysik, Georg-August-Universität Göttingen, Geiststraße 11, D-37073 Göttingen, Germany Abstract: The disintegration of Nb layers in Nb/Cu multilayers during heat treatments were investigated by means of X-ray diffraction (XRD), transmission electron microscopy (TEM), and X-ray microscopy (XRM) (Ref. 1). Spherically shaped Nb particles were observed after a heat treatment at 870 K for two hours. The growth velocity of the Nb particles depends strongly on the initial interface roughness and the Nb layer thickness. The XRM investigations indicate a process of self-organisation, leading to a non-statistical distribution of the particles. 1 Introduction Due to their special mechanical, optical, electrical, and magnetical properties nano-sized materials are of current interest in modern material sciences. In these materials the characteristic size of the particles is reduced to only a few nanometers in one or more dimensions. Nb/Cu multilayers were used as a model system to prepare nano-sized particles in a metallic matrix. Such multilayers can easily be produced by conventional thin-film deposition techniques. Nb and Cu were selected because of the low solubility of these compounds in each other. Disintegration of filamentary Nb3Sn/Cu structures during heat treatments was indeed observed (Ref. 2). Nevertheless, the mechanism of disintegration in such multilayered structures is not well understood. As far as we know, theoretical investigations of this process are only published concerning a cylindrical geometry of the interface (Ref. 3). From this calculations a strong dependence of the intercalation on the initial interface roughness and on the filament dimensions is expected (Ref. 4). At the latest stage of the reaction, spherical particles with a minimum surface should occur, because the driving force for the diffusion is the surface energy at the interface between Cu and Nb. Furthermore, the final distribution of the Nb particles in the Cu matrix is of interest. A process of self-organisation might occur, resulting in a non-statistically distribution of the particles. Due to its rather large area of observation XRM was used to investigate the distribution. TEM investigations were performed to investigate the microstructure. 2 Experimental The UHV set-up for the preparation of the Nb/Cu multilayers is shown in Fig. 1. Two triode magnetron sputter sources with single-metal targets are directed towards a sub- II - 124 P. Troche et al. Fig. 1. Experimental set-up for the preparation of multilayers. strate holder. The substrate holder has been cooled with liquid nitrogen during the deposition. Thus its temperature was always lower than 120 K. Ar was used as working gas for both sources. The Ar pressure during the deposition was around 10-2 mbar. The content of impurity gases like O2, N2, and H2O was reduced by a preceding sputtering and the use of cooling shields filled with liquid nitrogen. The total pressure of these gases was lower than 10-8 mbar. After the deposition of a single Nb layer a shutter, mounted in front of the sources, was moved to the Nb source and the source was switched off. After a short delay, the second layer, Cu, was deposited. Due to this special deposition technique the intermixing at the interface between Nb and Cu is strongly reduced. The deposition rates for both metals amount to about 0.1 nm/sec. The thickness of a single bilayer was 5 nm (1 nm Nb / 4 nm Cu). The number of these bilayers amounts to 100 for X-ray diffraction measurements and transmission electron microscopy or 10 for X-ray microscopy. Sapphire as well as glass and Silicon were used as substrate materials. For both the later 50 nm thick ZrO2 buffer layers were first deposited. These buffer layers prevent interdiffusion between the substrate and the metallic film compounds during the heat treatments. Heat treatments of the samples were carried out between 700 K and 900 K in the same UHV chamber. Furthermore, in-situ XRD measurements were performed on a hot stage of the diffractometer under a pressure of less than 10-5 mbar. X-ray scans were recorded as a function of time every 5 minutes at a fixed temperature or at a fixed heating rate of 0.3 K/min as temperature-depending measurements. The lattice constant of the compounds as well as the grain size were determined from these scans. The grain size was calculated from Scherrer’s law: 0.9 ⋅ λ (1) Dgrain = ∆ ⋅ cos Θ λ is the X-ray wavelength (Co-Kα), θ the angle position of the intensity maximum, and ∆ is the full width half maximum value of the intensity distribution. The microstructure of the samples was investigated by means of TEM and XRM. For the TEM investigations in cross-section the samples were polished, grounded and ion Thermally Driven Shape Instabilities of Nb/Cu Multilayer Structures II - 125 milled. For the XRD investigation the Si respectively glass substrate was removed chemically. Due to the ZrO2 buffer layers, the metallic layers were not etched during the treatment. 3 Results and Discussion Figure 2 shows the X-ray diffraction patterns of a Nb/Cu multilayer before and after a heat treatment at 870 K for 2 h. After the heat treatment only the Nb (110) reflection and the Cu (111) reflection are visible. In the samples without heat tratment the intensity distributions of these reflections are modified due to the periodic structure of the multilayers. Additional satellite reflections have been observed in the XRD scans. 35 30 100 Layers: 4,5nm Nb + 4nm Cu; T=600°C 25 100 Layers: 1nm Nb + 4nm Cu; T=550°C Nb-(110)-Peak 14000000 12000000 Multilayer after heat treatment Cu-(111)-Peak 20 Intensity 10000000 Nb particle size [nm] 16000000 8000000 100 Layers: 1nm Nb + 4nm Cu; T=450°C 15 6000000 Multilayer as-prepared 2000000 0 42 100 Layers: 1nm Nb + 4nm Cu; T=400°C 10 4000000 5 0 44 46 48 50 52 54 2 Theta [°] Fig. 2. XRD intensity of a sample before and after annealing. The heat treatment was performed at 870 K for 2 hours. 0 100 200 300 400 500 600 Time [minutes] Fig. 3. Isothermal growth of Nb particles at different temperatures and Nb layer thickness. The calculation of the intensity distribution for multilayered structures is given in Ref. 5. The observed reflections can be explained by a superimposition of two contributions. According to Braggs law, a maximum in the intensity occurs, if (2) 2 ⋅ d ⋅ sinΘ = n ⋅ λ . In this law θ is the angle position of the maximum, n is an integer number and d the distance between the scattering planes (Ref. 6). The two contributions can be ascribed to the scattering at the atomic lattices of the two metals as well as at the multilayer lattice, where d corresponds to the thickness of a bilayer. In perfectly grown superlattices the atomic lattices of both metals only contribute with an averaged lattice constant. Therefore, only one intensity distribution centre with additional satellite reflections should occur. The experimental observed intensity distribution can only be explained assuming contributions of each atomic lattices. Therefore, the multilayer structure is imperfect due to the internal strain at the interfaces between Cu and Nb and due to the initial interface roughness. II - 126 P. Troche et al. The single layers are highly strained due to the lattice mismatch between Cu (111) and Nb (110), which amounts to 14%. The Nb (110) plane spacing of the as prepared films corresponds to a lattice spacing of 0.307 nm, which is much lower than the bulk value (0.330 nm). The heat treatment causes strong relaxation, so that the lattice spacing increases up to the bulk value. After this treatment, TEM dark-field images (Fig. 3) reveal spherical Nb particles with a typical size of 10 nm in the copper matrix. The disintegration of the Nb layers is however not complete. TEM observations in cross section reveal undisintegrated layers close to the substrate (Fig. 4). The driving force of the intercalation is related to the initial interface roughness (the variation of the chemical potential along the interface). The first deposited bi-layers reveal a rather flat interface. The roughness of the interface between Nb and Cu increases with the number of deposited bi-layers. Therefore, disintegration appears at some distance from the interface to the substrate. Fig. 4. Dark field TEM picture of a multilayer Fig. 5. TEM image of a multilayer after anafter annealing. The light areas correspond to nealing. The arrow indicates non-disintegrated Nb particles. layers close to the ZrO2 buffer-layer. The results concerning the growth kinetics of the intercalation are summarised in Fig. 5. The vertical Nb grain sizes eq. (1) are plotted versus the time for different multilayers and different temperatures of heat treatments. Disintegration occurs at temperatures above 670 K. After a sharp increase of the grain size at short times, the grain growth follows almost a logarithmic time dependence. This long-term saturation tendency is expected, if grains from different bi-layers grow together. The disintegration however is mainly indicated by the sharp increase of the grain size at short times. The growth velocity of the Nb particles increases with decreasing Nb layer-thickness and with increasing temperature. Thermally Driven Shape Instabilities of Nb/Cu Multilayer Structures II - 127 Fig. 6 and 7. Multilayer (10 x 1 nm Nb, 4 nm Cu) before and after annealing observed with XRM. The upper pictures show the X-ray images taken at λ = 2.4 nm, the lower ones line scans of the intensity distribution of the Xray images. In order to observe the large-scale particle distribution XRM-investigations in transmission were performed. Up to a thickness of a few hundred nanometers this method does not require any thinning of the metallic film. Only the substrate has to be removed. For the system Nb/Cu the phase shift as well as the difference in absorption are sufficient to reach a resolution of the order of 20 nm. Therefore, single Nb-particles can be detected. Figures 6 and 7 show X-ray images of a non heat-treated (left image) and a heattrated sample (right image) taken at λ = 2.4 nm with the Göttingen X-ray microscope at BESSY in Berlin and intensity line scans of these samples. In both pictures equal density corresponds to equal specimen thickness. The fluctuations observed for the untreated samples are small and caused by variations of the total film thickness or of the single layer thickness. Strong variations are observed after the heat treatment. The white areas correspond to Cu, the dark to Nb. An examination of the complete material shows that the distribution of the particles is not statistical. The Cu forms network paths, which delimit areas of a high Nb density. This indicates that some self organisation processes occur. The Nb-particles almost show an ellipsoidal shape, because of the lower reaction temperature compared to the TEM-investigation. II - 128 P. Troche et al. 4 Summary The disintegration of Nb/Cu multilayers was investigated by means of XRD, TEM, and XRM. A heat treatment at 870 K for two hours leads to the formation of spherical Nbparticles with a minimum surface energy. The intercalation is complete with exception of the first bi-layer close to the interface of the substrate, where the initial interface roughness is too small. The growth velocity of the Nb-particles increases with temperature and decreasing bi-layer thickness. For the first time, XRM was used to investigate particle distributions in metallic matrices. The observed distribution is not statistically, indicating a self-organisated process in this system. References 1 2 3 4 5 6 G. Schmahl et al., Naturwissenschaften 83, (1996), 61–70. L. Schultz, R. Bormann, J. Appl. Phys. 50, (1979), 418. H.E. Cline, Acta Met., 19, (1957), 481. J. Van Suchtelen, J. of Crystal Growth, 43, (1978), 28. C. Michaelsen, Phil. Mag. A, 72 (1995), 813–828. B.D. Cullity, Elements of X-Ray Diffraction, Addison-Wesley Publishing Company, 1967.