Investigation of the Unique Cryogenic Pumping System of

advertisement

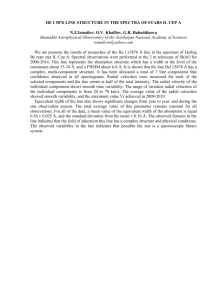

Investigation of the Unique Cryogenic Pumping System of the CHAFF-IV Spacecraft-Thruster Interaction Facility -i f\ /•} __ r\ Andrew D. Ketsdever , Marcus P. Young , Andrew Jamison , Brian Eccles and E.P. Muntz2 1 Air Force Research Laboratory Propulsion Directorate (PRSA) Edwards AFB, CA 93524 USA 2 University of Southern California Department of Aerospace and Mechanical Engineering Los Angeles, CA 90089-1191 USA Abstract. Chamber -IV of the Collaborative High Altitude Flow Facility was designed to obtain high fidelity spacecraftthruster interaction data. CHAFF-IV uses a total chamber pumping concept by lining the entire chamber with an array of cryogenically cooled, radial fins. Details of Monte Carlo numerical simulation and experimental investigation of the radial fin target array pumping efficiency are presented. INTRODUCTION Interactions between propulsion system effluents and sensitive surfaces have received considerable interest within the spacecraft community in recent years. The impact of potential interactions is becoming more critical as mission life and payload sensitivity requirements increase. The adsorption of propellant gases on spacecraft surfaces can change the spectral absorptivity of thermal control surfaces, alter reflectivity of optical surfaces, alter transmission through solar cell coverglass, and induce environments that can alter scientific results. Ion electric thrusters add further complications due to material sputtering from high energy propellant impact and the possible alteration of spacecraft potentials. Because of the cost and time requirements associated with space-based experiments, ground-based examination of spacecraft-thruster interactions is necessary to compliment the limited data returned from space. In order for ground-based experiments to be effective, facilities must faithfully and consistently reproduce the space environment. The major limitation of ground facilities in accurately predicting the effects of thruster operations on spacecraft systems has been driven by the facility background pressure. Although some fraction of the background gas is composed of the residual laboratory atmosphere, the largest complication arises from the fact that the overwhelming majority of the background pressure is thruster derived. These thruster-borne components are largely responsible for experimental measurement errors. Minimizing the effects of these effluents on interaction results requires extremely high pumping rates; therefore, improvements in the accuracy of ground-based interaction data come at the expense of more efficient chamber pumping. A general review of interaction facilities and advanced pumping concepts has been compiled by Ketsdever. [1] Chamber IV of the David P. Weaver Collaborative High Altitude Flow Facility (CHAFF) was designed in an effort to obtain meaningful spacecraft-thruster interaction data by maximizing the facility's high vacuum pumping. [2] As shown in Figures 1 and 2, CHAFF-IV incorporates a total chamber pumping (TCP) concept by lining the entire facility with an array of cryogenically cooled, radial fins. The aluminum finned arrays are contained inside a 3m diameter by 6m long stainless-steel vacuum chamber. Details of the initial investigation of CHAFF-IV s cryogenic pumping system are presented along with results from a simple Monte Carlo numerical model. For the experiment, the target section of the radial fin array and a simple flat panel have been independently investigated. CP585, Rarefied Gas Dynamics: 22nd International Symposium, edited by T. J. Bartel and M. A. Gallis © 2001 American Institute of Physics 0-7354-0025-3/01/$18.00 916 Both Bothpumping pumping configurations configurations were were cooled cooled toto liquid liquid nitrogen nitrogen (LN2) (LN2) temperatures temperatures (77-80K) (77-80K) with with aa sonic sonic orifice orifice introducing a carbon dioxide gas flow on the axis of the chamber. introducing a carbon dioxide gas flow on the axis of the chamber. 1.0 m Diffusion Pumps Radial RadialFin Fin Arrays Arrays FIGURE FIGURE1.1. CHAFF-IV CHAFF-IVCryogenically CryogenicallyCooled, Cooled,Radial RadialFin FinTotal TotalChamber ChamberPumping Pumping Arrangement. Arrangement. FIGURE FIGURE2.2. Fabricated FabricatedAluminum AluminumFinned FinnedArrays ArraysInstalled Installedin inCHAFF-IV. CHAFF-IV. FACILITY FACILITYBACKGROUND BACKGROUNDPRESSURE PRESSURE REQUIREMENTS REQUIREMENTS InInaatypical typicalground-based ground-basedfacility facilitywith withaasmall smallfraction fractionffppofofits itsinner innersurface surfaceoccupied occupiedby bypump pumpinlets, inlets,the the thruster thruster effluents effluents are aretypically typically stopped stopped and and randomized randomized by by the the facility's facility’s surfaces. surfaces. The The random random motion motion of of the the scattered scattered propellantmolecules moleculesinefficiently inefficientlybrings bringsthem themtotoaapump pumpinlet. inlet. The Thebackground background pressure pressure of of the the propellant propellant gas gas can can propellant approximatedby by bebeapproximated __ ˙k T T ˙ kT 4M b p M MkT hb (1) p = = Pb b = mvjA mv ′f p As mV˙ mV ˙ isisthe were MM thepropellant propellantmass massflow, flow,kkisisBoltzmann's Boltzmann’s constant, constant, TTbb and and TTpp are are the the background background and and propellant propellant gas gas were temperaturesrespectively, respectively,mmisisthe the molecular molecular mass mass of of the the propellant propellant gas, gas, v'v ′ isis the the average average thermal thermal speed speed of of the the temperatures backgroundgas, gas,f pfpisisthe thefraction fractionofofthe thefacility facilityinner innersurface surfaceoccupied occupiedby bypump pumpinlets inlets or or pumping pumping surfaces, surfaces, A Ass is is the the background innersurface surfacearea areaofofthe thefacility, facility,and and VV˙isisthe the facility's facility’spumping pumping speed. speed. In In order order to to minimize minimize the the effects effects of chamber inner inducedcharge chargeexchange exchangecollisions collisionsininxenon xenonion ionthrusters, thrusters, background background pressures pressures on on the the order order of of 33 xx 10~ 10-66 Torr Torr are are induced 917 required. [1] For a typical Hall thruster propellant mass flow rate of 5 mg/s, Eq. (1) indicates that pumping rates in required. [1] For a typical Hall thruster propellant mass flow rate of 5 mg/s, Eq. (1) indicates that pumping rates in excess of 2.5 x 105 5L/s are required. For a cold gas system with a nitrogen propellant flow rate of 1 g/s, pumping excess of 2.5 x 10 L/s are required. For a cold gas system with a nitrogen propellant flow rate of 1 g/s, pumping rates on the order of 107 7L/s are required to maintain free molecular flow in the plume backflow region. rates on the order of 10 L/s are required to maintain free molecular flow in the plume backflow region. Clearly a critical background number density for thruster plume interaction studies is reached when the Clearly a critical background number density for thruster plume interaction studies is reached when the background mean free path becomes less than or equal to the largest internal dimension of the facility Lc. Therefore, background mean free path becomes less than or equal to the largest internal dimension of the facility Lc. Therefore, the background number density should be the background number density should be 1 (2) nb ≤ 2σ b Lc where σb is the background gas collision cross section and λc is the critical mean free path. where Gb is the background gas collision cross section and ?lc is the critical mean free path. As Eq. (1) indicates, background gas pressure can be minimized by having large available pumping areas (fpAs). As Eq. (1) indicates, background gas pressure can be minimized by having large available pumping areas (f As). For a given chamber geometry, the pumping rate is maximized by increasing the fraction of the inner surface parea For a given chamber geometry, the pumping rate is maximized by increasing the fraction of the inner surface area which acts as a pump. This suggests that high pumping rates can be achieved when the entire inner surface of the which acts as a pump. This suggests that high pumping rates can be achieved when the entire inner surface of the facility is a pumping surface. The TCP concept has driven the design of several interaction facilities. [2-4] facility is a pumping surface. The TCP concept has driven the design of several interaction facilities. [2-4] For the array array that that is is able able to to return return to to Forthe theradial radialfin finTCP TCP array, array, the the fraction fraction of of efflux efflux from from aa thruster thruster impinging impinging on on the the thruster vicinity is given by the thruster vicinity is given by 2 w2 t Do (3) Fr = (1 −η) + 2h(w + t) (w +t) X where the axial direction, tt whereηr| isisthe thesticking stickingcoefficient, coefficient, wwisisthe the radial radial fin-to-fin fin-to-fin spacing, spacing, hh is is the the length length of of the the fin fin in in the axial direction, isisthe fin thickness, D is the characteristic thruster diameter, and X is the distance from the thruster exit plane to the the the fin thickness, Do0 is the characteristic thruster diameter, and X is the distance from the thruster exit plane to front edge of the radial fin array. Design of the radial fin arrays can be optimized through the minimization of the front edge of the radial fin array. Design of the radial fin arrays can be optimized through the minimization of the geometric For the the CHAFF-IV CHAFF-IV radial radial geometricterm termininthe the brackets brackets of of Eq. Eq. (3) (3) by by an an appropriate appropriate selection selection of of the the fin fin geometry. geometry. For fin target array, h = 25.4 cm, t = 0.32 cm, and w varies from 1 to 6 cm due to the radial nature of the array. fin target array, h = 25.4 cm, t = 0.32 cm, and w varies from 1 to 6 cm due to the radial nature of the array. EXPERIMENT EXPERIMENT In target section array shown shown in in Fig. Fig. Inorder ordertotodetermine determinethe the pumping pumping capabilities capabilities of of the the 112 112 fins fins that that make make up up the the target section array 3,3, LN centerline. Carbon Carbon dioxide dioxide 2 was 2 gas LN2 was used used toto cool cool the the panels panels while while CO CO2 gas was was introduced introduced on on the the chamber chamber centerline. pumping xenon) pumping pumping on on 152 surface pumpingatatLN LN2 surface temperatures temperatures of of ~80 ~80 K K was was used used to to simulate simulate other other gases gases (including (including xenon) 1520 K surfaces since the sticking coefficients are similar as shown in Table 1. [5] 20 K surfaces since the sticking coefficients are similar as shown in Table 1. [5] Radial RadialFin Fin Array Array Patterson Probe Probe Patterson Sonic SonicOrifice Orifice FIGURE FIGURE3. 3. Experimental Experimental Configuration Configuration of of Radial Radial Fin Fin Array. Array. For orifice (diameter (diameter == For the the radial radial fin fin configuration, configuration, the the CO CO2 was introduced introduced into the chamber through a sonic orifice 2 was 0.178cm) 0.178cm)on onthe thechamber chambercenterline centerline located located 79.1cm 79.1cm from from the the front front of of the the array array as shown shown in Fig. 4(a). The density of the the free free jet jet flow flow field field decreases decreases as as the the inverse inverse square square of of the distance distance x from the source as measured along a streamline. function of streamline. The The number number density density also also varies varies from from streamline streamline to to streamline. streamline. The number density as a function position positionfrom from the thesonic sonicorifice orifice isis given given by by [6] [6] 918 (4) where x is the axial distance downstream of the orifice, 0 is the angle from the orifice centerline, D0 is the orifice diameter, and § is a constant based on the gas specific heat ratio and is 1.7 for CO2. The CO2 flow rates introduced into the facility ranged from 10 to 120 seem although pumping rate data was obtained for mass flows up to 24,750 seem. TABLE 1. Sticking coefficients of some common gases as a function of gas and surface temperature. [5] The radial fin system was instrumented with five temperature sensors to ensure that the panel system was at appropriate pumping temperatures. To determine the pressure at various locations inside the chamber, five BayardAlpert type ion gauges were used. The data presented is typically in terms of pressure differences as measured from the facility pressure without gas flow. In this study, CHAFF-IV ultimate pressures were typically below 1.5 x 10"6 Torr. One of the ion gauges was attached to a Patterson Probe allowing 360 degree rotation along the chamber length and a tunable distance from the side wall to the chamber centerline, r, as shown in Fig. 5. The angle a is measured from the probe centerline, and a = 0" indicates that the probe is pointing towards the cryogenic arrays. In order to accurately assess the data obtained by the Patterson probe, the flow near the probe orifice must be free molecular. Based on Eq. (4), the flow from the sonic orifice can be considered free molecular near the Patterson probe at flow rates below 100 seem. Much of the discussion for this research will be confined to flow rates in this range. A cryogenic flat panel pumping surface was also tested in the facility in an attempt to assess any pumping improvement afforded by the finned geometry. Figure 4(b) shows the experimental set up for the flat panel array. In this case, the sonic orifice was adjusted to a distance of 110.2 cm from the panel to maintain constant coverage (-90%) from the sonic orifice between the two tests. In both experiments, one of the two available 1.0 meter diameter diffusion pumps was used to pump incondensible gases in the facility. The effective pumping speed of the diffusion pump on CO2 gas was measured to be between 10,600 and 11,800 L/s with a theoretical maximum of about 20,000 L/s without conduction losses. MONTE CARLO NUMERCIAL MODELING A computational investigation was used to further understand the pumping characteristics of the radial fin array. The CHAFF-IV array has 112 similar wedge shaped sections. The computational domain involved only one wedge section for simplicity. Free molecule flow was assumed in the volume between the panels which allowed individual molecules trajectories to be followed. Pumping statistics were built from individual particle dynamics to represent the physical problem. Molecules were emitted from a point source on the centerline of the facility a distance of 79.6 cm from the front edge of the fin array. The particles were given randomly selected velocity components in the horizontal and vertical directions based on the distribution in Eq. (4). All surface interactions are treated as fully diffuse implying that the molecules accommodate to the surface temperature. The sticking coefficient can be updated based on the gas temperature and the presumed temperature of the wall from a database based on Table 1 for CO 2. Initially, the incident molecules can either strike the front thickness of the radial fin or enter the volume between two fins. The molecules are followed until they effectively stick to the panel or cross the front plane of the radial array in which case they are considered backscattered molecules. The sticking probability model is based on a Monte Carlo acceptance-rejection scheme. The initial sticking coefficient of 300 K carbon dioxide molecules on a liquid nitrogen cooled cryogenic surface is assumed to be 0.63. [5] 919 Thesurface surfacebehind behindthe theradial radialfin finarray arrayisismodeled modeledasasa aflat flatplate. plate.This Thissurface surfacecan caneither either cryogenically cooled The bebecryogenically cooled to represent a pumping surface or at room temperature to represent a chamber wall. Results were obtained using to represent a pumping surface or at room temperature to represent a chamber wall. Results were obtained using both configurations of the back wall. For future CHAFF-IV investigations, the radial fin temperature will be 10-15 both configurations of the back wall. For future CHAFF-IV investigations, the radial fin temperature will be 10-15 suppliedby byaagaseous gaseoushelium heliumcryostat, cryostat,and andthe theback backwall wallwill willbebeliquid liquidnitrogen nitrogencooled. cooled.Therefore, Therefore, this model KK supplied this model cancan be used to address future CHAFF-IV configurations without modification. be used to address future CHAFF-IV configurations without modification. a) a) b)b) r r x x 215.9 Sonic Orifice 299,7 Sonic Orifice Patterson PattersonProbe Probe Patterson PattersonProbe Probe FIGURE Radial FinFin Array, (b)(b) Flat Panel Array. FIGURE4.4. Experimental ExperimentalPosition PositionofofSonic SonicOrifice Orificeand andPatterson Pattersonprobe, probe.(a)(a) Radial Array. Flat Panel Array. a α==90° 90° Ion IonGauge Gauge r α = 0° x Cryopumping Cryopumping Arrays Arrays Probe ProbeOrifice Orifice -90° −90° FIGURE 5. Patterson Probe Geometry and Experimental Configuration. FIGURE 5. Patterson Probe Geometry and Experimental Configuration. 920 RESULTS RESULTS The results of the Monte Carlo simulations for the fraction of backscattered molecules from the radial fin array The results of the Monte Carlo simulations for the fraction of backscattered molecules from the radial fin array and the flat panel are shown in Fig. 6 as a function of sticking coefficient. The solid radial fin data line is for and the flat panel are shown in Fig. 6 as a function of sticking coefficient. The solid radial fin data line is for simulations with aa surface. surface. If If the the molecule molecule strikes strikes aa simulations which which update update the the sticking sticking coefficient coefficient for for each each interaction interaction with cryogenic surface and is not pumped, the sticking coefficient becomes unity if the molecule should hit another cryogenic surface and is not pumped, the sticking coefficient becomes unity if the molecule should hit another cooled surface. If the molecule strikes a chamber wall, the sticking coefficient is reset to the original orifice cooled surface. If the molecule strikes a chamber wall, the sticking coefficient is reset to the original orifice expansion value. The dashed data line is for a constant sticking coefficient throughout the simulation. The radial fin expansion value. The dashed data line is for a constant sticking coefficient throughout the simulation. The radial fin arrays outperform the simple flat panel for free molecule flow for sticking coefficients less than approximately 0.55. arrays outperform the simple flat panel for free molecule flow for sticking coefficients less than approximately 0.55. As Figure 66 shows shows the the utility utility of of the the As expected, expected, the the two two radial radial fin fin results results converge converge for for large large sticking sticking probabilities. probabilities. Figure radial fin arrays for the pumping of high energy propulsion system flows where the initial sticking coefficients are radial fin arrays for the pumping of high energy propulsion system flows where the initial sticking coefficients are expected to be extremely low. expected to be extremely low. i.o 1.0 Flat Pane! Flat Panel - Radial Radial Fin Fin -- Constant Constant Sticking Sticking Radial Fin Fin -- Updated Updated Sticking Sticking Radial 0.80 Pumping Efficiency 0.80 0.60 0.60 0.40 0.40 0.20 0.20 0.0 0 0.2 0.4 0.6 0.8 1 Sticking Coefficient Sticking Coefficient FIGURE as aa Function Function of of Sticking Sticking Coefficient. Coefficient. FIGURE 6. 6. Monte Monte Carlo Carlo Results Results for for Pumping Pumping Efficiency Efficiency as The opposite end end of of the the pumping pumping The measured measured pressure pressure in in the the sonic sonic orifice orifice backflow backflow region (i.e. measured at the opposite arrays) was used to determine the pumping rates for the radial fin array. As a function of mass flow, the calculated arrays) was used to determine the pumping flow, the calculated ˙ = 10 sccm) ˙ ==24,750 facility seem) and 2.6 x 10 1066 L/s L/s ((M 24,750 sccm). seem). facilitypumping pumping speed speed was was between between 0.65 (M (M M Figure of mass mass flow flow rate rateatatthe thecenter centerofofboth both Figure 77 shows shows the the pressure pressure measured measured at the Patterson probe as a function of pumping arrays (r = 0) and at the edge of the arrays (r = 98 cm). The general trend indicates that the radial fin array pumping arrays (r = 0) and at the edge the indicates that the radial fin array pumps seem on the chamber centerline. centerline. For For higher higher mass mass pumps more more efficiently efficiently for for mass mass flows flows up up to to approximately 60 sccm flow radial fins fins are are outperforming outperforming the the flat flat flow rates, rates, the the flat flat panel panel array array outperforms outperforms the radial fins. The fact that the radial panel below the expected expected value value of of panelindicates indicates that that the the effective effective sticking coefficient coefficient for the experimental results may be below 0.63 since the the array array temperature temperature was was measured measuredinin 0.63 (Table (Table 1) 1) based based on on the the Monte Monte Carlo simulations. This is possible since the theexperiment experimentto tobe bebetween between 81 81 and and 88 K. Above 60 60 seem, sccm, collisions collisions between between plume molecules and backscattered Above backscattered molecules molecules from from the the pumping pumping arrays arrays beginto tobecome become important. important. Molecular Molecular collisions act to return molecules to the arrayss begin arrayss that that are are not not initially initially pumped. pumped. For the the flat flat panel panel array, array, the the return return flux flux to to the the array is at a somewhat lower temperature For temperature having having interacted interacted with with the the pumping surface surface once once before before making making the the effective effective sticking coefficient higher as pumping as indicated indicated in in Table Table 1.1. For Forthe theradial radial finarray, array,the thereturn return flux flux once once again again passes passes through the fin geometry and interacts with the chamber fin chamber back back wall wall atat 300 300 K. The The molecules molecules partially partially accommodate accommodate to the chamber wall temperature K. temperature (depending (depending on on the the temperature temperature dependent accommodation accommodation coefficient); coefficient); thus, there is not a significant increase dependent increase in in the the effective effective sticking sticking coefficient coefficient for the the radial radial fin fin array. array. Since Since the the Monte Monte Carlo Carlo results assume a free molecule condition, for condition, this this effect effect would would not not be be reproduced in the model. A direct simulation Monte Carlo technique is required at higher flow rates. reproduced in the model. A direct required at higher flow rates. The fraction fraction of of impinging impinging flow flow on the pumping arrays which is backscattered The backscattered to to the the Patterson Patterson probe probeisisshown showninin Fig. 8. 8. The The ratio ratio is is obtained obtained by by dividing the measured Patterson probe pressure Fig. pressure at at αa == 0° 0° by by that that atat αa ==180° 180°(i.e. (i.e. pointed in in the the direction direction of of the the orifice orifice expansion). expansion). At 15 sccm, pointed seem, the backscattered fraction fraction from from the the radial radial fins fins isis approximately 0.052. 0.052. This This agrees agrees well well with a free free molecule backscattered fraction approximately fraction of of 0.055 0.055 derived derivedfrom from Eq. Eq.(3). (3). Figure 99 shows shows aa radial radial profile profile for for the the fin fin and and the the flat flat panel panel pumping pumping configurations Figure configurations for for aa mass mass flow flow of of 20 20 sccm. seem. This data data indicates indicates that that the the finned finned array array is is more more effective effective than This than aa flat flat panel, panel, and and in in some some cases, cases, the the pumping pumping ratio ratio reaches aa factor factor of of more more than than 4. 4. Similar Similar results results were were obtained reaches obtained for for flow flow rates rates up up to to approximately approximately 65 65sccm. seem. The Thedata data indicates relatively relatively high high backscattered backscattered flux flux from from the the center center of indicates of the the radial radial fins. fins. This This is is due due to to aa maximum maximum in in incident incident 921 flux on on the the centerline centerline from from the the sonic sonic orifice orifice expansion expansion and and aa lack lack of of pumping pumping surface surface in flux in the the center center of of the the finned finned array due due to to construction construction tolerances. tolerances. The The increase increase in in pressure pressure as as the the probe array probe radial radial position position increases increases (i.e. (i.e. tends tends towards the the edge edge of of the the fins) fins) can can be be caused caused by by several several factors. towards factors. First, First, the the width width of of the the radial radial fins fins increases increases as as aa function of of distance distance from from the the chamber chamber centerline. centerline. Second, Second, the the temperature temperature at at the the far far edge somewhat function edge of of the the fins fins is is somewhat warmer (~ (~ 6-10 6-10 K) K) than than that that near near the the center center of of the warmer the array array due due to to heat heat transfer transfer issues issues making making the the pumping pumping less less efficient. Finally, there is some fraction of the orifice mass flow that does not impinge directly on efficient. Finally, there is some fraction of the orifice mass flow that does not impinge directly on the the pumping pumping arrays due due to to the the high high angle angle gas gas expansion expansion that that can can act act to to increase increase the arrays the background background pressure pressure at at the the array array edge. edge. a) b) 2.0 a) 1.5 b) 2.0 ∆P (Torr x 106) o X 0.5 1.0 1.0 0.50 Radial Fins Flat Panel 0 0 20 20 40 40 60 60 80 80 100 100 Radial Fins Flat panel 120 120 0.0 0.0 40 60 40 60 Mass Flow (seem) Mass Flow (sccm) 20 0 20 Mass Flow (seem) Mass Flow (sccm) 80 80 FIGURE 7. 7. Patterson Patterson Probe Probe Change Change in in Pressure Pressure as as aa Function Function of of Mass Flow, (a) FIGURE Mass Flow. (a) rr = = 00 cm, cm, (b) (b) rr = = 98 98 cm. cm. 0.08 0.08 Pressure Probe Flux Ratio o £ £ £g PH | 5a 0.07 0.07 0.06 0.06 0.05 0.05 0.04 0.04 0.03 0.03 CO £ 0.02 0.02 - Radial Fins _ Radial Fins - Flat Panel Flat Panel 0.01 0.01 0 0 0 0 40 60 40 60 Mass Flow (seem) Mass Flow (sccm) 20 20 100 100 80 80 FIGURE 8. Fraction of Backscattered Molecules from Pumping Arrays as a Function of Mass Flow. FIGURE 8. Fraction of Backscattered Molecules from Pumping Arrays as a Function of Mass Flow. 2.5 2.0 ∆P (Torr x 106) ∆P (Torr x 106) 1.5 1.5 1 I 1.5 1.0 53 0.50 0.50 0.0 0 Flat Panel Radial Fins 20 20 40 60 40 60 Radial Distance (cm) Radial Distance (cm) 80 80 100 100 FIGURE 9. Patterson Probe Change in Pressure as a Function of Radial Position for a Flow Rate of 20 SCCM. FIGURE 9. Patterson Probe Change in Pressure as a Function of Radial Position for a Flow Rate of 20 SCCM. 922 100 100 Figure of the the Patterson Patterson probe probedata dataatatvarious variousfinned finnedarray arrayradial radialpositions positionsforfora a Figure 10 10 shows shows the the angular angular variation variation of mass the pressure pressure isis minimized minimized for foran anangle angleofofαa ==0˚0°where wherethe theprobe probeisispointed pointed mass flow flow of of 20 20 seem. sccm. As As expected, expected, the directly There is is very very little little angular angular dependence dependenceofofthe thebackscattered backscatteredmolecule moleculepopulation population directly atat the the pumping pumping surfaces. There for the edge edge of of the the finned finned array. array. At Atthis thislocation, location,the thepumping pumpingisisknown knowntotobebeless less foraaposition position of of 98 98 cm cm which which is is near near the efficient efficientas as discussed discussed previously. previously. 1 0.8 ∆P (Torr x 106) € X 0.6 V 13 - -cr" 0.4 -e—r r= =9898cmcm - B- r- = r =57.5 57.5cmcm -n- r- r= =0 0cm cm 0.2 0.2 00 -100 -100 -50 -50 00 5050 ' 100 100 Angle Angle(degrees) (degrees) FIGURE 10. 10. Patterson Patterson Probe Probe Data Data as 2020 SCCM. FIGURE as aa Function Function of of Sampling SamplingAngle AngleatatSeveral SeveralRadial RadialPositions PositionsforforFlow FlowRate Rateofof SCCM. CONCLUSIONS CONCLUSIONS Numerical and and experimental experimental comparison Numerical comparison of of the the pumping pumping efficiencies efficiencies ofofthe theradial radialfinfinarray arraywith witha asimple simpleflatflat panel array indicates that the radial fins are more efficient for free molecular flows (i.e. mass flows less than 60 panel array indicates that the radial fins are more efficient for free molecular flows (i.e. mass flows less than 60 sccm on the chamber centerline). The radial fins consistently outperform the flat panel at off-axis positions (i.e. r > seem on the chamber centerline). The radial fins consistently outperform the flat panel at off-axis positions (i.e. r > 0) for the range of experimental mass flows investigated in this study. It is expected that the radial fin array will 0) for the range of experimental mass flows investigated in this study. It is expected that the radial fin array will significantly outperform a flat panel array for thruster efflux at elevated temperatures and for energetic ion flows. significantly outperform a flat panel array for thruster efflux at elevated temperatures and for energetic ion flows. For neutral gas at elevated temperature and energetic ion flows, the radial fin array backed by a LN2 shield For neutral gas at elevated temperature and energetic ion flows, the radial fin array backed by a LN2 shield should perform optimally. The sticking coefficient increases for a given surface temperature as the gas temperature should perform optimally. Thefin sticking for by a given temperature as the gas temperature decreases. When the radial array coefficient is at 15-20increases K backed a LNsurface 2 shroud, the energetic molecules will decreases. When the radial fin array is at 15-20 K backed by a LN shroud, the surface energeticwith molecules will 2 accommodate (at least partially) to the 77 K surface. After scattering from the LN a velocity 2 accommodate (at least partially) to the 77 K surface. After scattering from the LN surface with a velocity 2 distribution function characteristic of the surface temperature, the effective sticking coefficient on the radial array distribution function the surface temperature, the effective sticking coefficient on the radial array will be lower therebycharacteristic increasing theof pumping efficiency. will The be lower thereby increasing the pumping efficiency. pumping rate for the radial fin array ranges from approximately 0.65 to 2.6 x 106 6L/sec depending on the The pumping forexperimental the radial finconfiguration array rangesutilized from approximately 10 L/sec depending source mass flow.rateThe approximately0.65 5.6%toof2.6thex total CHAFF-IV radialonfinthe source Thethat experimental configuration utilized1.0 approximately the total CHAFF-IV radial array. mass This flow. indicates pumping rates of approximately to 4.5 x 107 75.6% L/sec of should be possible for cold gasfin array. Thisthe indicates that pumping of approximately 1.0 pumping to 4.5 x rates 10 L/sec should be for cold gas flows with entire facility pumpingrates configuration active. The for energetic ionspossible are expected to be flows with the entire facility pumping configuration active. The pumping rates for energetic ions are expected to similar. Although the rate should increase due to the flux energy to the pumping surface, pumping efficiencybe similar. the due ratetoshould increaseofdue to the gases flux energy to the pumping surface, pumping efficiency decreasesAlthough are expected the sputtering condensed and facility material (graphite protective layers). decreases are expected due to the sputtering of condensed gases and facility material (graphite protective layers). REFERENCES REFERENCES 1. Ketsdever, A., “An Overview of Ground Based Spacecraft-Thruster Interaction Studies: Facility Design Issues,” AIAA paper th 2000-0463,A., 38"An Aerospace Sciences Meeting, Reno, NV, 2000. 1. Ketsdever, Overview of Ground Based Spacecraft-Thruster Interaction Studies: Facility Design Issues," AIAA paper th 2. 2000-0463, Lutfy, F., Vargo, S., Muntz,Sciences E.P., Ketsdever, “TheNV, David P. Weaver Collaborative Flow Facility’s CHAFF-IV for Studies 38 Aerospace Meeting,A., Reno, 2000. of Spacecraft Propulsion and Contamination,” AIAAP.paper 98-3654, 34th JointFlow Propulsion Conference, 2. Lutfy, R, Vargo, S., Muntz,Plumes E.P., Ketsdever, A., "The David Weaver Collaborative Facility's CHAFF-IVCleveland, for Studies 1998. Propulsion Plumes and Contamination," AIAA paper 98-3654, 34th Joint Propulsion Conference, Cleveland, ofOH, Spacecraft 3. Dettleff, G., Plahn, K., “Initial Experimental Results form the New DLR-High Vacuum Plume Test Facility STG,” AIAA OH, 1998. paper 97-3297, 1997. 3. Dettleff, G., Plahn, K., "Initial Experimental Results form the New DLR-High Vacuum Plume Test Facility STG," AIAA 4. Stephens, J.B., “Space paper 97-3297, 1997. Molecular Sink Simulator Facility Design,” NASA TR-32-901, 1966. Welch, K.,J.B., Capture Pumping Technology, Pergamon Press,Design," 1991. NASA TR-32-901, 1966. 4.5.Stephens, "Space Molecular Sink Simulator Facility Ashkenasn, H., Sherman, “StructurePergamon and Utilization of Supersonic Free Jets in Low Density Wind Tunnels,” in 4th 5.6.Welch, K., Capture PumpingF.S., Technology, Press, 1991. International Symposium on Rarefied Gas Dynamics, ed. J. Academic Press,inNew 1966,Wind pp. 84. 6. Ashkenasn, H., Sherman, F.S., "Structure and Utilization de of Leeuw, Supersonic Free Jets LowYork, Density Tunnels," in 4th International Symposium on Rarefied Gas Dynamics, ed. J. de Leeuw, Academic Press, New York, 1966, pp. 84. 923