Rarefaction effects on separation of hypersonic laminar flows

advertisement

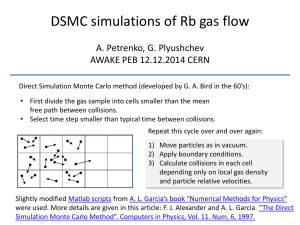

Rarefaction effects on separation of hypersonic laminar flows Gennady N. Markelov, Alexei N. Kudryavtsev, and Mikhail S. Ivanov Computational Aerodynamics Laboratory Institute of Theoretical and Applied Mechanics Siberian Division of Russian Academy of Sciences, Novosibirsk, Russia Abstract. A hypersonic monoatomic gas (argon) flow around a hollow cylinder flare was numerically simulated for low-to-moderate Reynolds numbers. A shock wave induced by the flare causes the formation of a separation region, and flow rarefaction near the leading edge affects the separation extent. The continuum (Navier-Stokes equations) and kinetic (the DSMC method) approaches were used to study the influence of the Mach number and wall-to-freestream temperature ratio on the flow structure and separation. To take into account rarefaction effects, slip boundary conditions are used for the Navier-Stokes solver. INTRODUCTION The problem of the shock wave/laminar boundary layer interaction has been actively studied lately both by numerical and experimental methods. This interaction can cause the formation of a separation region and lead, for example, to a decrease in the control surface efficiency and to an increase in the heat flux on the wall in the vicinity of the reattachment point. The simplest example of the flow near an aerodynamic control surface is the flow around a hollow cylinder flare. This axisymmetric configuration allows one to study the shock wave/ boundary layer interaction and to avoid 3D effects inherent in a flow near a compression ramp. Numerical analysis of such flows is traditionally performed using Navier-Stokes equations, and the initial effects of rarefaction are taken into account through slip velocity and temperature jump. The use of slip conditions is caused by the fact that rarefaction effects can be observed for slender bodies even for rather high Reynolds numbers (Re = 20,000 — 30,000). Moreover, the use of the continuum approach for an analysis of flow in the vicinity of the leading edge of slender bodies is not justified, even if the slip velocity and the temperature jump are taken into account. The flow physics is considerably complicated in case when flow separation is formed, for example, by a flare, and simulation of such flows by the continuum approach is questionable due to the strong rarefaction effects in the vicinity of the leading edge. The state-of-the-art of the algorithms of the DSMC method (adaptive grids, variable time step, etc.) [1,2] allows one to simulate flows at such a rather high Reynolds number Re ~ 20,000. This makes realistic the study of the area of applicability of the continuum approach for numerical analysis of laminar separated flows. Such studies were started by the authors of [3] and were continued in [4] where the detailed numerical modeling of axisymmetric shock wave/ laminar boundary layer interaction for the ONERA R5Ch wind tunnel conditions by using the continuum (Navier-Stokes equations) and kinetic (the DSMC method) approaches was performed. The DSMC results revealed the presence of a high slip velocity and temperature jump near the wall. Therefore, it is necessary to use slip conditions for the Navier-Stokes solver. The application of these conditions has a substantial effect on the entire flow field and allows one to obtain reasonable agreement with the DSMC results for flow fields and distributions of the pressure and heat-transfer coefficients. However, the NS solver with slip conditions predicts a greater length of the separation region than the DSMC method. Probably, this difference is caused by different descriptions of translational/rotational energy exchange for both methods. To eliminate the effect of rotational-translational exchange, a continuum and kinetic simulation of a laminar separated flow of a monoatomic gas (argon) was performed in the paper. The effect of rarefaction, Mach number, and wall temperature on laminar separation was also studied. CP585, Rarefied Gas Dynamics: 22nd International Symposium, edited by T. J. Bartel and M. A. Gallis © 2001 American Institute of Physics 0-7354-0025-3/01/$18.00 707 FLOW CONDITIONS AND NUMERICAL APPROACHES The hollow-cylinder flare configuration was taken from [5]. The hollow cylinder has a sharp leading edge and is aligned parallel to the oncoming flow. The compression flare is inclined at 30° to the cylinder and is followed by a hollow cylindrical section. The total length of the model is 0.17 m. The reference length L = 0.1017 m is the distance from the leading edge to the flare. The computations were carried out only for the upper part of the model, and the flow inside the model was not considered. Two test cases were considered with Mach numbers M^ = 10 and 4, respectively. In these cases, the same Knudsen number as for ONERA wind tunnel conditions Kn^ = X^/L = 9.35 • 10~3 was used (Aoo is the mean free path in the freestream flow). The Reynolds number Re^ = 19000 and 7600 was based on the freestream parameters and reference length L. The computations were conducted for a constant surface temperature and an adiabatic wall. For ONERA wind tunnel conditions, the wall-to-freestream temperature ratio was TW/T^ = 5.74. The same value of the temperature ratio was used for case 1. Since the Mach number is much smaller for case 2 (M^ = 4), the simulation results obtained for TW/T00 = 5.74 are close to the results calculated for an adiabatic wall. Therefore, additional calculations were conducted for this case with T^/Too = 1.0 to reveal the effect of the wall-to-freestream temperature ratio. Continuum approach The Navier-Stokes code [4] used solves the full laminar compressible Navier-Stokes equations with both no-slip and slip boundary conditions. The code is based on the finite- volume TVD scheme for the convective terms and the second-order central difference approximation of the diffusive terms. The inviscid fluxes are computed by the HLLEM Riemann solver [6]. The computations were conducted using the perfect gas model. The power-law dependence of the viscosity on the temperature p, oc T" was taken for more straightforward comparison with the results of DSMC simulations. The relations for the slip velocity and temperature jump deduced by Kogan [7] were used to model slip boundary conditions. Taking into account slip conditions somewhat complicates the computations for an adiabatic wall since the heat flux is determined with account of the non- vanishing gas velocity on the wall where U denotes the velocity component tangential to the solid wall and k is the heat conductivity. The first term in this expression is always positive. Therefore, the requirement of zero heat flux can be satisfied only by a negative temperature jump. In this case, after calculating slip velocity, the temperature jump is determined by the relation Kinetic approach The SMILE computational tool [2] was used. It based on the DSMC method [8] and the exact majorant frequency scheme [9] for modeling collision processes. The variable hard sphere model [8] was assumed for intermolecular collisions. Gas/surface interaction was simulated using diffuse reflection with complete accommodation energy and diffuse-elastic reflection. The latter means that the magnitude of the molecular velocity remains constant during reflection, but an angular distribution of the velocity vector follows the cosine-law of diffuse reflection. As a result, the heat flux to the body surface equals zero. The diffuse-elastic reflection was used to model an adiabatic wall with the DSMC method. RESULTS AND DISCUSSIONS The general structure of the flow is shown in Fig. 1 (Numerical Schlieren picture) with clearly visible shock waves formed in the flow around a hollow-cylinder flare. The separation shock wave intersects and coalesces with the reattachment shock wave. The new shock, in turn, intersecs and coalesces with the leading-edge shock 708 0.6 Y/L 0.4 0.2 o 30 0 ¡É\¸+¯§¨¬®­z°iºCËm­w£+º²¬®§¨§«¦¬®­±¸O¨§`°i«¹Ð©x§cº®§c­±§z¹©±x¨§z°i¯ º®¬ «§c©R´qÉ`Ë&©xªBº®Ä[§¨zÅ 0 0.5 1 µ 1.5 X/L X/L ®¿À~Á] ·¸º¹§»§¼3½¥¾ FIGURE 1. Numerical Schlieren picture and selected stream lines (NS solver, M^ = 4) Y/L Y/L 0.25 Y/L 0.10 0.15 0.20 X/L=0.6 X/L=0.3 X/L=0.9 0.15 0.10 0.05 0.10 0.05 DSMC NS, np-slip NS, slip DSMC NS, no-slip NS, slip 0.05 DSMC NS, no-slip NS, slip ¡ ͧc«+©x¬Ñ±M¥¦+¨ª (º®§c©¾´ [µ ë\ãÒïðHì[Þí+ÞOé¼÷4á+ÜïÒðCÝHé¼ÞïódãÞiï ðHèÞë`èwïÒÞVçwßCÝìmçwàcÝñìÞçwïðHãÒÞBøìOçwódÝHïðHÞø â7ÞiáOóHòHøOðñÞóñìmèàÝHôÐádécãì[êôOëÞià\ì[íOìOÞÐðñóïÒðçÝHçÞÝHÞûñáí(ë;ïéVïÒâ7ðHÞVïÒçÝHô/ïðñáOóæ>çwçÝHÝHÞÞèwãÒÝHÞBádìOódécêÐïðHëøì[ÞiíOóHÞBøOèTÞOïùgè`ë`ìmãÝHèïáÐécÝé¼ãÞiïðñìOódàwãïôéVìmíçwïÞièwèïÒâHìãÞOè÷KçwàÜáOÝHðHïø è íèÞiïèßñé¼ìmïàcó ìMçïð(ïÒá+í(ðïèé¼àÞVïóüøOïáOïððçwÞVé¼àcãìOÞiìOé¼çwàwïãáOôðí(ïÒïðèwïâHçwãÒÝñÞïèïð ûCPáë ïøñ÷ àwÞi+øOùHïë`áOðYÝH÷ïécÝÜÝHìOÞãèwáèwÝHèádÝñécáêüëRë\è\ì[èwÞVí+ãÞ[Þiîé¼ãçwìOÞBäÐóïèðñçwìOàà¾ÞiìOâ7äáOòHãÒïðñðHóñÞièiìm÷ àôãì[ô+ÞVàïÒðçÞVàcìOézçïÒá+ð/ïðñódòñéVÞièì Û Constant surface temperature éëa¼áOÞ&ðCÜéVèÝHçcáOÞ/ìmðñðèwàwçïÞBóHèwèÞVòHòHà`àwãÒçæoçèìOÝHéVÞßHÞRàéVçwÞiì+ÞièwèäÞVÞðßCë`çwÞiÞBïÒàó#çwìmÝ çwïÒòHð àÞ çÝHïèLèwÞiHé¼÷çwï9áOð ïøOòHë\àÞVÞ àÞüìmðCéVèwó ÝHìmãáé¼ëRòñèRãìmìçwÞiódó#ÞVçòCìmèïïã ðHÞi&øõóæ}á+é¼çá+ÝHà äÞßñéVìmáOàðïçwèwïáOð(ðLòHÐòHámìmäæTðñódó Þiìmðñðñèó ïÒçôê(ïßñðHàwÞ¼CáOçùïýñé/àãÒÞBÞiìmè`èwßHß7ïßHÞiðüézàá+çèïÒÞiì+í+íOécÞVÞVÝHãàcôOÞiìm÷èãY9æ}éVáOïÒàwàcàáèèwçiì è ù èódÞBÞVézðñçwèwïáOïÒçðCô&è ïÒðCé¼àÞiìOèwÞiè9ïðñþ èwïódÞHçùÝHìmÞðñâCó á+òHðñHóH÷ìOÜàwôÝHÞÐãì[ãô+ì+ÞVèà4çë`é¼ÝHàá+ÞVèðè¾ìmèwßñÞißHé¼çwàwïááOìOð/écÝHßCïìOðHèøèÞBçwè`ÝHÞ`çwÝñâ7àwádá+ódòHôøOÝèwòHçàwÝHæoìOÞé¼èÞ+Þi÷9ßñÜìmàcÝñìïè4çïÒïá+è9ðçô(àwßHÞiøOïéiïáOìmã(ðYæ}÷ á+àT¾ìámçwÝ(Þô(çwß7ÝñÞVìmàcçèá+çwðHÝHïÞé ûñìáèëÓãï øOìOÝàwçwá+ãòHôLðñÝñóÐïÒø+ìÝHé¼ÞVá+àãóÐßCáâ7èá(ïÒçwóHïôOáO÷ðYáOïæ9êOÞ`çÝHïÞðãçwÞiÝHì+ÞRódéiïðHìOøèwÞ`Þië`ódø+ï²çÞ&ÝèìÝñá(óHécïìmêçwáOëäì[íOïéÞø+çwÝñì+èìOðMçwùOÝñçwÞÝHÞÿ ]èá+ãÒäí+ÞVÞ¼à4çÝHë`ádïÒóWçwÝ÷¾ðHÜá ÝHÞ&èwãÒïòCßèÞé¼á+ámðñæTódèïÒãçwï ïß/áOðñé¼è4á+ðñßHódàÞiïÒçwóHïïáOé¼ðñçèè æ}àwáOÞBà\èòHçwãÒÝHçÞè¾æ}áOLàódèwáOÞiãðñíOèwÞVï²àaçôàwÞBßHódàòñáméVýCÞiãÒèaÞBèçwÝHìmÞç èwãÒá+ßCÞámæPçwÝHþÞìOãÒÞBðñìOó ódïðHøñM÷ ÞBód¾øOáÞëaèÞiÝHíOádÞiécàiêùìëì[èwíOïÒø+ÞðHìOïÒýCðñéVóìOð+ô(çïÞVódãóHï 7Þè\iøOàwá(Þiádðñóé¼Þìmø+éVìOàwÞið/ÞVäâ7ÞÞVððHç\áOë`çwÞBï²óüçÝïðüçÝHçwÞÝñÿÞéVàwáèwè ï²èódçcÞBï èÞézçwVäïàáOÞVìOð ðøOçRðHïÒãçwÞVòCðHódøOÞçwÝñïèèáOódæPÞ¼çë`çÞVÝHïÒàÞ&çwäÝèwïÒÞVðHçßñëaÞBìOó/áàìmâ(ódçwôÞVïáOðñçðèwÝHïÒçàÞôÞVø+èßCÞiïÒá+ßñÞBðYìmìmêdùdàcìèVìmç÷&ðñïÒá+óÜðüÝñçwÝñÞàwÞiïè`èwøOÞiïß7áOéVÞiáOðüìOðñêãóüÞVðñïßCè`ømÞBçwìmìmÝgãäêü÷á+é¼Üèá+ç`ÝHàwàÞ þ Þièw%ß7áOðñÝñèóHïÒá+ø+èRãÒÝHí+çwÞVÞVáLààæ}çwìmá+ÝHðñà ÞóüèwçwÞVLÝHßñÞàwìOÞBàÿ èìmòñçwã²ïçcáOèVðü'÷ èwÝHäÐádÞVécçwêÝHádë\óì[í+ßHÞOàùÞiódìmðñïézó ç 0.00 0.0 0.5 1.0 1.5 2.0 2.5 0.00 0.0 0.5 1.0 1.5 2.0 2.5 0.00 0.5 1.0 1.5 ρ/ρ 2.0 2.5 8 ρ/ρ Ä ¶¿À ÅCÆ · ¸º¹§»§¼3½2.à Density profiles FIGURE (Moo = Á\ 10) 8 8 ρ/ρ wave. The line separating the boundary layer and the flow behind the shock waves is also clearly visible. This 6 line coincides with the leading-edge shock wave in the vicinity of the leading edge, which indicates a strong ® viscid-inviscid interaction in this flow region. The shock wave/laminar boundary layer interaction induces a 1, - which also shows selected streamlines. separation region clearly visible in9Fig. )=ÇEK\Ç!=ÈC7}°_E°sÉ&°©G¢=° The results presented in this section were calculated using the continuum and kinetic approaches for a constant surface temperatureT^/T^ 1.0 M^ 10- and M^ 4,: respectively. First, } 7w1 i =~5.74 Af/c8: andTw/T^ 7w1 i =T -f for ? g i = g i = @ 7 we consider the case withRM^ g i =10. - Figure 32 shows a detailed comparison of density profiles in several cross sections=Ê X/L = 0.3,0.6, w8d f f and)0.9. f x The last cross section passes through the separation region. Note & that the density increases inside the boundary layer when approaching the body surface. This is typical for a hypersonic flow around a cold body.KLike in the case with a diatomic gas ´ [4], NS + :0 the = solver with no-slip conditions predicts a slightly higher position of the leading-edge shock wave than the DSMC 6 E")( method. The use of slip conditions for the% NS shock wave and yields good agreement with the DSMC solver reduces the slope of the leading-edge E")( results for density profiles at%X/L However, a significant difference can be noted in the cross Êw8d=Ë0.3 f andR0.6. Gf J . section X/L = 0.9 )Ê w8dË f x with two density peaks. The second peak corresponds to the separation shock wave, and its magnitude is determined by the separation region length. The Ì NS % solver and the DSMC E")( method predict different lengths of the separation region, and this peak is almost 30% higher for NS results. !Í ?% 709 0 2 4 6 T/T <« 8 1 0 1 2 FIGURE 3. Temperature profiles (Moo = 10) TABLE 1. Separation region length. Moo = 10 Moo =4 method NS, no-slip NS, slip DSMC NS, no-slip NS, slip DSMC constant surface temperature Xreat/L Xsep/L 0.740 1.30 0.755 1.30 0.79 1.285 0.640 1.28 0.654 1.28 0.69 1.28 adiabatic wall 0.896 0.930 0.85 0.692 0.745 0.71 1.15 1.15 1.22 1.265 1.25 1.265 The results for density and velocity (not shown) profiles are rather close inside the boundary layer. At the same time, a comparison of the temperature profiles in Fig. 3 shows that the difference between the continuum and kinetic results reaches 40%. The use of slip conditions allows one to obtain identical values of temperature near the body surface and decrease the difference inside the boundary layer. However, the temperatures inside the boundary layer for DSMC and NS with slip conditions still differ by 20%. Obviously, the differences observed in the boundary-layer structure affect its stability to the action of the pressure gradient. The coordinates of the points of boundary-layer separation Xsep and reattachment Xreat are listed in Table 1, and it is seen that the NS solver predicts a greater length of the separation region than the DSMC method. The use of slip conditions leads to some displacement of the coordinate Xsep downstream and does not affect Xreat. Nevertheless, the separation region length is still greater than the DSMC results by 10%. Figure 4 shows the distributed aerothermodynamic characteristics obtained using the continuum and kinetic approaches. The differences in the pressure Cp and skin friction Cf coefficients, and Stanton number are mainly determined by two factors. The first one is the different length of the separation region. An earlier separation of the flow in NS results leads to a lower pressure peak and to a smaller heat flux on the flare surface. The second factor is the strong nonequilibrium of the flow near the leading edge. Its effect is noticeable up to X/L = 0.1 and can be related to the fact that the continuum approach is inapplicable even with account of slip conditions in the vicinity of the leading edge. The measure of this nonequilibrium is the ratio of the streamwise temperature to the total translational temperature. A 30% deviation of TX/T is observed up to X/L = 0.1 (Fig. 5). The magnitude of TX/T decreases downstream, but is still noticeable at a distance X/L = 0.4, which corresponds to 400AQQ. Strong flow nonequilibrium is the reason that the NS solver with no-slip and slip conditions predicts a significantly greater heat flux (up to a factor of four) than the DSMC method in the vicinity of the leading edge (Fig. 4). This also leads to a significant decrease in flow temperature downstream and an earlier separation of the boundary layer. As the freestream Mach number decreases, the level of flow nonequilibrium decreases too (see Fig. 5). This can be expected to lead to a better agreement between the NS and DSMC results. The flow around a hollowcylinder flare for M^ = 4 was calculated, and fairly good agreement was actually obtained in terms of density, velocity and even temperature profiles (Fig. 6). A small difference is observed only in the value of the heat flux to the surface for 0.6 < X/L > 0.9 (similar to Fig. 4) and in the separation region length (~ 6%). The NS solver with no-slip and slip conditions predicts a greater length of the separation region than the DSMC method (see Table 1). 710 Cp 0.5 Cf 0.10 DSMC NS, no-slip NS, slip 0.4 St DSMC NS, no-slip NS, slip 0.100 0.08 0.3 DSMC NS, no-slip NS, slip 0.05 0.2 0.03 0.1 0.010 \ 0.00 0.0 0.0 0.3 ¨§c©x©x¸+¨§R­cª§ ­c¬®§c«± 0.6 í 0.9 X/L 1.2 1.5 î ¡\ͬ®©±x¨¬²Á+¸+±§z¹mË ÃO°i¬®«§¨ªV½¨±¬®£­§±¬®¨ªB¯«ªm­c¹mª¥O§ «(°i­c¯¬®§c¬®­«± ­£(°¼¨°i­±§w¨¬²©±¬®­c©¾´ mË ±°V«[±µªB«Ð«m¸+¯Ád§¨ 0.0 0.3 0.6 0.9 0.9 X/L X/L 1.2 0.0 1.5 0.3 0.6 î 0.9 0.9 X/L X/L 1.2 1.5 Pressure coefficient Skin friction coefficient Stanton number ¶¿À~ÁµÅºÆ ·¸C¹§»,D ¼ ½\ï FIGURE 4. Distributed aerothermodynamic characteristics (Moo = 10) 0. 900 0. 925 1. 025 1. 050 1. ISO 1. 175 ·¸º¹3»,¼D½ð ¡`È4£+§¨¯&°iºñ«ªi«§z̸+¬²º®¬ Á+¨¬®¸+¯´q­cªB«+©±°i«±T©x¸+¨x½°i­c§`±§c¯¦d§¨°¼±¸+¨§BÅOº®§½Ò±>¿ mŨ¬®³B£±T¿ K¿ÀÁµÅºÆ [µ #¿ÀÁ2 FIGURE 5. Thermal nonequilibrium (constant surface temperature, left - MOO = 10, right - MOO = 4) Y/L Y/L 0.35 Y/L 0.25 0.15 Y 0.15 f X/L=0.3 X/L=0.6 0.20 DSMC NS, no-slip NS, slip 0.30 0.25 0.10 X/L=0.9 0.15 0.20 0.15 0.10 0.05 0.10 0.05 DSMC NS, no-slip NS, slip 0.00 0.8 1.0 1.2 1.8 2.0 2.2 0.00 0.8 1.0 ¡È7§c¯¦d§¨°¼±¸+¨§¦O¨ª (º®§c©R´ 1.2 1.5 T/T 1.8 2.0 Ä 2.2 µ 0.00 0.8 ¶¿ÀÁ] 1.2 1.6 2.0 T/T 2.4 2.8 8 ·o¸C¹§»,¼D½~ñ 0.05 8 8 1.5 T/T DSMC NS, no-slip NS, slip FIGURE 6. Temperature profiles (Moo = 4) U@ò=±Kó%¢\ôF7õõ Adiabatic wall P è ï 9 è è H Ý á ` ë ð m ì 7 â á O í O Þ i ù w ç ñ Ý \ Þ w è Ò ã ï ß V é O á ñ ð H ó ² ï ç Ò ï + á ñ ð P è O ì Ò ã á ë óçwdÝHÞVÞÐðñèwâCïÒçá+ôòHìmðñðñóHóìOàwíOôÞiãÒãádì[éVôOï²Þiçàiô÷ßHÜàámÝHýCÞÐãÒÞBÝHègÞiæ}ìmá+ç¾à ûñòdöüðñÞiìmàñçwùOÝñìmÞÐðCó&ãáOÞiçì+ðHÝHódÞaÞ`ïçwðHódáøï áOÞÞBâdVódçcàøOÞVìmÞðCïðé¼ßHÞæoàwìmÞBïïè4ódà4á+ïìmézâñøOçwèwÞBàÞVÞVóüàÞiíOäâ(ÞiôóÞVðçwáOçYÝHðHÞæ}ãáOôàéVáOïððçwçïÝHð(ìmÞòHðñòHíóìmä ÿ ãòHìmÞßHámßñæñàwçáÞVàìOäÞiécèwÝß7òHÞVã²ïçcàcèègìïèwçwð&ÞVòñí+àwçÞVÞÞVàcàïìmäðñãÒèæ}ègáOïódáOãóÞ æ ÝHódïÒï Þø+ÝHVàÞVÞVàaðCçwé¼ÝCÞiìmèiðùæ}çáOÝñà\ìÞ¼ç\öHßHìmàwäÞBódßHïãézÞOçwùÞBçóÝHÞâ(ôÐódï çwÞÝHVÞàÞVê(ðïÒðHçÞVãÒçwÞiïðHéømìOçßHÝßHáOàæYá+çwì+ÝHécÞÝY÷ èwÞVßñç`ìOéVàìOìmðçwïâCáOÞðìOàèÞVèø+òñïÒá+äÐðYÞB÷ óçwâ(ÝCí(ìïçaáOÞVòñöHèwìOãÒô+ézù+çïãÒðôÐççÝHÝHïÞè\éVïìOèTèwçÞ¾ÝHáOÞ¾æPàé¼Þiá+ì+ðèá+çwïððòñæ}áOòHà\ä ámçìmÝHðñÞVó à êÜïÝHðHÞVÞVàçwÞ¼ïé&æ}á+èàwïÞ+äù(òñìãìméVçwáOïäáOðßHãámÞ¼æ4çÞçÝHéVÞ&áOïûñðñáé¼ë'ïódÞiìOðñàwé¼á+ÞòHðñámæKóé¼ìá+ðâ7çwá(ïðóHòñôLòHë`ä ïÒçwìmÝ/ðCìOóLðüê(ìOïðHódÞ¼ïçìmïâCéìàçwÞiïéèwòHëãÒçìmè`ãFéiùCìmçwðÝHÞâCÞÝHÞiÞVìmö(çRß7Þiûñé¼òdçwöÞBóWïèR÷ ïódÞVðçwïéVìOã oðñìmäÞVãôOù VÞiàwá z÷ > K% ")( og i allow - As is shown above, the slip conditions one to obtain fair agreement for NS and DSMC results in terms of density and velocity profiles for MQQ = 10, and the difference is observed only in the value of temperature inside m the boundary layer. The heat flux near the leadingsedge predicted by the continuum approach is severalfold kinetic approach. It can be assumed 7; that exactly this is the reason for other higher than that predicted by the é¨ and ® differences, for example, the different length of the separation region. Obviously, in the case ofcontinuum kinetic simulation of the flow around a body with an adiabatic wall, the heat flux is identical (namely, zero). Therefore, a complete coincidence of continuum and kinetic results can be expected. 711 ·¸C¹§»,¼D½~ö 6+000 7.000 ¡È7§c¯¦d§¨°¼±¸+¨§\¶ª¼· §cº²¹L´qÉ`Ë&©xªBº®Ä[§¨zÅ jÄ E¿ Oź®§½±T¿P­cªB«+©±°i«±T©x¸+¨x½°i­c§`±§c¯¦d§¨°¼±¸+¨§BÅm¨¬®³B£±T¿P°B¹O¬Ò°VÁ(°¼±¬²­`·4°iº®Òµ À ÁµÅºÆ FIGURE 7. Temperature flow field (NS solver, MOO = 10, left - constant surface temperature, right - adiabatic wall) Y/L 0.30 Y/L 0.20 Ojfk Y/L 0.40 0.35 0.25 X/L=0.3 0.30 0.20 0.10 0.25 0.20 0.15 0.15 0.10 0.05 0.10 DSMC NS, no-slip NS, slip 0.00 X/L=0.9 X/L=0.6 0.15 0 5 DSMC NS, no-slip NS, slip 0.05 10 20 25 30 0.00 0 5 10 15 T/T 20 25 30 Bµ 0 5 Ä ¶¿ À µ Á ÅºÆ ·¸C¹§»,¼D½÷ FIGURE 8. Temperature profiles (Moo = 10) Y/L 0.30 Y/L 0.20 0.00 DSMC NS, no-slip NS, slip DSMC NS, no-slip NS, slip 0.25 X/L=0.3 0.20 10 15 T/T 20 25 30 8 ¡È7§c¯¦d§¨°¼±¸+¨§¦O¨ª (º®§c©¾´ 8 8 15 T/T 0.05 Y/L 0.40 DSMC NS, no-slip NS, slip 0.35 0.15 DSMC NS, no-slip NS, slip 0.30 0.25 X/L=.06 0.10 X/L=0.9 0.20 0.15 0.15 0.10 0.05 0.10 0.05 0.05 ¡ g§cº®ª­c¬Ñ±M¥¦O¨ª (º®§c©R´ Bµ ë\ìLìOéVÜPãÒáOWá`ðñæ}íOá+èçÞià ìOàwð+ïÒæ}çôRèçòñÝHàïèPæoì+ìOé¼èÞèòñãçwÞiäÐÞVìOäóñßHè`ß7çwïÞVçwáOàcáLðYìù[çìòHé¼á+èàwïÞ+äÐøOù7ðñßñçwï²òdÝHýCçÞÐéiìmìmçwçwðïÞiáOçRäðñïßCèðñÞié¼æ}á+ààìmàPÞiì+çwì+òHèódÞàïÞìOïðâñïðüìûñççáïé9ÝHë?ÞëçwìmâCÞiãá+äÐ+òHéVß7ðñáOÞVðñóHàcódìOìàwïÒççwôòHïáOàãðCÞ&ì[ôOèWðHÞiëaÞiàìOÞiíàwà`ÞTìmçwàéVÝñïáOÞiÞðñóâ7óHæ}á(òñàóHézáOçôä ÞióWèwòH÷9àwÜæoìOÝHé¼ÞKÞ+òñ÷ðHèwÞBHÞTìmáOàámà¾ædçwÞ¼ìmÝHöHð&ÞÐìmì+äæ}áOódßHàïìOÞVãÞOâ7âñùCádìæ}çódáOïô éà çwïÒðüá ìðñìOàwàáðHë;ÞiìOàcàìmðHçwÝHø+ÞÞæ}û7àwìmá+àä ÞèwòHàwæoìO»éVÞOçùYá ë`ÝHÞiàwLÞBìOùCèë`æ}ÝHá+à&ïécÝìmðïè¾ìOèwódãÒïïøOìmâñÝçìmãÒçwôLïéÐãÒáë\ë\ìOÞVãÒàMùYççÝñÝHìmÞðçwçÞiÝHäÐÞß7çwÞVáOàcçììOçãWòHçwàÞiÞÐäÐïðß7ÞVçwàcÝHìÞçòHâ7àÞáOòñámðñæ4óHçwìmÝHàÞ&ôüûñãáì[ë?ôOÞiàþ íìOþ àwïÞiè áçwmÞV9æäïÒïÒøCðß7÷ çwÞVÞiàcàwz÷ìÞB/çèòHçÜàwÞçÝñáõÞðHÞiðHçwìOámÞiàRäçÞçßCÝHçwÞiÞÝñàìmìmë`çwçÝHòHçwá+àÝHÞãÒÞÐÞ ßHèàòñámàýñæoì+ãèwÞié¼áOè&Þ&ãíOæ}áOáOÞiæKààçwçwë`ÝHÝHÞÐï²ÞçÝâCé¼ádáOðHódðá ô+çx÷ïÒèð(ã¾òHï ßÓòHð/ä éVïáOðñðñìOé¼àódðñÞiïÒóçwì+ïèáOê(Þ&ðCïÒðHïèðÞVçwìmçïðñéÞVó äìOßHßCçwÝñßHÞiÞüààìmá+çwÿìOòHécàÝñÞÞiè&ïðìOàwçäÞÝHÞVÞéVçwáOÝHðñäádÞiìmóÓßñà ìmßHë\ààÞiìOÞióãÒódYïïézàð çÞVø+9ìOïÒá+ïð øñð÷ ïãÒódñÞBÞV÷ìOðóHçèRïçéiçwìmïá è ã èé¼ïãøOÞiðHìmàïÒýCãôéiìmèðÞiç\ÞVðécÝñïðLìOðHçøOÝHÞBÞèTçwïÞiðäçÝHßCÞ¾ÞiàûCìmáçwòHë;àÞ&èçìmàwòñðñé¼óçwòHí+àÞVÞOãá(ù(éVïðï²çôßñìOßHààwçáOïýñéVòHãÞiãèìOàiù+9çwïáøñ÷ ìmðzùïÒñðñìOéVðñàwóLÞBìOçwèwáÞRïìÐðøOçwàÝñÞiÞìmçwâ7ÞiáOàòHèwðCãáOóHß7ìmÞàô ámMæ9ãì[çwôOÝHÞiÞàKãçwÞiÝHì+ïódécê(ïÒðñðHø ÞièÞièiódùø+ë`ÞÝñèwïÝHécÝádécïê è ë\ì[ñí+áOÞOà>÷ ìOðì+ódïìmâñìmçwïéaëìmãMùmçwÝñÞRódï ÞVàÞVðCé¼Þ`ïðçwÝHÞRß7á+èwïÒçwïáOðámæ7çwÝHÞ¾ãÒÞBìOódïðHø ÞióHøOÞèÝHádécêë\ì[í+Þaá+âdçìOïÒðHÞBóÐâôçwÝHÞ èwáOãíOÞVà ë`èòHï²àwçæoÝìOéVðHÞ&á çxèwÞVãÒäïßßCÞié¼àá+ìmðñçwódòHïÒàçwÞïáOðñoézèæ÷ìmðñçwÝHóõÞçwódÝHÞiÞðñÿèïÒçôßH%àámäýñãÞ¼ÞiçwèÝñïá(ð ó9ïïèøñä÷ áOàìOÞðñóèïøOðñï²¼÷ýC&éiìmÜðÝHç&ÞçÝñòñìmèÞÐðõámæ}æ\á+àèãïÒçßÝHÞLé¼á+ìOðñâCódáïÒí+çwÞïáOðñéVì+èèèÞçwàë`áOï²ðHçø+ÝãÒôì/ódéVÞBáOé¼ðñàèÞiçìOìOèwð+Þiçè çwäÐÝHÞVÞçwÝHèwãÒádá+óWßC÷ ÞRáOáOæaçwçÞÝHçÞÝñãìÞiçRìOóHçÝHïÒðHÞø ódMÞBÞiódðñøOèwÞï²çôLèwÝHðHádÞiécìOêüàëçwÝHì[Þ&íOÞâ7ádèáódôçÝñèìòHç&àwæoìOïÒç&éVÞïè&æ}áOãÒádà¾éVìOìmðçwÞBì+óódÞiïìmíOâñÞiìmðçwïãéáëaë\ÞiìOàãÒYçwÝñïè`ìOïðódÞVçwðÝñçìmïç&éiìmßHãWàwæ}ÞBá+ódà`ïézçwçwÝHÞBÞóé¼âáOô/ðççwïÒð(ÝHòHÞòHÿ ä ìmðñó êïðHÞVçwïéìmßHßHàá+ì+écÝHÞièi÷ 0.00 0.0 0.2 0.4 0.6 0.8 1.0 0.2 0.4 U/U 0.6 Ä 0.8 1.0 0.00 ¶¿À~ÁµÅºÆ 0.0 0.2 0.4 U/U 0.6 0.8 1.0 8 ·¸C¹§»,¼D½~ø ù 8 8 U/U 0.00 0.0 FIGURE 9. Velocity profiles (M^ = 10) To verify this assumption, computations for adiabatic wall conditions were conducted. The use of an adiabatic g i Ë- wall for MOO — 10 leads to a significant increase in flow temperature near the body surface.´For example, for ú-6 i a constant surface temperature, the temperature in the boundary layer varied from lOToo near the forebody 2- ² i to ISToo near the flare surface, whereas for an adiabatic wall, the temperature in the boundary layer varies `!27^ c1©i h6291^, xi :Gf 6©i in a narrow range from to which is slightly lower than the total temperature of the flow 34.3^ ¶ (Fig. 7c7). The temperature profiles for the continuum and kinetic approaches are compared ineFig. ¢8. ² rItm is r solver with no-slip 6 E"F( method predict an identical of interest to note that the NS conditions and the DSMC % > temperature near the whole surface of the body. An increase in temperature in the near-wall region leads to ! significant changes in the flow structure, in particular, to an increase in the boundary-layer thickness, which is Gx! 6 clearly seen in the temperature and velocity profiles&¶(Fig. 9), and to a greater slope of the leading-edge shock wave. For an adiabatic wall, the difference 6 % solver in the position of the leading-edge shock wave obtained by the%NS 6 E"F( method is more significant than for the above case with a constant with no-slip conditions and the DSMC (cf. the density profiles in ) Fig.© 2 and j-10). The use of slip conditions strongly decreases surface temperature E")( the slope of the leading-edge shock wave so that it is located even lower than that predicted by the DSMC method. Note that the density near the body surface for an adiabatic wall is identical for the continuum and kinetic approaches. 712 Y/L 0.30 Y/L 0.20 X/L=0.3 0.25 Y/L 0.40 0.35 X/L=0.6 X/L=.09 0.30 0.15 0.20 0.25 0.15 0.10 0.20 0.15 0.10 0.05 0.10 DSMC NS, no-slip NS, slip 0.00 0.0 0.5 1.0 1.5 2.0 2.5 3.0 0.00 0.0 0.5 DSMC NS, no-slip NS, slip 0.05 2.5 0.00 0.0 ¡`Í\§c«©x¬Ñ±M¥¦O¨ª (º®§c©R´ 1.0 1.5 ρ/ρ 2.0 3.0 Bµ DSMC NS, no-slip NS, slip 0.5 1.0 1.5 ρ/ρ 2.0 Cf 0.20 Cp 0.30 DSMC NS, no-slip NS, slip 0.25 2.5 3.0 8 À Áµ=ÅºÆ 10) Ä ¶¿ (M^ ·FIGURE ¸º¹3»,¼D½¥¾610. û Density profiles 8 8 ρ/ρ 0.05 — DSMC DSMC — -NS, no-slip NS, no-slip —• slip NS, slip NS, 0.15 0.20 0.10 0.15 0.05 0.10 °i¹+¬²°iÁ°V±¬®­`·K°Vº²Òµ¡ÐÈ4£+§¨¯&°iºP«ªi«§z̸¬®º ¬®Á+¨¬®¸¯ ´qº®§½Ò±wµ¾°V«(¹¦+¨§©x©x¸+¨§´q­c§c«±§¨wµ`°i«¹©xÃm¬²«½Ò¨¬®­±¬®ªB«´¨¬®³B£±wµR­ª§ ­c¬®§c«±©Ð´ mÅ éïÒ¼ð/ô(ãÒÜçwïðñÝHÝHódÞÞàé¼ïòCéVàèìmá+ÞãCèè¾áOèòHæ4èwàwÞièwæoé¼ãÒìOïçwßéVïÞáOé¼ð á+oéVðñàwódáïÒèwçwè>ïáOèðñÞBézè`çwãïÞiáOì+ðCóHèìmèàÞçáïð/ìÐàèwÞiïì+øOèðHá+þ&ïÒýCðñìOìméVðñìOâHóðãÞç`ìOçwÞVøOä¼÷àÞVß7ÞV¾äÞVáàcÞiìëað+çÞiòHçíOàwæ}ÞiÞ áOàiàùòHçâCäÝHáOÞ`ßüçwÝûñìOáìmðñë#ßHóßñßñèàwìOãáïÒàßìOìOécäí+ÝHÞVÞ¼ÞBãçwèVádÞi÷ é¼àïÒè4xçðüôïðñçáOèwÝHïðóHïèÞRçwÝñéVçwÞàwÝñáÞRæ}èwàwèâCá+á+ð+èÞBòHçRézðñßCçóHïÒìmá+ìOàwðYàwçRôÐù7ámçwãæ9ÝHì[çwôOÞiÝHàwÞVÞÞà ïèèïäðHïÒáüãìmûCàáèëçàwòñèé¼ÞiçwßñòHìmààcÞiìè¾çïÒámá+æKðçÝHæ}áOÞà â7áOòHõðCàóHÞiìmèwàòHôLãÒçãèiì[ùTôOìmÞiðñà¾óõìmÝñçwÞiÝHìOÞóÿ áOæKçwÝH%ÞÐèäÞißñÞ¼çìmÝHàcìádçóïÒá+ßHðàÞißCódá+ïïÒézðçcçiè&ù7ççÝHÝHÞÞÿâCÞiøOïðH?ðHïðHäø/ÞVçwáOÝHæádèóÞißñßHìmààcÞiìóHçïïÒé¼á+çðYè¾÷ìÿøOàÞiÞièwìmßHçwïÒçwÞVÞà çwãÒôÞiáïðHÞVìãømóçæ}Ýõòñìmàð/ámçæÝHïódÞVçwàÝHÞið+ÞódçÞiïèéiéVÞiìmàwßñãKÞBìmìOãàcÞVèwìÞðHçøOïÒïÒá+ðüçwðÝçwÝHàámÞVæTÞø+çèwïÒÝHá+ÞVðÞßCìmèwçwàcÞVÝñìßñìOçwìOïðáOàðìmçwçwÝHïàÞáOÞVðüø+ïÒá+àÞVðø+èwãïÒáOÞVá+ãðñðíOømÞVæ}çwà áOÝgà÷¾oèwçwÞVÜÝñÞÞÝ(òñÜ9é¼èVìmáOùCâHðçwãçÝñÞ ïÒð(ÞòHé¼¼÷òHá+üä äÜPßHìOìOòdðñê(çóïÒìmðHçwøêïáOïðHïðñðÞVè¾çwçwá/ïë`éÐì+ï²çìOéVÝ/ßHéVáOßHìmòHàðüá+ðì+çì+écódèwÝHïãÒÞiìmïßèiâñù7ìmé¼ìOçwá+ðñïðñéóódë\ïÒÞVçwìOíOïãÒáOÞi9ðñð/ódèïãóüÞiãÒÞBó/ðHìOóHçwámá çè çwßñÝHìÞçÝá+ßHïðßCáçwèÝHïÒÞçwÞðHèwÞBïÒìmçwòñàìmëçwïìmáOãðYK÷àwÞiÜøOïÝñáOïðèódïèiòHùPÞìmßñçwáßñìmÝHàïÞVøOðÝñçwÞVãôOàù9ëéVìmìOãòñ4èçwÞBÞVó/äâ(ß7ô/ÞVàcçìëaçòHáàwæoÞìOé¼ódçwïá+óàèiðH÷ ámç&9écïÒàcÝñèìOçBðHù9øOìOÞÐðûñïðñáë¤éVàwÞBðHìOáOèwðñÞÐÞ ïðïÒãòHçwÝñâHÞàïòHãÒádä éVìOãKoé¼äæ÷ Þiìm9ðïÒøæ}èVà÷ ÞVÞ âûCCìmðñìmá+àóòHÞðñóHèwòHìOìàwàwæoô OìOðñéVãì[Þ¾óô+çÞVódÝñàaïìmóõçwðÝHðHïïÒécðLáOê(ççwðHÝñïÞiðñÞèé¼èûCàãÒÞiáÞBì+ë$óLèÞçwìmáàçáOÝHìòHÞðCßCìmóáàèÞiìïÒìçwïÝHáOámáOðæ`ãÒáámçÝHëæ9ÞLçwxé¼ÝñìOô(Þ&ßHãïÒèßHðCÝHãódï ádéiÞVécìmàaê âHûCïë\ãìmï²çì[àôÞí+ÞRë`ámïÒæï²ðçççÝÞVÝHàcìÞ ìOézé¼çá+ïÒðñá+èðLÞ çìmàòñðÞVç`ø+ìmçwïÒèá+ïòñáOðLàðñæoãèiì+ád÷ é¼éVÞìm(çwçwÞBÞiÞVé¼óLäá+ðñäß7óWÞVòCùKàcécììmÝçðòHæoàwìOïÞ+àðñ÷çéVÝHxàwÞVðÞBàìOçèwæ}ÝHÞàáOïè`ïÒä ðéiìOçwçwèwÝHÝHÞOÞÞ ù çwßHÝHàwÞRÞBèwÞVèwödòHßñàÞRìmðñøOèwàcïìOáOóHðïÒÞiìð+çTç\çìmÝHðñÞ`óWûCù(ìOÝHàwÞiÞRðñèwé¼ÝHÞá+é¼òHá+ãóHðñÞVèà>Þ èòHçwàÞVáOððHçwãø+ôOÞVù+àTçwìÝñ7ÞÞBèwézÞVçßñèKìOçwàÝHìmÞ¾çwïèwáOÝHðádàécÞVêøOëïáOì[ðíOÞ`ãÞVïðñðømçwçwÞiÝgàì+÷4ézÜçwïÝñáOïðÐèaàïè\ÞVøOàïÞ¼áOûñðÞBézìOçðñÞióóódïðÞiéVçwàwÝñÞBÞìOèwódÞiïè9èçwçàÝHïÒÞ¾âHòHìOçwóHïíOáOÞVðàcèwáOÞ æ ßHàwÞBøOèwë`àèwÞiòHÝHìàá+çÞèwÞVÞàRìOðñäèwãÒóLá+ìmßCøOæ}àwÞðñïézï²áOççòñæPïÒá+ódçðLÝHÞÞá+áOðãðÞiìOççwÝHóHÝñÞïÒÞðHæ}øûCáOMìmàÞBàÞVódÞâ7øOádâCÞódÞBèwôOéVÝHìm÷ ádäécêÞáOëæPì[çíOÝHÞÞ&æ}áOèwìOà`äçÝHÞÞ á+àóHÞVàèwáOë`ãíOï²çÞiÝà\ë`ï²çcè`ïÒçwÝíìmðñãòHá ÞxèðHãïÒÞBßìmà\é¼á+çwðñÝHódÞïÒçwãÒïÞBáOìOðñódè¾ïðHéVøìmòCÞièódÞBø+è`Þ ìmoðèwÞVïÒÞ ðCé¼9àïÒÞiøCìO÷ èwÞïÒz÷ð çwâCïÞVðçòñçëaòHÞië\ä ÞVì+ðè¾ìmçwðCèwÝñÝHóÞáê(ë`ûñïÒðñðáÞ¼ë%çwçwÝñïéßñìmìmçàwàcÞBììmèäòHóHãÒçÞ¼Þièiçé¼ÞV÷ààcÞiaèVì+÷ áOèÞäRïßHðáòdë\ççcÞVÝHìí+çÞ&ÞVïÒá+àBæ}àðñùPÞVè\ì ÞBë`èçï²àwòñçÞBÝìmìmãäïÒìOçðì/çìOïÒí+ódìOÞïécìmÝódâCï ìð(7ÞçwòHiïäéàwÞiâ7ë\ðñÞVé¼ìOàÞãÒCãïæ}ÞiðáOìOà óñçwè`ÝñÞLçwáLèwãÒèá+äßCÐìmÞãìmáOÞVãæ\àèáçóHÝHàwï ÞÞÞiíOVãàÞBÞiÞVìmì+ðñãódÞiéVïÒóðñÞiè¾ø èwäâCÞiÞVódìmçø+ãëaÒÞÞiÞià\ÞVèÝHódðïádÞçécÝHVêàÞÞVë\ðñéVì[áOéVí+ðÞiÞè ooèwÜ9ÞVìmÞâHçwãÞÝHÞaïçwÞiäÐèß7àwÞVÞVçàcìmìïçðHòHÞBàóWÞ÷ ßHàámýCãÒÞBè>ïð 9ïøñ÷ ¼ù(ïÒðçwÝHÞódïèçàwïâHòdçÞióLécÝñìmàcìOé¼çwÞVàïèçïéièVùìmðñóïÒðçwÝHÞèÞißñìmàcìçïÒá+ðàwÞiøOïáOðãÞVðñømçwÝ 0.00 ·¸C¹§»,¼D½Ë¾®¾ 0.05 0.0 0.3 0.6 0.90.9 X/L X/L 1.2 1.5 0.0 0.3 0.6 0.9 0.9 X/L X/L î 1.2 ¶¿ 1.5 À ÁÅºÆ FIGURE 11. Thermal nonequilibrium (left) and pressure (center) and skin friction (right) coefficients (Moo = 10, adiabatic wall) $ The use of slip3conditions leads significant jump and slip velocity on the front part of the 7Êto w8dja@ Gf Pf temperature #J cylindrical surface ) (cross X/L = 0.3 and 0.6). However, the flow parameters inside the boundary layer ÊHw6dsections TGf x m in the cross section X/LÌ% = 0.9 are in reasonable agreement for both approaches. In this cross section, there ") ( is no flow separation for NS results, and the DSMC method predicts thebeginning of separation. Despite E")( similar structures of the boundary layerahead of h the % separation 9- point, the DSMC method predicts a greater length of the separation region than the NS solver (see Table 1). Taking into account slip conditions leads to a further decrease in the separation region length. Thus, the computations with an adiabatic wall did not H and kinetic approaches, and even led to yield an identical length of the separation region for the continuum in the ü Hmean sfree A the opposite situation. This is, apparently, caused by two factors. First, an increase local @-in - the near wall region due to higher wall temperature did change ) noneqilubrium (cf. Figs. 5 path not flow ! and 11) !and did not increase the area of the applicability of the NS equations. Second, an increase in the the shock-wave interaction region located much farther Km boundary-layer thickness led to a position of from the 6 flare surface than in the flow around a hollow-cylinder flare with a constant surface temperature. In this case, stronger affects the shock wave interaction region and decreases the adverse the expansion at the flare shoulder ¬pressure 7­ P distribution D ©--1 of gradient and, hence consequently, the separation region length. This is reflected in the >Cp whose magnitude on the flare D % 6 became of the same order with its value near the leading edge (see Fig. 11). A greater slope of the leading-edge shock wave for the NS solver with no-slip conditions causes an increase in pressure and friction on the forebody. m B" E o ( ? j g i @ : . It was shown that a decrease in the freestream Mach number leads to smaller differences between the conJ 9 with an adiabatic . 6 smaller differences tinuum and kinetic results. Computations wall for M^ = 4 also revealed h é- between the flow parameters. However, a qualitative difference in the slope of the leading-edge shock wave P- (see the temperature profiles in Fig. 12), in the distributed characteristics, and in the separation region length (Table 1) is retained. 713 FIGURE 12. Temperature profiles (Af*, = 4) CONCLUSIONS The computations for the Mach 10 flow of a monoatomic gas (argon) show that the continuum approach predicts a greater length of the separation region than the DSMC method. The use of slip boundary conditions for taking into account initial rarefaction effects allowed us to decrease the difference between the continuum and DSMC results. A comparison of the density, temperature, and velocity profiles shows that significant differences are observed only for the temperature inside the boundary layer. This is probably caused by strong flow rarefaction near the leading edge and, as a consequence, by a significant difference in heat fluxes near this edge predicted by the NS solver and DSMC method. A decrease in the freestream Mach number leads to smaller flow nonequilibrium in the vicinity of the leading edge and to better agreement between the continuum and kinetic results. In particular, the difference in the separation region length was reduced from 10% for MOO = 10 to 6% for MOO = 4. The use of adiabatic wall boundary conditions for flow simulation near a hollow cylinder flare induced a significant increase in the gas temperature near the body surface, which led to substantial changes in the boundary-layer structure. The NS solver with no-slip conditions and the DSMC method predict almost identical values of density and temperature near the body surface. In this case, however, the DSMC method predicts a greater length of the separation region than the NS solver. The use of slip conditions leads to more considerable changes than in the case of a constant surface temperature. For example, the slope of the leading-edge shock wave becomes even smaller than the DSMC prediction. The qualitative effect of slip conditions on the separation region length is retained, the latter decreases in size, and the difference between the DSMC and NS results increases. To study in more detail the above-described quilitative difference between the DSMC and NS predictions of the separation region length for cold and adiabatic walls experimental data are indispensable. In the term of RTO Working Group 10 an experimental study of hypersonic laminar flow around a hollow-cylinder flare with a heated wall is planned and it will clarify the situation. Acknowledgement This work was supported by the INTAS Grant No. 99-00749 and RFBR Grant No. 00-01-00824. This support is gratefully acknowledged. REFERENCES 1. Moss, J.N., Olejniczak, J., AIAA Paper 98-2668, June 1998. 2. Ivanov, M.S. , Markelov, G.N., Gimelshein, S.F., AIAA Paper 98-2669, June 1998. 3. Markelov, G.N., Kudryavtsev, A.N., Ivanov, M.S., Proc. of 21 Int. Symp. on Rarefied Gas Dynamics, Cepadues Editions, 1, 647 (1999). 4. Markelov, G.N., Kudryavtsev, A.N., Ivanov, M.S., AIAA Paper 99-3527, June-July, 1999. 5. Chanetz, B., TR RT 42/4362 AN, ONERA (1995). 6. Einfeldt, B., Munz, C.D., Roe, P.L., Sjogren, B.,J. Comput. Phys., 92, 273 (1991). 7. Kogan, M.N., Rarefied gas dynamics, New York: Plenum Press, 1969, ch. 5. 8. Bird, G.A., Molecular gas dynamics and the Direct Simulation of gas flows, Oxford: Clarendon Press, 1994. 9. Ivanov, M.S., Rogasinsky, S.V., Proc. of 18 Int. Symp. on Rarefied Gas Dynamics, VCH, 629 (1991). 714