Microfilter Simulations and Scaling Laws

advertisement

Microfilter Simulations and Scaling Laws

David R. Mott, Elaine S. Oran, and Carolyn R. Kaplan

Laboratory for Computational Physics and Fluid Dynamics

U. 5. Naval Research Laboratory, Washington, B.C. 20375

Abstract. This work presents DSMC simulations used to quantify the effect of Knudsen number on flows

through filters with micron-scale holes. The empirical scaling laws currently used to predict pressure drop

as a function of flow conditions and filter geometry are based on experiments and calculations within the

continuum regime. We illustrate that noncontinuum effects are significant for filters designed to capture

biowarfare agents and pathogens of current interest. We also suggest a scaling based on Knudsen number

for correcting the classic scaling laws to include these effects.

I

INTRODUCTION

Biological agents and other airborne contaminants may be isolated by a filtering process in which air is pulled

through grates with micron-sized holes. Filters with holes that are smaller than the target particles are used

so that these particles do not pass through the filter and can be gathered at the filter surface. Such filtering

processes require that large amounts of air be filtered since the concentrations of these agents can be minute.

Unfortunately, filtering such large volumes of air becomes costly since the power requirement for filtering is the

product of the volume flow rate and the pressure drop across the filter that induces this flowrate. Therefore,

filters must be designed to minimize this pressure drop to enhance efficiency.

Conventional filters appear in a variety of practical applications, from isolating particulates in a gas sample

to controlling turbulence levels in a wind tunnel. Researchers have long tried to predict filter performance

based on some global geometric properties and flowfield conditions [1,2]. These studies led to "scaling laws," or

algebraic expressions which indicate how the pressure drop across a screen or filter scales with these parameters.

Most recently, experimental and computational studies have been conducted in the continuum regime for

filters with circular holes with diameters from 5 to 12 microns [3,4], which is well outside the parameter range

of previous work. These studies yielded empirical relationships between pressure drop and flow rate in terms

of two geometric parameters and one flow parameter: the ratio of hole area to filter area (which is called the

opening factor, /?), the ratio of filter thickness to hole diameter, t/d, and the Reynolds number, Re, given by

The density, velocity, and viscosity of the inflow are given by /?2-n, [/,-„ and /^-n, respectively. This definition of

Re includes the blockage effect of the filter by scaling [/,-„ by /?. Using the effective flow through the filter holes

in the definition for Re improves the correlation of results for various hole geometries and flow conditions [2].

In these recent studies, initial computational results did not agree well with experiment [3]. However, closer

inspection of the filters revealed discrepancies between the intended hole geometry (which was used in the

computations) and that which was actually fabricated. Calculations performed using a more accurate hole

geometry agreed well with experiment, and led to the expression [4]

(10/Ee + 0.22)

(2)

for the nondimensional pressure drop, K, across the filter. Equation (2) indicates that K is inversely proportional to the square of the opening factor, linear in t/d, and linear in I/Re.

CP585, Rarefied Gas Dynamics: 22nd International Symposium, edited by T. J. Bartel and M. A. Gallis

2001 American Institute of Physics 0-7354-0025-3

480

Equation (2) was developed using solutions to the Navier-Stokes equations and then compared to experimental results. The calculations included noncontinuum effects in the form of a slip boundary condition at the

filter surface, but these effects were minor for the cases tested. Rather than include an additional parameter

such as the Knudsen number, Kn, in the scaling law, these effects have been incorporated into the values of

the constants in Eq. (2). Filters for biodetection, however, will require holes that are even smaller than those

tested in these studies. As hole diameters are reduced to 1 micron or less, Knudsen-number effects will be

substantial, and a continuum Navier-Stokes solver will not provide accurate predictions. Furthermore, these

effects must be included explicitly in the scaling law.

This paper describes current two-dimensional DSMC calculations used to quantify the relationship between

power consumption and flow rate for filters in the high Knudsen number regime. These simulations led to a

refinement in the scaling laws based on Knudsen number which expands the range in which these expressions

accurately predict filter performance.

II

NUMERICAL APPROACH

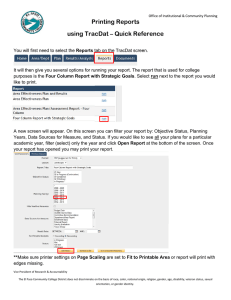

Two-dimensional DSMC calculations were first performed for a "baseline" case described in Fig. 1, and

then parameter studies were performed by varying the flow conditions are geometry relative to this case. The

Symmetry Boundary

1.5 Jim

-7

t = 3 jim

/ Diffuse Wall at

Local Temperature

Symmetry Boundary

FIGURE 1. Baseline geometry.

baseline case consisted of a filter three microns thick with one micron holes spaced four microns apart. These

dimensions give t/d = 3 and /3 = 1/4. For the current studies, we fix /3 and t/d so that variation in the results

is limited to Re effects and Kn effects. The domain shown in Fig. 1 exploits planes of symmetry along the

centerline of a filter hole and along the boundary between adjacent holes to reduce the computational expense

of each calculation. The baseline inflow conditions are air at roughly sea-level temperature and density, flowing

at 4 m/s towards the filter from the left. The Knudsen number for this baseline case, defined as

Kn =

~~ characteristic length

d

in terms of the mean free path of the inflow, A« n , is 0.0576.

The code used for these calculations is a modified version of Bird's DSMC2.FOR [5]. The modified code

allows the user to include an arbitrary number of surfaces within the domain and impose an adiabatic, diffusereflection condition at the surface. The filter is then modeled as a step-shaped blockage as shown in Fig. 1. In

order to control Re from case to case, the mass flux through the domain was specified by the inflow conditions.

The pressure drop across the filter is then measured at the end of each simulation. Particles entering from the

downstream side of the domain were sampled from a prescribed distribution. This condition overspecifies the

subsonic outflow, and close to the exit plane the solution adjusts in an attempt to resolve the inconsistency. By

placing the downstream boundary sufficiently far away from the filter, we prevent this effect from corrupting

the calculation near the filter.

Ill

RESULTS AND DISCUSSION

Contour plots of the x- velocity and the density for the baseline case are shown in Figs. 2 and 3. The velocity

plot shows how the flow accelerates through the hole in order to maintain mass flux, reaching a maximum speed

along the hole centerline around 24 m/s. The flow also exhibits a distinct boundary-layer structure as it passes

481

y (µm)

y (µm)

U: 000

U:

U:

22

22

44

66

10 12

12 14

18 20

20 22

22 24

24

10

12

14 16

16 18

888 10

00

-2-2

-10

-10

-5-5

00

(µm)

xx(µm)

55

10

10

FIGURE2.2.2.Contours

Contoursofofofx-velocity

x-velocityfor

forthe

thebaseline

baselinecase

case

FIGURE

FIGURE

Contours

x-velocity

for

the

baseline

case

y (µm)

y (µm)

DENSITY: 1.06

1.061.07

1.071.08

1.081.09

1.091.10

1.101.11

1.111.12

1.121.13

1.131.14

1.141.15

1.151.16

1.161.17

1.17

1.18

DENSITY:

DENSITY:

1.06

1.07

1.08

1.09

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.171.18

1.18

2

2

00

-2-2

-10

-10

-5

-5

-5

000

x(µm)

(µm)

xx(^im)

555

10

10

10

FIGURE3.3.3.Density

Densitycontours

contoursfor

forthe

thebaseline

baselinecase.

case.

FIGURE

FIGURE

Density

contours

for

the

baseline

case.

throughthe

thechannel.

channel. The

Thedensity

densityplot

plotindicates

indicatesaaaslight

slightincrease

increaseinin

inthe

thedensity

densityasas

asthe

the

lter

approached.

through

through

the

channel.

The

density

plot

indicates

slight

increase

the

density

thelter

filterisis

isapproached.

approached.

This\ram

\rameect"

eect"isisisproduced

producedby

byour

ourforcing

forcingthe

theow

owinininatatataaaspecied

speciedmass

massux.

ux.This

Thisincrease

increaseofof

ofaround

around

2%

This

This

"ram

effect"

produced

by

our

forcing

the

flow

specified

mass

flux.

This

increase

around2%

2%

in

the

density

is

followed

by

an

expansion

through

the

lter

that

gives

a

nal

density

value

approximately

10%

inin the

the density

density isis followed

followed by

by an

an expansion

expansionthrough

throughthe

the lter

filter that

thatgives

givesaanal

finaldensity

densityvalue

valueapproximately

approximately10%

10%

belowthat

thatofofofthe

theincoming

incomingow.

ow.

below

below

that

the

incoming

flow.

Plots

of

the

pressure,

x-velocity,

andthe

thedensity

densityare

aregiven

giveninininFig.

Fig.4.4.4.The

Thecurves

curvesfor

forthe

thedensity

densityand

andx-velocity

x-velocity

Plots

of

the

pressure,

x-velocity,

Plots of the pressure, x-velocity,and

and

the

density

are

given

Fig.

The

curves

for

the

density

and

x-velocity

mirror

the

contour

plots

above.

The

noise

seen

in

these

curves

is

due

to

the

disparity

between

the

thermal

mirror

the

contour

plots

above.

The

noise

seen

in

these

curves

is

due

to

the

disparity

between

the

mirror the contour plots above. The noise seen in these curves is due to the disparity between thethermal

thermal

velocity

of

the

particles

in

the

simulation,

which

is

on

the

order

of

500

m/s,

and

the

mean

ow

velocity.

Even

velocity

of

the

particles

in

the

simulation,

which

is

on

the

order

of

500

m/s,

and

the

mean

ow

velocity.

velocity of the particles in the simulation, which is on the order of 500 m/s, and the mean flow velocity.Even

Even

with

this

noise,

however,

the

plateaus

in

pressure

in

front

of

and

behind

the

lter

are

easy

to

identify,

and

the

with

this

noise,

however,

the

plateaus

in

pressure

in

front

of

and

behind

the

lter

are

easy

to

identify,

and

with this noise, however, the plateaus in pressure in front of and behind the filter are easy to identify, andthe

the

dierence

in

these

levels

is

the

value

of

p

that

our

scaling

laws

attempt

to

predict.

dierence

p that

difference in

in these

these levels

levels isis the

the value

value of

ofAp

that our

ourscaling

scalinglaws

lawsattempt

attempttotopredict.

predict.

Theresults

resultsofofofthe

thebaseline

baselinecase

case and

andseveral

several other

othercases

cases obtained

obtainedbyby

byvarying

varying the

theow

ow conditions

and

the

scale

The

The results

the baseline

caseand

severalother

casesobtained

varyingthe

flowconditions

conditionsand

andthe

thescale

scale

the

geometry

are

included

in

Fig.

5.

Figure

5

also

includes

Yang

et

al.'s

scaling

law

from

Eq.

(2),

as

well

as

ofofofthe

geometry

are

included

in

Fig.

5.

Figure

5

also

includes

Yang

et

al.'s

scaling

law

from

Eq.

(2),

as

well

the geometry are included in Fig. 5. Figure 5 also includes Yang et al.'s scaling law from Eq. (2), as wellasas

some

of

their

experimental

data

[4].

The

experimental

data

is

for

cases

in

the

range

0

:0057Kn

Kn0:00127.

:0127.InIn

some

of

their

experimental

data

[4].

The

experimental

data

is

for

cases

in

the

range

0

:

0057

some of their experimental data [4]. The experimental data is for cases in the range 0.0057 < Kn < 0.0127. In

Fig5,5,squares

squaresindicate

indicatedata

datafor

forconstant

constant Kn

Kn==0:00576

:0576 as denedininEq.

Eq. (3).

(3).These

These points

pointslielie

below

the

curve

Fig

Fig 5,

squares indicate

data for

constant Kn

= 0.0576asasdened

defined in Eq.(3).

Thesepoints

liebelow

belowthe

thecurve

curve

for

Eq.

(2)

by

around

a

factor

of

2,

but

the

experimental

data

lie

below

the

curve

as

well

at

low

Re. .Considering

Considering

for

Eq.

(2)

by

around

a

factor

of

2,

but

the

experimental

data

lie

below

the

curve

as

well

at

low

Re

for Eq. (2) by around a factor of 2, but the experimental data lie below the curve as well at low Re. Considering

thatthe

thecurrent

currentsimulations

simulationsare

aretwo-dimensional

two-dimensionalcompared

compared to the

thethree-dimensional

three-dimensional data

dataofof

ofYang

Yang

et al.,

and

that

that the

current simulations

are two-dimensional

comparedtotothe

three-dimensionaldata

Yangetetal.,

al.,and

and

that

we

are

operating

well

outside

the

parameter

range

in

which

the

empirical

t

was

derived,

agreement

is

that

that we

we are

are operating

operating well

well outside

outside the

the parameter

parameter range

rangeininwhich

whichthe

the empirical

empiricaltfitwas

wasderived,

derived,agreement

agreementisis

good.

A

linear

dependence

of

Konon1=Re

1

=Reisisseen

seen

in

the

Kn==0:00576

:0576data,

data,

which

reinforces

the

form

used

in

good.

A

linear

dependence

of

K

in

the

Kn

which

reinforces

the

form

used

in

good. A linear dependence of K on I/Re is seen in the Kn = 0.0576 data, which reinforces the form used in

Eq.(2)

(2)for

forthe

theRe

Re term.

Eq.

Eq. (2)

for the

Re term.

term.

The

circular

data

pointsinininFig.

Fig. 55correspond

correspondtototoKn

Kn =0.0309,

0.0309,0.117,

0.117, and

and0.233

0.233asas

asone

one travels

travelsaway

away

form

The

circular

data

points

form

The

circular

data

points

Fig. 5indicate

correspond

Kn ==

0.117,and

0.233

onetravels

away

form

the

empirical

curve.

These

points

that

varying

Kn0.0309,

while

holding

the

parameters

in

Eq.

(2)

constant

the

empirical

curve.

These

points

indicate

that

varying

Kn

while

holding

the

parameters

in

Eq.

(2)

constant

the

empirical

curve.

These

points

indicate

that

varying

Kn

while

holding

the

parameters

in

Eq.

(2)

constant

resultsinininsignicant

signicantdierences

dierencesinininKKKthat

thatthe

thescaling

scalinglaw

lawcannot

cannotpredict.

predict. Consider

Considerthe

thecircular

circular

data

point

results

point

results

significant

differences

that

the

scaling

law

cannot

predict.

Consider

the

circulardata

data

point

farthest

from

the

empirical

curve,

for

which

Kn

=

0

:

233

and

Re

=

0

:

68.

If

K

showed

no

dependence

on

Kn, ,

farthest

from

the

empirical

curve,

for

which

Kn

== 00.233

:233 and

Re

==00.68.

:68. IfIfKK showed

nonodependence

ononKn

farthest

from

the

empirical

curve,

for

which

Kn

and

Re

showed

dependence

Kn,

then

this

Kn

=

0

:

233

data

point

would

fall

in

line

with

the

Kn

=

0

:

0576

data.

This

is

clearly

not

the

case;

the

then

this

Kn

== 00.233

:233 data

point

would

fall

ininline

with

the

Kn

==00.0576

:0576 data.

This

isisclearly

not

the

case;

the

then

this

Kn

data

point

would

fall

line

with

the

Kn

data.

This

clearly

not

the

case;

the

valueofofKKinterpolated

interpolatedatatReRe==0:068:68from

fromthe

theKn

Kn==0:00576

:0576data

dataisisapproximately

approximatelythree

threetimes

timesthat

thatgiven

givenbybythe

the

value

value

of

K

interpolated

at

Re

=

0.68

from

the

Kn

=

0.0576

data

is

approximately

three

times

that

given

by

the

simulationforforKn

Kn==0:0233

:233atatthe

thesame

sameReRe. .The

Thesimulation

simulationresults

resultsindicate

indicatethat

thatasasKn

Knincreases,

increases,KKdecreases.

decreases.

simulation

simulation

for

Kn

=

0.233

at

the

same

Re.

The

simulation

results

indicate

that

as

Kn

increases,

K

decreases.

Therefore,ififwewewere

weretotorun

runmore

moresimulations

simulationsforforKn

Kn!!0,0,the

theresulting

resultingvalues

valuesofofKKwill

willlielieabove

abovethe

thecurrent

current

Therefore,

Therefore,

if we

were toapproaching

run more simulations

for curve

Kn —>•or0,possibly

the resulting

values

of K will lie

above the current

datapoints,

points,

perhaps

theempirical

empirical

providing

aconsistent

consistent

continuation

the

data

perhaps

approaching

the

curve

or

possibly

providing

a

continuation

ofofthe

data

points, perhaps

approaching

theregion.

empirical curve or possibly providing a consistent continuation of the

experimental

data

into

the

lower

Re

experimental

data

into the

lower

Re region.

experimental

data into

the in

lower

Re

Canweweinclude

include

afactor

factor

Eq.(2)

(2)toregion.

toaccount

accountforforthis

thisreduction

reductionininKKasasKn

Knincreases?

increases?IfIfwewebase

basethis

thisfactor

factor

Can

a

in

Eq.

Can

we

include

a

factor

in

Eq.

(2)

to account for this reduction in K as Kn increases? If we base this factor

Knand

andinclude

includeititasas

f fononKn

/ on Kn and include it as

482

ρp (kg/m

(kg/m3))

2

3

P (n/m )

U

U (m/s)

(m/s)

25

25

113000

112000

- 1.2

1.2 _

20

20

111000

110000

109000

15

15

108000

- 1.15

1.15

107000

ρ

U

P

106000

105000

10

10

104000

1.1

5

103000

102000

101000

-20

-20

-15

-15

-10

-10

-5

-5

00

X,

µm

X,|am

5

10

15

20

0

FIGURE

FIGURE4.

4. Centerline

Centerline pressure,

pressure, velocity,

velocity, and

and density

density for

for the

the baseline

baseline case.

case.

K = f ;

2

0-2

t

33.5

:5 + 3

d

(10

=Re +

:22) ;

(lO/fle

+ 00.22),

(4)

(4)

@f

df < 0:

@Kn

dKn

(5)

(5)

wewemust

mustrequire

requiref/ to

tosatisfy

satisfy

ff(Kn

(Kn == 0)0)== 11,;

and

and

InInother

otherwords,

words,the

thescaling

scalinglaw

lawshould

should return

return the

the continuum

continuum limit

limit as

as Kn

Kn !

—»•0,0,and

andf/ decreases

decreases as

asKn

Kn increases

increases

from

fromKn

Kn ==0.0.AAsimple

simpleexpression

expression that

that satises

satisfies both

both of

ofthese

these requirements

requirements and

and has

has only

only one

one free

free parameter

parameter is

is

a

f/ ==

Kn

aa++Kn

(6)

(6)

Thisform

form has

has obvious

obviousproblems,

problems, such

such as

as predicting

predicting aa zero

zero pressure

pressure drop

drop for

for free-molecular

free-molecular ((Kn

—»•1

oo)

flow.

This

Kn !

) ow.

However,we

wedo

donot

not intend

intend to

to push

push the

the approximation

approximation that

that far.

far. Our

Our goal

goal is

is to

to provide

provide aa rough

However,

rough rule-of-thumb

rule-of-thumb

forlters

filtersthat

that can

canisolate

isolatecurrent

current biological

biological agents,

agents, which

which pins

pins us

us to

to aa range

range around

around the

the 11 micron

for

micron scale

scale under

under

atmosphericconditions.

conditions. Additional

Additionaltheoretical

theoreticalanalysis,

analysis, physical

physical reasoning,

reasoning, and

and comparisons

comparisons with

with experimental

experimental

atmospheric

andcomputational

computationalresults

results are

arerequired

required to

to develop

develop aa form

form of

of f/ with

with aa wider

wider range

range of

of applicability,

applicability, and

and will

will be

be

and

the focus

focus ofoffuture

future research.

research.

the

By choosing

choosing one

one data

data point

point at

at each

each of

of the

the four

four Knudsen

Knudsen numbers

numbers tested,

tested, the

the constant

constant in

By

in Eq.

Eq. (6)

(6) was

was

determined. Using

UsingEq.

Eq.(2)

(2)and

and the

the DSMC

DSMC result

result for

for each

each case,

case, aa target

target value

determined.

value for

for /f isis obtained

obtained for

for each

each Kn.

Kn.

Then,the

the constant

constant ccin

in Eq.

Eq. (6)

(6) isisdetermined

determined by

by minimizing

minimizing the

the error

error in

in matching

matching these

these four

four ((Kn,f)

data

Then,

Kn; f ) data

points. This

This procedure

procedure gives

gives cc == 00.05765.

close-up of

of the

the DSMC

DSMC results

results are

are shown

shown in

in Figure

Figure 6,

6, along

points.

:05765. AA close-up

along

withEq.

Eq.(2)

(2)and

and the

the scaled

scaled version

version Eq.

Eq. (4)

(4) evaluated

evaluated at

at the

the four

four values

values of

of Kn

Kn that

that correspond

correspond to

to the

the DSMC

with

DSMC

data.The

Thescaling

scalingprovides

providesreasonable

reasonableagreement

agreement considering

considering that

that we

weare

are trying

trying to

to match

match data

data at

at four

four dierent

different

data.

Knudsennumbers

numberswith

withone

onefree

free parameter

parameter and

and aacrude

crude form

form for

for f/.. The

The scaled

scaled curves

curves at

at the

the highest

highest and

Knudsen

and lowest

lowest

483

K β / [3.5(t/d) + 3]

102

co

10 1

2

u

10°

10

0

•

•

•

10

-1

10 -1

j_i

DSMC,

DSMC, Kn

Kn== 0.0576

0.0576

DSMC,

DSMC, 0.0309

0.0309 << Kn

Kn<<0.233

0.233

Equation

Equation of

of Yang

Yang et

et al.

al.

Experimental

Experimental Results

Results of

ofYang

Yang et

etal.

al.

i i i i 111___i_i

0

10

i i i i 111___i_i

1

10

i i i i 111

10 2

Re

Re

FIGURE 5.

Nondimensional pressure

pressure drop

FIGURE 5. Nondimensional

drop for

for various

various cases,

cases, including

including DSMC

DSMC calculations,

calculations, experimental

experimental results,

results, and

and

Yang

et

al.'s

empirical

t

given

in

Eq.

(2).

Yang et al.'s empirical fit given in Eq. (2).

Kn values

values miss

miss their

their respective

respective DSMC

Kn

DSMC data

data points

points by

by around

around 15%.

15%. The

The middle

middle values

values do

do better,

better, especially

especially

the

Kn

=

0

:

0576

cases.

Only

one

Kn

=

0

:

0576

data

point

was

used

in

determining

c

,

so

the

the Kn = 0.0576 cases. Only one Kn = 0.0576 data point was used in determining c, so the good

good agreement

agreement

is not

not due

due to

to this

this data

data being

being weighted

weighted improperly

is

improperly when

when cc was

was determined.

determined. This

This error

error of

of 15%

15%isissubstantial,

substantial,

but

it

is

a

considerable

improvement

over

the

factor

of

2

to

5

dierence

seen

between

the

unscaled

but it is a considerable improvement over the factor of 2 to 5 difference seen between the unsealed empirical

empirical

formula and

and the

the DSMC

DSMC results.

results.

formula

IV

IV CONCLUSIONS

CONCLUSIONS

As microfilters

microlters are

fabricated with

As

are fabricated

with smaller

smaller and

and smaller

smaller holes,

holes, noncontinuum

noncontinuum eects

effects will

will become

become more

more imporimportant. The

The scales

scales required

required for

for filtering

ltering bio-agents

tant.

bio-agents of

of current

current interest

interest experience

experience strong

strong Knudsen

Knudsen number

number eects,

effects,

which requires

requires an

an expansion

expansion of

which

of the

the classic

classic scaling

scaling laws

laws used

used to

to predict

predict lter

filter performance.

performance. By

By including

including aa simple

simple

factor

based

on

the

Knudsen

number,

a

reasonable

adjustment

can

be

made

in

the

pressure

factor based on the Knudsen number, a reasonable adjustment can be made in the pressure drop

drop calculation

calculation

that isis within

within about

that

about 15%

15% of

of the

the solutions

solutions calculated

calculated in

in the

the current

current study

study using

using the

the DSMC

DSMC method.

method. Additional

Additional

theoretical

analysis,

physical

reasoning,

and

comparisons

with

experimental

and

computational

theoretical analysis, physical reasoning, and comparisons with experimental and computational results

results will

will be

be

pursued

in

order

to

develop

scaling

laws

that

accurately

predict

lter

performance

over

a

wider

range

of

pursued in order to develop scaling laws that accurately predict filter performance over a wider range of lter

filter

parameters and

and flow

ow conditions.

parameters

conditions.

ACKNOWLEDGMENTS

ACKNOWLEDGMENTS

This work

work isis funded

funded by

This

by DARPA

DARPA Design

Design for

for Mixed

Mixed Technology

Technology Integration

Integration Program.

Program. D.

D. Mott

Mott isis aa National

National

Research

Council-Naval

Research

Laboratory

Postdoctoral

Research

Associate.

The

authors

Research Council-Naval Research Laboratory Postdoctoral Research Associate. The authors would

would like

like to

to

thank

Professors

Chih-Ming

Ho

and

Yu-Chong

Tai

for

suggesting

this

problem

and,

along

with

Dr.

Joon

thank Professors Chih-Ming Ho and Yu-Chong Tai for suggesting this problem and, along with Dr. Joon Mo

Mo

Yang, discussing

discussing their

their results

results with

Yang,

with us.

us.

484

K β / [3.5(t/d) + 3]

2

10

102

DSMC,

DSMC, Kn

Kn==0.0309

0.0309

DSMC,

Kn

DSMC, Kn==0.0576

0.0576

DSMC,

DSMC, Kn

Kn==0.1166

0.1166

DSMC,

Kn

DSMC, Kn==0.2330

0.2330

Equation,

Equation,Yang

Yanget

et al.,

al., no

noscaling

scaling

Equation,

scaled

by

f(Kn

= 0.0309)

- - - - Equation, scaled by f(Kn=

0.0309)

Equation,

Equation,scaled

scaledby

byf(Kn

f(Kn==0.0576)

0.0576)

— — — - Equation,

Equation,scaled

scaledby

byf(Kn

f(Kn==0.1166)

0.1166)

Equation,

scaled

by

f(Kn

_.._.._.._ Equation, scaled by f(Kn==0.2330)

0.2330)

CO

u

2

si

1

10

101

0

10

1 -1

1010

10'1

10 0

10 1

Re

Re

FIGURE

FIGURE 6.

6. Comparison

Comparison of

of DSMC

DSMC results

results with

with the

the scaled

scaled empirical

empirical t

fit given

given in

in Eq.

Eq. (4).

(4).

REFERENCES

REFERENCES

1.1. Wieghardt,

K.E.G. \On the Resistance of Screens." The Aeronautical Quarterly, Vol. IV, February 1953.

Wieghardt, K.E.G. "On the Resistance of Screens." The Aeronautical Quarterly, Vol. IV, February 1953.

2.2. Derbunovich,

G.I., Zemskaya, A.S., Repik, Ye.U., and Sosedko, Yu.P. \Hydraulic Drag of Perforated Plates." Fluid

Derbunovich, G.I., Zemskaya, A.S., Repik, Ye.U., and Sosedko, Yu.P. "Hydraulic Drag of Perforated Plates." Fluid

Mechanics

{

Soviet

Research, Vol. 13, No. 1, January{February 1984.

Mechanics - Soviet Research, Vol. 13, No. 1, January-February 1984.

3.3. Yang,

X., Yang, J.M., Tai, Y.-C., and Ho, C.-M., Sensors and Actuators A: Physical 73, No. 1-2, pp. 184-191, 1999.

Yang, X., Yang, J.M., Tai, Y.-C., and Ho, C.-M., Sensors and Actuators A: Physical'73, No. 1-2, pp. 184-191, 1999.

4.4. Yang,

Yang, J.M.,

J.M., Yang,

Yang, X.,

X., Ho,

Ho, C.-M.,

C.-M., and

and Tai,

Tai, Y.-C.,

Y.-C., \Micromachined

"Micromachined particle

particle lter

filter with

with low

low power

power dissipation,"

dissipation,"

submitted

to

Journal

of

Fluids

Engineering

.

submitted to Journal of Fluids Engineering.

5.5. Bird,

G.A., Molecular Gas Dynamics and the Direct Simulation of Gas Flows, Oxford University Press, 1994.

Bird, G.A., Molecular Gas Dynamics and the Direct Simulation of Gas Flows, Oxford University Press, 1994.

485