Low Density Heat Transfer to Blunt Cylinders Sujith, R. L andKurian, J.

advertisement

Low Density Heat Transfer to Blunt Cylinders

Anshuman Awasthi*, I. H. Thaker*, Alfred E. Beylich*,

Sujith, R. L+ andKurian, J.+

* Shock Wave Laboratory, RWTH Aachen, Germany

+ Dept. of Aerospace Engineering, IIT Madras, India

Abstract. Experimental studies of heat transfer to blunt bodies were performed in the transition regime. The studies were

at Mach numbers of 6.38 and 7.6 at stagnation temperatures of 500, 600 and 700 K. The heat flux was measured using

slug gauges inserted in Macor models. The data is presented in terms of non dimensional parameters such as Stanton

number, Knudsen number and Cheng's rarefaction parameter.

INTRODUCTION

When an aerospace vehicle flies through the atmosphere at very high speeds, it is subjected to aerodynamic

heating. The extent of heating depends, among other factors, on the density of air through which the vehicle is

travelling. Aerospace missions involve design and deployment of vehicles that encounter all density flow regimes

during their flight path. The physics of flight in the free-molecular and in the continuum regimes has been

reasonably well understood, whereas that in the transitional regime is still subjected to considerable study and

research. In continuum flow, the mean free path length is extremely small in comparison to the boundary layer

thickness and analysis at the macroscopic level with the energy and Navier-Stokes equations yield valid solutions.

With increasing gas rarefaction, the intermolecular collisions become lesser and the macroscopic analysis is not

feasible. In the free molecule regime, the frequency of intermolecular collisions becomes much less and analysis is

possible in a microscopic level with the use of kinetic theory. Thus the basic formulation of the flow phenomena and

heat transfer in the continuum and free molecule regimes is much more refined compared to the other regimes of

rarefied flows. One of the aspects of flight in the transitional zone that remains to be understood is the heat transfer

to the bodies flying at high speeds. The present work attempts to shed light on this aspect.

There is already a large amount of data available for stagnation point heat transfer to hemispherical bodies in the

continuum and near continuum flow regimes. Potter [1] has shown that at high Reynolds numbers there is good

agreement between experimental data and widely used theories such as that by Fay and Riddell [2]. At lower

Reynolds numbers, continuum theories initially under-estimate and progressively over-estimate the heat transfer

when compared to experimentally determined data. There is much less heat transfer data available [3] on bluff

bodies with flat leading surfaces in the transition flow regime. Such a geometry is particularly of interest and

currently available data show that large changes, relative to the hemisphere, occur in the heat transfer distribution

across the face of the body. In continuum flow, the stagnation point heat transfer rate to the flat face is only half of

that to a hemisphere but it rises to higher values towards the edge. In free-molecule flow conditions, the heat transfer

rate at the stagnation point on these two shapes is equal. Furthermore, the heat transfer distribution across the flat

face is constant in free molecular flow whereas for the hemisphere it is very similar to that found in continuum flow.

Metcalf et al. [4] generated experimental data for the heat transfer to hemispheres and bluff cylinders in the

transition regime. They presented the measured stagnation point heat transfer rates in terms of Stanton numbers.

From the plot of Stanton number versus Knudsen number they show the influence of stagnation temperature. This

effect is very noticeable in the Monte-Carlo computation made by Bird [5] for a hemisphere at a speed ratio of 10.

They made a comparison between the variation of Stanton number with Cheng's rarefaction parameter Kr2 [6] for

flat faced and hemispherical cylinders. It is shown that the variation in the data for a bluff cylinder between the

continuum and free molecule limits is quite similar to that found on a hemisphere. It appears that the rapid rise in

Stanton number with decreasing Cheng's parameter and that the ratio of heat transfer rates at stagnation point on the

bluff face and hemisphere is maintained at a value of 0.5 down to Cheng's parameter of the order of 4. Both shapes

appeared to produce a free molecule Stanton number at Cheng's parameter~0.1.

The heat transfer rates can be predicted with sufficient accuracy both in the continuum and free molecular

regimes. The difficulty lies in calculations in the transition regime. The heat transfer in the transition regime is

usually calculated using approximate bridging relations in terms of the heat transfer rates in continuum and free

CP585, Rarefied Gas Dynamics: 22nd International Symposium, edited by T. J. Bartel and M. A. Gallis

© 2001 American Institute of Physics 0-7354-0025-3/01/$18.00

146

molecular regimes and a weighing function based upon the Nusselt number. These approximate bridging relations

can be obtained from the literature [7]. Recent studies using DSMC simulations have shown that the weighing

function that should be used is also a function of the geometry involved [8]. However, not much experimental data

is available to undertake such studies. The availability of an accurate bridging relation that can be used with

confidence will be of much value, since it simplifies the calculations for the designer. From the data generated in

this study, attempt can be made to obtain suitable bridging relations. Hence the objective of the present work is to

make measurements of heat transfer to (i) flat headed cylinder (ii) hemi-spherical headed cylinders under low

density conditions. The low density conditions covering Knudsen number range corresponding to that from

continuum to free molecular are included in the experiments.

DETAILS OF EXPERIMENTS

The experiments for the measurements of low density heat transfer were held on the Low Density Wind Tunnel,

Shock Wave Laboratory (SWL), Aachen. The tunnel consists of two crossed cylinders made of stainless steel with

diameters of 1.8m and 2.4 m and lengths 6m and 4m respectively as the vacuum tank. The vacuum tank has a total

volume of 28m3. An x-y-z traverse is located inside the tank. In free jet experiments the stagnation chamber and

nozzle assembly is mounted on the traverse unit. Minimum pressure achieved during experimental runs was 0.0004

mbar. The stagnation chamber which has an effective volume of 0.32 m3 is mounted on the traverse located inside

the vacuum tank. A heating unit is fitted in the rear part of the stagnation chamber by which temperatures up to

700°C are possible to be achieved. Empty space between the two heaters as well as that between the stagnation

chamber and the heaters is filled with ceramic balls of 5mm diameter to enhance the heat transfer to the test gas.

Two thermocouples of K type (chromel - alumel) were connected spaced annularly close to the stagnation chamber

into the heater region. The ceramic meshes at the ends of the heater chamber prevents the loss of pebbles due to the

flow.

Two models of 10mm diameter were used in these experiments. The models were made of Macor. The flat

headed cylindrical model had two slugs of copper located on the front surface of the model One of them was at the

center and the other close to the outside edge of the front surface. The hemispherical model has cylindrical afterbody

of the same dimension as the flat headed cylinder and has one slug on the forward stagnation point. . The calibrated

thermocouples fused to the slugs are of K-type.

The investigated free jet was produced by letting the gas expand from the high pressure stagnation chamber to the

low pressure vacuum tank through a sharp edge orifice of 10mm diameter. The Mach number distribution along the

centerline of the free jet can be calculated empirically from the equation given below [9] :

M = 326(X/D

- 0.40)7-1 ——

" 1 + 02(X/D

- Q.

V

V

'

'

326(X/D-Q.13T1

'

forX/D>1.0

Here, M is the Mach number and X/D the axial distance normalized by the orifice diameter.

The heat flux on the model was measured using slug gauges. A slug of a metal is buried in the surface across

which the heat transfer rate is to be measured. Neglecting losses through the insulation and through the wires used

for temperature sensing,

Heat transferred in = energy stored

Aqdt = McdT

2

where A = surface area of slug, m , q = local heat transfer rate, W/m2, M = mass of slug, kg, c = sp. heat of slug

J / kg.K, T = slug temperature, K

Then,

dT

Thus q may be determined by measuring dT I dt if Me I A is known. Since the thermocouple reads T rather than

dT I dt, a graphical or numerical differentiation is done to get q . The equation for q written above can be

employed ignoring the heat losses to the casing. The equation predicts that for a constant q , T increases linearly

with time and without limit. Actually the unavoidable heat losses eventually make dTldt approach zero.

147

The measurement of heat flux using the slug gauges involves recording the time rate of rise of the slug

temperature when subjected to the impingement of the low density hot jet under the various operating conditions. To

enable the operating conditions to be set before the jet is let on to the model fitted with the slugs, a magnetically

operated shield was hung between the exit of the orifice and the model. The complete rising of the shield requires

about 20 seconds. The temperature rise of the slug on the model was recorded with zero time corresponding with the

switching on of the movement of the shield. The rise in temperature of the slug was recorded up to about 150

seconds at intervals of about 1.0 sec. The experimental values of temperature showed an almost steady increase with

time.

The recorded values of temperature against time obtained from the experiments were deduced to obtain the rate

of rise of the slug temperature. The slopes of the temperature - time plots were determined graphically. The graphs

were plotted neglecting the first 20 seconds of the experimental values because the jet flow field over the model

was fully established only after the complete lifting of the shield. For the experiments reported in this paper the

slugs used were of copper. The size of the slugs were 2.0 mm and 1.5mm long. The mass of the slugs varied

between 0.0415 gm and 0.0505 gm.

RESULTS AND DISCUSSION

Experiments were performed for Mach numbers (M) of 6.38 and 7.6 for stagnation temperatures of 500K, 600K

and TOOK.The measured values of heat flux are plotted against Knudsen number for the case of the flat headed

cylinder in Figure 1, corresponding to a stagnation temperature of 700 K. In Figure 2, plots are made for the three

stagnation temperatures at a Mach number of 7.6. The values of heat flux measured by the slugs at the center and at

the edge are given in the plots. As expected, the heat flux decreases with increasing value of Knudsen number. It is

also seen that the heat flux measured at the edge of the flat headed cylinder is consistently more than that at the

center. One plausible explanation for this behavior is the proximity of the bow shock formed to the body surface at

the edges. The dependence of heat flux on the stagnation temperature irrespective of the degree of rarefaction is

evident from Figure 2.

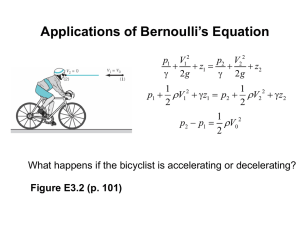

The plot of heat flux against Cheng's parameter (Rr2) against heat flux for M=7.6 and stagnation temperature of

700 K is given in Figure 3. The measured values are well correlated with the Cheng's parameter which is defined as

& 2 = e (r,/r o r 5 Re 2

where e = (7-1)727, r* = (T2 +Tw)/2 and Re2 and T2 represent post shock Reynolds number and temperature

respectively and Tw the adiabatic wall temperature.

In Figure 4, the plot of Stanton number against Knudsen number is given. The plot corresponds to the

experiments on flat headed cylinder and to the three stagnation temperatures employed in the experiments. The

experimental points fall in between the calculations made using the closed form equations given by Fay and Riddell

[2]for continuum flows and by Schaaf and Talbot[10] for free molecular flows. In Figure 5, the calculated values of

Stanton number for all experiments on the flat headed cylinder are plotted against the Cheng's parameter. Because

of limitations of the facility, experimental points are not available in the continuum range corresponding to Kr2 >

3.0. In the transition regime (beyond Kr2 = 0.4, which is generally considered as the free molecular limit) the plots

give a very linear behavior.

Figure 6 depicts the effect of Mach number on heat flux which is plotted as a function of Knudsen number. The

plot corresponds to experiments done on hemispherical headed cylinder at Mach numbers of 7.6 and 6.38. As seen

in the figure, for the constant stagnation temperature of 600 K, higher heat flux is measured in the case of M=6.38.

This possibly is due to the lower stream temperature of the higher Mach number stream which causes lesser heat

transfer to the model. The corresponding plot of Stanton number as a function of the Cheng's parameter is in

Figure 7.

The values of heat flux under identical operating conditions on the flat headed and hemispherical headed

cylinders are plotted in Figure 8. As is evident from the Figure there is not much quantitative difference between the

heat flux values at the edge of the flat headed cylinder and that on the forward stagnation point of the hemispherical

headed model. At higher density regions represented by the higher values of Kr2, the heat flux on hemispherical

model is marginally higher.

148

Stagnation Temperature = 700 K, M = 7.6

Stagnation

Stagnation Temperature = 700 K, M = 7.6

2

Heat

HeatFlux

Flux(W/m

(W/m)2)

1000

1000

1000 -,

800

1= 800

SOD600 &

S' 600

600X

r3n

400

rr 400

400200

1 200

200X

0

0n

0

00

88

1

11

.

Centre, M = 7.6, 700 K

0 Centre, M = 7.6,

7.6, 700

700 K

Edge, M = 7.6, 700K

dEdge,M

= 7.6,700K

Edge, M =

7.6, 700K

2

2

Knudsen Number

Knudsen

Number

Knudsen

Number

3

3

4

4

FIGURE 1. Variation of heat flux with Knudsen number for a flat headed cylinder.

FIGURE 1.

1. Variation

Variation of

of heat

heat flux

flux with

with Knudsen

Knudsen number

number for

FIGURE

for aa flat

flat headed

headed cylinder.

cylinder.

Centre, M==7.6,700

7.6, 700 K

O Centre,

Centre, M

M = 7.6, 700KK

Edge, M==7.6,

7.6, 700K

A Edge,

Edge, M

M = 7.6,700K

700K

centre,

M

=

7.6, 500K

+centre,

centre, M

M==7.6,500K

7.6, 500K

Edge,M

M==7.6,

7.6,500K

500K

x Edge,

Edge, M = 7.6, 500K

centre,M

M==7.6,600K

7.6, 600K

-centre,

centre, M = 7.6, 600K

edge,M

M==7.6,

7.6,600K

600K

x edge,

edge, M = 7.6, 600K

2

Heat

HeatFlux

Flux(W/m

(W/m)2)

900

900 -,

900

800

800800

700

^700700

600

g 600

600500

^500500

400

1400400

300

73300300

200

^ 200

200100

100100

0

00 0

00

1

1

2

2

Knudsen Number

Number

Knudsen

Knudsen Number

3

3

FIGURE

temperature on

on heat

heat flux

flux for

for aaflat

flatheaded

headedcylinder.

cylinder.

FIGURE 2. Effect of Stagnation temperature

FIGURE 2. Effect of Stagnation temperature on heat flux for a flat headed cylinder.

149

4

4

900

900

900

800

800

800

^p.N

700

700

700

^ 600

600

600

^>

500

500

X 500

400

400

LT 400

300

300

08 300

0

200

200

I

200

100

100

100

0

0n

2

2

Heat

Heat Flux

Flux (W/m

(W/m ))

-,

Centre,

entre, M

M === 7.6,

7.6, 700

700 K

K

0 CCentre,

M

7.6,

700

K

Edge, M

M === 7.6,

7.6, 700K

700K

DEdge,

M

7.6,

700K

Edge,

g

8

8

8

- 0

n

o

g

g

E

o

0.2

0.2

0.2

000

0.4

0.4

0.4

0.6

0.6

0.6

0.8

0.8

0.8

11

2

Cheng's

C heng's Parameter

Param eter (Kr

(K r2 ))

C heng's Param eter (K r )

FIGURE

3.

Heat

flux

on

Flat

headed

cylinder

Vs

Cheng's

Parameter.

FIGURE3.

3.Heat

Heatflux

fluxon

onFlat

Flatheaded

headedcylinder

cylinderVs

VsCheng’s

Cheng’sParameter.

Parameter.

FIGURE

11

Stanton

Stanton Number

Number

0.8

0.8

0.80)

.a

0.6

0.6

0.6-

0.4

0.4

ia4H

rcs

Centre,M

M===7.6,

7.6,700

700KK

0 Centre,

7.6,700

Edge,M

M===7.6,

7.6,700K

700K

n Edge,

7.6,700K

Theory

ATlreory

Theory

centre,MM==7.6,600K

7.6,600K

600K

7.6,

X centre,

edge,MM==7.6,600K

7.6,600K

600K

7.6,

x edge,

centre,M

M===7.6,

7.6,500K

500K

* centre,

7.6,500K

Edge,M

M===7.6,

7.6,500K

500K

+ Edge,

7.6,500K

0.2

0.2

8

00

00

22

444

666

888

KnudsenNumber

Number

Knudsen

Knudsen

Number

FIGURE 4. Stanton numbers from experiments and theory (flat headed model)

FIGURE4.4. Stanton

Stantonnumbers

numbersfrom

fromexperiments

experimentsand

andtheory

theory(flat

(flatheaded

headedmodel)

model)

FIGURE

150

10

10

10

Stanton

Number

Stanton

Number

0.18

0.18

0.18-.

Centre, M = 7.6, 700 K

0.16

O Centre,

Centre, M

M==7.6,

7.6,700

700 KK

0.16- D

0.16

Edge, M = 7.6, 700K

0.14

D Edge, M = 7.6,

7.6, 700K

700K

0.14- O

centre, M = 7.6, 600K

0.14

A centre,

j^

centre, M

M==7.6,

7.6,600K

600K

n

0.12

edge,

M

=

7.6,

600K

_g 0.12

0.120 edge,

Q

edge, M

M==7.6,

7.6,600K

600K

centre, M = 7.6, 500K

E 0.1

D

0

X centre,

centre,M

M==7.6,

7.6,500K

500K

- 0.1

0.1Edge, M = 7.6, 500K

A °& D

X Edge,

0.08

Edge, M

M== 7.6,

7.6, 500K

500K

o 0.08

0.08 c

X

x &° $_ 0.

0.06

§ 0.06

0.06 x^ ° ^ ^ o^

0.04

0.040.04

^

X

%

0.02

0.020.02

0n

0

0

0.2

0.4

0.6

0.8

1

1.2

1.2

0.2

0.4

0.6

0.8

00

0.2

0.4

0.6

0.8

1

1.2

2

Cheng's Parameter

Parameter(Kr

(Kr22) )

Cheng's

Cheng's Parameter (Kr )

FIGURE

on flat

flat headed

headed cylinder

cylinder Vs.

Vs.Cheng's

Cheng’sparameter.

parameter.

FIGURE 5.

5. Stanton

Stanton number

number on

FIGURE 5. Stanton number on flat headed cylinder Vs. Cheng’s parameter.

800

800

800

7.6,600K

600K

OMM==7.6,

M = 7.6, 600K

6.38,600K

600K

XMM==6.38,

M = 6.38, 600K

2

Heat

HeatFlux

Flux(W/m

(W/m)2)

/Nv

600

600

°E 600

x>

400400

400

0 0

CO

(D

x 200

200 H

200

00

0

00

0

o

0.5

0.5

0.5

x

Knudsen

KnudsenNumber

Number

Knudsen Number

11

1

FIGURE 6.

6. Effect

Effect of

of Mach

Mach number

FIGURE

number on

on heat

heat flux

flux on

on hemispherical

hemisphericalmodel.

model.

FIGURE 6. Effect of Mach number on heat flux on hemispherical model.

151

1.5

1.5

1.5

Stanton Number

Number

Stanton

CD

_Q

00.08

0.0

.088 n

HO

00.07

0.0

.077 00.06

0.0

.066 -

hhem

M

7 .6

.6 ,, 6

60

0 00 K

K

em is

ispphh eric

eric a

a l,

l, M

M ==

=7.6,

7

Ohemispherical,

600K

o

E 00.05

0.0

.055 -

n

0

o

{*>

v

Z

00.04

0.0

.044 O

•+— »

00.03

0.0

.033 CO

o5 00.02

0.0

.022 -

hhem

M

6 .3

.3 8

8 ,, 6

6 00 00 K

K

em is

ispphh eric

eric a

a l,

l, M

M ==

=6.38,

6

Dhemispherical,

600K

D

&

c

o^

r—i

on

o

00.01

0.0

.011 0n0

000

00.5

0.5

.5

n

11

1

n

'— '

1 .5

1.5

2

C

PPaara

(K r2 )

Chheenngg's

's Parameter

ram

meete

terr (Kr2)

Cheng's

FIGURE

parameter

for aahemispherical

hemisphericalmodel.

FIGURE7.

Stantonnumber

numberas

asaafunction

function of

of Cheng’s

Cheng’sparameter

parameterfor

model.

FIGURE

7.7.Stanton

Stanton

number

function

Cheng's

600 -.

600

600

Heat

Heat Flux

Flux (W/m2)

(W/m2)

500 500

500

hemispherical,M

M===7.6,

7.6,600K

600K

hemispherical,

Ohemispherical,

M

Flat,centre,

centre,M

M===7.6,

7.6,600K

600K

OFlat,

Flat,

centre,

M

7.6,

600K

Flat,edge,

edge,M

M===7.6,

7.6,600K

600K

DFlat,

Flat,

edge,

M

7.6,

600K

<> D

CM

400 H

E 400

400

300 300

300

0

200

200

200

O

100 100

100

$

n

<D

0

8

00

00

0.2

0.2

0.2

0.4

0.4

0.4

0.6

0.6

0.6

0.8

0.8

0.8

2

Cheng's Parameter

Parameter (Kr

(Kr22)))

Cheng's

Cheng's

Parameter

(Kr

FIGURE8.

Comparisonbetween

betweenheat

heatflux

fluxto

toflat

flatand

andhemispherical

hemisphericalheaded

headedcylinders.

cylinders.

FIGURE

8.8.Comparison

Comparison

between

heat

FIGURE

flux

to

flat

and

hemispherical

headed

cylinders.

152

11

CONCLUSIONS

The low density heat transfer to blunt cylinders has been experimentally studied under predominantly transition

flow conditions. The influence of model shape, stagnation temperature and Mach number on low density heat

transfer has been investigated. The dependence of Stanton number on Knudsen number and on Cheng's parameter is

seen to be following the same trends as the earlier [4] experimental results. The free molecular limit identified by the

rapid rise in Stanton number is occurring at a value of Kr2~0.5.The values of stagnation point Stanton number

determined from the experimental values in the transition regime fall in between the calculated limits for continuum

and free molecular regimes.

REFERENCES

1. Potter, J.L., Proc. 5th RGD Symposium, Oxford Vol.11, pp. 881-937, Academic press (1967).

2. Fay, J. A., and Riddell, F. R., Journal of the Aeronautical Sciences, Vol.25, No.2, pp. 73-85, (1958).

3. Potter, J.L. and Miller, J. T., A.LAA. Journal Vol. 1, 2, 480-481(1963)

4.

Metcalf, S. C., Coleman, G. T. and Berry, C. J., Proc. 9th RGD Symposium, Vol.2. (1974).

5.

6.

7.

8.

Bird, G. A., A.I A A. Journal Vol. 4, 1, pp. 55-60 (1966).

Cheng, H. K. and Chang, A. L., A.LAA Journal Vol. 1, pp. 231-233 (1963).

Mating, Fred W., Journal of Spacecraft and Rockets, 8(1), pp.35-40 (1971),

Swaminathan, P. K., Jeff, C. Taylor., Didier, F. G. R., R. E. Erlandson and C. I. Meng, Journal of Spacecraft

and Rockets Vol.33, No.5, sep-oct (1996).

9.

Ashkenas, H. and Sherman, F. S., Proc. 4th RGD Symposium, pp. 84-105, (1964).

10. Schaaf, S. A. and Talbot, L., Handbook of Supersonic Aerodynamics, Section 16, Mechanics of Rarefied Gases

(1959).

153

![Jeffrey C. Hall [], G. Wesley Lockwood, Brian A. Skiff,... Brigh, Lowell Observatory, Flagstaff, Arizona](http://s2.studylib.net/store/data/013086444_1-78035be76105f3f49ae17530f0f084d5-300x300.png)