I B S

advertisement

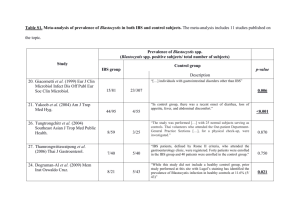

Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) IMPLEMENTING INDUSTRIALISED BUILDING SYSTEM (IBS) IN MALAYSIA: ACCEPTANCE AND AWARENESS LEVEL, PROBLEMS AND STRATEGIES Mohamad Ibrahim Mohamad1, Mardhiah Zawawi2, M.A.Nekooie2 1 Director, 2Postgraduate Student, Construction & Technology Management Centre (CTMC), Faculty of Civil Engineering, Universiti Teknologi Malaysia, 81310 Skudai, Johor Bahru, Malaysia Abstract: Construction Industry Development Board (CIDB) has been actively promoting the use of Industrialised Building System (IBS) in Malaysian Construction Industry since 1998. Unfortunately, previous study was shown the use of IBS for building project in Malaysia only stands at 10% out of 50% as forecasted by CIDB in 2006. This research project explored the acceptance level of the current IBS implementation and existing problems faced by construction industry practitioners. It also identified suggestions to improve IBS implementation in Malaysia. The methods adopted for this study included interview and questionnaire survey. The study determined the level of IBS acceptance and awareness among Malaysian construction industry and analyzed root and frequent problems faced by the practitioners while implementing IBS. Based on the information gained, strategies to improve IBS implementation was suggested. Keywords: Industrialised Building System (IBS), Construction Industry, Precast Concrete and Prefabrication 1.0 Introduction Considered old technology in developed countries, Industrialised Building System (IBS) is still categorised as relatively new technology developing countries such as those in the Asian region. Although the implementation of IBS in Malaysia has started since 1960’s, it became popular only in 1998 when Cabinet of Ministers endorsed IBS Strategic Plan as the blueprint for the total industrialisation of the construction sector. Since then, the Construction Industry Development Board (CIDB) has been actively promoting the use of IBS in Malaysian Construction Industry.The first step taken by CIDB was formulating IBS Roadmap which stated several strategies and aggressive steps to promote the use of IBS in Malaysia. The main objectives of introducing IBS at that time were Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 220 to gradually reduce the dependency on foreign labours and to increase productivity and improving construction quality. The main features of IBS construction process are as follows: I. II. The division and specialisation of the human workforce. The use of tools, machinery, and other equipment, usually automated, in the production of standard, interchangeable parts and products. To implement IBS, there are several activities involved which can be categorised as upstream activities and downstream activities. Upstream activities can be listed as design, planning, and production works. On the other hand, procurement system, supply chain, transportation system, legislation and regulation can be classified as downstream activities. 1.1 Background Information Over the past decade, the level of IBS usage in Malaysia is still very low even though its implementation has started since early 1960’s. Construction industry practitioners seem reluctant to use IBS as their construction method. Their reluctance to use the system is suprising its benefits have been pointed out by researchers. Warszawski (1999) highlighted that by adopting IBS, some saving in manual labour on-site can be achieved, increasing construction speed and providing higher construction quality. Thanoon et al. (2003) also underlined cost saving, faster construction time and improvement of overall construction quality as the result of IBS implementation. These proved that, the use of IBS is advantageous as it fulfils the basic goal of construction; time, resources and quality. For instance, in 2002, Badir studied the building system technologies in Malaysia and examined problems and constraints associated with this technology. The study concluded that the problems related to IBS technology were the higher initial capital investment and the needs for expert labour to deal with heavily mechanised approach in IBS. Therefore, extra cost was needed to train existing semi skilled labour to be highly skilled labour. In 2007, Chung has investigated current awareness of the usage of IBS in Malaysia and his study has analyzed ways to improve the implementation of IBS in terms of the current policy and guideline available to implement the usage of IBS in the local construction industry. The study focused on the usage of 50% of the IBS elements in terms of cost. The Strength, Weakness, Opportunity and Threat (SWOT) Matrix has been used in analyzing the current scenario in the local construction industry. Strategic implementation plan has been suggested in Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 221 this study; the government needs to provide a governing body that is only in charge of the legislations, training, financing, controlling, research and development so that an effective strategy can be formulated and applied to all the parties involved. In 2008 Noriwani studied the critical success factor in adopting IBS for Malaysian Construction Industry. The study focused on success factors and barriers for IBS adoption in Malaysian building construction industry. The information and data were gathered through questionnaire and then analysed using average index method. Based on the study, the most critical success factors in adopting IBS were flexibility, client expectancy, and market security. Meanwhile, in technical aspect and design process was the critical factor in successful IBS adoption. Based on the findings of these studies, IBS appears as the most suitable system to overcome several problems in construction industry especially overuse of foreign labour and low productivity rate. Unfortunately, the level of IBS usage in local construction industry is considerably low about 15% in 2003 (IBS Survey, 2003) and 10% which is less than one third of total completed construction project using at least one IBS product, in 2006 (CIDB, 2007). Moreover, Jamilus (2009) the CEO of top Malaysian management & consultant company has stressed that construction industry are still far from achieving the ideal objective as articulated in recent IBS Roadmap even though almost all activities identified in the roadmap have been implemented. Based on the Roadmap mid-term review, one of the major barriers is negative perception of consumers and practitioners. Even contractors, whom experienced in IBS construction project before, were reluctant to use IBS in their next project. Currently, the only available standard and regulation on IBS implementation is in The Uniform Building By Law (UBBL). It has introduced several clauses to encourage the use of IBS. In addition, through conventional method, local authorities needed to inspect the project upon completion. This rule is not suitable since IBS projects require immediate inspection right after the IBS components delivered to the site. In 2001, the Government set the Malaysian Standard 1064 in order to standardise the IBS components in terms of dimensions. However the Malaysian Standard 1064 still can be improved. However the standards must not be too rigid as to allow for technological improvements in construction method and system. If Malaysian construction practitioner acceptances on IBS implementation isn’t in line with the researcher studies and government hope, probably there is a gap between the IBS and construction industry which resulted on various problems when IBS is being implemented. Three main objectives were Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 222 formulated for this research: (1) to determine the level of IBS acceptance and awareness in construction industry in Malaysia; (2) evaluate the problems of IBS implementation in construction industry; and (3) develop a strategy to propose IBS in Malaysian Construction Industry based on survey results. 2.0 Methodologies The data collection process was carried out by using unstructured interviews and distributing an industry wide questionnaire survey. The unstructured interviews with 5 experienced personnel and professionals regarding the implementation of IBS technology were conducted to obtain preliminary ideas for designing the questionnaire. Furthermore the result rationalised the importance of this study in Malaysia. The questionnaires, distributed directly to engineering and construction firms, gathered data from respondents including engineers, contractors, manufacturers and consultants. The questionnaire consisted of four main parts: A. Information of Respondents; B. Acceptance & Awareness of IBS; C. Problems Related to IBS; D. Strategy to Improve IBS Acceptance. Part A covered information on respondent, such as total years of experience in industry, their company (manufacturer, contractor, consultant, client) and company contract value. Part B asked about their acceptance and awareness on current IBS implementation and part C and D covered on problems which they would face with them in the IBS implementation and strategies to mitigate or solving problems respectively. The questionnaires were distributed to the respondents in Johor, Melaka, Negeri Sembilan, and Selangor via email, by hand and fax. The modes of sending the questionnaires were determined by first contacting the respondents through phone prior distributing them. Out of 50 questionnaires distributed, 27 were returned. The data gained were analysed using frequency distribution analysis to find more frequent elements which have enough or less awareness and acceptance. Also more frequent problems and suggested strategies were attained by frequency distribution analysis. Nonparametric statistical analysis defined significant level of differences for relationship between nominal data about respondent and ordinals from parts B, C and D in questionnaire. Mann-Whiteny Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 223 U and Kruskal-Wallis H were used for show level of differences between respondents in different group using part A. Although in construction management 90% confidence could be satisfied and 0.1 level of difference is acceptable, this study considered significant level of differences around 0.05 for more precise result. The differences in respondents' opinion were grouped based on period of Personal Experience, job sector, dealing with IBS before and company identifications for nonparametric test. Figure 1 shows the distribution of 27 respondents, stacked by company types, grouped by level of company’s experiences on IBS project, and further categorised based on company contract value, which indicates company sizes or company’s financial capabilities. On the other hand, Figure 2 shows the distribution of respondents, categorised based on respondent’s personal experience, grouped by level of company’s experiences on IBS project, but further stacked by company types. Figure 1: Breakdown of respondents based on company financial capabilities 3.0 Figure 2: Breakdown of respondents based on respondent’s personal experience Level of Acceptance and Awareness The study on acceptance and awareness were divided into Awareness, Understanding and Readiness. The frequency analysis results showed that, almost three quarter of the respondents aware that IBS has been implemented in Malaysian construction industry and government has given encouragement to implement IBS. Therefore, aggressive promotion on IBS through media and Malaysian International IBS Exhibition (MIIE) in February 2009 gave much contribution on this element. Moreover, obligation from government stated that Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 224 all government projects are compulsory to use IBS at least 70% of completed project, really indicate government encouragement to implement IBS in Malaysian construction industry. However, the study found that despite the respondents’ awareness on IBS existence but they are quite unaware on the availability of various IBS references and short courses provided by CIDB to support IBS implementation. In general the result of the study indicated that, the level of understanding on IBS was not good at all; especially on management and technical tasks involved while implementing IBS. Less than majority of respondents understood technical task (e.g. designing, erecting, maintaining, handling the components, and etc) involved in IBS implementation. Only 59% respondents understood management task (e.g. procurement method, planning, utilising the component, etc) while implementing IBS. This was due to low awareness among practitioners on the availability of short courses and references which could help and guide them to implement IBS effectively. Table 1: Frequencies on level of IBS acceptance and awareness 1. Awareness a. b. Aware that IBS has been implemented in MCI Aware on government encouragement to implement IBS c. Aware on various types of IBS component d. Aware on various IBS references in market e. Aware on various short courses to support IBS implementation 2. Understanding a. Basic concept of IBS principles b. Procedure on how to implement IBS c. Management task in implementing IBS d. Technical task in implementing IBS 2. Readiness a. Mentally ready b. Technically ready c. Financially capable d. If the client required Percentage of positive responses 70% 74% 67% 52% 56% 67% 63% 59% 48% 70% 67% 70% 74% Looking at the responding to implement IBS, almost 70% of the respondents were ready to implement IBS even though there was some lack of readiness in management and technical understanding which resulted on least readiness in Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 225 technical part. Almost three quarter respondents were ready to implement IBS required by the client which indicated that the practitioners were willing to try if the clients say so. Moreover, actually 70% of them were financially ready, provided the client measures the project cost according to IBS price. It was impossible for them to win the tender using IBS price if at the same time other companies were biding to use conventional price for ordinary construction method. All these variables show that, IBS project was client driven and the practitioners were willing to learn to remain competitive in the industry. Table 1 summarised the frequency analysis among the respondents. Since the study was faced with nominal and ordinal data and variable violated from normality assumption it would be more wisely to use nonparametric test to attain any significant differences in each sector made by Personal Experience, IBS experience, Company type and Company size . The study has adopted Mann-Whiteny U for analysing personal and IBS experiences. In personal experience, population answer divided to two parts: High Experience (more than 8 years) and Low Experience (less than 8 years). H0: Null hypothesis that the respondents’ ideas about awareness, understanding and readiness for IBS implementation questions came from the same population and there were not any significant differences derived from Experience of respondent. H1: Alternative hypothesis whether observations in one sample tended to be different than observations in the other depended on their personal Experience. Despite all questions in this area computed with personal Experience by Mann-Whiteny U, but found that our computation on just readiness corresponded to a significance level of p= 0.042 which was less than 0.05 and absolute value of z=2.035 which was more than 1.96. Since this result conformed normal social science cut off, we could reject the null hypothesis. It would indicate that samples were significantly different on the Personal experience as an ordinal variable. Thus it was subjected to respondent with high personal experience was generally more ready for IBS implementation especially mentally and technically indicated in table 2. According to Experience on IBS, the responds on Awareness, Readiness and Understanding clustered by less than 4 projects for low Experience on IBS and more than 4 projects for High Experience on IBS. Our hypotheses were same as above on personal Experience. Then the result introduced significance level of p= 0.023 on awareness on government encouragement and p= 0.062 on awareness on various type of IBS component and p= 0.076 on awareness on procedure to implement in IBS and p= 0.025 on Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 226 awareness on management task in IBS implementation. Also p= 0.083 and p= 0.057 on mentally and financially readiness on IBS implementation which were less than or around 0.05 and all lower than 0.1 and absolute value of z for all of them was more than or around 1.96 which was illustrated in table 3. The results conducted to reject the null hypothesis and obtained that higher experienced persons on IBS had more intensive idea on mentioned sectors and questions which are also detailed in table 2. Table 2: Acceptance level based on different groups Group Personal Experiences Company sizes Experiences on IBS Acceptance Respondent with high personal experience is generally more ready for IBS implementation especially mentally and technically. Smaller company nowadays are more aware and interested in IBS training (short courses) A higher experience on IBS project has more awareness on government encouragement to use IBS and various type of IBS component available in market. A higher experience on IBS project contributes to more understanding on procedure and management task while implementing IBS. A higher experience on IBS project has more readiness in terms of mental, technical, and financial. Table 3:P and z values for Mann-Whiteny U test awareness on government encouragement awareness on various type of IBS component awareness on procedure to implement in IBS awareness on management task in IBS implementation mentally readiness on IBS implementation financially readiness on IBS implementation p 0.023 0.062 0.076 0.025 0.083 0.057 z 2.266 1.866 1.776 2.235 1.736 1.904 The results showed that, engineers with high personal Experience had better idea on IBS and they made a better sense by significantly ready for IBS implementation. Somehow it concluded that Malaysian experienced engineers were ready and strongly agreed to apply IBS in Malaysian construction industry. Moreover, it also showed that there was an effective encouragement by Malaysian construction society such as CIDB to involve in more IBS projects because of strong awareness of government encouragement among companies who involved in more IBS projects. In addition, it also proved that the Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 227 knowledge of IBS construction in Malaysia is reachable, easy to learn, and also convenient to be used by simply face with IBS project in more than 3 or 4 projects. Due to size of companies, the responds on Awareness, Readiness and Understanding clustered by less than RM 20milion as a contract value for small size and more than RM 50milion for Big size Company. By estimating p=0.045 and z=2.007 for attractiveness in training courses it would reject null hypothesis and declared small company were more interested in this case. It indicated that IBS knowledge was seen as one of the important criteria for them to expand and get the higher recognition in Malaysian construction sector in short term which was shown by opportunity for improvement in figure2. Figure : upportunity for improvment 4.0 Problems with IBS Implementation Overall, the problems being asked in questionnaire was about standardisation, monopoly, technical problems, and financial capabilities. The level of agreement fell between 63% and 33% and level of disagreement fell between 37% and 11%. Even though, it could be seen generally that level of agreement was higher than disagreement, it just could be categorised as moderate level of agreement. The frequencies of responds were illustrated in table 4. Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 228 Table 4: Root problems in implementing IBS Problems 1. Manufacturers supply component with higher price due to high transportation cost 2. Higher capital cost 3. Lack of manufacturer distributed all over the country 4. Monopoly due to limited manufacturer 5. Monopoly by establish contractor due to lack of know how to implement IBS project 6. Lack of manufacturing capacity 7. Lack of joint standardization 8. Lack of beam standardization 9. Lack of column standardization 10. Problems on jointing work due to lack of standardization 11. Lack of proper utilization increased the cost Percentage of agreed 63% 63% 56% 56% 56% 56% 56% 56% 52% 52% 52% All questions in this area computed with personal Experience by MannWhiteny U, carried out significant difference driving from their idea about cost rising for converting design. It corresponded to a significance level of p= 0.049 which was less than 0.05 and absolute value of z=1.966 which was more than 1.96. Since this result confirmed rejection of the null hypothesis. It would demonstrate that high personal experienced respondents were more agreed to Problem of cost rising for converting design which was also depicted in figure 3. Figure 3: Problem of cost rising for converting design Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 229 Also in clustering by IBS experience, less than 4 projects defined as low Experience on IBS and more than 4 projects as High Experience on IBS. Both group of respondent (High and low experiences on IBS) agreed that manufacturer supplied components with higher price due to least order and higher transportation cost as shown in figure 4. Figure 4: most of the respondent agree with high price of IBS manufacturing As data were collected from more than two types of company thus is subjected to chalenge another approprate nonparametric test. Kruskal-wallis test is used to define any significant diffrences exist between our responds samples.This test ables to compare three or more independent groups of sampled data. Grouping respondents by company type carried out with contractors, manufacturers and others contain consultants and clients. The hypotheses for the comparison of independent groups are: Ho: The samples come from identical population; Ha: The samples come from different population. Notice that the hypothesis makes no assumptions about the distribution of the populations. In Kruskal-wallis test, if H exceeds the critical value for H at some significance level (0.05 - 0.1) it means that there is evidence to reject the null hypothesis in favour of the alternative hypothesis. The sampling distribution of H is a very close approximation of the chi-square distribution. The Chi-square with k-1 (the number of groups-1) degrees of freedom can be used to approximate the significance level for the test. For 3 Company types, and measured Chi-square should be compared with 5.991 for 0.05 Error and not Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 230 less than 4.605 for approximate 0.1 of error and uncertainity. Rejection of null hypothesis perceived from results, is illustrated in table 5 for some implementation problems. The significant diffrences drived from company type for respondents indicated that there were two strong problems which are not yet understood by manufacturers. One drove from standardisation’s needs, mentioned by consultant. It referred to lacking of unique and known standard components to be used in design stages. The other one was stated by contractor which indicated the weaknesses of IBS process (e.g. installing, labelling) and availability of the component either main component (e.g. beam, column) or miscellaneous component (e.g. door, window) while implementing IBS project. Also, both contractor and consultant agreed that there was a lack of manufacturing capacity to supply all necessary components in any time when needed. Table 5: Kruskal-Wallis result Problems in implementation IBS Lack of standardisation on door and window components Lack on beam standardisation Lack on column standardisation Problems on labelling component due to lack of standardisation 5.0 Chi-square 5.659 7.979 9.123 6.904 p 0.059 0.019 0.010 0.032 Suggestion for Strategies & Implementation IBS Suggestions for strategies and implementation of IBS in questionnaire survey form were about education, integrated working system, flexible financial package, and improving open building system. The responses have been analysed using average index method and surprisingly, almost all variables fell between 4.5 and 3.50 which indicated that all of them were important strategies which were demonstrated in table 6. In general, all respondents strongly agreed that by offering more incentive for users of standardised drawings in catalogue could improved the effectiveness of IBS implementation. On the other hand, they ranked reducing IBS score as moderate important and other strategies as important. This was good to know that in overall, reducing IBS score strategy was least preferred strategy to improve IBS implementation. It means that, even with various problems faced in implementing IBS, practitioners still agreed to maintain the requirement of 70% IBS components for each project. Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 231 Table 6: Strategies to improve IBS implementation Strategies 1. Offer more incentive for users of standardized drawings referred to catalogue provided by CIDB 2. Offer flexible financing and tax reduction to manufacturer and constructor 3. Work closely with manufacturer to ensure manufacturer’s capabilities 4. Make continual professional development programs for designers, easily reach 5. Offer flexible financing package to whoever wants to be IBS suppliers 6. Work closely with manufacturer to avoid mistakes in production stage 7. Work closely with consultant to avoid redesign work 8. More awareness and education programs for practitioner 9. Formal education on business process The average index gained can be explained as; 1:Most less important 1.000 ≤ Average Index < 1.500 2:Less important 1.500 ≤ Average Index < 2.500 3:Moderate important 2.500 ≤ Average Index < 3.500 4:Important 3.500 ≤ Average Index < 4.500 5:Most important 4.500 ≤ Average Index ≤ 5.000 Average index 4.148 Indicator Important 3.963 Important 3.963 Important 3.963 Important 3.926 Important 3.926 Important 3.926 3.926 3.926 Important Important Important Most of the companies fairly agreed that site visit was an important strategy to improve IBS implementation and also agreed that inspection and the evaluation of service should be conducted by government to avoid unscrupulous parties taking advantage of their client. Contractors needed more to do proper planning and installation to reduce IBS construction cost and manufacturer to register their available components at CIDB. By dividing companies by company sizes, small companies stressed on inspection of installation work on the spot to find out mistake earlier and medium companies preferred the manufacturer to register their available components at CIDB. Finally, big companies had more suggestion on this part which being listed below: - Provide a proper assessment & verification scheme for IBS products, manufacturers, contractors, and workers; Offer incentive for the users of IBS catalogue; Manufacturers to promote their product wisely to produce enough distributed suppliers for their products. Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 232 Moreover, respondent with lower IBS experiences prefer to reduce IBS score target (currently 70%) till the practitioner fully ready. For more perceive, suggestions had moulded by Personal Experience and Experience on IBS. Thus by using Mann-Whiteny U nonparametric test some of p and z showed significant differences attained from responds as indicated in table 7. Table 7:Mann-Whitenyresults for strategies questions Area of Strategies Questions Personal Experience arranging site visit to IBS construction site for student Experience on IBS offering flexible financing and tax reduction to manufacturers and constructor offering flexible financing and tax reduction to whoever want to be IBS suppliers p z 0.017 2.391 0.005 2.822 0.009 2.597 By challenging Personal Experience, high experienced respondents dedicated their stress on the importance of arranging site visit to IBS construction site for student which was depicted in figure 7. Figure 5: Importance of site visit for engineering student vs. experience effect Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 233 Furthermore, by Mann-Whiteny results, respondents with more experiences in IBS suggested offering flexible financing and tax reduction to manufacturers and constructor and whoever wanted to be IBS suppliers. University or any high education body whom produced young engineers for construction sector should provided a syllabus on IBS which covered technical, business process, and all miscellaneous things which needed while implementing IBS. In addition, the practitioners themselves needed to give full support to improve the implementation of IBS. Registering IBS products to CIDB could solve many problems such as standardisation problems and extra cost due to conversion of conventional design into IBS design. It would be conducted to consultants to obtain direct design building by referring to published catalogue and if all manufacturers registered their available IBS components, the designers could make choice while designing project. 6.0 Conclusion The awareness and acceptance for current IBS implementation did not cover the whole elements of IBS implementation process and not all practitioners could accept it implementation especially company and personnel with less experiences in handling IBS project. The study has shown there was not satisfied level of understanding for Malaysian industry members. Also lack of standardization even existed as a problem in main components. Stronger strategies targeted the method of engineering education and registration of IBS design and collaboration between all parts of industry and developing applied code, also offering flexible financing and tax reduction. Applying of these strategies would improve implementation of IBS in Malaysian industry. Acknowledgement Two anonymous reviewers are thanked for their helpful and constructive criticism. Malaysian Journal of Civil Engineering 21(2) : 219-234 (2009) 234 References Badir, Y.F., Abdul Kadir, M.R. and Hashim, A.H. (2002), “Industrialised Building Systems Construction in Malaysia”, Journal of Architectural Engineering, Vol. 8, No.1 Blismas, N. (2007) Offsite Manufactured in Australia: current state and future direction, Corporative Research Centre for Construction Innovation, Brisbane Chung, L. P. & Kadir, A. M. (2007) Implementation Strategy for Industrialized Building System. Master thesis, Universiti Teknologi Malaysia (UTM), Johor Bahru IBS Survey 2003 (2003), Construction Industry Development Board Malaysia (CIDB), Kuala Lumpur Jamilus Hussein. Moving Construction up the Value Chain Using IBS. Malaysia IBS International Exhibition (MIIE 09) – International Seminar on IBS. January 21-23, 2009. Kuala Lumpur, Construction Industry Development Board Malaysia (CIDB). 2009. 2-6. Noriwani & Azirudin Resang (2008) Critical Success Factor for IBS Adoption in Malaysian Construction Industry. Master Thesis, Universiti Technologi Malaysia (UTM), Johor Bahru Construction Industry Development Board (CIDB) Malaysia (2007) Roadmap Review: Implementing The Ibs Roadmap 2003-2010, Construction Industry Development Board Malaysia (CIDB), Kuala Lumpur. Thanoon, W. A. M., Peng, L. W., Abdul Kadir, M. R., Jaafar, M.S. and Salit, M.S. (2003), The Experiences of Malaysia and Other Countries in Industrialised Building System in Malaysia, Proceeding on IBS Seminar, UPM, Malaysia Warszawski, A. (1999) Industrialized and Automated Building System, Technion-Israel Institute of Technology, E & FN Spoon