PERFORMANCE MODELLING OF REFRIGERANTS IN A VAPOR COMPRESSION REFRIGERATION CYCLE

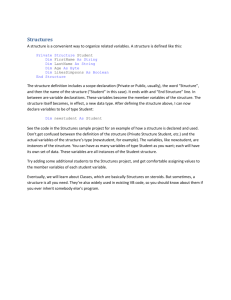

advertisement