AN ARCHITECTURE FOR CLIENT-SERVER BASED CONTROL CHART PATTERNS RECOGNITION SYSTEM

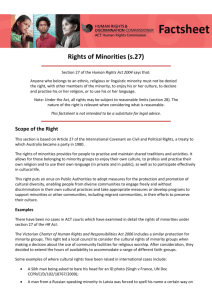

advertisement

AN ARCHITECTURE FOR CLIENT-SERVER BASED CONTROL CHART

PATTERNS RECOGNITION SYSTEM

KOH CHING HAO

A thesis submitted in fulfillment of the

requirements for the award of the degree of

Master of Engineering (Mechanical)

Faculty of Mechanical Engineering

Universiti Teknologi Malaysia

MAY 2009

iii

ACKNOWLEDGEMENTS

I would to take this opportunity to express my sincere appreciation to my

supervisor, Associate Professor Dr. Adnan Hassan. He has given a lot of advices,

guidances, comments and contructive critics as well as a lot of encouragement and

support in order to accomplish this study. In addition, I am also very thankful to my

co-supervisor Associate Professor Dr. Abdul Samad Ismail for his guidances,

suggestions and valuable support along the way to accomplish this study.

I would like to express my appreciation to my parents and family members

for continous support and care. Their support and understanding always become my

motivator along the path of accomplishing this study.

Finally, thanks to all friends for their impressive, valuable helps and

suggestions throughout the duration of this study.

iv

ABSTRACT

In any industrial process, regardless of how well designed or carefully

maintained it is, a certain amount of process variation will always exist. One of the

commonly used methods to monitor and diagnose the process variation is Statistical

Process Control (SPC) chart. Some enhancements have been made by researchers to

introduce the SPC chart system with patterns recognition feature. However, these

SPC chart patterns recognition systems are limited to local and standalone system.

There is a need to develop a client-server based system which would enable data

sharing and remote access. The purpose of this study is to develop an architecture for

a client-server based control chart patterns recognition (CCPR) system. Specific

focus of this study is to investigate design and development aspects of the proposed

client-server based CCPR system. A suitable client-server (CS) architecture and load

passing procedure are investigated. Proper selection of CS architecture and load

passing procedure are crucial to ensure each functional tier can be effectively

integrated, system resources can be optimized and the system workload can be fairly

distributed. The selection of design parameters are based on computer simulation

studies using synthetic data. Candidate designs are evaluated based on calculation

time, memory, processor usage and classification accuracy. The CS architecture with

load passing procedure at server tier and patterns recognition at engine tier gave the

best results among the investigated alternatives. This CS architecture is able to

support more users and process more data. The load passing procedure with the

combination of Nelson Run Rules and EWMA test resulted in better performance

compared to Run Rules and CUSUM, CUSUM and EWMA and capable to prioritize

the unstable processes to access the engine tier. The proposed CS architecture and

load passing procedure can be used as a guideline for the development of a clientserver based CCPR system.

Keywords: Control Chart Patterns Recognition, Client-Server, Load Passing.

v

ABSTRAK

Bagi sebarang proses industri, tidak mengambil kira bagaimana ianya

direkabentuk atau dijaga dengan baik, sedikit sebanyak variasi proses akan berlaku.

Salah satu cara untuk memerhatikan dan menganalisa variasi proses adalah dengan

mengggunakan carta kawalan proses berstatistik. Beberapa pembaikan telah

dilakukan oleh penyelidik dengan memperkenalkan carta kawalan yang mempunyai

fungsi pengecam corak. Walau bagaimanapun, kebanyakan sistem pengecam corak

carta kawalan masa kini hanya terhad kepada sistem setempat dan individu. Satu

sistem pengecam corak carta kawalan yang berasaskan pelanggan and pelayan perlu

dibangunkan. Tujuan utama kajian ini adalah membangunkan satu senibina untuk

pembangunan sistem pengeram corak carta kawalan yang berasaskan pelanggan dan

pelayan. Satu senibina pelanggan-pelayan dan penyimbang beban yang sesuai perlu

dipilihkan. Pemilihan senibina pelanggan-pelayan yang sesuai adalah penting untuk

memastikan setiap lapisan dalam sistem dapat diintegrasikan. Manakala pemilihan

penyimbang beban yang sesuai dapat memastikan beban pemprosesan dapat

dikongsikan ke semua lapisan sistem. Cara rekabentuk senibina ini adalah berasaskan

simulasi komputer. Rekabentuk ini akan dinilai berasaskan masa pengiraan,

penggunaan memori, pemproses dan ketepatan pengecaman. Senibina sistem dengan

penyimbang beban berada di lapisan pelayan dan pegecam corak di lapisan enjin

telah dipilih. Senibina ini dapat menyoking lebih ramai pengguna dan memproses

lebih banyak data. Bagi penyimbang beban pula, teknik Nelson Run Rules dan

EWMA telah dipilih berbanding dengan Nelson Run Rules dan CUSUM, CUSUM

dan EWMA dan ia dapat mengutamakan proses yang tidak sihat untuk mencapai ke

pengecam corak. Senibina ini boleh dijadikan sebagai panduan bagi pembangunan

sistem pengecam corak carta kawalan yang berasaskan pelanggan-pelayan.

Kata Kunci : Pengecam Corak Carta Kawalan, Pelanggan-pelayan, Penyimbang

Beban.

vi

TABLE OF CONTENTS

CHAPTER

CHAPTER 1

TITLE

PAGE

ACKNOWLEDGEMENTS

iii

ABSTRACT

iv

ABSTRAK

v

TABLE OF CONTENTS

vi

LIST OF TABLES

xii

LIST OF FIGURES

xv

LIST OF ABBREVIATIONS

xviii

LIST OF APPENDICES

xix

INTRODUCTION

1.1

Background of the Problem

1

1.2

Statement of the Problem

3

1.3

Purpose and Objective of the Study

4

1.4

Scope of the Study

4

1.5

Significance of the Study

5

1.6

Organization of the Thesis

5

vii

CHAPTER 2

LITERATURE REVIEW

2.1

Introduction

6

2.2

Process Variation and Statistical Process Control

7

2.3

Control Chart and Pattern Recognition

9

2.3.1

Control Chart

9

2.3.2

Control Chart Patterns Recognition (CCPR)

11

2.3.3

Existing Framework for Standalone CCPR

13

2.4

2.5

2.6

Web-based Manufacturing System

16

2.4.1

Application Area

17

2.4.2

Web-based Process Monitoring

20

Web-based Statistical Process Control System

21

2.5.1

Previous Researches

21

2.5.2

Commercial of the Shelf

25

Design Considerations in Development of Client-

29

Server based Application

2.7

2.6.1

Data Modeling

29

2.6.2

Network Security

30

2.6.3

Communication Standard

30

2.6.4

Load Balancing

32

2.6.5

Client and Server System Integration

33

Load Balancing and System Performance

33

Measurement

2.7.1

Application of Load Balancing

33

2.7.2

Performance Measurement

35

2.7.3

Summary of Performance Measurement

35

viii

2.8

2.9

Client and Server (CS) Architecture

36

2.8.1

Mainframe System and File Sharing System

37

2.8.2

Two – tier CS System

38

2.8.3

Three – tier CS System

39

2.8.4

N – tier CS System

40

2.8.5

Example of CS Architecture

41

2.8.6

User Requirement and CS Architecture

45

Tools and Techniques for Web-based System

46

Development

2.10

2.9.1

JSP Language

46

2.9.2

Apache Tomcat Server

47

2.9.3

My-SQL Database Server

48

2.9.4

The Mathworks Matlab

50

Summary

51

CHAPTER 3 RESEARCH METHODOLOGY

3.1

Introduction

52

3.2

Problem Situation and Solution Concept

52

3.3

Development Phases

55

3.3.1

57

Phase One –Analyze Existing

Standalone System

3.3.2

Phase Two – Determine a Suitable

57

Load Passing Procedure

3.3.3

Phase Three – Determine a Suitable

57

CS Architecture

3.3.4

Phase Four – Prototype System

Implementation & Evaluation

58

ix

3.4

3.5

Source of Data

58

3.4.1

Synthetic Data

58

3.4.2

Published Data

58

3.4.3

Industrial Data

59

Instruments and Equipments

59

3.5.1

Hardware Requirement

59

3.5.2

Software Requirement

60

3.6

Performance Measures

62

3.7

Summary

62

CHAPTER 4 CLIENT AND SERVER ARCHITECTURE

FOR CLIENT-SERVER BASED CCPR

SYSTEM

4.1

Introduction

63

4.2

Overview of Client and Server Architecture

63

4.3

Client and Server Architecture for Client-Server

64

based CCPR System

4.3.1

Standalone System

64

4.3.2

CS Design 1 – Load Passing Procedure and

66

Patterns Recognition at Engine Tier

4.3.3

CS Design 2 – Load Passing Procedure at

68

Server Tier and Patterns Recognition at

Engine Tier

4.4

Performance Comparison on the Candidate Designs

70

4.4.1

Engine Tier Performance

70

4.4.2

Web Server Tier Performance

75

4.4.3

Volume of Data

79

4.4.4

Intensity of Traffic

80

x

4.5

Selection of A Suitable Client and Server

82

Architecture

4.6

CHAPTER 5

Summary

84

LOAD PASSING PROCEDURE FOR

CONTROL CHART PROCESS

MONITORING

5.1

Introduction

85

5.2

Overview on the Load Passing Procedure

85

5.2.1

Nelson Run Rules Test

86

5.2.2

CUSUM Test

87

5.2.3

EWMA Test

88

5.3

Load Passing Procedure for Client-Server based

90

CCPR System

5.3.1

Procedure 1: Load Passing Using

97

Nelson Run Rules and CUSUM Test

5.3.2

Procedure 2: Load Passing Using

99

Nelson Run Rules and EWMA Test

5.3.3

Procedure 3: Load Passing Using

101

CUSUM and EWMA Test

5.4

Analysis and Comparison among the Load Passing

103

Procedures

5.4.1

Classification Accuracy

103

5.4.2

System Resources

105

5.4.3

Process Time

108

5.5

Selection of Suitable Load Passing Procedure

112

5.6

Summary

113

xi

CHAPTER 6 PROTOTYPE SYSTEM IMPLEMENTATION

AND VALIDATION

6.1

Introduction

114

6.2

Web-enabled Control Chart Patterns Recognition

115

System Operational Framework

6.2.1

System Management and Administration

115

Module

6.2.2

Operational Module

116

6.2.3

Client Module

117

6.3

Data Flow Diagram

118

6.4

Database Design

120

6.5

System Integration

121

6.6

Graphical User Interface

122

6.7

System Validation

124

6.8

6.7.1

White Box Testing

124

6.7.2

Black Box Testing

125

Guideline for Transforming the Standalone to

135

Client-Server based CCPR system.

6.9

Summary

137

CHAPTER 7 DISCUSSION AND CONCLUSION

7.1

Introduction

138

7.2

Research Achievement and Contribution

138

7.3

Comparison with Previous Research

140

7.4

Research Limitation

143

7.5

Research Implication and Practically

144

7.6

Recommendation for Future Works

144

7.7

Closing Note

145

REFERENCES

146

APPENDICES

160

xii

LIST OF TABLES

TABLE NO.

TITLE

PAGE

2.1

Application of ANN in Control Chart Patterns

ecognition

12

2.2

Conventional and Future Manufacturing (Jay, 2003)

17

2.3

Researchers’ Contributions in Web-based SPC System

25

2.4

Web-based SPC System and Provided Features

28

2.5

Summary of Load Balancing Performance

Measurement Methods

35

3.1

System Performance Measurement

62

4.1

Standalone system Engine Tier Performance

71

4.2

System Performance for Engine Tier

71

4.3

ANOVA Analysis for Engine Tier Performance

73

4.4

Result for Web Server Tier Performance

75

4.5

ANOVA Analysis for Engine Tier Performance

77

4.6

Process Time for Different Volume of Data (second)

79

4.7

Process Time for the Experiment on Intensity of Traffic

(second)

81

4.8

Overall Ranking on Engine Tier and Server Tier

Performance

82

4.9

Overall Ranking on Volume of Data and Intensity of

Traffic

83

5.1

Suitable λ and L value for EWMA chart with ARL ≈

500 (Montgomery,2004)

89

5.2

Example of calculation to determine the process

priority at time, t = 0

92

xiii

5.3

Example of calculation to determine the process

priority at time, t =100ms

93

5.4

Load passing Algorithm

94

5.5

Sample of clients being scheduled and waiting for

process

95

5.6

Classification of Stable and Unstable Process Procedure 1

97

5.7

System Resource Usage - Procedure 1

98

5.8

Process Time for Procedure 1 (millisecond)

99

5.9

Classification of Stable and Unstable Process Procedure 2

99

5.10

System Resource Usage - Procedure 2

100

5.11

Process Time for Procedure 2

100

5.12

Classification of Stable and Unstable Process Procedure 3

101

5.13

System Resource Usage - Procedure 3

102

5.14

Process Time for Procedure 3

102

5.15

Summary of Classification Accuracy for Candidate

Procedures

104

5.16

Summary of System Resources Usage

106

5.17

Summary of Process Time for Candidate Procedure

108

5.18

Comparison among the Candidate Procedure

110

5.19

Summary of Process Time in term of Different Delay

Time

111

5.20

Comparison among the Different Delay Time

112

5.21

Overall Ranking for the Candidate Load Passing

Procedures

112

6.1

System Validation Result for the Published Dataset 1

127

6.2

System Validation Result for the Published Dataset 2

128

6.3

System Validation Result for the Industrial Dataset 1

130

xiv

6.4

System Validation Result for the Industrial Dataset 2

131

6.5

Calculation for dataset 3 to determine the process

priority (t=a)

132

6.6

Calculation for dataset 3 to determine the process

priority (t=a+100ms)

133

6.7

Sample of measurement data schedule by load passing

procedure

134

6.8

Guideline for converting the standalone to Client-server

based system

135

7.1

Comparison between standalone and the proposed

system.

140

7.2

Comparison between the Previous and Author’s

Research

141

xv

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

2.1

Example of Control Chart

10

2.2

Control Chart Zones

10

2.3

Control Chart Patterns (Wani and Pham, 1999)

11

2.4

Flow Chart for Online Recognition of Developing

Control Chart Patterns (Adnan, 2002)

14

2.5

Application Areas of Web-based Manufacturing

18

2.6

Research Issues in Development of the ClientServer based Application

29

2.7

Web Services for Different Platform Integration

31

2.8

Separation of Public and Private Network (Tony,

2001)

32

2.9

Simple Client / Server Computing Architecture

37

2.10

Two – tier Client and Server Architecture

39

2.11

Three- Tier Client and Server Architecture

40

2.12

N-Tier Client and Server Architecture

41

2.13

Design for Client – Server based Mobile Robot

Control

42

2.14

CS Architecture for Distributed Multimedia

Environment

42

2.15

Diagram for CS Telemedical system

43

2.16

Structure of an Http-based Remote Controlled

Laboratory

44

2.17

CS and Ad-Hoc Communication Platform

44

xvi

2.18

Example of Tomcat Web Application Manager

48

2.19

Interface of MySQL Control Center

49

2.20

MATLAB Interface Example

50

3.1

Enhancement from Standalone into a Client-Server

based CCPR System

53

3.2

Proposed Operation Framework for Web-enabled

CCPR System

54

3.3

Client-Server based CCPR System Architecture

Development Phases

56

4.1

Operational Framework for Standalone System

64

4.2

Logical Flow Chart for Standalone System

65

4.3

Operational Framework for CS Design 1

66

4.4

Logical Flow Chart for CS Design1

67

4.5

Operational Framework for CS Design 2

68

4.6

Logical Flow Chart for CS Design 2

69

4.7

Comparison Chart for the Engine Tier Performance

72

4.8

Radar Chart for Engine Tier Performance

74

4.9

Comparison Chart for the Web Server Tier

Performance

76

4.10

Radar Chart for Web Server Tier Performance

78

4.11

Line Chart for the Experiment on Volume of Data

80

4.12

Line Chart for the Experiment on Intensity of

Traffic

81

5.1

Nelson Run Rules

86

5.2

Sample of CUSUM Chart

87

5.3

Sample of EWMA Control Chart (Montgomery,

2004)

90

5.4

Client-Server based CCPR system with Multiple

Clients Access

91

xvii

5.5

Basic Architecture for CS based CCPR System

96

5.6

Summarize of Classification Accuracy using Bar

Chart.

104

5.7

Radar Chart for Classification Accuracy

105

5.8

Summarize of System Performance using Bar Chart

106

5.9

Radar Chart for System Performance

107

5.10

Summary of Process Time for Candidate Procedure

109

5.11

Radar Chart for Candidate Procedures Process Time

109

6.1

Functions provided for Administration Module

116

6.2

Functions for Operational Module

117

6.3

User Functions provided at Client Side

118

6.4

Context Diagram for Web-enabled CCPR System

118

6.5

Data Flow Diagram for Web-enabled CCPR System

119

6.6

Web-enabled CCPR System Database Structure

120

6.7

System Integration for the Web-enabled CCPR

122

6.8

Client Module Interface: Manufacturing Process

Listing

123

6.9

Operational Module Interface: Adding

Manufacturing Process Data

123

6.10

Administration Module: Display the Control Chart

Information

124

6.11

White Box Testing for User Authentication

125

6.12

Web-enabled CCPR System Validation Framework

using Published and Industrial Dataset

126

6.13

Control Chart Plotting for Published Dataset 1

127

6.14

Control Chart Plotting for Published Dataset 2

128

6.15

Control Chart Plotting for Industrial Dataset 1

130

6.16

Control Chart Plotting for Industrial Dataset 2

131

7.1

An Architecture for the Development of a ClientServer based CCPR System

139

xviii

LIST OF ABBREVIATIONS

AI

Artificial Intelligent

AFL

Average Frame Length

ANOVA

Analysis of Variance

CCPR

Control Chart Patterns Recognition

CPU

Centra Processing Unit

CS

Client and Server

CUSUM

Cumulative Sum

DBMS

Database Management System

DNS

Domain Name Service

EWMA

Exponentially Weighted Moving Average

I/O

Input and Output

JSP

Java Server Page

JVM

Java Virtual Machine

LCL

Lower Control Limit

MIB

Management Information Base

NA

Not Applicable

P2P

Peer to Peer

PDM

Product Data Management

PLC

Programmable Logic Control

SCM

Supply Chain Management

SNMP

Simple Network Management Protocol

SPC

Statistical Process Control

UCL

Upper Control Limit

XML

eXtensible Markup Language

WWW

World Wide Web

xix

LIST OF APPENDICES

APPENDIX

TITLE

PAGE

A

Factor for computing control limits for x-bar chart

160

B

Database Scheme

161

C

Measurement Result for Engine and Server Tier

Performance

163

D

Measurement on Silicon Wafer Width in the

Semiconductor Processing

168

E

Measurement on the Metallic Film Thickness

169

F

Measurement on PCB Solder Height

170

G

Measurement on Edge Wave Using Taper Gauge

171

H

Tin Plating Process

173

CHAPTER 1

INTRODUCTION

1.1

Background of the problem

For the last ten years, business and manufacturing have shifted from local entities

towards globalization entities. Quality has become one of the most important decision

factors in making selection among worldwide competing products and service. To be a

winner in this global competitive edge, the manufacturer needs to produce product with

high quality within the shortest delivery time and lowest cost (Shariff, 2005).

There are several methods which can be used to improve product quality. One of

the commonly used methods is the Statistical Process Control (SPC). SPC can be

defined as using statistical techniques to improve and implement quality control. Since

the introduction of SPC by Walter A Shewart in year 1920s, SPC have been widely

adopted and applied in manufacturing industrial. It has been used for monitoring and

diagnosis manufacturing process variation. SPC can be used to achieve process stability

and improve process capability through the reduction of process variability.

Currently there are several computer aided SPC systems introduced by software

vendors and researchers. These computer aided SPC systems can assist the

manufacturers in automating the quality control functions. Nevertheless, these systems

2

still have some limitations. For example, the current computer aided SPC system only

provides some basic functions such as automating the plotting of control charts. The

most important part, the control chart data analysis still heavily relies on the operators

and engineers. Usually, the operator and engineer are very busy with other production

task and may not have sufficient time to perform analysis on the control chart data

(Thompson et al., 1998).

As noted earlier, the current computer aided SPC system are mainly based on

standalone system. These standalone systems do not allow co-operation and information

sharing. The accessibility of these control chart data should not be limited to the operator

and engineer only. They should also be accessible to managers and customers. The

control chart data can assist the manager or customer to have a better understanding on

production line status and helps them in making better decision.

Beside that, the current computer aided SPC system does not allow remote

access. It is only limited to one production area or factory side. The operator and

engineer cannot access the status of production line remotely. Some managers and

customers may not have quality engineering background. The burden of analysis the

production data should not be assigned to them. The manager and customer maybe

interested to know the result and status of the production line. An automated and

computerized SPC system should assist them to diagnose the production line.

These are the quality control problems facing by the operator, engineer, manager

and customer. So there is a need to develop a Client-Server based Control Chart Pattern

Recognition (CCPR) system which would enable data sharing, remote access and

intelligent diagnosis of the production line status.

3

1.2

Statement of the problem

Existing control chart pattern recognition systems are mainly local and

standalone system. They do not provided data sharing and remote access. There is a

need to enhance the standalone system towards a Client-server based control chart

patterns recognition system. Several design issues need to be considered in developing

such a client-server system.

The client-server based CCPR system needs to have a client-server architecture

which can support multiple users simultaneously and better resource allocation.

Inappropriate allocation of resources can cause certain functional tier become

overloaded while the others are under loaded. An effective assignment of functional

modules can enable the CCPR system to support multiple users simultaneously without

additional computing resources.

Due to unique characteristics of SPC data stream, the load passing procedure as

implemented in the voice and network packet system are not directly applicable in the

CCPR system. A customized load passing procedure is needed for a client-server based

CCPR system. Specifically, the load passing algorithm must be able to prioritize the

client access based on the severity of process instability. Without a customized load

passing procedure, the unstable process will have the same priority with stable process,

which may result in delayed detection of unstable process data.

4

1.3

Purpose and Objective of the Study

The purpose of this study is to enhance the existing standalone control chart

patterns recognition system towards a client-server based system which would enable

efficient data sharing, remote access and intelligent diagnosis of production line.

The specific objectives of this study are:

i.

To design a customized client and server architecture for a control chart patterns

recognition system.

ii.

To customize a load passing procedure for the client-server based control chart

patterns recognition system.

iii.

To provide a guideline for transforming the standalone system to a client-server

based CCPR system.

1.4

Scope of the Study

Below are the scopes for this study:

i.

Data stream for process variation are limited to univariate data plotted of Shewart

x -chart.

ii.

Design and evaluation are limited to the computer simulation studies. The

published and real data are used for validation. .

iii.

The simulation data arrive to the system with constant rate and speed.

iv.

Different combination of computing resources are not taken into consideration.

Fixed type and amount of computing resources are used.

v.

Data encryption and network security issues are not included in this study.

5

1.5

Significance of the study

This client-server based CCPR system enables information sharing among

different entities in the manufacturing system. By taking the advantageous of internet

technology, this web-enabled system is accessible anytime, anywhere using a personal

computer with Internet connection. Client-server based CCPR system makes the

manager and customer feel easy and comfortable while interacting with the control chart

system. The suitable client and server architecture ensures each functional tier can be

successfully integrated. This architecture should be able to support multiple users

simultaneously and ensure fair distribution of the system workload. With all these

features, this client-server based control chart patterns recognition system could

overcome the limitation of the standalone system. This study also provides a guideline

for transformation from a standalone to the client-server based CCPR system.

1.6

Organization of the Thesis

This report is organized into seven chapters. Chapter 1 gives explanation on the

background, statement of problem, objective, scope and significance of study. Chapter 2

presents literature review on board and focus area of the study. Techniques and

technologies for the client-server based system development are presented here. Chapter

3 discusses the research methodology for this study. It begins with discussion on the

problem situation, solution concept followed by the researches planning, source of data,

equipment used and performance measurement methods. Chapter 4 describes the

experiments and statistical analysis carried out to select a suitable client and server

architecture. Chapter 5 describes the experiment and statistical analysis carried out for

selecting a customized load passing procedure for the client-server based CCPR system.

Chapter 6 presents the techniques and methods used for the prototype system

implementation and validation. Lastly, Chapter 7 summarizes the research finding and

concludes the study.

CHAPTER 2

LITERATURE REVIEW

2.1

Introduction

This chapter provides literature review on the broad and focus area of this

study. First of all, introduction on the process variation and Statistical Process

Control. Following with explanation on the parameters for building a control chart,

a control chart pattern recognition and a framework for standalone Control Chart

Patterns Recognition (CCPR) system. Coming section provides review on the webbased manufacturing system.

The application areas of the web-based

manufacturing are presented. Next section discusses previous researches and

commercial of the shelf web-based SPC systems. Design considerations in the

development of the client-server based application are presented. The design

consideration are included data modeling, network security, communication

standard, client and server system integration and load balancing. Next discussion

on the load balancing and client and server (CS) system integration. Tools and

techniques for the web-based system development are presented. Finally, a

summary of the literature review is given.

7

2.2

Process Variation and Statistical Process Control

In any industrial process, regardless of design and careful maintenance, a

certain amount of inherent and natural variation will always exist. There are many

reasons for it, such as (Eugene and Richard, 1996):

a.

Variation noise: the variation we observe between products manufactured

under the same conditions and specifications.

b.

External cause: such as environmental temperature, humidity, etc.

c.

Process causes: due to the process itself, such as build-up of waste products,

ageing of a catalyst, variation of loading of a kiln etc.

d.

Assignable causes of variation: this variation may be due to improperly

adjustment of machines, operator errors or defective raw materials.

A process is said to be operating in process control when the only source of

variation is due to natural causes. This natural cause or “background noise” is

referred to as the cumulative effect of many small, essentially unavoidable causes.

A process that is operating in the presence of an assignable cause is said to be out

of control. Once the out of control process is identified, it is up to the various

people involved to use their creativity and ingenuity to correct these variations

(Doty, 1996). There are several methods which can be used to implement quality

control. One of the frequent used methods is Statistical Process Control (SPC).

SPC can be defined as using a statistical technique to implement quality

control. SPC was first introduced in the 1920s by Walter A. Shewart of Bell

Telephone Laboratories. A sketch of a modern control chart was developed by him,

Dodge H. F., Romig H. G., Jennett W. J. and others. But, SPC was not widely

accepted until World War II. During World War II, SPC was used extensively by

UK and USA to improve material quality and reduce the large amount of defective

8

materials being produced. After the war, SPC lost its importance as industries

converted it to be used in peacetime production.

However, in 1950s, people in the West taught SPC to the Japanese. W.

Edwards Deming and Joseph M. Juran in particular made a big impact in Japanese

industries. Japanese industries applied SPC widely and proved that SPC saves

money and attracts customers. The Japanese philosophy is that good quality

products sell, consistent good quality leads to greater productivity, and that there is

no conflict between price and quality. Now, the US and UK are forced to introduce

SPC in order to compete with the Japanese (Wetherill, 1990).

Currently, seven basic tools for the implementation of SPC are histogram,

check sheet, pareto chart, cause and effect diagram, defect concentration diagram,

scatter diagram and control chart. However in this study, focus is done on the

control chart. The control chart can be used to achieve process stability and

improving capability through the reduction of variability. More explanation on the

control chart can be found in Section 2.3.

We need to keep in mind the eventual goal of the SPC is to eliminate

variations in the process. However, it may not be possible to completely eliminate

all variations. The control chart can be used as an effective tool to improve quality,

productivity and reducing variability.

9

2.3

Control Chart and Patterns Recognition

This section begins by introducing the control chart and patterns

recognition. It is then proceeds to the discussion on the framework for the

standalone control chart patterns recognition system.

2.3.1

Control Chart

The control chart is a graphical representation of a quality characteristic that

computed from a few samples which are taken over a fixed period of time. The

control chart can be divided into a variable control chart and attribute control chart.

The variable is the measurement of quality characteristic using a numerical scale.

Examples of variable dimensions are the length, width, temperature, volume, speed

and weight. The X-bar chart and R-chart are the most common control chart for

monitoring the variable process.

The attribute is measurement of quality characteristic that cannot be

conveniently represented numerically. We usually classify this item as either

present or absent, conforming or nonconforming, acceptable or defective to the

specific characteristic. Normally, the percentage of defect in a sample, p-chart and

the count number of defect in a sample, c-chart can be used to show the attribute of

the control chart.

A typical control chart is shown in Figure 2.1. Normally, the control chart

contains a center line, an upper control limit and a lower control limit. The center

line represents the average value of the characteristics while the upper control limit

(UCL) and the lower control limit (LCL) represents the range of acceptable

characteristics. If the process is within control, all the sample points will fall

between the control limits.

10

Control Chart Example

14

UCL=13.494

13

Individual Value

12

11

_

X=10.446

10

9

8

LCL=7.397

7

1

4

7

10

13

16

19

Observation

22

25

28

Figure 2.1: Example of Control Chart

As shown in Figure 2.2, a control chart can be divided into Zones A, B and

C. Each of these three partition zones has a 1 sigma width. If one of the points is

plotted outside these zones, then the particular process is considered out of control.

Although all points are plotted within control limits; if they behave in a nonrandom manner, then this could indicate that the process is unstable. These control

zones with a series of rules (Nelson Run Rules) and other charting techniques

(EWMA and CUSUM) can be applied to detect abnormality in a process. This is to

prevent an unstable process from deteriorating into an out of control process.

Further explanation on Nelson Run Rules, EWMA and CUSUM can be referred to

Chapter 5.

Zone Chart of C3

8

+3 StDev=6.319

4

Zone A

2

0

0

Zone B

Zone C

0

0

+2 StDev=6.014

2

0

0

2

0

2

0

Zone

C

-1 StDev=5.099

Zone B

Zone A

4

+1 StDev=5.709

_

_

X=5.404

-2 StDev=4.793

-3 StDev=4.488

8

1

2

3

4

5

6

7

8

Sample

Figure 2.2: Control Chart Zones

11

2.3.2

Control Chart Patterns Recognition (CCPR)

The interpretation of the control chart depends on the capability to

distinguish the pattern existing in the control chart. As illustrated in Figure 2.3,

there are six types of main pattern that may exist in the control chart: random,

cyclic, decreasing trend, increasing trend, downward shift and upward shift. Except

for the random pattern, the existence of other unnatural patterns indicate that the

process is abnormal due to the presence of an assignable causes such as new

workers, raw material, machine settings and environment effect (Pham and Wani,

1999). Recognition of these unnatural patterns is essential in detecting situations of

special disturbances in a process and in eliminating their causes.

Figure 2.3: Control chart patterns (Wani and Pham, 1999)

12

Artificial neural network (ANN) can be used to classify these unnatural

patterns. Several researchers like Hwarng (1997), Pham and Wani (1997), Guh and

Tannock(1999), Guh(2003), Hassan et al. (2003), Gauri and Chakraborty (2006)

and Bunthit and Jonathan (2007) had adopted artificial neural network for CCPR.

The researchers’ achievements are summarized in Table 2.1.

Table 2.1: Application of ANN in Control Chart Patterns Recognition

Author

Summary

Hwarng

(1997)

Developed a pattern recognition which is suitable for

real time cycle pattern recognition.

Pham and Wani

(1997)

Used features extracted from a CCP instead of the

unprocessed CCP data.

Guh and

Tannock

(1999)

Used Back-Propagation Network to detect concurrent

pattern which exists in the control chart.

Guh

(2003)

Applied a hybrid artificial intelligence technique in

building a real time SPC system.

Hassan et al.

(2003)

Evaluated the relative performance of feature-based

recognizer compared with raw data-based recognizer.

Al-Assaf

(2004)

Used multi-resolution wavelets analysis to extract

distinct features from unnatural patterns.

Guh

(2005)

Developed a CCP identification system using selforganizing approaches neural network and decision tree

learning.

Hwarng

(2005)

Proposed a neural network based identification system

for both mean shift and correlation parameter change.

Yang and Yang

(2005)

Presented a control chart pattern recognition system

using a statistical correlation coefficient method.

Zorriassatine

et al (2005)

Proposed the chi-squared statistic as a compact format

for representing the input to neural network.

Zan et al.

(2006)

Use the linear transformation to improve the character

of the patterns, and then the two kinds of neural

networks are applied to recognize the control chart

patterns.

Gauri and

Chakraborty

(2006)

Develop two feature-based approaches using heuristics

and artificial neural network (ANN) are developed,

which are capable of recognizing eight most commonly

observed CCP.

Bunthit and

Jonathan (2007)

Reported the comparative results of an empirical study

on the non-parametric versus parametric neuron

network.

13

2.3.3

Existing Framework for Standalone CCPR

In this study, the existing framework developed by Adnan (2002) for online

recognition of developing control chart patterns will be referred. This framework

was designed for the application of standalone local system. As shown in Figure

2.4, basically this CCPR framework consists of a stability test, features extraction

and patterns recognition module.

Basically, the work flow of this standalone CCPR system can be described

as following. First of all, the SPC monitoring window receive data stream from the

manufacturing process measurement. Next, the stability test will be conducted. If

the data stream passes the stability test, then the process will continue as normal. If

the data stream is identified as an unstable process, then the process will be passed

to the features extraction module. Features extraction module will extract the

statistical features. Subsequently, the feature set will be presented to the patterns

recognition module.

The pattern recognition module will try to classify the data stream pattern.

If there is no conclusive result and further recognition is needed, then the process

will continue monitoring to get more data. If there is no conclusive result and the

limit of recognize attempts has achieved, the process will be stopped for further

diagnosis. On the other hand, if there is a conclusive result, then the predicted

control chart pattern type will be checked. If the result is a random pattern, this

mean it is a stable process, indicates a false alarm happened. Therefore, the process

will continue as normal. If a non-random pattern (trend-up, trend-down, shift-up,

shift-down or cycle) is recognized then the corrective action is needed. After the

correction action, the monitoring process can be resume as normal.

14

Figure 2.4: Flow Chart for Online Recognition of

Developing Control Chart Patterns (Adnan, 2002)

15

Although the standalone CCPR system has provided the feature of control

chart monitoring and diagnosis, but there are several limitations of the standalone

system. Inside the standalone system, the manufacturing process monitoring is

done locally. The process data is not shareable and accessible remotely. It is unable

to fulfill the requirement of current manufacturing trend which are geographical

distributed.

A dedicated personal computer (PC) is needed for the standalone CCPR

system. However, not all the time, the computer recourses are utilized. Most of the

time, the PC is used for the purpose of collecting measurement data and then

analysis the control chart data. Only small portion of processing time is used for

control chart patterns monitoring and recognition.

The implementation cost for the current standalone system is relatively

expensive. The manufacturer needs to purchase separate license for each pair of the

standalone system. For example, if a manufacturer has five processes to be

monitored, then they need to purchase five pair of standalone system licenses. Each

license cost is quite expensive due to the price of patterns recognition module.

Therefore there is a need to enhance the existing standalone CCPR system

toward a client-server based CCPR system. This client-server based CCPR system

should be accessible remotely, enable resources sharing and affordable by the

manufacturer. Such a system also provides centralized records tracking and

keeping.

16

2.4

Web-based Manufacturing System

Facing the intense competition in the global market, the manufacturing

industry is actively seeking technology solutions that enable timely response to

satisfy customer demand. The success of manufacturing companies depends on

their ability to identify the needs of customers and quickly create products that

meet their requirements; at the same time manufacturing the products at low costs,

and delivering them within the shortest time possible (Mohd Shariff, 2005).

To overcome these problems, information technology has been applied to

the manufacturing sector. The use of this new technology is known as web-based

manufacturing or e-manufacturing. This web-based manufacturing makes use of the

internet speed, reach and collaboration capabilities to connect plant floor operations

to overall business systems across the entire supply chain. It attempts to associate

various product development activities which are distributed at different locations

into an organic and coordinated environment (Jay, 2003).

As described in Table 2.2, future demand on manufacturing will be

significantly different compared with conventional manufacturing. In the

conventional manufacturing, the manufacturing process model only makes the

assumption that the product is marketable and that it can be manufactured. But with

the advent of new information technology, the way new products are introduced

has changed. The manufacturers not only need to know what the product is, but

they also need to have a proactive view of forthcoming changes from both of the

demand and supply side (Toussaint and Cheng, 2002).

17

Table 2.2: Conventional and Future Manufacturing (Jay, 2003)

Conventional Manufacturing

•

New

Product

Need to invent new

Future Manufacturing

•

product.

Need to invent new product,

better quality and shorter

design life-cycle.

Existing

•

Product

Product

Investigation

•

Modifying an existing

•

Changes now come from

product to improve its

both the demand and the

features.

supply sides.

Investigation done on

- Function of the product

- Its appearance

•

Investigation done on

- Functionality of the

product

- Its appearance required or

defined on the web

By using the internet facilities, information distributed at different location

can be accessed and shared by both demand and supply side without the problem of

data recreation and distribution. As such it can satisfy the customer demands,

improve the product quality, and reduce the product development time, thus

providing better global competitiveness of product in the worldwide marketplace

(Jay, 2003).

2.4.1

Application Areas

As shown in Figure 2.5, web-based manufacturing are implemented in

collaborative product design, product data management, supply chain management,

product support and process monitoring (Yang and Xue, 2003). Since the clientserver based CCPR system provides data sharing and remote access of production

18

line status, its manifestation can be classified as one of the applications in process

monitoring.

Web-based Manufacturing System

Collaborative Product

Design

Product

Support

Product

Data Management

Supply

Chain Management

Process

Monitoring

Client-server based SPC

Figure 2.5: Application Areas of Web-based Manufacturing

Collaborative product design is one of the application areas in web-based

manufacturing system. Collaborative design enables teams of designers, engineers

and manufacturers from diverse geographical locations to work together over a

collaborative computer network. Researchers such as Ahn and Bharadwaj (2002),

Huang (2003), Zhou and Chin (2003), Li et al. (2004) and Ming et al.(2007) have

reported researches on web-based application in product design. Collaborative

product design is a very effective medium for conducting the design reviews and it

does save time and cost (William and Jeffrey, 2004). It provides an appropriate

communication platform that breaks down the barriers in the process of product

development.

Another area of web-based manufacturing application is product data

management (PDM). In today’s industry, billions of dollars is spent each year for

regenerating the product data which are stored in diverse software format. With the

introduction of PDM, it does allow information sharing and data exchange among

product designs using different software tools. Researchers such as William and

Tony (2003), Helen et al. (2004), Huang et al.(2004), Zeng and Liu (2004) and

19

Edmond and Yu (2007) have reported researches on web-based product data

management. Web-based PDM has led to significant improvement in all facets of

product design, documentation, manufacturing and support (Alan, 2004).

Another area of web-based manufacturing application is supply chain

management (SCM). SCM encompasses all activities associated with a firm

moving its composite flow of information, materials and services from the stage of

raw materials through production to the end customer. The sudden increase in ecommerce has resulted in new opportunities to improve the performance of supply

chain (Claudio, 2003). Researchers such as Sheremetov and Rocha (2004), Stavros

and Nikos (2004) and Tserng, et al. (2005) have reported researches on SCM. SCM

has increased the service level and established a cooperative environment among

all parties involved in the supply chain.

Product support is one of the application areas in web-based manufacturing

system. The competitiveness of a product does not only depend on its quality and

cost but also the post production support considerations such as service,

maintenance, system upgrade, recycle and disposal. The Internet is chosen as the

medium to improve the product support function. Researchers such as Schubert et

al. (2002), Sean and Teresa (2002), Anon (2005) and Ashaab (2007) have reported

studies on web-based product support. The overall web-based product support has

led to reduction response time of customer service problems (Morita and Hidaka,

2004). The two way communication capability of the Internet has a profound effect

on cementing the customer-firm relationship.

Process monitoring is one of the application areas in web-based

manufacturing system too. Since the client-server based CCPR system is under this

category, process monitoring is explained in the following section.

20

2.4.2

Web-based Process Monitoring

As described in the previous section, process monitoring is one of the

application areas in web-based manufacturing system. Web-based process

monitoring enables the technician, engineer and manager to remotely access, view

and analyse the production line status. Web technology are used to monitor and

control the manufacturing shop floors (Shen et al., 2003).

Web-based multimedia application such as graphics representation with

Java Applet can be implemented for remote representation of production line. Ming

(1998) had developed a distributed intelligent multimedia system for real-time

process monitoring. Wang (2003) had integrated Java 3D model for remote

monitoring and control of the manufacturing process. Virtual control panel also can

be imposed in remote process monitoring. Zhao et al. (2003) had developed a

virtual control panel written in Active-X for user to directly send command and

receive message from the Computer Numerical Control machine.

In addition, several sensors and Programmable Logic Control (PLC) also

can be integrated into web-based process monitoring system. Subu et al. (2003) had

integrated sensors, PLC with embedded web server for remote process monitoring.

Szabados (2003) integrated remote instrumentation to manufacturing process

monitoring. This approach has extended the scope for a wired environment with

fixed stations for data access.

Web-based process monitoring has solved low efficiency problems which

occurred in physically monitoring of production line (Zhu et al., 2005). By

converting the manufacturing system into the web accessible system, it is found to

be reliable, steady, flexible, extendable and effective in real-time monitoring and

controlling of the manufacturing process (Shi, 2007).

21

2.5

Web-based Statistical Process Control System

As discussed in Section 2.2 and 2.3, SPC charts are tools for process

monitoring. Various researchers have contributed to the development of CCPR

system. This area of research has been extended to integrated web technology into

CCPR system. The following section review previous works on web-based SPC

system. Reviews are presented from two perspectives, specifically Section 2.5.1

presents the findings and contributions of previous researches, and Section 2.5.2

presents commercial of the shelf web-based SPC system.

2.5.1

Previous Researches

Several researches have been carried out on web-based SPC system. This

section presents reviews and investigations that have been done by researchers on

the development of a web-based SPC system.

Thompson et al. (1998) investigated how internet-based technologies can be

integrated into the SPC process in order to provide more responsive and customercentered system. They described how the manufacturing sector has benefited from

the integration of an internet-based SPC system into the manufacturing process.

They explained the feasibility of using the internet for a web-based SPC system.

Basic explanation and overview of internet benefits are given by them.

Soperi et al. (2000) proposed a web-based statistical process system. They

converted the standalone system which produces x-bar and R charts using

Microsoft Visual Basic 5.0, Microsoft Access and Crystal Report into a web-based

SPC chart generator. This web-based SPC chart generator was developed using

Active Server Page, Active Data Object, Microsoft Access as database, Microsoft

Internet Information Server as web server and Microsoft NT Server as operating

22

system. This web-based SPC system have some basic features like generating xbar, R charts and doing some analysis such as summarizing the percentage of

points plotted above UCL, below LCL and between UCL and LCL. This study

produced the preliminary framework for web-based SPC with a prototype system

development and implementation.

Han and Oh (2001) elaborated SPC system is widely used to satisfy the

ever-increasing quality control requirements. They noted that most commercial

products in the market are not flexible enough, still semi-automatic and difficult to

interface with other tools. They proposed a SPC system which is web-enabled and

supporting XML protocol. A graphic facility and file system to handle the data in

real time have been developed. They introduced the XML protocol and graphical

interface for web-based SPC system.

Lee et al. (2003) implemented of Simple Network Management Protocol

(SNMP) for web-based SPC system. A Management Information Base (MIB) that

represents the status of facilities are defined. Based on the MIB, SNMP agents are

used to collect data from a machine. They claimed that their clients can access

those SPC charts and statistics using any web browser and can change control

parameters if they are permitted.

Their investigation suggested that the

communication protocol such as SNMP can be used as a communication media for

a web-based SPC system.

After analyzing the future of virtual enterprise and deficiencies of

traditional SPC, Wang et al. (2003) proposed the function structure to integrate the

SPC based quality control system on web. This web workflow is adopted to control

the production quality of extended and internal enterprises intelligently. The control

of SPC procedure, pattern recognition of control chart and analysis and diagnosis of

fault reasons were combined together. The study illustrated the workflow of

designed and encapsulated toolkits, which makes the Web workflow convenient.

23

Choudhury et al. (2003) implemented wireless technology for real time

process data transferring over the Internet. It created the opportunity for accessing

the live process data from the classroom and then analysis the data for process

improvement. A multivariable process station involving pressure, temperature, flow

and liquid level was utilized to simulate industrial process. The wireless and webbased information technology are utilized to retrieve and transmit the refined real

time process data. Their main contribution is in the application of the wireless

technology into remote process monitoring.

Bhavin and Zhou (2003) investigated the middleware for web-based

manufacturing. They developed a methodology and software that use AI,

Simulation and Modeling coupled with Virtual Reality and Resource Management

concepts for the automation of various material design, analysis and visualization

process. This environment is designed to be a platform independent and accessible

over the World Wide Web (WWW). This research concentrated issues on the

development of middleware for load balancing and parallel processing. It has

demonstrated the use of WWW as the middleware for efficient load balancing,

resource management and distributed processing in the digital age.

Zhao and Wang (2004) introduced a web workflow model for quality

control system. They introduced web service and extensible Markup language

(XML) technology into web workflow model. The function structure of the quality

control system is based on the web workflow. It does compose system

management, quality control, system resource management, quality information

management and information trace releasing module. Their study focused on the

implementation of web service and XML technology for quality control system.

In addition, it has been proven that the web-based SPC can be implemented

in other areas such as computer security. Michlin et al. (2004) proposed a method

24

for reliability improvement of web servers through statistical process control. This

method is intended for timely detection of hacker attacks and faults, before they

become critical and disrupt the normal activity of a web server. It is based on

observation of the correlations between the variables measured in the course of

server activity. This recommendation has been implemented and is used as a basis

for an automated protection system.

Literature reviews suggest that each researcher have contributed to a

different area by introducing new technology into the web-based SPC system.

Table 2.3 summarizes the previous researchers’ contribution. However, there is no

significant comparable relationship that can be summarized from these researches.

These researchers introduced and integrated different technology and ideas for the

web-based SPC system.

No investigations have been done on selecting a suitable CS architecture

and a load passing approach. It is not appropriate to direct implement a normal web

server into the CCPR system, since each module of CCPR system has its own

characteristic and can achieve better performance by separate out and customize

them into different functional tier. With an appropriate CS architecture, using the

same amount of resources, a CCPR system able to process more data and support

more users. On another side, without a load passing procedure will causes the

CCPR system no able to timely recognize an unstable process, the stable process

will stay a same priority with unstable process. Timely recognition of unstable

process is crucial to ensure corrective action can be taken earlier. Thus, this

research is trying to propose and investigate an suitable CS architecture and load

passing approach for a client-server based CCPR system.

25

Table 2.3: Researchers’ Contributions in Web-based SPC System

Author

Year

Contributions

Thompson et

al.

1998

Introduced the feasibility of internet for web-based

SPC system.

Soperi et al.

2000

Proposed the preliminary framework for web-based

SPC system.

Han and Oh

2001

Introduced the XML protocol and GUI for web-based

SPC system.

Lee et al.

2003

Used SNMP as communication media for web-based

SPC system.

Wang et al.

2003,

Integrated production quality monitoring with internal

enterprise system.

2004

Choudhury

et al.

2003

Introduce wireless technology into remote process

monitoring.

Bhavin and

Zhou

2003

Convince the use of WWW as middleware for

efficiently load balancing and distributed processing.

Zhao and

Wang

2004

Introduced XML and web service technology into

quality control system.

Michlin

2004

Implemented SPC in computer network security.

2.5.2

Commercial of the Shelf Web-based SPC System

Several vendors have taken the opportunity to develop commercial versions

of the Shelf web-based SPC system. This section discusses examples of the webbased SPC systems which have been implemented in the manufacturing industry.

eNet SPC is a web-based process control system developed by Quality

America Inc. This product comes with several functions like access control,

customizable analysis, viewing options and a fully programmable interface. Process

data can be collected and stored in various source such as spreadsheet or any

ODBC compliant database. This system has access control features which datasets

26

are restricted to a predefined set of user to maintain its confidentiality. A remote

system user can customize the view option to suit his requirement.

The NWA Quality Analyst Web Server 2.1 is the web-based SPC software

developed by Northwest Analytical (NWA) Inc. This web server provides real-time

monitoring of remote plant and contract manufacturing facilities. NWA quality

analyst web server is not only included the conventional SPC chart generator but

the user can accumulate several charts and format them in multi-chart layouts. The

user can select and key in assignable cause and corrective action taken at the related

control chart point. The latest version includes exception reporting capabilities to

generate product exception reports.

The Factory Server SPC is developed by Factory Server SPC Mass Group,

Inc. This web-based SPC system has features like data entry, data import,

customized analysis, view options, access control datasets, software updates and

fully programmable again using Visual Basic. Factory Server SPC has similar

features provided by NWA Quality Analyst Web Server 2.1. In addition, control

charts such as Pareto chart, Scatter Diagram, Bullseye Chart and Reproducibility

Chart can be generated. This system had been integrated with other sub-modules of

factory server such as production control, production scheduling and production

reporting.

Basically, most of the web-based SPC system assists user in automating the

process of plotting the control chart. All of the control chart data are stored in a

database system. The control chart data can be retrieved later for more details

analysis. Some security policies have been enforced to ensure the authenticity of

user and confidentiality of data. Table 2.4 summarizes the features provided by

various commercial of the shelf web-based SPC system.

It is found that most of the web-based SPC products have included the

automated data collection, access control features, record assignable cause and fully

27

programmable programming interface. Besides that, the commercialized web-based

SPC product is accessible using any internet connected web browser. The web

server and database server chosen by these company is mostly Microsoft-based

product or license based product.

However, none of these systems provided CCPR features. This feature is

needed to identify the existent of an unstable pattern in control chart. The CCPR

result is helpful for narrows down the scope of the assignable cause and speeds up

the troubleshooting process. Beside that, the customer who wishes to implement

SPC needs to purchase separate licenses for the installation of a web server and a

database server. It is quite expensive and unaffordable for small and medium

company. The client-server based SPC service can be published at somewhere,

small company who wish to use the system can subscribe this service through

internet.

Product

eNET SPC

Quality

Analyst

Web

Server

Factory

Server

SPC

Company

1 Quality

America Inc.

2 Northwest

Analytical

Inc.

3 Factory

Server SPC

Mass Group,

Inc.

Production

personnel,

workstation,

parts,

assemblies,

lots and

work orders

can be

automatically

collected.

Keyboard

input, scales

measuremen

t devices and

barcode

readers.

Data may be

collected and

analyzed

real-time.

Data entry

Admin

can

provide

access

based on

each

user’s

role.

Anyone

authorized

can access

and view

charts.

Each production

process is constantly

changing and unique;

so many proprietary

functions can be

created as needed in

VB or standard

development tools.

Included visual design

to configure plant

floor workstations

interface. Fast and

easy alternative to

writing complicated

programming scripts.

Can customize the

interface to suit your

users' needs. Adding

company logos, entry

forms, and displaying

part drawings are just

modifications.

Programmable

Control

Datasets

are

restricted

to a

selected

set of

users.

Fully Customize &

Access

Windows

2000 or

XP,

Microsoft

IE 6.0

and

TCP/IP

Network

Access.

Any web

browser

Any

Internet

browser

Side

Client

Features Provided

Tables 2.4: Web-based SPC System and Provided Features

Own

developed

and

integrated

database

system.

Microsoft

SQL Server

Server

Database

Microsoft Microsoft SQL

Server 2000,

IIS Web

Windows

Server,

2000 Server

VB,

or Windows

ASP.NET,

Server 2003.

COM

Technolog

y and

crystal

reports.

Microsoft

Windows

NT4,

2000, XP,

and

Server

2003.

Windows

NT Web

Server

Server

Web

28

29

2.6

Design Consideration in Development of Client-Server based

Application

There are several issues that need to be considered in developing a clientserver based application. As illustrated in Figure 2.6, there are data modeling,

network security, communication standard, client and server (CS) system

integration and load balancing to be taken into consideration. The following section

gives explanation on these issues.

Design Consideration in Development of Client-server based Application

Data

Modeling

Network

Security

Communication

Standard

Load

Balancing

Client / Server

System

Integration

Figure 2.6: Research Issues in Development of the Client-Server based Application

2.6.1 Data Modeling

Data modeling is one of the issues that need to be addressed. Data modeling

is a conceptual representation of the data structure. The data structure included data

objects, associations between data objects, and rules which govern operations on

objects. In the last few years, Extensible Markup Language (XML) data

management system has been intensively studied for data modeling.

Originally, XML is designed to meet the challenges of a large-scale

electronic publishing. It plays an important role in the exchange of a wide variety

of data on the Web application (Carey et al., 2000). Several researchers such as

Nurmilaakso et al. (2002), Yang and Zhang (2003), Wusteman (2003), Peter and

30

Henry (2003) and Stephen and Bruce (2003) have implemented XML technology

for web-based application.

Data modeling is probably the most labor intensive and time consuming

part of the development process. The designer needs to ensure all the data objects

required by the database are accurately and completely represented in a data model

(Silverston, 2001). For web-based SPC system, investigation can be done on

investigating the proper data model to represent the control chart data.

2.6.2

Network Security

Network security is another issue needs to be investigated for the

development of a web-based application. Owing to many threats and software

vulnerabilities, the risk to unauthorized access ad intrusion via the computer

network is growing. Unauthorized access or intrusion can cause data lost, privacy

lost and corruption on data.

Researchers such as Fabisiak (2003), Gillespie and Gordan (2003), Dong

and Liu (2004), Zheng et al. (2004) and Marin (2006) have reported research on

network security. To prevent unauthorized access or intrusion, the system

administrator must keep all security related hardware and software up to date. This

is also applicable for the web-based SPC system. The confidentiality of control

chart data which represent the process capability can be the main secrecy concern.

2.6.3

Communication Standard

Communication standard is another issue that needs to be considered for the

development of a web-based application. The communication standard is referred

to as how network system exchange information. Among the commonly used

communication standard are Hypertext Transfer Protocol, File Transfer Protocol,

31

Simple Main Transfer Protocol, Post Office Protocol, Simple Network

Management Protocol, Common Object Request Broker Architecture (CORBA)

and Web Service (Andrew, 2003). The most recent communication standard can be

referred to as CORBA and Web Service.

The CORBA is an emerging open distributed object computing

infrastructure being standardized by the Object Management Group. CORBA

automates many common network programming tasks such as object registration,

location, and activation; request demultiplexing; framing and error-handling;

parameter marshalling and demarshalling; and operation dispatching (Schmidt et

al, 2003). Web Service is a new and powerful model for creating applications from

reusable software models supported on the Internet using HTTP technology. Web

Service provides loosely coupled, flexible, and dynamic solutions by using

emerging techniques such as SOAP, WSDL and UDDI. Figure 2.7 shows

integration of different platforms using web services.

Figure 2.7: Web Services for Different Platform Integration

Researchers such as Jun et al. (2003) and Rodolfo et al. (2005) have

implemented CORBA in the manufacturing process. On the other hand, Rainer and

Schahram (2005) and Deependra and Ganesh (2005) and Park and Lee (2006) have

implemented web services for the manufacturing process. Further research

expansion can be done to identify the appropriate communication protocol for the

web-based Statistical Process Control system.

32

2.6.4

Load Balancing

Load balancing is another issue needs to be considered. Load balancing is

important for the server whereby it is difficult to predict the number of requests that

will be issued to a server. By distributing the server workload among the group of

servers, a better performance, resource utilization and scalability can be achieved.

There are various ways of implementing load balancing. Basically, the load

distribution can be done through hardware or software based techniques.

Hardware load balancers can route TCP/IP packets to various servers in a

cluster. As shown in Figure 2.8 the load balancer can be used to separate public and

private network. The software based load balancer is the most commonly used in

the current market. It is often comes as an integrated component of the

commercialized web and application server packages. Normally, the software based

load balancer is cheaper than the hardware load balancer. Since the special

objective for this study is on the load passing procedure for client-server based

CCPR system, further explanation on load balancing is presented in Section 2.7.

Figure 2.8: Separation of Public and Private Network (Tony, 2001)

33

2.6.5

Client and Server System Integration

Another issue to be considered for the development of the web-based

application is the CS system integration. The CS system integration has created a

communication medium for a heterogeneous web-based system to exchange

information. Researchers such as Anosike and Zhang (2004), Zheng and Wans

(2004), Saygin (2004) and Martin (2006) have reported research on CS system

integration for the manufacturing system. Further review and explanation on CS

architecture are presented in Section 2.8, since the special objective of this study is

to investigate and proposed a customized system architecture for client-server

based CCPR system.

2.7

Load Balancing and System Performance Measurement

Load balancing improves system response time by utilize the available

system resources. It is mainly used in distributed systems for maximizing the

system throughput. The following section presents several methods used for system

load balancing.

2.7.1

Application of Load Balancing

Many computer applications use load balancing to improve system

performance. The ability to divide the server workload among the available system

resources can significantly improve the system throughput. Load balancing is

applied for a computer network. The high computer network growing rate has lead

to a decrease in ‘Quality of Service’ of computer networks. Researchers such as

Hui and Samuel (1997) and He (2000) have reported review on load balancing for

LAN and WAN networks.

34

Load balancing can be implemented in the cellular network. Load balancing

distribution techniques are used to distribute cellular base-station workload.