vii TABLE OF CONTENTS CHAPTER

advertisement

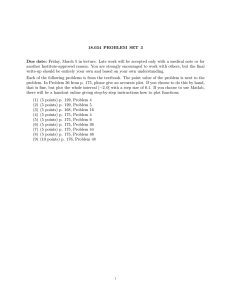

vii TABLE OF CONTENTS CHAPTER 1 TITLE PAGE DECLARATION ii DEDICATION iii ACKNOWLEDGEMENTS iv ABSTRACT v ABSTRAK vi TABLE OF CONTENTS vii LIST OF TABLES xi LIST OF FIGURES xiii LIST OF ABBREVIATIONS AND SYMBOLS xv LIST OF APPENDICES xvi INTRODUCTION 1 1.1 Background 1 1.2 Research Statement 4 1.3 Problem Statement 4 1.4 Objective Of Project 4 1.5 Scope Of Project 5 viii 2 LITERATURE REVIEW 6 2.1 Introduction 6 2.2 Plastics Material 7 2.2.1 Injection Moulding Processing Conditions 8 2.2.2 Advantage 8 2.3 Injection Molding 2.3.1 Components 2.3.2 8 9 2.3.1.1 Injection System 10 2.3.1.2 Mold System 11 2.3.1.3 Delivery System 13 Warpage Problem 14 2.4 Product Design 15 2.4.1 Uniform Walls 16 2.4.2 Voids And Shrinkage 19 2.4.3 Warpage 20 2.5 Moldflow 22 2.5.1 The Benefits Of Predictive Analysis 23 2.5.2 Optimize Warpage 24 2.5.3 Reduce Warpage 25 2.5.4 Mould Temperature (°C) And Melt Temperature 27 2.5.5 Injection Time (S) 28 2.5.6 Packing Pressure (Bar) 29 2.5.6.1 Packing Methods 2.5.7 Packing Time (S) 2.6 Mould Design Software 30 31 31 2.6.1 Easy Interfaces for Mould and Casting 33 2.7 Previous Research 34 2.8 Design of Experiment (D.O.E) 36 2.8.1 When to Apply Design of Experiments 37 ix 2.8.2 What Is A Designed Experiment? 37 2.8.3 What Is A Process Diagram? 38 2.8.4 What Is A Factor? 39 2.8.5 What Is A Response? 40 2.8.6 Planning the Experiment 41 2.8.7 A Process Diagram for Injection 3 Molding Experiment 43 2.8.8 An Orthogonal Array 45 2.8.9 Example Data 49 2.8.10 The Pareto Chart 49 2.8.11 The Main Effects Plot 50 2.8.12 Contour Plot 51 2.8.13 Summary 53 RESEARCH DESIGN 54 3.1 Introduction 54 3.2 Factorial Design 54 3.3 Fractional Factorial Design 55 3.4 Flow Chart of Classical Method 56 3.5 Factor Considered 57 3.5 Experimental Layout 57 3.6 Overall Evaluation Criteria 59 3.7 Methodology 60 3.7.1 Step Of Methodology 3.7.1.1 Step 1 : Product Drawing 60 60 3.7.1.2 Step 2 : Choosing The New Run In Moldflow 62 3.7.1.3 Step 3 : Mesh Model 63 3.7.1.4 Step 4: Select Best Gate Location 64 3.7.1.5 Step 5 : Selected Analysis Sequence 65 x 4 5 3.7.1.6 Step 6: Selection of Plastic Material 66 3.7.1.7 Step 7: Process Setting 67 3.7.1.8 Step 8: Run the Analysis 67 3.7.1.9 Step 9: D.O.E Analysis 68 RESULT AND ANALYSIS 69 4.1 Introduction 69 4.2 Simulation Results 70 4.3 Individual Response Analysis 73 4.3.1 Warpage 73 4.3.2 Volumetric Shrinkage 79 4.3.3 Sink Index 85 4.3.4 Shear Stress 90 4.4 Multiple Response Analysis 96 4.5 Confirmation Test Run 104 4.6 Mould Design 109 CONCLUSION 110 5.1 Conclusion 110 5.2 Recommendations for Future Work 112 REFERENCES 114 APPENDICES 116 xiii LIST OF TABLE Table No. Title Page 2.0 Material Properties 7 2.1 Finding of Previous Research 34 2.2 Factor and corresponding level 46 2.3 Design Matrix 47 2.4 Design Matrix 47 2.5 Design Matrix 48 2.6 Completed Data 49 3.1 Selection of the controllable factors and levels 57 3.2 Experiment layout of full factorial designs 58 3.3 Properties of PC/ABS 66 4.1 Selection of the controllable factors and levels 70 4.2 Experimental Plan 71 4.3 Experimental Result 72 4.4 ANOVA table for warpage 74 4.5 Warpage Optimization Data 78 4.6 ANOVA table for volumetric shrinkage 79 4.7 Volumetric Shrinkage Optimization Data 84 4.8 ANOVA table for Sink Index 85 4.9 Volumetric Shrinkage Optimization Data 89 4.10 ANOVA table for Shear Stress 90 xiv 4.11 Volumetric Shear Stress Optimization Data 95 4.12 Data for OEC calculation 96 4.13 Result for OEC 97 4.14 ANOVA table for OEC 98 4.15 OEC Optimization Data 103 4.16 An example of the set goals for OEC Optimization 105 4.17 Possible solutions for OEC Optimization 4.18 An example of output from the point prediction 105 Tool 106 4.19 Analysis of confirmation experiments for OEC 106 4.20 Actual result analysis of confirmation experiments for OEC 4.21 Analysis of confirmation of experiments for Warpage 4.22 5.1 107 Analysis of confirmation experiments for Sink Index 4.24 107 Analysis of confirmation experiments for Volumetric shrinkage 4.23 106 107 Analysis of confirmation experiments for Shear Stress 108 Optization of Response by Number of Run 111 xiii LIST OF FIGURE No. Title Page 1.1 Moldflow Analysis of Injection Moulding Product 3 2.1 Injection Moulding Machine 9 2.2 A single screw injection-molding machine for 11 thermoplastics, showing the plasticizing screw, a barrel, band heaters to heat the barrel, a stationary platen, and a movable platen 2.3 A typical (three-plate) molding system 12 2.4 (a) Two-plate mold (b) Three-plate mold 13 2.5 Delivery System 13 2.6 Warping 17 2.7 Transition of Wall Thickness 18 2.8 Coring to Eliminate Sinks 18 2.9 Gusseting to Reduce Warping 19 2.10 Boss Design to Eliminate Sinks 20 2.11 Warpage caused by Non-Uniform Wall Thickness 21 2.12 Moldflow Logo 22 2.13 Filling Analysis 24 2.14 Optimize Warpage 25 2.15 Reducing Warpage 26 2.16 Effect increasing mold temperature 27 xiv 2.17 Packing Method Graph 30 2.18 Pro/Engineer Modelling 32 2.19 Process Diagram 38 2.20 A Process Diagram for an Injection Molding Experiment 44 2.21 Tree Diagram 46 2.22 Example of Pareto Chart 50 2.23 Example of Main Effects 50 2.24 Contour Plot for this example 52 3.1 Flow Chart of DOE Methodology 56 3.2 Formulation of OEC 59 3.3 Laptop Lid Casing 61 3.4 Analysis Methodology Flow Chart 61 3.5 Creating a project name 62 3.6 Selecting the Mesh type 62 3.7 Mesh Window 63 3.8 Mesh Model of Product 64 3.9 Gate Location Window 64 3.10 Analysis Sequence Selection 65 3.11 Selection of Plastic Material 66 3.12 Process Setting Window 67 4.1 Half-Normal % Probability Plot for Warpage 75 4.2 Pareto Chart for Warpage 76 4.3 Interactions factor plot for warpage for BC and BD 77 4.4 Interactions factor plot for warpage for CD 77 4.5 Half-Normal % Probability Plot for Vol. Shrinkage 81 4.6 Pareto Chart for Volumetric Shrinkage 82 4.7 Main effect interaction plot of BC and BD 83 4.8 Main effect interaction plot of CD and CE 80 4.9 Main effect interaction plot of DE 80 4.10 Half-Normal % Probability Plot for Sink Index 86 4.11 Pareto Chart for Sink Index 87 xv 4.12 Main effect interaction plot of BD and BE 88 4.13 Main effect interaction plot of DE 88 4.14 Half-Normal % Probability Plot for Shear Stress 92 4.15 Pareto Chart for Shear Stress 93 4.16 Main effect interaction plot of BC 93 4.17 Main effect interaction plot of CD and CE 94 4.18 Half-Normal % Probability Plot for OEC 100 4.19 Pareto Chart for OEC 101 4.20 Main effect plot of D and E 101 4.21 Main effect interaction plot of BC 102 xv LIST OF ABBREVIATIONS AND SYMBOLS PC/ABS - Polycarbonate-Acrylonitrile-Acrylonitrile-Butadine-Styrene ANOVA - Analysis of variance CAD - Computer aided design CAE - Computer aided engineering C.I. - Confidence interval Deg. - Degree DOE - Design of experiment OEC - Overall evaluation criteria P.I. - Prediction interval Pro-E - Pro-Engineer QC - Quality characteristic SE - Standard deviation Sec. - Seconds W - Weighting |x| - Absolute value for reading XA… XD - Sample Reading Value of response XA1… XD1 - Worst reading value of response XA2… XD2 - Best reading value of response Y - Response α - Alpha phase xvi LIST OF APPENDICES APPENDIX TITLE PAGE A-1 Result of Warpage 116 A-2 Result of Volumetric Shrinkage 116 A-3 Result of Sink Index 117 A-4 Result of Shear Stress 117 A-5 Moldflow Log file 118 B-1 Core and Cavity Insert 119 B-2 Mould Design 119 B-3 Mould Opening 120 B-4 Mould Assembly Drawing 121 C-1 Schedule for Project 122