Document 14540222

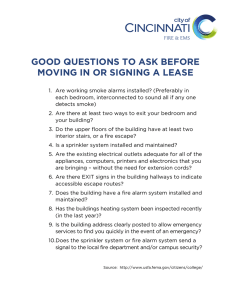

advertisement