Team

advertisement

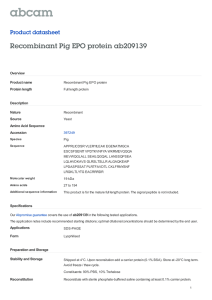

Team Eporis consists of four Chemical Engineering seniors at Calvin College (Figure 1). Core strengths include biochemistry research experience, pharmaceutical process development, and financial management. They are coordinating their efforts to reduce the high costs associated with the biotechnology industry. Project Background Figure 1. Eporis: Zion Lee, Nick Giles, Stephen Tubergen, Abby Leistra, left to right. Erythropoietin (EPO) is a glycoprotein hormone that promotes red blood cell production (Figure 2). It is naturally made by the human kidneys; however, it is often prescribed to treat anemia in patients undergoing medical treatments, including dialysis, chemotherapy, and HIV therapy. It represents a $4 billion annual market in the US. EPO is a biologic drug, meaning it is produced in a living cell system. Currently, commercial varieties are produced from mammalian cells. These systems are slow-growing and require many purification steps. We propose production of EPO in the faster growing Pichia Pastoris (P. Pastoris) yeast cell line. Furthermore, this method reduces the number of purification steps required. Design Genetic Modification Eporis plans to use genetically engineered P. Pastoris strains to allow the mammalian protein, EPO, to be produced by simple yeast. Genetic changes to the yeast strain will enable it to produce bioactive EPO and produce it at greater yields. PEGylation Further product modification is necessary for P. Pastorisproduced EPO to be as effective as mammalian cellproduced EPO. A polyethylene glycol (PEG) group will be added to the protein to increase its molecular weight and negative charge, increasing bioactivity to a level equivalent to current commercial products. Figure 2. Erythropoietin structure. (glycam.org) Fermentation Genetically engineered P. Pastoris will be grown in a type of reaction vessel known as a fermenter (Figure 3). In order to maximize EPO production, the fermentation process will be semi-batch, i.e. a few materials will be added with time over the course of the fermentation while most will be added in bulk at the start of fermentation. Feedstock composition and flow rate, oxygenation, and agitation will all affect cell growth and EPO production. Separation The separation processes associated with EPO produced from P. Pastoris are more effective than with those associated with EPO produced from CHO cells. Because P. Pastoris secretes few native proteins, our process will produce a much cleaner bioreactor effluent, resulting in higher purity with fewer chromatography steps. Furthermore, virus transmission is impossible with yeast, so viral inactivation stages can be neglected with this Figure 3. Stainless steel fermenter. (en.wikipedia.org) process. Business Model The expiration of American EPO patents is a great opportunity for entry of new biopharmaceutical companies. When several other companies wish to join this market for biosimilar EPO (based on similar historical instances), there will be demand for Eporis’ drug substance. On the off chance that other companies do not enter the market, Eporis has the option to contract out drug product manufacturing and enter the market until there is competition. With the current markup of on-patent drugs, Eporis will command a significant margin from its manufacturing cost leadership. With the expected approval of the FDA, Eporis can also consider entering (or supplying) other global markets. Figure 4. Eporis considers all aspects of the biopharmaceutical market landscape. This includes drug production, distribution, and administration. (sparkblog.emc.com)