MINITAB & Six Sigma Hong Kong Society for Quality March 1, 2004 1

advertisement

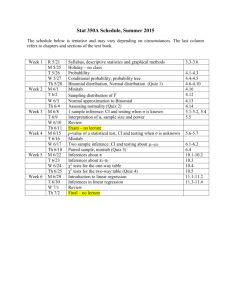

MINITAB & Six Sigma Hong Kong Society for Quality March 1, 2004 1 © Minitab Inc., 2000 Presented By Kristina T. Konrath Minitab Inc. Customer Services Manager tkonrath@minitab.com 2 © Minitab Inc., 2000 Local Representative Buxway Consultants Ltd. Iza Ng Business Development Manager (852) 2783 9299 iza@buxway.com 3 © Minitab Inc., 2000 Agenda 4 • Introduction to Six Sigma • Minitab History and Products • DMAIC Methodology • MINITAB and MQC Tools • Tutorials (time permitting) • Questions © Minitab Inc., 2000 Statistics & Six Sigma Six Sigma is a methodology that aims to remove variation from any process. It is a data driven program that is focused on financial return. Successful Six Sigma practitioners must have strong communication and quantitative skills. They must have excellent process knowledge and need to apply to appropriate tools. Statistics is one of the key tools used in Six Sigma. 5 © Minitab Inc., 2000 Statistics & Six Sigma Good statistical software is essential tool for a successful Six Sigma initiative • Takes away “hand” calculations - reduces the chances for error • Must be intuitive – practitioners are not usually statisticians • Allow for exploration – must offer a well-rounded suite of tools • Clear and consistent presentation of results 6 © Minitab Inc., 2000 Why MINITAB? MINITAB has been the standard for global Six Sigma operations since the mid 1990’s • Developed in 1972 to teach introductory statistics, designed for non-statisticians • Began developing for quality in the late 80’s • Strong customer focus and support • Developing translated product • Developing companion products 7 © Minitab Inc., 2000 Minitab Products MINITAB Release 14 • Statistical software Minitab Quality Companion • Process Improved Soft Tools Minitab Quality Trainer • Multimedia training tool available in 2005 8 © Minitab Inc., 2000 DMAIC Model Define • Where are your current problems and opportunities? • What do your customers require & want? Measure • Where is your process currently? Analyze • What are the sources or variation? Improve • What can make the process better? Control • How do you ensure your improvements last? 9 © Minitab Inc., 2000 Define • Determine the process to be improved • Identify your customers • Identify your problems and scope Measure • Determine the extent of problem • Identify your inputs & outputs (X’s & Y’s) • Measure it 10 © Minitab Inc., 2000 MQC •Project Charter •C&E Matrix •Critical To Matrix •FMEA •Brainstorming •Process Mapping •Data Collection Plan MINITAB •Pareto •Gage R&R •Control Charts •Capability Analysis •Graphics Analyze • Screen potential causes • Identify sources or root causes of problem • Draw Conclusions MINITAB •Gage R&R •Hypothesis Tests •ANOVA •Correlation 11 © Minitab Inc., 2000 •Regression •Capability Analysis •Graphics •DOE Improve • Identify what improvements to implement • Determine optimal settings • Confirm results MINITAB •Gage R&R •Hypothesis Tests •ANOVA •Regression 12 © Minitab Inc., 2000 •Graphics •Capability Analysis •Response Optimizer •DOE Sustain the gains • Permanent change Sample Mean • 1 1 603 UC L = 6 0 2 .4 602 601 M e an=6 0 0 .2 600 599 L C L = 5 9 8 .1 598 S ub g ro up Sample Range Control X bar/R C h art for T ech S u pport 0 10 20 9 8 7 6 5 4 3 2 1 0 UC L = 7 .8 6 6 R =3 .7 2 LC L=0 P r o c e s s C a p a b ilit y A n a ly s is fo r S a le s MINITAB •Control Charts •Capability Analysis US L T a rg e t LSL M ean P ro c e s s D a ta 6 0 5 .0 0 0 * 5 9 5 .0 0 0 5 9 9 .5 4 8 S a m p le N S tD e v (W i th i n ) S tD e v (O v e ra ll) © Minitab Inc., 2000 USL W it h in O v e r a ll 100 0 .5 7 6 4 2 9 0 .6 2 0 8 6 5 P o te n ti a l (W i th i n ) C a p a b i li ty 2 .8 9 Cp 3 .1 5 CPU CPL C pk 2 .6 3 2 .6 3 C pm * O v e ra ll C a p a b i li ty 13 LSL Pp PPU PPL 2 .6 8 2 .9 3 2 .4 4 Ppk 2 .4 4 595 597 O b s e rv e d P e r fo rm a n c e 0 .0 0 PPM < LSL 0 .0 0 PPM > USL 0 .0 0 P P M T o ta l 599 601 E x p . " W i th i n " P e rfo r m a n c e 0 .0 0 PPM < LSL 0 .0 0 PPM > USL 0 .0 0 P P M T o ta l 603 605 E x p . " O v e ra ll" P e rfo r m a n c e 0 .0 0 PPM < LSL 0 .0 0 PPM > USL 0 .0 0 P P M T o ta l Tutorials Download Meet MINITAB for free from www.minitab.com/downloads/ • Data is included in MINITAB – SHIPPINGDATA.MTW • Emphasis on Analyze, Improve, Control phases of Six Sigma 14 © Minitab Inc., 2000 Questions? Our technical support staff is also available to help you whether you have purchased or are considering buying MINITAB. Please contact them at http://customer.minitab.com. 15 © Minitab Inc., 2000 Thank you! 16 © Minitab Inc., 2000 Linked Pages 17 © Minitab Inc., 2000 MINITAB Release 14 – Pareto Chart Identify Potential Root Causes Pareto Chart of Defects 100 400 80 Count 60 200 40 100 Defects 0 g in si s M Count Percent Cum % 18 © Minitab Inc., 2000 20 re Sc w s 274 64.8 64.8 g in si s M C s lip y ak Le 59 13.9 78.7 et sk a G i us Ho rt Pa e e et pl ti v c m fe co De In 43 19 10 10.2 4.5 2.4 88.9 93.4 95.7 r he t O 18 4.3 100.0 0 Percent 300 MINITAB Release 14 – Gage R&R Measurement Systems Analysis Gage R&R (ANOVA) for Response G age name: Date of study : Reported by : S hift #2 Tolerance: M isc: Line #2 10/20/2003 Response by Part Components of Variation 100 % Contribution 1.00 Percent % Study Var 0.75 50 0.50 0 Gage R&R Repeat Reprod 1 Part-to-Part 2 3 Sample Range 2 3 0.10 7 8 9 10 1.00 0.75 0.05 _ R=0.0383 0.00 LCL=0 1 0.50 1 2 2 Operator 0.75 0.50 _ UCL=0.8796 _ X=0.8075 LCL=0.7354 1.00 Operator 0.75 2 3 1 0.50 1 © Minitab Inc., 2000 3 Operator * Part Interaction 3 1.00 Average Sample Mean 6 Response by Operator UCL=0.1252 Xbar Chart by Operator 19 5 Part R Chart by Operator 1 4 2 3 4 5 6 Part 7 8 9 10 MINITAB Release 14 – Attribute Gage Study for Acceptances Measurement Systems Analysis Attribute Gage Study (Analytic Method) for Acceptances Reported by : Tolerance: M isc: G age name: Date of study : Bias: P re-adjusted Repeatability : Repeatability : 99 0.0097955 0.0494705 0.0458060 95 80 A IA G Test of Bias = 0 v s not = 0 T DF P -V alue 6.70123 19 0.0000021 50 20 5 1 20 © Minitab Inc., 2000 -0.05 -0.04 -0.03 -0.02 Reference Value of Measured Part -0.01 Probability of Acceptance Percent of Acceptance F itted Line: 3.10279 + 104.136 * Reference R - sq for F itted Line: 0.969376 L Limit 1.0 0.5 0.0 -0.050 -0.025 0.000 Reference Value of Measured Part MINITAB Release 14 – Attribute Agreement Analysis Measurement Systems Analysis of Appraisers Date of study : Reported by : Name of product: Misc: Assessment Agreement Appraiser vs Standard 100 95.0% C I P ercent Percent 80 60 40 20 0 Duncan 21 © Minitab Inc., 2000 Hayes Holmes Appraiser Montgomery Simpson MINITAB Release 14 – Graphing Techniques Descriptive Statistics Summary for Pulse1 A nderson-D arling N ormality Test 50 60 70 80 90 A -S quared P -V alue 0.98 0.013 M ean S tDev V ariance S kew ness Kurtosis N 72.870 11.009 121.192 0.397389 -0.442443 92 M inimum 1st Q uartile M edian 3rd Q uartile M aximum 100 48.000 64.000 71.000 80.000 100.000 95% C onfidence Interv al for M ean 70.590 75.149 95% C onfidence Interv al for M edian 68.000 95% Confidence Intervals 9.615 Mean Median 68 22 © Minitab Inc., 2000 70 72 74.000 95% C onfidence Interv al for S tD ev 74 76 12.878 MINITAB Release 14 – Control Charts Is your process in control? Xbar-R Chart of Supp2 1 1 Sample M ean U C L=602.474 602 _ _ X=600.23 600 598 LC L=597.986 2 4 6 8 10 Sample 12 14 16 18 20 U C L=8.225 Sample Range 8 6 _ R=3.890 4 2 0 LC L=0 2 23 © Minitab Inc., 2000 4 6 8 10 Sample 12 14 16 18 20 MINITAB Release 14 – Capability Analysis (Sixpack) How Capable is your process? Process Capability Sixpack of Supp1 C apability H istogr am Xbar C har t Sample Mean UCL=600.321 600.0 _ _ X=599.548 599.5 599.0 LCL=598.775 2 4 6 8 10 12 14 16 18 20 598.0 598.5 Sample Range R C har t 3.0 UCL=2.835 1.5 _ R=1.341 0.0 599.0 4 6 8 10 12 14 16 18 20 601.0 598 600 Within S tDev 0.57643 Cp 1.16 C pk 0.90 C C pk 1.16 598.5 Within Overall Specs 5 10 Sample 602 C apability P lot 600.0 © Minitab Inc., 2000 600.5 Nor mal P r ob P lot A D : 0.844, P : 0.029 Last 2 0 Subgr oups 601.5 24 600.0 LCL=0 2 Values 599.5 15 20 O v erall S tD ev 0.62086 Pp 1.07 P pk 0.83 C pm 0.87 Project Charter – (Form Tool) 25 © Minitab Inc., 2000 Cause and Effect Diagram 26 © Minitab Inc., 2000 FMEA – (Form Tool) 27 © Minitab Inc., 2000 Process Mapping Tool 28 © Minitab Inc., 2000 MINITAB Release 14 – Gage R&R Measurement Systems Analysis Gage R&R (ANOVA) for Response G age name: Date of study : Reported by : S hift #2 Tolerance: M isc: Line #2 10/20/2003 Response by Part Components of Variation 100 % Contribution 1.00 Percent % Study Var 0.75 50 0.50 0 Gage R&R Repeat Reprod 1 Part-to-Part 2 3 Sample Range 2 3 0.10 7 8 9 10 1.00 0.75 0.05 _ R=0.0383 0.00 LCL=0 1 0.50 1 2 2 Operator 0.75 0.50 _ UCL=0.8796 _ X=0.8075 LCL=0.7354 1.00 Operator 0.75 2 3 1 0.50 1 © Minitab Inc., 2000 3 Operator * Part Interaction 3 1.00 Average Sample Mean 6 Response by Operator UCL=0.1252 Xbar Chart by Operator 29 5 Part R Chart by Operator 1 4 2 3 4 5 6 Part 7 8 9 10 MINITAB Release 14 – Hypothesis Testing & Graphics Graphical and Statistical Analysis of Data Two-Sample T-Test and CI: BTU.In, Damper Boxplot Two-sample T for BTU.In N 40 50 Mean 9.91 10.14 StDev 3.02 2.77 SE Mean 0.48 0.39 Difference = mu (1) - mu (2) Estimate for difference: -0.235250 95% CI for difference: (-1.450131, 0.979631) T-Test of difference = 0 (vs not =): T-Value = -0.38 Value = 0.701 DF = 88 Both use Pooled StDev = 2.8818 15 P- BTU.In Damper 1 2 20 10 Test and CI for Two Proportions Sample 1 2 X 537 778 N 1000 1000 Sample p 0.537000 0.778000 Difference = p (1) - p (2) Estimate for difference: -0.241 95% CI for difference: (-0.281232, -0.200768) Test for difference = 0 (vs not = 0): Z = -11.74 = 0.000 30 © Minitab Inc., 2000 5 1 P-Value 2 Damper MINITAB Release 14 – ANOVA & Graphics Graphical and Statistical Analysis of Data Boxplotof DurabilitybyCarpet One-way ANOVA: Durability versus Carpet DF 3 12 15 S = 3.691 Level 1 2 3 4 N 4 4 4 4 SS 146.4 163.5 309.9 MS 48.8 13.6 F 3.58 20.0 17.5 R-Sq = 47.24% Mean 14.483 9.735 12.808 18.115 P 0.047 StDev 3.157 3.566 1.506 5.435 R-Sq(adj) = 34.05% Individual 95% CIs For Mean Based on Pooled StDev ---------+---------+---------+---------+ (-------*-------) (-------*--------) (-------*-------) (-------*-------) ---------+---------+---------+---------+ 10.0 15.0 20.0 25.0 Pooled StDev = 3.691 Durability Source Carpet Error Total 22.5 15.0 12.5 10.0 7.5 5.0 1 2 3 Carpet 31 © Minitab Inc., 2000 4 MINITAB Release 14 – Regression & Correlation Determining Significant Factors Regression Analysis: Score1 versus Score2 FittedLine Plot The regression equation is Score1 = - 4.667 + 4.397 Score2 S = 0.572711 R-Sq = 95.7% Score1 = - 4.667 +4.397 Score2 12 R-Sq(adj) = 95.1% 10 Analysis of Variance DF 1 7 8 SS 51.3529 2.2960 53.6489 MS 51.3529 0.3280 Correlations: Verbal, Math, GPA Math Verbal 0.275 0.000 Math 0.322 0.000 0.194 0.006 F 156.56 P 0.000 S R-Sq R-Sq(adj) 8 Score1 Source Regression Error Total Regression 95%CI 95%PI 6 4 2 0 GPA Cell Contents: Pearson correlation P-Value 32 © Minitab Inc., 2000 1.50 1.75 2.00 2.25 2.50 Score2 2.75 3.00 3.25 0.572711 95.7% 95.1% MINITAB Release 14 – Design of Experiments (DOE) Determining Significant Factors Factorial Fit: Yield versus Block, Time, Temp, Catalyst Normal Probability Plot of the StandardizedEffects (response is Yield, Alpha = .05) Estimated Effects and Coefficients for Yield (coded units) S = 0.381847 2.9594 2.7632 0.1618 0.8624 0.0744 -0.0867 0.0230 Coef 45.5592 -0.0484 1.4797 1.3816 0.0809 0.4312 0.0372 -0.0434 0.0115 R-Sq = 98.54% SE Coef 0.09546 0.09546 0.09546 0.09546 0.09546 0.09546 0.09546 0.09546 0.09546 T 477.25 -0.51 15.50 14.47 0.85 4.52 0.39 -0.45 0.12 P 0.000 0.628 0.000 0.000 0.425 0.003 0.708 0.663 0.907 33 DF 1 3 3 1 7 15 © Minitab Inc., 2000 Adj SS 0.0374 65.6780 3.0273 0.0021 1.0206 Adj MS 0.0374 21.8927 1.0091 0.0021 0.1458 B Factor Name A Time AB 50 B C Temp Catalyst 10 1 -5 0 5 Standardized Effect 10 15 Pareto Chart of the StandardizedEffects (response is Yield, Alpha = .05) R-Sq(adj) = 96.87% Seq SS 0.0374 65.6780 3.0273 0.0021 1.0206 69.7656 Effect Type Not Significant Significant A 2.36 A B Analysis of Variance for Yield (coded units) Source Blocks Main Effects 2-Way Interactions 3-Way Interactions Residual Error Total P er cent Effect 90 F 0.26 150.15 6.92 0.01 P 0.628 0.000 0.017 0.907 T er m Term Constant Block Time Temp Catalyst Time*Temp Time*Catalyst Temp*Catalyst Time*Temp*Catalyst 99 AB C BC AC ABC 0 2 4 6 8 10 Standardized Effect 12 14 16 Factor Name A B C Time Temp Catalyst MINITAB Release 14 – Hypothesis Testing & Graphics Confirming Improvements Two-Sample T-Test and CI: BTU.In, Damper Boxplot Two-sample T for BTU.In N 40 50 Mean 9.91 10.14 StDev 3.02 2.77 SE Mean 0.48 0.39 Difference = mu (1) - mu (2) Estimate for difference: -0.235250 95% CI for difference: (-1.450131, 0.979631) T-Test of difference = 0 (vs not =): T-Value = -0.38 Value = 0.701 DF = 88 Both use Pooled StDev = 2.8818 15 P- BTU.In Damper 1 2 20 10 Test and CI for Two Proportions Sample 1 2 X 537 778 N 1000 1000 Sample p 0.537000 0.778000 Difference = p (1) - p (2) Estimate for difference: -0.241 95% CI for difference: (-0.281232, -0.200768) Test for difference = 0 (vs not = 0): Z = -11.74 = 0.000 34 © Minitab Inc., 2000 5 1 P-Value 2 Damper MINITAB Release 14 – ANOVA & Graphics Confirming Improvements Boxplotof DurabilitybyCarpet One-way ANOVA: Durability versus Carpet DF 3 12 15 S = 3.691 Level 1 2 3 4 N 4 4 4 4 SS 146.4 163.5 309.9 MS 48.8 13.6 F 3.58 20.0 17.5 R-Sq = 47.24% Mean 14.483 9.735 12.808 18.115 P 0.047 StDev 3.157 3.566 1.506 5.435 R-Sq(adj) = 34.05% Individual 95% CIs For Mean Based on Pooled StDev ---------+---------+---------+---------+ (-------*-------) (-------*--------) (-------*-------) (-------*-------) ---------+---------+---------+---------+ 10.0 15.0 20.0 25.0 Pooled StDev = 3.691 Durability Source Carpet Error Total 22.5 15.0 12.5 10.0 7.5 5.0 1 2 3 Carpet 35 © Minitab Inc., 2000 4 MINITAB Release 14 – Regression Prediction Methods Regression Analysis: Score1 versus Score2 The regression equation is Score1 = - 4.67 + 4.40 Score2 Predictor Constant Score2 Coef -4.6674 4.3975 S = 0.572711 SE Coef 0.8572 0.3514 R-Sq = 95.7% FittedLine Plot Score1 = - 4.667 +4.397 Score2 T -5.44 12.51 P 0.001 0.000 12 10 8 SS 51.353 2.296 53.649 MS 51.353 0.328 F 156.56 P 0.000 Score1 DF 1 7 8 S R-Sq R-Sq(adj) R-Sq(adj) = 95.1% Analysis of Variance Source Regression Residual Error Total Regression 95%CI 95%PI 6 4 Predicted Values for New Observations 2 New Obs 1 2 3 4 5 6 7 8 9 Fit 4.567 1.929 2.808 6.326 8.525 4.567 9.405 7.646 6.326 36 SE Fit 0.214 0.363 0.305 0.196 0.290 0.214 0.346 0.242 0.196 95% CI (4.060, 5.074) (1.071, 2.787) (2.087, 3.530) (5.864, 6.789) (7.839, 9.212) (4.060, 5.074) (8.586, 10.224) (7.074, 8.217) (5.864, 6.789) © Minitab Inc., 2000 95% PI (3.121, 6.013) (0.326, 3.532) (1.274, 4.343) (4.895, 7.757) (7.007, 10.043) (3.121, 6.013) (7.822, 10.987) (6.176, 9.116) (4.895, 7.757) 0 1.50 1.75 2.00 2.25 2.50 Score2 2.75 3.00 3.25 0.572711 95.7% 95.1% MINITAB Release 14 – DOE & Response Optimizer Determine Optimal Settings Response Surface Regression: BeanYield vs Nitrogen, PhosAcid, Potash Estimated Regression Coefficients for BeanYield S = 0.9960 Coef 10.4623 -0.5738 0.1834 0.4555 -0.6764 0.5628 -0.2734 -0.6775 1.1825 0.2325 R-Sq = 78.6% SE Coef 0.4062 0.2695 0.2695 0.2695 0.2624 0.2624 0.2624 0.3521 0.3521 0.3521 T 25.756 -2.129 0.680 1.690 -2.578 2.145 -1.042 -1.924 3.358 0.660 P 0.000 0.059 0.512 0.122 0.027 0.058 0.322 0.083 0.007 0.524 BeanYield < 8 8- 9 9 - 10 10 - 11 11 - 12 12 - 13 > 13 2.5 PhosAcid Term Constant Nitrogen PhosAcid Potash Nitrogen*Nitrogen PhosAcid*PhosAcid Potash*Potash Nitrogen*PhosAcid Nitrogen*Potash PhosAcid*Potash Contour Plot of BeanYieldvs PhosAcid, Nitrogen 2.0 1.5 Hold Values Potash 2.42 1.0 1 2 3 4 Nitrogen 5 Surface Plot of BeanYieldvs PhosAcid, Nitrogen R-Sq(adj) = 59.4% Hold Values Potash 2.42 Analysis of Variance for BeanYield Source Regression Linear Square Interaction Residual Error Lack-of-Fit Pure Error Total 37 DF 9 3 3 3 10 5 5 19 Seq SS 36.465 7.789 13.386 15.291 9.920 7.380 2.540 46.385 © Minitab Inc., 2000 Adj SS 36.465 7.789 13.386 15.291 9.920 7.380 2.540 6 Adj MS 4.0517 2.5962 4.4619 5.0970 0.9920 1.4760 0.5079 F 4.08 2.62 4.50 5.14 P 0.019 0.109 0.030 0.021 8 10 BeanYield 12 2 14 2.91 0.133 4 3 2 1 6 PhosAcid Nitrogen