-

advertisement

A Group Technology Based Methodology for Maintenance Scheduling

Ji-hong Yan, Xin Li

Department of Industrial Engineering, Harbin Institute of Technology, Harbin, China

(jyan@hit.edu.cn, 23joe@163.com)

Keywords - Group Technology, maintenance scheduling,

Hierarchical Clustering, similarity, weight allocation

I. INTRODUCTION

Proper maintenance scheduling not only reduces

maintenance cost, but also increases the availability,

reliability, and life span of facilities. Current research on

maintenance scheduling mainly concerns with Preventive

Maintenance (PM) scheduling [1], including Periodical

Maintenance [2, 3], Condition Based Maintenance [4, 5],

etc., due to its effectiveness to avoid or mitigate the

consequences of failure of facilities.

Particularly, for multiunit systems, research on PM

focuses on Opportunistic Maintenance (OM) [6, 7] and

Group Maintenance (GM) [8-11]. Under OM, the failure

of a subsystem results in possible opportunity of other

subsystems to undertake maintenance. And under GM,

facilities are maintained in groups under certain

conditions, so that more reasonable logistics of spare parts

and smaller scale of scheduling problem can be achieved

[10]. However, for either OM or GM, little research is

conducted on complex systems, and method for grouping

facilities is scarcely studied.

In this paper, we proposed a novel methodology for

maintenance scheduling of complex system based on GT,

in which OM and Clustering-based Group Maintenance

(CGM) are combined. Facilities’ structural dependence

are studied and described with a structure model. HC [10]

is employed to group facilities according to factors such

as their similarities and interrelationships. And TS is

applied to optimize the weight allocation of the

considered factors in clustering. A case study of a

complex series-parallel production system is presented to

verify the methodology.

1.0

Reliability

Abstract - A novel Group Technology (GT) based

methodology for maintenance scheduling of complex seriesparallel production system is proposed. Hierarchical

Clustering (HC) method is employed to group facilities

according to their similarities in location, facility type,

maintenance type, structural position and maintenance time.

And weight allocation of these considered factors is

optimized using Tabu Search (TS). Simulation results

validate the methodology’s effectiveness in reducing

maintenance cost.

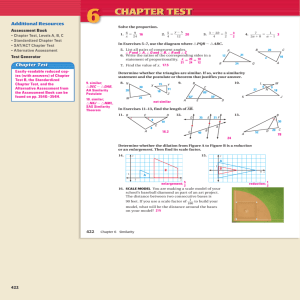

A. Facility Performance & Maintenance Effect Modeling

Th2

Th3

0.6

t1

0

t2

t3

4000

8000

Life Time (Day)

t4

12000

Fig.1. Reliability evolution of a facility with maintenance

We’ve studied the modeling of the performance of

facilities and the effect of four types of maintenance

actions, i.e. minor maintenance, medium maintenance,

overhaul and replacement in previous work [14], which

are also applied in this paper. As shown in Fig. 1, minor

maintenance, medium maintenance, overhaul and

replacement are carried out at t1, t2, t3 and t4 respectively.

No improvement of reliability is obtained after minor

maintenance, whereas reliability degradation is slowed

down; after medium maintenance and overhaul, the

reliability is improved, and overhaul has more significant

effect; after replacement, the facility is as good as new.

The first three types of maintenance are triggered by

1

2

referring to three thresholds of reliability, Th , Th , and

3

Th . When improvement of reliability is below a certain

level denoted as LR, the reuse of facility is no more

economic, and replacement should be carried out.

C. Production System Structure Modeling

To describe the structural dependence between

facilities, the structure of the system is modeled, in which

each facilities is assigned with a facility number and a 3digit code [s1, s2, s3] recording its structural position in the

system. s1 stands for the production line; s2 for work stage

(each work stage carries out a certain process); and s3

stands for the label of the facility in the corresponding

work stage. For instance, facility 3 in the system shown in

Fig. 2 is the 2nd paralleled facility in Work Stage 2 of

Production Line 1, whose structural code is [1, 2, 2], etc.

The input and the output of the system are regard as

facilities and assigned with facility numbers.

Production Line 1

Work Stage 1

Input

0

[0, 1, 1]

II. PRODUCTION SYSTEM MODELING

Th1

0.8

1

[1, 1, 1]

Work Stage 2

2

[1, 2, 1]

Production Line 3

3

[1, 2, 2]

8

[3, 1, 2]

Production Line 2

4

[2, 1, 1]

5

[2, 2, 1]

7

[3, 1, 1]

9

[3, 1, 3]

Fig. 2. Structure model of a series-parallel system

Output

10

[4, 1, 1]

i, j

B. Maintenance Cost Modeling

similarity in facility type S p between facilities i and j

The maintenance cost of the kth maintenance activity

k

consists of direct maintenance cost C m and indirect

can be calculated by (6).

0, if l1i l1j

i, j

i

j

i

j

S p 1, if l1 l1 and l2 l2

0.5, else

k

production loss Lp . Direct maintenance cost, including

k

cost of maintenance actions for maintenance units C u and

k

set-up cost C s , can be calculated by (1) and (2).

Cm Cu Cs

k

k

k

(1)

M

Cu

k

(C

k ,i

p

Ct Ch Cc )

k ,i

k ,i

k ,i

(2)

i 1

k ,i

k ,i

k ,i

k ,i

where C p , Ct , C h , and C c

are cost of spare parts,

maintenance tools, maintainers, and consumables for

maintenance unit i.

Commonly, the productivity of a production system

P(t) at time t depends on its bottle neck then. In this paper,

it is assumed that there’s no buffer between any two

connected work stages, production of the system has been

balanced, facilities in the same work stage has same

k

productivity. Hence, the Lp can be calculated by (3).

Lp P0 (tk tk 1 )

k

t k 1

tk

P(t )dt

(3)

where P0 is the normal productivity of the system; tk is

the time when kth maintenance activity starts and tk+1 is

when the maintenance activity ends. And P(t) equals to

the lowest productivity of all work stages at time t.

III. CLUSTERING BASED GROUPING METHOD

Based on Group Technology, products or processes

with high similarity can be grouped together to achieve

higher efficiency [13]. In this paper, according to OM, a

maintenance activity is triggered once any facility calls

for overhaul or replacement, and then HC is employed to

group facilities that need maintenance according to their

similarities. Particularly, similarities in facilities’ location,

type, maintenance type, structural position and

maintenance time are considered in this paper.

To measure the similarity of facilities in location, the

distance between any two facilities is calculated according

to a relative coordinate system on shop floor. Facility i is

assigned with two coordinate values, i.e. xi and yi. Thus

i, j

the similarity in location S l between facilities i and j

can be calculated by (4) and (5).

Ddis

i, j

( xi x j ) ( yi y j )

2

2

Sl ( Ddis Ddis ) / ( Ddis Ddis )

i, j

i, j

max

i, j

max

min

(4)

(5)

min

where Ddis is the distance between facilities i and j; Ddis

max

and Ddis

are the minimum and maximum distances

between any two facilities.

To measure the similarity of facilities in their types,

each facility is assigned with a two-digit code [l1, l2]. l1

stands for facility type, and l2 stands for its subtype. The

(6)

To measure the similarity of facilities in their

maintenance type, a one-digit code m is assigned to each

facility. Particularly, in this paper, maintenance is

categorized into 4 types, i.e. minor maintenance, medium

maintenance, overhaul, and replacement, and each type of

maintenance is assigned with a certain value. The

similarity between facilities i and j in maintenance

i, j

type S n , can be calculated by (7).

0, if m m

i, j

(7)

Sn

i

j

1, if m m

In group maintenance, maintenance actions of

facilities in the same group are carried out at the same

time and finished simultaneously. Hence facilities in

different work stage should be assigned to a same group

to accelerate the recovery of productivity of the system.

For example, in a maintenance activity, Facility 1, 2 and 3

in the system shown in Fig. 2 need maintenance and all of

them should be divided into 2 groups, which can’t be

maintenance simultaneously. If facilities 1 and 2 are

clustered in Group 1 and Facility 3 in Group 2 and Group

1 is maintained first, the productivity can recovered to

half of normal productivity once Group 1’s maintenance

ends. The similarity between facilities i and j in their

i, j

structural position, S s , can be calculated by (8).

i

j

0, if s1i s1j & s2i s2j & s3i s3j

Ss

1, else

i, j

(8)

To prevent too many facilities clustered in one group,

the fifth measurement of similarity is introduced, denoted

i, j

as S t . The sum of maintenance time for two facilities is

used to measure their similarity which can be calculated

by (9) and (10).

i, j

St

St ( St

i, j

min

where, S t

max

max

and S t

tm tm

i

j

(9)

St ) / ( St

i, j

max

St )

min

(10)

are the minimal and maximal time

needed to maintain any two facilities considered in

clustering. Hence the similarity Si,j between facility i and j

can be calculated by (11).

S

i, j

Wl Sl Wp S p Wn Sn Ws S s Wt St (11)

i, j

i, j

i, j

i, j

i, j

where Wl, Wp, Wn, Ws and Wt are corresponding weights

for the five similarities.

In this paper, Weighted Average Linkage method is

employed to measure the similarity between two clusters.

P ,Q

The similarity between clusters P and Q, denoted as S C ,

can be calculated by (12)

0

Bearing Cap Production Line

Similarity

0.2

L1

0.4

0.6

1

6

3

7 5 1 10

Facility Number

0

L4

L2

4

2

8

9

Fig. 3. Dendrogram

P ,Q

SC

S

i, j

11

16

5

12

17

22

Assembling

Line

23

L3

0.8

4

1

/ (nP nQ )

(12)

iGP , jGQ

where, GP and GQ are clusters P and Q, nP and nQ are

numbers of facilities in clusters P and Q.

In this way, the similarity between two objects

(clusters or facilities) can be calculated, and dendrogram

is utilized to establish the groups, in which pairs of

objects in close proximity are linked, until all facilities are

clustered into one group. An example of dendrogram is

shown in Fig. 3, in which each upside-down U-shape line

is named a “link” between two objects. The height of a

link is its similarity value. Then the partition process is

carried out according to the inconsistency coefficient of

each link. If the inconsistency values of one link and all

the links below it are smaller than a prescribed threshold

d

Th , all objects connected by these links are clustered into

one group.

As is shown in Fig. 3, the three links, i.e. L1, L2, and

L3 have similarities S1, S2, and S3. The inconsistency value

Icon of L2 can be calculated by (13).

I con S2 avg( S1 , S2 , S3 ) / std( S1 , S2 , S3 )

(13)

where avg(S1, S2, S3) and std(S1, S2, S3) are the average

and standard deviation of S1, S2, and S3. In this context

only one level of links below L2, i.e. L1 and L3, are used to

calculate its inconsistency value. In fact, the depth of

level, dL, can also be adjusted so that more links below

can be included into calculation. For instance, if the depth

of levels is set as 2, link L4 will also be included. For links

that have no other links below them, their inconsistency

values are set as 0.

In this paper, the depth of levels dL is set as 3, and the

d

threshold Th is set as 0.8.

With the method above, facilities that need

maintenance in one maintenance activity can be grouped

according to their similarities under a certain level.

However, for different production systems with

different characteristics, fixed weight allocation of the

considered factors in clustering may not achieve

reasonable grouping result. For example, in a series

system, the consideration of structural positions of

facilities loses its importance. Furthermore, the quantity

and types of facilities that need maintenance vary from

one maintenance activity to another. Even a facility in

different maintenance activity may has different

maintenance need. Hence, weight allocation should be

considered in clustering process.

In this paper, weight allocation is optimized each time

a maintenance activity is carried out via TS due to its

Bearing Pedestal Production Line

18

6

13

9

19

2

7

15

10

20

3

14

8

21

25

24

Fig. 4. Sliding bearing production system

property of fast convergence.

In addition, Hybrid Genetic Algorithm [15] is

employed for scheduling after grouping.

IV. CASE STUDY

A. Case Description and Parameter Settings

In this section, a case study on maintenance

scheduling of a sliding bearing production system with 24

facilities is presented and maintenance cost is set as the

objective of maintenance scheduling, which should be

minimized. As shown in Fig. 4. facilities 0 and 25 are

input and output respectively, which are assumed to have

no maintenance need. Milling machines are labeled from

1 to 10, vertical drilling machines 11 to 15, radial drilling

machines 16 to 22, and boring machines 23 and 24. And

the layout of the workshop is also presented in Fig. 4. All

the facilities form 3 production lines, i.e. a bearing cap

production line, a bearing pedestal production line and an

assembling line.

It is assumed that there are enough spare parts and

consumables, while maintenance tools and maintainers

are limited, which are out sourced according to the

maintenance need of the maintenance activity.

Particularly in this paper, the total number of maintainers

or tools equals to 1/3 of the total need if all maintenance

actions are carried out simultaneously. In addition, tools

and maintainers assigned to a maintenance group are

according to the maximum need to maintain any one

facility in this group.

For each facility of the same type, the two parameters

for reliability modeling, and , are derived from

randomly generated simulation data subject to a same

distribution; and all facilities of one type has the same

price and the resources and time needed for each kind of

maintenance actions.

1

2

3

The three thresholds, Th , Th , and Th , are set as 0.9,

0.75, and 0.6 respectively; and LR is set as 0.2.

The set-up cost Cs of each maintenance activity is set

as 1000; the unit prices for four types of maintenance

resources i.e. spare parts, tools, maintainers, and

consumables are set as 100, 50, 50, and 10 respectively;

the normal production value v0 is set as 1000/hour.

B. Advantage Measurement of GM

in maintenance group k; the average distance can be

calculated by (14).

k

k

N g 1 N g

Davg 2 Ddis / [ N g ( N g 1)]

i, j

k

i 1

k

k

(14)

j i 1

Suppose the possible maximal, mean, and minimal

values of distance between any two facilities on the shop

mean

max

min

are Davg , Davg and Davg . Assume that when the average

max

min

k

With GT, several advantages can be gained when

maintaining a group of facilities. Time can be saved by

maintaining facilities within a close distance; similarities

in structure and failure mode of a certain type of facilities

can be utilized to accelerate maintenance; similar

maintenance processes of a certain maintenance type can

be carried out on a group of facilities simultaneously so

that the efficiency can be improved. In this paper, a

reduction factor is introduced to quantify the advantage,

which is the weighted average of three subfactors, i.e.

reduction factors considering distance, facility type

similarity, and maintenance need similarity among

facilities in one group.

Reduction factor considering distance can be obtained

by firstly averaging the distances between any pairs of

k

facilities in that group. Set N g as the number of facilities

f1 ( Davg )

1.3

1

max

Davg

mean

Davg

4

Davg

6

8k

10

12

Davg

Fig. 5 f () obtained by fitting to {4, 6, 12} and {0.7, 1, 1.3}

1

C. Simulation and Result Analysis

The maintenance scheduling is carried out for a time

period of 1000 working days in three scenarios i.e. only

OM. OM & Rule-based Group Maintenance (RGM) [14],

and OM & CGM.

Four maintenance activities occur in the simulation.

The total cost and maintenance cost of each maintenance

activity under the three maintenance policies are shown in

TABLE I. GM cost less, not only because of the advantage

of group technology that shortens the maintenance time,

but also due to smaller scale of the scheduling problem

with which satisfactory result can be obtained more easily.

Especially, CGM achieves least cost.

TABLE I

OPTIMAL MAINTENANCE COST IN THREE SCENARIOS

distance in group k equals to Davg or Davg , the maintenance

Maintenance Activity

time of this group will be reduced by 30% or increased by

30%. Then the reduction factor considering distance in

maintenance group k can be calculated by a function f1 ()

1

2

3

4

Total

obtained by fitting a quadratic curve to two data sets, i.e.

min

mean

max

{Davg , Davg , Davg } and {0.7, 1, 1.3}. An example is

min

0.7

OM

22443

17508

27081

42863

109895

Maintenance Policy

OM & RGM

OM & CGM

24892

21052

18265

16510

25455

23481

39203

37529

107815

98572

shown in Fig. 5.

Similarly, the average similarity in facility type and

k

k

maintenance type in one group S p , avg and Sn , avg can be

calculated by (15).

k

k

N g 1 N g

S x , avg 2 / [ N g ( N g 1)] S x

k

k

k

i, j

i 1

(15)

j i 1

It is assumed that when the average similarity of

group k in facility type or maintenance type equals to 1,

the time needed for maintenance actions in this group can

be reduced by 40 % or 30% respectively. The reduction

factor considering facility type and maintenance type in

k

k

group k can be calculated by f2 ( S p , avg ) and f3 ( Sn , avg ) .

Fig. 6. Gantt chart of the 3rd maintenance activity under OM & RGM

Function f 2 () is obtained by fitting a linear function to

data sets {0, 1} and {1, 0.6}, and function f3 () is obtained

by fitting a linear function to data sets {0, 1} and {1, 0.7}.

Finally, the reduction factor Fdus in group k can be

calculated by (16).

Fdus W1 f1 (Davg ) W2 f2 (S p , avg ) W3 f3 (S n , avg ) (16)

k

k

k

k

where W1, W2, and W3 are weights of the three sub

reduction factors, particularly in this case, set as 0.4, 0.4

and 0.2. The time needed for any maintenance actions in

k

maintenance group k is reduced by (1 Fdus ).

Fig. 7. Gantt chart of the 3rd maintenance activity under OM & CGM

Compared with RGM, CGM possesses more

flexibility by adjusting its weight allocation on five

factors in clustering process. In 3rd maintenance activity,

facilities 2, 8, 10 to 12, 15, 23 and 24 need minor

maintenance; facilities 13, 14, 18 to 20, and 22 needs

overhaul; and no facility needs replacement. The grouping

and scheduling results under OM & RGM and OM &

CGM are shown in Fig. 6 and Fig. 7 respectively. Among

the facilities, numbers of facilities that call for minor

maintenance and medium maintenance are relatively

balanced, which are 7 and 5 respectively, and facilities

requiring maintenance are mainly vertical drilling

machines and radial drilling machines, with a number of 5

and 7 each. By optimization, a weight allocation of [0.12,

0.2, 0.24, 0.06, 0.38] is obtained. Among the weights, the

weight for maintenance type and facility type are

relatively larger, with which time can be reduced by

grouping facilities with same maintenance type need or

facility type. To avoid too many facilities grouped

together, a large weight for maintenance time is obtained.

As shown in Fig. 6, under OM & RGM, the group

comprised of facilities 18 to 21 is unreasonable because of

its long time consumed, while as shown in Fig. 7, under

OM & CGM, facility 21 is singled out and no group’s

maintenance lasts more than 9 hours.

V. CONCLUSIONS

In this paper, a novel maintenance methodology

based on GT for complex systems is proposed.

Structure model of system is established to describe

the structural dependence between facilities, upon which

the production loss during a maintenance activity can be

calculated with higher consistency with practice.

In the methodology, comprehensive consideration of

the clustering factors leads to more satisfactory grouping

results. And the flexibility derived from an optimized

weight allocation of such factors enhances the

methodology’s adaptability to different systems and

varying maintenance requirements. Furthermore, more

factors could be included in clustering to expand the

consideration in grouping, and the influence of such

factors on maintenance could be analyzed. In this way, a

system’s characteristics could also be studied, upon which

an optimized RGM could be obtained, which is often

more easily implemented in practice.

In the future, similarity measurements in clustering

would be investigated and refined, and the considered

factors would be analyzed and selected. Moreover, the

methodology to extract the characteristics of a system in

terms of maintenance by analyzing the considered factors

and their corresponding weight would be developed.

ACKNOWLEDGMENT

This research is funded by the National Natural

Science Foundation of China (#70971030).

REFERENCES

[1] A. Khanlari, K. Mohammadi, and B. Sohrabi, "Prioritizing

equipments for preventive maintenance (PM) activities

using fuzzy rules," Computers & Industrial Engineering,

vol. 54, no. 2, pp. 169-184, 2008.

[2] F. Ángel-Bello, A. Álvarez, J. Pacheco, “A heuristic

approach for a scheduling problem with periodic

maintenance and sequence-dependent setup times,”

Computers & Mathematics with Applications, vol. 61, no. 4,

pp. 797-808, 2011.

[3] D. H. Park, G. M. Jung and J. K. Yum, “Cost Minimization

for periodic maintenance policy of a system subject to slow

degradation,” Reliability Engineering & System Safety, vol.

68, no. 2, pp. 105-112, 2000.

[4] Z. Tian, H. Liao, “Condition based maintenance

optimization for multi-component systems using

propotional hazards model,” Reliability Engineering &

System Safety, vol.77, no. 2, pp. 151-165, 2002

[5] Z. Tian, T. Jin, and B. Wu, “Condition based maintenance

optimization for wind power generation systems under

continuous monitoring,” Renewable Energy, vol. 36, no. 5,

pp. 581-589, 2011.

[6] R. Radner and D. W. Jorgenson, "Opportunistic

replacement of a single part in the presence of several

monitored parts," Management Science, vol. 10, p. 15, Oct.,

1963.

[7] H. Wang, "A survey of maintenance policies of

deteriorating systems," European Journal of Operational

Research, vol. 139, no. 3, pp. 469-489, 2002.

[8] P. Ritchken and J. G. Wilson, "(m, T) Group maintenance

policies," Management Science, vol. 36, p. 8, May, 1990.

[9] S.-H. Sheu and J.-P. Jhang, "A generalized group

maintenance policy," European Journal of Operational

Research, vol. 96, no.2, pp. 232-247, 1997.

[10] I. B. Gertsbakh, "Optimal Group Preventive Maintenance

of a System with Observable State Parameter," Advances in

Applied Probability, vol. 16, p. 3, Dec., 1984.

[11] A. Abdelhadi, "Preventive maintenance grouping using

similarity coefficient methodology," PhD in Engineering

Dissertation, Industrial and Manufacturing Engineering

Department, University of Wisconsin – Milwaukee,

Milwaukee, 2010.

[12] A. J. Vakharia and U. Wemmerlöv, "A comparative

investigation of hierarchical clustering techniques and

dissimilarity measures applied to the cell formation

problem," Journal of Operations Management, vol. 13, no.

2, pp. 117-138, 1995.

[13] A. Ünler and Z. Güngör, "Applying K-harmonic means

clustering to the part-machine classification problem,"

Expert Systems with Applications, vol. 36, no. 2, Part 1, pp.

1179-1194, 2009.

[14] J. Yan, D. Hua, and Z. Wang, "Reuse oriented group

maintenance scheduling based on Hybrid Genetic

Algorithm and Tabu Search," Industrial Engineering and

Engineering

Management

(IEEM),

2011

IEEE

International Conference on , pp.1524-1528, 6-9 Dec. 2011

[15] H. Esbensen and P. Mazumder, "SAGA : a unification of

the genetic algorithm with simulated annealing and its

application to macro-cell placement," in VLSI Design,

1994., Proceedings of the Seventh International Conference

on, pp. 211-214, 1994.