HIGH-SPEED ELECTRET CHARGING METHOD USING VACUUM UV IRRADIATION

advertisement

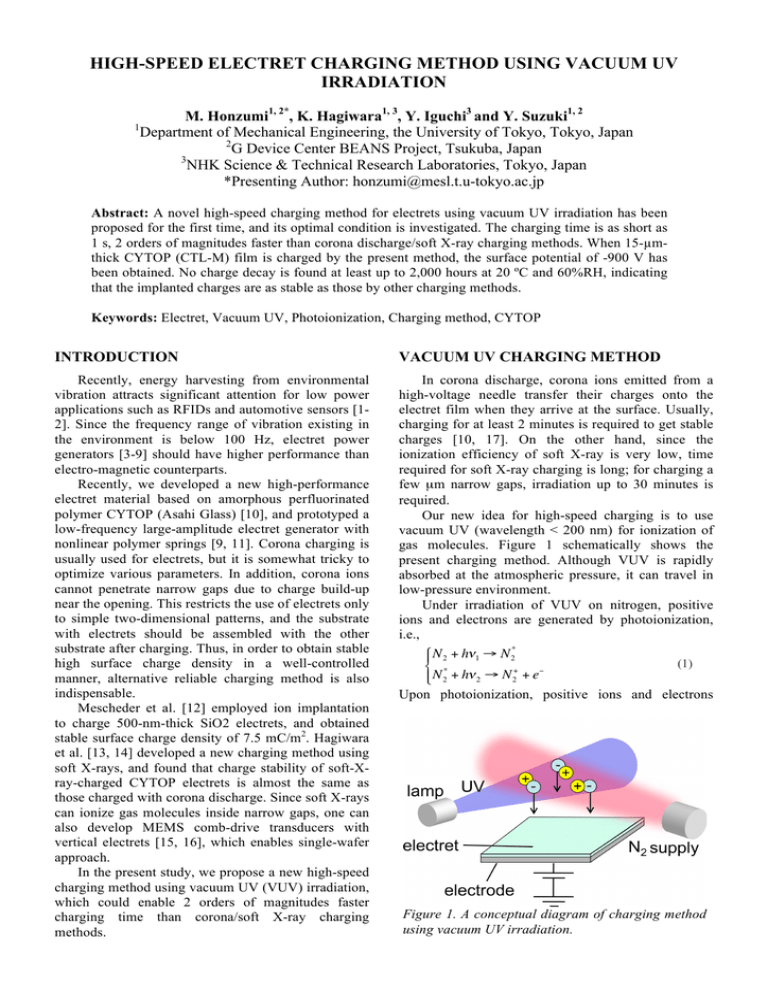

HIGH-SPEED ELECTRET CHARGING METHOD USING VACUUM UV IRRADIATION 1 M. Honzumi1, 2*, K. Hagiwara1, 3, Y. Iguchi3 and Y. Suzuki1, 2 Department of Mechanical Engineering, the University of Tokyo, Tokyo, Japan 2 G Device Center BEANS Project, Tsukuba, Japan 3 NHK Science & Technical Research Laboratories, Tokyo, Japan *Presenting Author: honzumi@mesl.t.u-tokyo.ac.jp Abstract: A novel high-speed charging method for electrets using vacuum UV irradiation has been proposed for the first time, and its optimal condition is investigated. The charging time is as short as 1 s, 2 orders of magnitudes faster than corona discharge/soft X-ray charging methods. When 15-µmthick CYTOP (CTL-M) film is charged by the present method, the surface potential of -900 V has been obtained. No charge decay is found at least up to 2,000 hours at 20 ºC and 60%RH, indicating that the implanted charges are as stable as those by other charging methods. Keywords: Electret, Vacuum UV, Photoionization, Charging method, CYTOP INTRODUCTION VACUUM UV CHARGING METHOD Recently, energy harvesting from environmental vibration attracts significant attention for low power applications such as RFIDs and automotive sensors [12]. Since the frequency range of vibration existing in the environment is below 100 Hz, electret power generators [3-9] should have higher performance than electro-magnetic counterparts. Recently, we developed a new high-performance electret material based on amorphous perfluorinated polymer CYTOP (Asahi Glass) [10], and prototyped a low-frequency large-amplitude electret generator with nonlinear polymer springs [9, 11]. Corona charging is usually used for electrets, but it is somewhat tricky to optimize various parameters. In addition, corona ions cannot penetrate narrow gaps due to charge build-up near the opening. This restricts the use of electrets only to simple two-dimensional patterns, and the substrate with electrets should be assembled with the other substrate after charging. Thus, in order to obtain stable high surface charge density in a well-controlled manner, alternative reliable charging method is also indispensable. Mescheder et al. [12] employed ion implantation to charge 500-nm-thick SiO2 electrets, and obtained stable surface charge density of 7.5 mC/m2. Hagiwara et al. [13, 14] developed a new charging method using soft X-rays, and found that charge stability of soft-Xray-charged CYTOP electrets is almost the same as those charged with corona discharge. Since soft X-rays can ionize gas molecules inside narrow gaps, one can also develop MEMS comb-drive transducers with vertical electrets [15, 16], which enables single-wafer approach. In the present study, we propose a new high-speed charging method using vacuum UV (VUV) irradiation, which could enable 2 orders of magnitudes faster charging time than corona/soft X-ray charging methods. In corona discharge, corona ions emitted from a high-voltage needle transfer their charges onto the electret film when they arrive at the surface. Usually, charging for at least 2 minutes is required to get stable charges [10, 17]. On the other hand, since the ionization efficiency of soft X-ray is very low, time required for soft X-ray charging is long; for charging a few µm narrow gaps, irradiation up to 30 minutes is required. Our new idea for high-speed charging is to use vacuum UV (wavelength < 200 nm) for ionization of gas molecules. Figure 1 schematically shows the present charging method. Although VUV is rapidly absorbed at the atmospheric pressure, it can travel in low-pressure environment. Under irradiation of VUV on nitrogen, positive ions and electrons are generated by photoionization, i.e., * N 2 + hν1 → N 2 (1) * + − N 2 + hν 2 → N 2 + e Upon photoionization, positive ions and electrons Figure 1. A conceptual diagram of charging method using vacuum UV irradiation. 8 !!N2!2!sccm Ion!Current![µA] generated can be separated with the electric field between a bottom electrode of electret and a grounded electrode or chamber wall. When positive bias voltage is applied to the bottom electrode, electrons are dragged toward the electret surface. The surface potential can be controlled by the applied voltage to the bottom electrode. Note that, when O2 molecules exist, quenching mechanisms shown in Eq. (2) coexiss; O2 and O3 molecules collide with excited-state N2 molecules and absorb energy of the N2 molecules, preventing generation of electrons [18]. O2 + N 2* → N 2 + O + O (2) O2 + O → O3 O + N * → O + O + N 2 2 2 3 N2! UV! Figure 2. Vacuum UV charging system. 4 2 0 0.1 2 3 4 5 6 2 1 3 4 5 6 10 2 3 4 5 6 2 100 Pressure![Pa] Figure 3. Ion current versus the chamber pressure for different bias voltage. EXPERIMENTAL SETUP 2.5 Ion!Current![µA] Figure 2 shows a photograph of the VUV charging system prototype we developed. Before charging, the chamber is evacuated to 5 x 10-3 Pa. Then, N2 gas (99.9995%) is introduced into the vacuum chamber at a constant flow rate with a mass flow controller (SECE40, Horiba TEC). The chamber pressure is measured with the ionization gauge (GI-M2, ULVAC). The chamber pressure is regulated with a butterfly valve connecting to a turbo molecular pump. A deuterium lamp (C9935, Hamamatsu Photonics), of which wavelength is from 120 to 160 nm, is used as the VUV source. Electret samples are fixed on a Teflon tube for applying a bias voltage to the bottom electrode. A source measure unit (Model 2410, Keithley Instruments) is used as a voltage source and an ammeter for the ion current measurement. We employ 15 µm-thick CYTOP CTL-M electrets, which are spun on a low-resistance Si substrate and cured at 185 ºC for 1.5 hours. After charging, the surface potential of the electret sample is measured with an electrostatic voltmeter (Model 279, Monroe Electronics). bias!voltage: !+1=>!kV !+>=2!kV !+>=A!kV !+>=2!kV !+>=1!kV 6 2.0 1.5 1.0 N2!7ressure!:!1!Pa 0.5 bias!voltage!:!+1kV 0.0 1 2 3 4 5 6 7 8 9 10 2 3 4 5 -lo/!0ate![sccm] Figure 4. Ion current versus the N2 flow rate for the bias voltage of 1 kV and the chamber pressure of 1 Pa. RESULTS Figure 3 shows the ion current under VUV irradiation for different chamber pressure. The N2 flow rate is 5 sccm. The ion current is increased with the chamber pressure because of higher number density of ionized molecules, while it decreases at much higher pressure. This is because excited-state N2 molecules are quenched by collisions with O2 or O3 molecules. The peak ion current is at around 20-40 Pa. The maximum ion current obtained in the present experiment is 6 µA, which is already 20 times as large as the ion current with soft X-ray irradiation [14]. It is noted that, when the chamber pressure is over 4 Pa and the bias voltage is above 0.5 kV, discharge occurs. We could expect one order of magnitude higher ion current with the bias voltage of 1 kV in a chamber that can suppress discharge at higher voltage. The ion current for different N2 flow rate is shown in Fig. 4. It is found that the ion current is independent on the flow rate. Thus, we keep the N2 flow rate at 5 sccm throughout this paper. Figure 5 shows the surface potential versus the chamber pressure. The bias voltage is +1 kV, and the irradiation time is 3 seconds. Up to -900 V has been obtained with 3 seconds irradiation. Due to large ion current, surface potential is saturated at the pressure of 0.1 Pa. Figure 6 shows the surface potential versus the Surface!Potential![V] -1000 -800 -600 -400 0 0.01 CONCLUSIONS bias!voltage!:!+1!kV irradiation!time!:!3!s -200 2 3 4 5 6 7 2 0.1 3 4 5 6 7 2 1 Pressure![Pa] Figure 5. Surface potential of CYTOP film versus the chamber pressure for the bias voltage of 1 kV. Irradiation time is 3 s. -800 Surface!Potential![V] charging time. Unlike time-consuming corona/soft Xray charging methods, only irradiation of 0.3 seconds is necessary to get high surface voltage of about -700 V. Therefore, the present charging method is at least 2 orders of magnitudes faster than the corona and the soft X-ray charging methods. The surface potential becomes saturated for charging time over 2 seconds. Figure 7 shows time trace of the surface potential after charging. Samples are kept at 20 ºC and 60%RH. The surface potential shows no distinct change for 2,000 hours. Therefore, the charge retention property with the present charging method should be as good as the one charged by corona discharge/soft X-ray irradiation. -600 -400 We have proposed a new high-speed charging method with VUV irradiation for the first time. Optimum pressure is around 20-40 Pa under the present condition examined, and the maximum ion current is 20 times that of soft X-ray irradiation. With CYTOP electrets, surface potential up to -900 V is obtained for the bias voltage of +1 kV. The present method is at least 2 orders of magnitudes faster than existing charging methods, and only a few seconds is enough to get high surface potential. In addition, we demonstrate that the surface potential is retained at least for 2,000 hours, indicating sufficient stability of the implanted charges. The present VUV charging method should be a useful tool for high-throughput fabrication of electret generators. ACKNOWLEDGEMENT -200 0 This work is supported by the New Energy and Industrial Technology Development Organization (NEDO) of Japan. bias!voltage!:!+1!kV N2!pressure!:!1.0!Pa 0 1 2 3 4 5 6 Irradiation!Time![s] REFERENCES [1] Figure 6. Surface potential of CYTOP electrets versus irradiation time. The chamber pressure and the bias voltage are 1 Pa and 1 kV, respectively . [2] !"#$a&'!()*'+*,a-!./0 -1000 [3] -800 -600 [4] -400 p#'55"#'67,a5!8)-*ag'6,##a:,a*,)+!*,m' !1<0!(a6>1!?/63!5 !1<0!(a6>A00!/6B0!5 -200 0 0 500 1000 1500 [5] 2000 1,m'!.30 Figure 7. Time trace of the surface potential of CYTOP electrets kept at 20 ºC and 60%RH. J. A. Paradiso, and T. Starner, “Energy scavenging for mobile and wireless electronics,” IEEE Pervasive Comp., Vol. 4, pp.18-27, 2005. S. P. Beeby, M. J. Tudor, and N. M. White, “Energy harvesting vibration sources for micro systems applications,” MEAS. Sci. Technol., Vol. 17, pp.175-195, 2006. J. Boland, Y. H. Chao, Y. Suzuki, and Y.-C. Tai, “Micro electret power generator,” Proc. 16th IEEE Int. Conf. Micro Electro Mechanical Systems (MEMS2003), Kyoto, pp.538-541, 2003. T. Tsutsumino, Y. Suzuki, N. Kasagi, and Y. Sakane, “Seismic power generator using highperformance polymer electret,” 19th IEEE Int. Conf. Micro Electro Mechanincal Systems (MEMS2006), Istanbul, pp. 98-101, 2006. M. Edamoto, Y. Suzuki, and N. Kasagi, “Electret-based energy harvesting device with parylene flexible springs,” 4th Asia-Pacific Conf. Transducers and Micro-Nano Technology (APCOT’08), Tainan, 2B3-1, 4pp, 2008. [6] [7] [8] [9] [10] [11] [12] [13] [14] [15] [16] Y. Naruse, N. Matsubara, K. Mabuchi, M. Izumi, and K. Honma, “Electrostatic micro power generator from low frequency vibration such as human motion,” J. Micromech. Microeng., Vol. 19, 094002, 5pp, 2009. H.-W. Lo, and Y.-C. Tai, “Parylene-based electret power generators,” J. Micromech. Microeng., Vol. 18, 104006, 8pp, 2008. U. Bartsch, C. Sander, M. Blattmann, J. Gaspar, and O. Paul, “Influence of parasitic capacitances on the power output of electret-based energy harvesting generators,” 9th Int. Workshop Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2009), Washington DC, pp. 332-335, 2009. Y. Suzuki, D. Miki, M. Edamoto, and M. Honzumi, A MEMS Electret Generator With Electrostatic Levitation For Vibration-Driven Energy Harvesting Applications J. Micromech. Microeng., Vol. 20, 104002, 8pp, 2010. Y. Sakane, Y. Suzuki, and N. Kasagi, "Development of High-performance Perfluorinated Polymer Electret and Its Application to Micro Power Generation," J. Micromech. Microeng., Vol. 18, 104011, 6pp, 2008. D. Miki, M. Honzumi, Y. Suzuki, and N. Kasagi, "Large-Amplitude MEMS Electret Generator with Nonlinear Spring,"23rd IEEE Int. Conf. Micro Electro Mechanical Systems (MEMS2010), Hong Kong, pp.176-179, 2010. U. Mescheder, B. Müller, S. Baborie, and P. Urbanovic, “Properties of SiO2 electret films charged by ion implantation for MEMS-based energy harvesting systems,” J. Micromech. Microeng., Vol. 19, 094003, 6pp, 2009. K. Hagiwara, M. Goto, Y. Iguchi, Y. Yasuno, H. Kodama, K. Kidokoro, and T. Tajima, “Soft Xray charging method for a silicon electret condenser microphone,” Appl. Phys. Exp., Vol. 3, 091502, 3pp, 2010. K. Hagiwara, M. Honzumi, M. Goto, T. Tajima, Y. Yasuno, H. Kodama, K. Kidokoro, K. Kashiwagi, and Y. Suzuki, "Novel Throughsubstrate Charging Method for Electret Generator Using Soft X-ray Irradiation," 9th Int. Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2009), Washington DC, pp.173-176, 2009. M. Honzumi, A. Ueno, K. Hagiwara, Y. Suzuki, T. Tajima, and N. Kasagi, “Soft-X-ray-charged vertical electrets and its application to electrostatic transducers,” 23rd IEEE Int. Conf. Micro Electro Mechanical Systems (MEMS2010), Hong Kong, pp.635-638, 2010. K. Yamashita, M. Honzumi, K. Hagiwara, Y. Iguchi, and Y. Suzuki, “Vibration-driven MEMS energy harvester with vertical electrets,” 10th Int. Workshop on Micro and Nanotechnology for Power Generation and Energy Conversion Applications (PowerMEMS 2010), Leuven, 2010, to be presented. [17] U. Bartsch, PhD thesis, University of Freiburg, 2010. [18] H. Inaba, T. Ohmi, T. Yoshida, and T. Okada, “Neutralization of static electricity by soft X-rays and vacuum UV radiation,” J. Electrostatics, Vol. 33, pp. 15-42, 1994.