Modeling, Fabrication and Characterization of a Silicon-based DMFC

advertisement

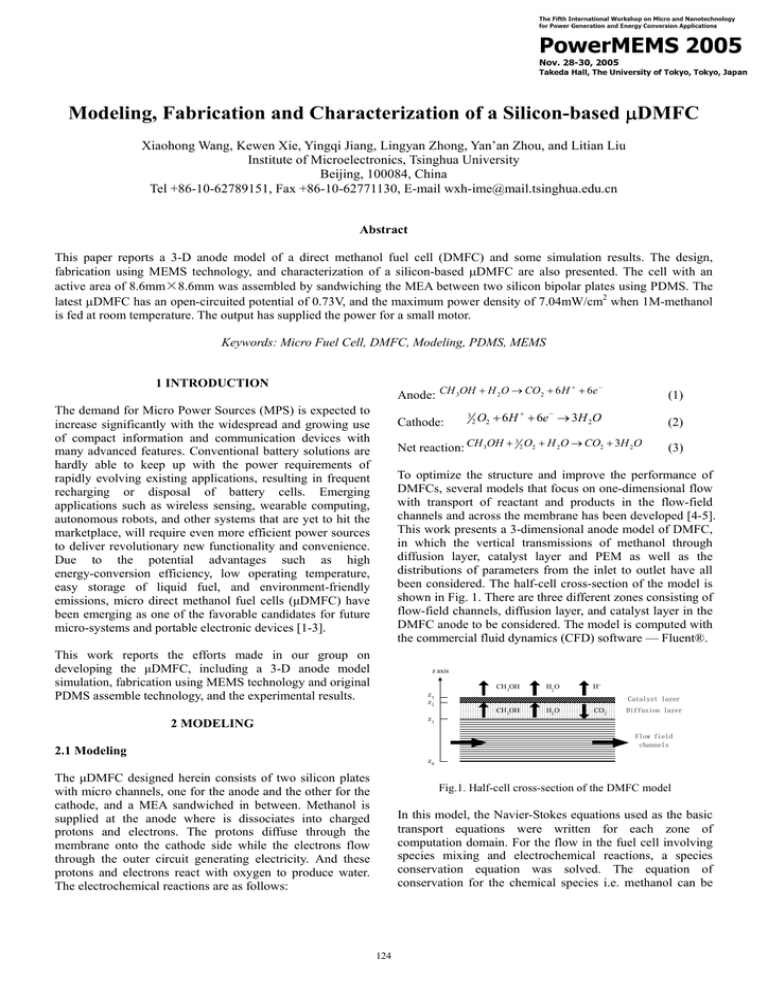

Modeling, Fabrication and Characterization of a Silicon-based μDMFC Xiaohong Wang, Kewen Xie, Yingqi Jiang, Lingyan Zhong, Yan’an Zhou, and Litian Liu Institute of Microelectronics, Tsinghua University Beijing, 100084, China Tel +86-10-62789151, Fax +86-10-62771130, E-mail wxh-ime@mail.tsinghua.edu.cn Abstract This paper reports a 3-D anode model of a direct methanol fuel cell (DMFC) and some simulation results. The design, fabrication using MEMS technology, and characterization of a silicon-based μDMFC are also presented. The cell with an active area of 8.6mm×8.6mm was assembled by sandwiching the MEA between two silicon bipolar plates using PDMS. The latest μDMFC has an open-circuited potential of 0.73V, and the maximum power density of 7.04mW/cm2 when 1M-methanol is fed at room temperature. The output has supplied the power for a small motor. Keywords: Micro Fuel Cell, DMFC, Modeling, PDMS, MEMS 1 INTRODUCTION + − Anode: CH 3OH + H 2O → CO2 + 6 H + 6e The demand for Micro Power Sources (MPS) is expected to increase significantly with the widespread and growing use of compact information and communication devices with many advanced features. Conventional battery solutions are hardly able to keep up with the power requirements of rapidly evolving existing applications, resulting in frequent recharging or disposal of battery cells. Emerging applications such as wireless sensing, wearable computing, autonomous robots, and other systems that are yet to hit the marketplace, will require even more efficient power sources to deliver revolutionary new functionality and convenience. Due to the potential advantages such as high energy-conversion efficiency, low operating temperature, easy storage of liquid fuel, and environment-friendly emissions, micro direct methanol fuel cells (μDMFC) have been emerging as one of the favorable candidates for future micro-systems and portable electronic devices [1-3]. Cathode: 3 2 (1) O2 + 6H + + 6e − → 3H 2O (2) 3 Net reaction: CH 3OH + 2 O2 + H 2O → CO2 + 3H 2O (3) To optimize the structure and improve the performance of DMFCs, several models that focus on one-dimensional flow with transport of reactant and products in the flow-field channels and across the membrane has been developed [4-5]. This work presents a 3-dimensional anode model of DMFC, in which the vertical transmissions of methanol through diffusion layer, catalyst layer and PEM as well as the distributions of parameters from the inlet to outlet have all been considered. The half-cell cross-section of the model is shown in Fig. 1. There are three different zones consisting of flow-field channels, diffusion layer, and catalyst layer in the DMFC anode to be considered. The model is computed with the commercial fluid dynamics (CFD) software — Fluent®. This work reports the efforts made in our group on developing the μDMFC, including a 3-D anode model simulation, fabrication using MEMS technology and original PDMS assemble technology, and the experimental results. z axis z3 z2 z1 2 MODELING CH 3OH H2 O H+ CH 3OH H2 O CO2 Catalyst layer Diffusion layer Flow field channels 2.1 Modeling z0 The μDMFC designed herein consists of two silicon plates with micro channels, one for the anode and the other for the cathode, and a MEA sandwiched in between. Methanol is supplied at the anode where is dissociates into charged protons and electrons. The protons diffuse through the membrane onto the cathode side while the electrons flow through the outer circuit generating electricity. And these protons and electrons react with oxygen to produce water. The electrochemical reactions are as follows: Fig.1. Half-cell cross-section of the DMFC model In this model, the Navier-Stokes equations used as the basic transport equations were written for each zone of computation domain. For the flow in the fuel cell involving species mixing and electrochemical reactions, a species conservation equation was solved. The equation of conservation for the chemical species i.e. methanol can be 124 written as follows: ( ∂ ρYCH 3OH vx ∂x ) + ∂(ρY CH 3 OH v y ∂y ∂YCH 3OH ∂ ⎛ w + ⎜⎜ ρDCH 3OH ∂y ⎝ ∂y ) + ∂(ρY CH 3 OH v z ∂z )= ( ∂Y ∂⎛ w ⎜ ρDCH 3OH CH 3OH ∂x ⎜⎝ ∂x ∂YCH 3OH ⎞ ∂⎛ w ⎟⎟ + ⎜⎜ ρDCH 3OH ∂z ⎠ ∂z ⎝ ∂ ρv x ∂x ⎞ ⎟⎟ ⎠ + ⎞ ⎟⎟ + RCH 3OH ⎠ (4) w DCH 3OH is the diffusion coefficient for the methanol in the mixture, and νx, νy, νz are the components of the velocity in γ ⎡ ⎛ 6αF ⎞ ⎛ 6(1 − α )F ⎞⎤ η anode ⎟⎥ ⎢exp⎜ RT η anode ⎟ − exp⎜ − RT ⎠ ⎝ ⎠⎦ ⎣ ⎝ (6) Avi0 ⎛⎜ cCH 3OH ref 6 F ⎜⎝ cCH 3 OH ⎛ 6(1 − α )F ⎞⎤ − exp⎜ − η anode ⎟⎥ RT ⎝ ⎠⎦ , ⎞ ⎟ ⎟ ⎠ γ ⎡ ⎛ 6αF ⎞ ⎢exp⎜ RT η anode ⎟ ⎠ ⎣ ⎝ ∂v ⎞ ∂p ∂ ⎛ + ⎜ 2μ x ⎟ ∂x ∂x ⎝ ∂x ⎠ (9) z 0 ≤ z ≤ z1 vx β x , z1 ≤ z ≤ z 3 (10) (11) The results of simulations include not only definite numbers such as the output voltage, the average output operating current density, methanol crossover, but also the distributions of operating current density, methanol concentration, the amount of methanol that has crossed over the PEM, and other important parameters of the fuel cell. The local distribution of current density of the half-cell is shown in Fig. 2 for the condition of the average current density of 511mA/cm2, output voltage of 0.53V, and the 2M-methanol feed concentration. On the whole, the current density decreases along the streamwise direction, especially at the beginning of the channel. In the equation above MCH3OH is the mole weight of methanol. Combining Eqs. (5) and (6), and considering that no reaction occurs in the flow distributor and diffusion layer, so the net reaction rate in different zones can be given as follows: RCH 3OH = − M CH 3OH =− Numerical simulations were performed with CFD software FLUENT 6.1. The electrochemical reaction rate of methanol oxidation (i.e. Butler-Volmer equation) in the anode was incorporated into solver through the User Defined Functions (UDFs) code written in C programming language. It was assumed that the cathode polarization is a constant. With designated conditions, the fuel cell unit electrical performance and local distributions could be obtained. From Eq. (1), the relationship between the rate of methanol consumption and current density distribution can be obtained as following: z0 ≤ z ≤ z2 ) 2.2 Simulations and Results (5) 3 , z In the equations above, βx denote the permeability of the porous material. ref RCH 3OH = 0 , S x = −μ CCH3OH is the local methanol concentration, CCH OH is the reference methanol concentration, which is associated with i0, α is the anodic transfer coefficient, ηanode is the anode overpotential, and the term di/dz presents the local proton current density distribution in the catalyst region. M CH 3OH di 6 F dz x ∂z ∂ ⎡ ⎛ ∂v y ∂vx ⎞⎤ ∂ ⎡ ⎛ ∂vz ∂vx ⎞⎤ ⎟⎥ + μ⎜ + + ⎟ + ρf x + S x ⎢μ ⎜ ∂y ⎣ ⎜⎝ ∂x ∂y ⎟⎠⎦ ∂z ⎢⎣ ⎝ ∂x ∂z ⎠⎥⎦ Sx = 0 where Aν is the specific area of reaction surface, i0 is the reference exchange current density, γ is the order of reaction, RCH 3OH = − y 3 For the electrochemical reaction occurs in the catalyst layer, methanol and water are consumed there. Butler-Volmer equation was used to describe the electrochemical reaction. It is usually given as follows: ⎞ ⎟ ⎟ ⎠ x ∂y When the fuel flows through porous media, the diffusion and catalyst layers, the pressure drop is given by Darcy’s law: CH OH is the net x-, y-, z-direction, respectively. electrochemical reaction rate of methanol consumption. ⎛ CCH OH di = Av i0 ⎜ ref 3 ⎜ CCH OH dz 3 ⎝ ) + ∂(ρv v ) + ∂(ρv v where Sx is the source term in the above equations for the x directions momentum. μ denotes the viscosity of the fluid in the medium. p is the intensity of pressure. fx is denotes the viscous force. The equation above is a convection-diffusion equation, where ρ is the density of the mixture solution, YCH3OH is the mass fraction of the methanol in the mixture solution fuel, R 2 Methanol crossover has great influence on the performance of DMFC, and it results from both the electro-osmotic drag and diffusion. Fig. 3 shows the variation of the methanol crossover with current density for various feed concentrations of methanol. It can be seen that, as the methanol feed concentration increases, the methanol crossover increases accordingly. (7) (8) z2 ≤ z ≤ z3 Because the steady state is presumed, the conservation equations of momentum are given as follows (only take xdirection as an example): The influence of the flow-field channels on the performance was studied. Fig. 4 shows the results of the fuel cell performances with two kinds of flow-field, serpentine and 125 parallel patterns. The comparison shows that the limiting current density of the serpentine flow-field channels is higher than that of the parallel. So the maximum power output of the serpentine flow-field channels is higher as well. While at low current density, the effect of different channels shape is insignificant. Such results agree with the experimental results in [6]. 3 DESINGN AND FABRICATION With the simulation results, we chose plates with serpentine flow-field channels in our practical experiments. The bipolar plates with micro channels were fabricated by micro-machining silicon wafers with photolithography, bulk-silicon etching, sputtering and other standard silicon MEMS techniques. After a series of experiments, considering physical stiffness of silicon wafer and fuel transmission, we finally determined the following dimensions of the micro channels: 8600μm in length, 200μm in width, and 120μm in depth, respectively. Toray carbon paper was chosen as the diffusion layer and Nafion® 117 attached with catalyst layers was used as the membrane electrode assembly (MEA). Fig. 5 shows the fabrication process of the μDMFC, roughly involving three steps: fabrication of plates, fabrication of a half-cell, and final assembly of the whole cell using PDMS. First, silicon plates were fabricated by using MEMS technologies, including LPCVD, KOH etching and sputtering (Fig. 5 (a) to (e)). The plate has an area of 18mm ×18mm with the active area of 8.6mm×8.6mm. Second, to make the half-cell, a piece of cured PDMS was glued to the back of the silicon plate with liquid-state PDMS. Two plastic pipes were fixed onto the PDMS block, and then Al foils and carbon papers were glued onto the front side of the plate using silver paste (Fig. 5 (f)). Finally, a MEA was sandwiched between two half-cells with PDMS to create a μDMFC (Fig. 5 (g)). This fabrication process combines the advantages of MEMS technology and the outstand properties of PDMS. Fig. 2. Local distribution of current density (mA/cm2) of the half-cell for the condition of the average current density of 511mA/cm2, output voltage of 0.53V, and 2M-methanol. Fig. 6 shows the photograph of an assembled μDMFC with a total size of 22mm×24mm×8mm. Fig. 3. Methanol crossover vs. current density for various feed concentrations of methanol SiO2/Si3N4 (a) PDMS (b) Aluminum foil (e) (f) (c) (d) (g) Fig. 5. Fabrication process of the μDMFC Fig. 4. Comparison of performances of parallel and serpentine flow-field channels 126 Pt/Ti Carbon paper 0.1M 1M 2M 4M 8 2 Power Density(mW/cm ) 7 6 5 4 3 2 1 0 -5 0 5 10 15 20 25 30 35 40 45 50 55 2 Current Density (mA/cm ) Fig. 8. Power density curves of the µDMFC tested for different methanol concentration; methanol: 0.40ml/min and oxygen: 15ml/min; room temperature(21℃) and ambient pressure Fig. 6. Assembled μDMFC 4 CHARACTERIZATION 5 CONCLUSIONS The performance of the μDMFC was measured at room temperature under ambient pressure. 1M-methanol solution with a feeding rate of 0.6ml/min was fed into the anode and oxygen was supplied to the cathode with a flow rate of 15ml/min. An electrochemical interface, Solartron 1287, was used to test the performance by the constant current method. This work reports the recent achievements made in our group on developing the μDMFC, including a 3-D anode model simulation, design, fabrication and assembly of a μDMFC with MEMS technology and original PDMS assemble technology, and its testing performance. The latest µDMFC has an open-circuited potential of 0.73V, and the maximum power density of 7.04mW/cm2 when 1M-methanol was fed at room temperature. The output has supplied the power for a small motor. It demonstrates that the power density of the μDMFC fabricated in our laboratory satisfies the requirements of power consumption of many electronic devices and has the potential of being used for practical applications. Fig. 7 presents the typical performance curves of the µDMFCs developed in our group at different periods. The latest µDMFC has an open-circuited potential of 0.73V, and the maximum power density of 7.04mW/cm2. The output has successfully supplied the power for a small motor. The characterization of the μDMFC has also been investigated. Fig. 8 presents the effect of methanol concentration on the performance. The best performance was achieved at 2M-methanol solution. Lower and higher concentrations both cause the performance degradation. It verifies the simulation results as Fig. 3 suggests that methanol crossover can cause the performance degradation at higher concentrations. ACKNOWLEDGEMENTS The authors are grateful for the support of this work by National Natural Science Foundation of China, Major Research Plan, and Grant No. 90207023. REFERENCES 8 0.6 [1] 6 Voltage (V) 0.5 4 0.4 0.3 2 0.2 Eiichi Sakaue, “Micromachining / Nanotechnology in Direct Methanol Fuel Cell,” Proc. MEMS2005, pp.600-605, 2005 [2] G.Q.Lu, C.Y. Wang, et al., “Development and Characterization of a Silicon-based Micro Direct Methanol Fuel Cell,” Electrochimica Acta, 49 (2004), pp.821-828 [3] Yingqi Jiang, Xiaohong Wang, et al., “A Micro Direct Methanol Fuel Cell Using PDMS Assembly Technology,” Proc. Transducers2005, Seoul, pp.303-306, 2005 [4] M.W. Verbrugge, “Methanol Diffusion in Perfluorinated Ion-conducting Membranes,” J. Electrochem. Soc., 136 (1989), pp.417-423 [5] K. Scott, P. Argyropoulos, K. Sundmacher, “A Model for the Liquid Feed Direct Methanol Fuel Cell,” J. Electroanal. Chem., 477 (1999), pp.97-110 [6] Masayuki Kunimatsu, Toshio Shudo, Yasuo Nakajima, “Study of Performance Improvement in a Direct Methanol Fuel Cell,” JSAE Review, 2002, 23 (1), pp.21~26 2 Voltage(1G) Power Denstiy(1G) Voltage(2G) Power Density(2G) 0.7 Power Density (mW/cm ) 0.8 0.1 0.0 0 20 40 60 0 80 2 Current Density(mA/cm ) Fig. 7. Progress in performance of a single cell. The cell operated fed with 1M-methanol solution and pure oxygen at room temperature. 1G(generation) ⎯ fabricated and tested in 2004 2G(generation) ⎯ fabricated and tested in 2005 127