Commercial CFD Code Validation for Heavy- Vehicle External Aerodynamics Simulation

advertisement

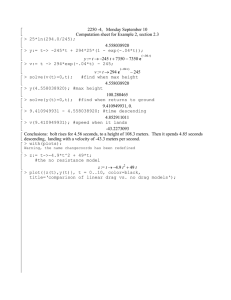

Commercial CFD Code Validation for HeavyVehicle External Aerodynamics Simulation W. David Pointer, Tanju Sofu, and David Weber Argonne National Laboratory, Nuclear Engineering Division The issue of energy economy in transportation has grown beyond traditional concerns over environment, safety and health to include new concerns over national security and energy self-sufficiency. As part of the U.S. Department of Energy Office of FreedomCAR and Vehicle Technologies’ Working Group on Aerodynamic Drag of Heavy Vehicles, Argonne National Laboratory is independently investigating the accuracy of aerodynamic drag predictions generated by commercial Computational Fluid Dynamics (CFD) Software. In this validation study, computational predictions from two commercial CFD codes, Star-CD [1] and PowerFLOW [2], will be compared with detailed velocity, pressure and force balance data from experiments completed in the 7 ft. by 10 ft. wind tunnel at NASA Ames [3,4] using a Generic Conventional Model (GCM) that is representative of typical current-generation tractor-trailer geometries. This paper highlights results from evaluations of drag coefficient predictions using standard two-equation steady RANS turbulence models and logarithmic wall functions that were completed as part of the first phase of these studies. Introduction The commercial CFD software validation effort undertaken by Argonne National Laboratory is currently nearing the completion of the first phase of a multi-stage project that will culminate in an evaluation of the capabilities of selected commercial CFD software for the simulation of aerodynamic drag of actual truck geometries. In the first phase, a roadmap is being developed for the more rigorous validation efforts to be completed in the remaining components of the study. This phase includes preliminary evaluations of solution sensitivity to the computational mesh construction, selection of turbulence model, and other simulation parameters. The evaluations completed in the development of the roadmap use simulations of the standard configuration of a Generic Conventional Model (GCM), which is a representative simplification of current generation tractor-trailer geometries. These simulations will use the commercial CFD software package Star-CD, which is a finite volume 474 W.D. Pointer, T. Sofu, and D. Weber code using a predictor-corrector-type solver. Computational meshes for these studies are developed using Star-CD’s automatic meshing capabilities and problem set up is completed using the aerodynamic problem definition tool, ES-Aero. The software package provides a wide variety of turbulence modeling options as part of the standard commercial release and allows for the use of alternative turbulence models through user-subroutine programming. Initial studies completed in this phase have focused upon the applicability of standard two-equation high Reynolds number steady-RANS (Reynolds-averaged Navier Stokes) turbulence models using wall functions in the near wall region for the prediction of aerodynamic drag. Future efforts may include evaluations of socalled two-layer models, which use the standard two-equation high Reynolds number models in the far field coupled with a low-Reynolds number model in the near wall field, or transient simulation methodologies. In the second phase, the agreement between simulations of the standard configuration of the GCM using Star-CD and the commercial CFD software package PowerFLOW will be evaluated. Since PowerFLOW is a latticeBoltzmann based code, the extensive modeling options available in a finite volume code are neither available nor necessary. Standard PowerFLOW modeling options will be employed in these evaluations. In the final phase of the studies using the GCM geometry, computational predictions of velocity fields, pressure fields, and drag coefficients will be compared with experimental measurements for four different configurations of the GCM. All wind tunnel tests considered in the study provide a Reynolds number of 1.1 million. In each experiment, three-axis Particle Image Velocimetry (PIV) and 490 pressure sensors are employed to record the velocity and pressure fields around the vehicle. A standard aerodynamic force balance is employed to capture drag force data. All cases will be treated as “blind” validation studies with no prior knowledge of the details of the experimental results. A set of best practice guidelines will be developed from the GCM studies for application to the simulation of a real truck geometry complete with mirrors, door handles and all standard decorative details. Through a cooperative research and development agreement, PACCAR Technical Center will provide detailed geometric data and experimental measurements of drag coefficient and surface pressure distributions for a 1/8th scale model of a commercial tractor and generic trailer under a range of yaw angles. Blind validation studies will be completed using standard options available within selected commercial CFD software. Generic Conventional Model The Generic Conventional Model (GCM) is a simplified representation of a conventional U.S. tractor-trailer truck. The model is 1/8th scale and can be configured in four different geometries as illustrated in Fig. 1. The nominal configuration is a representative model of a current-generation tractor-trailer truck. Alternate configurations include the addition of a low-boy device under Commercial CFD Code Validation 475 Standard truck Low boy trailer Faired truck Faired truck with low boy trailer Fig. 1. Generic Conventional Model (GCM) geometric configurations the length of the trailer, a full fairing between the cab and the trailer, and the combination of the fairing and low-boy device. Computational Model The computational model employed in these studies was developed using the ES-Aero tool for aerodynamic drag simulation that is available as part of the Star-CD software package. The mesh is developed using a semi-automated process that progresses in seven stages: 1. A three-dimensional hexahedral mesh is created that completely fills the volume of the wind tunnel. 2. The mesh is refined in successively smaller zones surrounding the vehicle until the mesh in a small region surrounding the vehicle reaches the pro- 476 W.D. Pointer, T. Sofu, and D. Weber scribed near-vehicle cell size. The result is an unstructured mesh of hexahedral cells which exhibit 2-to-1 matching at the unstructured interfaces. 3. The near-vehicle mesh is locally refined based upon features of the vehicle surface definition. Local refinements are determined by both minimum feature size limits and by user identification of feature zones of interest. 4. The surfaces that define the vehicle are “wrapped” by projecting the refined hexahedral mesh onto the surface. In this manner, the multiple components of the vehicle are merged into a single surface, and a quadrilateral surface definition is created. 5. The quadrilateral surface definition is spatially expanded to create a subsurface. 6. The sub-surface is used to cut away the parts of the unstructured hexahedral mesh that fall within the sub-surface. 7. A brick and prism extrusion layer is created to fill the gap between the subsurface and the quadrilateral surface definition. Thus, the polyhedral trimmed cells are not in the critical boundary layer region of the problem. 8. Upon completion of the basic mesh, the wake and ground layer regions are automatically further refined to better capture important flow features. In this study, the generated mesh has a near-wall cell size of 8.0 mm. The minimum cell size used in local refinements is 0.5 mm, and a minimum of 16 points are required to define any full circle. In addition to automatic refinements, cells adjacent to the surface are refined to a size of 2.0 mm in order to preserve the quality of the surface in the wrapping stage and improve the quality of the trimmed cells. The extrusion layer consists of two layers of brick and prism cells where the outer layer has a thickness of 1.0 mm and the inner layer has a thickness of 0.5 mm. A sample computational mesh is illustrated in Fig. 2. In order to reduce computational cost for these preliminary studies, only half of the GCM is included in the model and a symmetric boundary condition is employed at the centerline. In all simulations discussed herein, the GCM is centered at zero yaw on the floor of a wind tunnel test section that is 2.133 m (7 ft.) tall by 3.048 m (10 ft.) wide. Since the GCM is approximately 2.5 m long, a total test section length of 10.0 m is assumed, where one model length is included upstream of the model and two model lengths are included downstream of the model. Based upon a Reynolds number of 1.1 million, a uniform velocity of 51.5 m/s is enforced at the inlet boundary. A uniform pressure condition is applied at the outlet boundary. In these studies, the surface of the standard configuration GCM is defined using approximately 500,000 triangular surface elements that are based upon CAD data representations taken from optical scans of the actual model. Commercial CFD Code Validation 477 Fig. 2. Two-dimensional projection of the near-vehicle region of the computational mesh employed in these studies. Turbulence Modeling While commercial CFD technology relies heavily upon traditional steady RANS turbulence modeling in combination with logarithmic wall functions for most flow field simulation applications, the applicability of these models to aerodynamic drag simulations is often questioned. Numerous studies have demonstrated mediocre predictions of separation regions under adverse pressure gradients such as those seen in backward facing steps or bluff bodies in cross flow when using these models. However, as with any problem, the applicability of these models to the heavy vehicle problem should be independently considered. These studies evaluate three formulations of this type of turbulence model: 1. the standard high Reynolds number k-e model, 2. the Menter k-e SST model [5], and 3. the renormalization group (RNG) formulation of the k-e model [6]. The standard high Reynolds number k-e model and the k-e SST model are identical in the far field, but the SST model uses a blending function that is dependent on the distance from the surface to incorporate the additional detail of the Wilcox k-e model in separation regions and near the walls. For the high Reynolds number k-e model, the near wall turbulence parameters are specified using the logarithmic “law of the wall” function. For the k-e SST, the w of the near wall cell is also fixed using a wall function dependent on the coefficients of the turbulence model. The SST model may be more sensitive to separation than the standard k-e model, but the two should show reasonable agreement. The RNG model is also similar to the standard k-e model, but the RNG model contains an additional term to account for the mean flow distortion of the dissipation. It is expected that a larger discrepancy will be seen between the standard k-e model and the RNG model. 478 W.D. Pointer, T. Sofu, and D. Weber Simulation Results For each turbulence model considered, a steady-state simulation consisting of 3000 iterations was completed. Convergence parameters that define the desired limits of the velocity, mass and pressure residuals were set to small values to allow the simulation to continue to the 3000th iteration before the standard flow parameter convergence criteria were satisfied. In addition to the standard flow parameter residuals, the convergence of the vehicle drag coefficient was monitored interactively. Although the drag coefficient shows slight oscillatory behavior in each simulation, near-constant drag-coefficients were obtained by the 1800th iteration in all three cases. At the 3000th iteration, the normalized global residual of each of the individual flow parameters have converged to less than 1x10-4. The normalized change in the drag coefficient has also con- Commercial CFD Code Validation 479 verged to less than 1x10-4 by the 3000th iteration. Since velocity and pressure data from the wind tunnel experiments will not be available for comparison with the computational studies until the “blind” validation phase of the projects, comparisons with the measured experimental pressure and velocity data have not yet been made. Only comparisons between the three computational cases can be made for the pressure and velocity distributions at this time. However, comparisons with experimental drag coefficient measurements are made herein since this data provides little information that could potentially be used to produce “tuned” solutions. Velocity Distribution Predictions Since the current simulations have employed a steady-state methodology, the predicted flow fields cannot be expected to capture such temporal behaviors as vortex shedding in the wake behind the trailer. However, such steady-state simulations may still provide useful insights about the general character of the flow field. Velocity magnitude profiles at the centerline of the GCM are shown in Fig. 3. In these figures, recirculation zones are clearly outlined by the regions of near-zero velocity magnitude, which are shown in violet. The simulations all show a large recirculation zone downstream of the trailer which in reality is a large unsteady wake. While a steady-state simulation cannot capture such a wake, these phenomena are characterized as steady recirculation zones which provide some insight into the location and distribution of vortex shedding and other wake field phenomena within the flow field. As one should expect, the predictions of the simulations using the standard k-e model and the SST model are very similar. However, the length of the recirculation zone following the trailer is somewhat reduced by the SST model, and the length of the recirculation under the trailer is extended by the SST model. The application of the RNG model leads to a more significant deviation from the case using the standard k-e model. The length of the recirculation zone at the base of the trailer is significantly increased and the interaction of the underbody flow with both the wake flow and the ground plane is much more significant. Pressure Distribution Predictions The accurate prediction of surface pressure distributions is critical for the prediction of drag forces acting on the vehicle. While comparisons will not be made with experimental measurements of surface pressure distributions, the surface pressure distributions should be consistent with flow field predictions. Furthermore, the predictions from the simulations using different turbulence models should show reasonable consistency since the differences between the selected models are not large. 480 W.D. Pointer, T. Sofu, and D. Weber A sample surface pressure distribution taken from the simulation using the standard k-e model is shown in Fig. 4. Data shown in the contour plot of surface pressure was generated by reflecting the calculated values across the symmetric boundary plane of the half-vehicle model. The surface pressure data clearly captures that stagnation of flow in front of the vehicle. Also seen are the regions of separated flow along the A-pillar, along the top of the cab fairing, along the sides of the cylindrical wheels, and along the expansion feature that would be located just downstream of the cab doors. Consistent with expectations, negative pressures are predicted along the rear surface of the cab and the trailer, but no large pressure gradients are seen observed within those regions. The largest pressure gradients are observed along the leading edge of the sides of the tires and along the recirculation region just under the front bumper. Significant stagnation and negative base pressure regions are observed on all tires and axels in this simulation. This is consistent with the static nature of the GCM model, but this distribution would be altered for real Cab Front View Trailer Base View Side View Fig. 4. Predicted pressure distributions on the surface of the GCM model as seen in isometric, front, side and back views. Data is taken from simulations using the k-e model and data has been reflected across the symmetric centerline boundary to generate a data set representing the full vehicle. Commercial CFD Code Validation 481 tractor-trailer vehicles while in service as a result of the rotation of these elements. Pressure distributions along the front of the tractor and the base of the trailer at the model centerline are shown in Fig. 5 for each of the turbulence models employed. As expected, there is very little deviation between the standard k-e model and the SST model. In a manner consistent with the deviations observed in the velocity field between the simulations using the standard k-e model and the RNG model, the pressure profiles from the RNG case show larger negative pressures in the separation zones. While a small difference is seen between the RNG model and the other models in the predictions along the trailer base, larger contributions to the difference in total body drag are found along the components in the under body flow. Drag Coefficient Predictions For each simulation, the vehicle drag coefficient was calculated using a frontal surface area of 0.158 m2. The experimental drag coefficient is reported as 0.4076 where a frontal area of 0.1544 m2 was assumed. However, the value frontal area used in the calculation of the experimental coefficient does not account for the area of the tires. When this area is accounted for, as in the calculation of the drag coefficient for the numerical predictions, the experimental drag coefficient becomes 0.398. As shown in Table 1, excellent agreement with the experimental result is obtained for all of the turbulence models employed. The best agreement is seen in the simulation using the k-e SST model, where the error in the prediction is 0.75 percent. Efforts are currently underway to establish the sensitivity of these results to the computational mesh structure and refinement. Table 1. Summary of drag coefficient predictions for each of the turbulence models employed. Predicted Drag Coefficient Percent Error in Prediction Experiment 0.398 -- High-Reynolds number k-epsilon model 0.402 1.00 Menter k-e SST model 0.401 0.75 RNG model 0.389 2.29 Turbulence Model 482 W.D. Pointer, T. Sofu, and D. Weber (a) Front of Tractor (b) Base of Trailer Fig. 5. Predicted pressure distributions along the centerline of the tractor front and trailer base surfaces of the GCM for each turbulence model considered. Commercial CFD Code Validation 483 Summary and Conclusion Argonne National Laboratory is currently investigating the accuracy of commercial CFD software for the prediction of the aerodynamic drag coefficient of heavy vehicles. Initial studies have examined drag coefficient prediction using standard two-equation steady-state RANS turbulence models in conjunction with wall functions in the commercial CFD software package Star-CD. These initial studies appear to indicate that these basic models can be used in conjunction with the computational mesh generated by Star-CD’s automatic meshing tools to make accurate predictions of the vehicle drag coefficient. Indeed, predicted drag coefficients are within as little as 0.75 percent of the measured wind tunnel value. Extensive mesh sensitivity analyses are currently underway to further establish the validity of these results. At the conclusion of “blind” numerical simulation activities using the GCM standard truck geometry, pressure and velocity field predictions will be compared with detailed pressure and velocity data from wind tunnel experiments. These results will be used to develop a set of best practice guidelines that will be employed in the simulation of a real tractor-trailer truck geometry for comparison with wind tunnel data collected for that system. References 1. Star-CD, version 3.150A, CD-Adapco Group, Melville, NY. 2. PowerFLOW, version 3.4, Exa Corporation, Lexington, MA. 3. Dale Satran, “ An Experimental Study of the Generic Conventional Model (GCM) in the NASA Ames 7-by-10-Foot Wind Tunnel,” United Engineering Foundation Conference on The Aerodynamics of Heavy Vehicles: Trucks, Buses, and Trains, Monterey, CA, Dec 2-6, 2002. 4. J. T. Heineck, Stephen Walker, Dale Satran, “The Measurement of Wake and Gap Flows of a 1/8th Scale Generic Truck Using Three-Component Particle Image Velocimetry,” United Engineering Foundation Conference on The Aerodynamics of Heavy Vehicles: Trucks, Buses, and Trains, Monterey, CA, Dec 2-6, 2002. 5. Yakhot, V., Orszag, S.A., Thangam, S., Gatski, T.B., and Speziale, C.G. “Development of turbulence models for shear flows by a double expansion technique”, Phys. Fluids, A4, No. 7, pp. 1510–1520, 1992 6. F. R. Menter, “Zonal Two Equation k-_ Turbulence Models for Aerodynamic Flows” in 24th Fluid Dynamics Conference (Orlando), AIAA paper 93-2906, July 1993.