CHEMICAL ANALYSIS OF FEEDSTUFFS Pages 93-100

CHEMICAL ANALYSIS OF

FEEDSTUFFS

Pages 93-100

FEED NUTRIENTS

FEED ANALYSIS SYSTEMS

• Needed to rationally group feed nutrients and requirements

– Makes analysis relatively easy and cost-effective

•

Feed analysis systems

– Proximate analysis system (Weende system)

• Developed in 1864 at Weende Experiment

Station in Germany

– Detergent analysis system (Van Soest system)

• Developed in 1964 at USDA Beltsville Research

Center

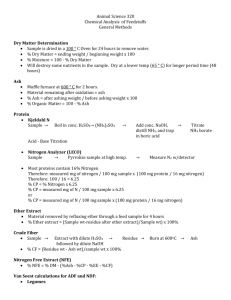

PROXIMATE ANALYSIS COMPONENTS

• Dry matter

• Ash

• Crude protein

• Ether extract

• Crude fiber

• Nitrogen-free extract

•

Dry matter (DM)

– Material remaining after a feed is dried in a

100 o C oven for 24 hours

• DM,% = wt after drying/wt before drying x 100%

• % moisture = 100 – DM,%

– Problems with method

• Errors from losses of volatile components

– Particularly a problem with fermented feeds

– Can be avoided by toluene distillation or freeze drying

• Drying at 100 o C destroys sample for further analysis

– Can be avoided by freeze drying or drying at 65 o C for

48 hours in preparation for analysis (Still need to run a total DM analysis of part of sample)

• Significance of DM

– Considerable variation in the DM, % of feedstuffs

• Corn grain, 88% DM

• Alfalfa hay, 90% DM

• Alfalfa silage, 45% DM

• Alfalfa pasture, 26% DM

• Whey, 7%

– Other nutrients are present within the dry matter

• Affects expression of concentrations of nutrients in feedstuffs

• Example Crude protein, %

DM,% Wet basis DM basis

– Dried distillers grains 93 27.9

30

– Modified distillers grains 50 15.0 30

– Wet distillers grain 40 12.0 30

– Affects storage properties of feedstuffs

•

Ash

– Material remaining after oxidation of a sample at 600 o C for 2 hours in a muffle furnace

• % Ash = wt after ashing/sample wt x 100%

• % Organic matter = 100 - % ash

– Problems

• No indication of amounts of individual minerals

• Some minerals (Sulfur, Selenium, Zinc, Iodine are lost)

– Significance

• May indicate soil contamination or adulteration of feedstuff or diet.

•

Crude protein (CP)

– % Crude protein = %N x 6.25

– %N determination

• Kjeldahl N

Sample→Boil in conc. H

2

SO

4

→(NH

4

)

2

SO

4

→Add conc. NaOH, → Titrate distill NH

3

, and trap NH

4 borate in boric acid

• N analyzer

Sample→Pyrrolize sample at high temp.→Measure N

2 w/detector

– Factor of 6.25 assumes that most proteins contain

16% N

CP,% = measured mg N/100 mg sample x 100 mg protein/16 mg N

= measured mg N/100 mg/sample x 6.25

• Problems with crude protein procedure

– Sources of N

• True protein

– Chains of amino acids bound by peptide linkages

– Can meet the protein requirements of either nonruminant or ruminant animals

• Nonprotein nitrogen

– Forms

» Free amino acids

» Nucleic acids

» Ammonia

» Urea

» Biuret

– Can meet the protein requirements of ruminant animals

» Urea and biuret commonly added to ruminant diets

– Can not meet the protein requirements of nonruminant animals

– Says nothing about the amino acid composition of the feed source

• Commonly assume that the concentration of individual amino acids is constant within the protein a given feedstuff

• Can analyze for individual amino acids

– Crude protein says nothing about the digestibility of a protein

• Varies with feedstuff

Soybean meal

% Crude protein % Protein Digestibility

45 90

Feather meal 80 75

• Varies with heat damage

– When overheated, protein will bind to the cell wall carbohydrates particularly across lysine

– Causes

» Molding of forages

» Over-heating during processing

» Over-drying of grains or soybeans

– Referred to as the Maillard or Browning Reaction

– Results

% Crude protein % Protein Digestibility

Well-preserved alfalfa hay

Heat-damaged alfalfa hay

18

18

90

60

•

Ether extract (EE)

– Also called crude fat

– Material removed by refluxing ether through a feed sample for 4 hours

% Ether extract = (Sample wt-residue after ether extract)/Sample wt x 100%

– Theoretically represents fat content of the feedstuff

• A high ether extract content should indicate a high energy concentration

– Problem with procedure

• Ether extract consists of:

– True lipids

» Fats and oils

– Non-nutritional ether soluble components

» Fat-soluble vitamins

» Chlorophyll

» Pigments

» Volatile oils

» Waxes

•

Crude fiber (CF)

– Procedure

Sample→Extract with dilute H

2

SO followed by dilute NaOH

4

→Residue→Burn at 600 o C→Ash

% CF = (Residue wt-Ash wt)/sample wt x 100%

– Theoretically represents

• the structural carbohydrates (Cellulose and hemicellulose)

– Limited digestibility in ruminants

– Poor digestibility in nonruminants

• Lignin

– Indigestible by ruminants and nonruminants

– Problems with procedure

• Poor recovery of components

– Lignin

% recovered

– Cellulose 90

– Hemicellulose 50-60

13-70

•

Nitrogen-free extract (NFE)

– No actual analysis

– Calculation by difference

• %NFE = %DM – (%ash+%CP+%EE+%CF)

– Theoretically represents:

• Starch

• Sugars

– Problems:

• Contains all of the errors from other analyses

– Largest error is unrecovered lignin will be placed in

NFE

WHY IS PROXIMATE ANALYSIS SYSTEM

STILL USED?

DETERGENT ANALYSIS SYSTEM

• Neutral detergent fiber (NDF)

– Consists of hemicellulose, cellulose, lignin, cell wall bound protein and insoluble ash

– Significance:

• Highly related to feed intake

• DMI, % BW = 120/% NDF

• Acid detergent fiber (ADF)

– Consists of cellulose, lignin, poorly digested protein, and insoluble ash

– Significance:

•

• Highly related to digestibility and energy concentration

• DDM% = 88.9 – (.779 x %ADF)

NE l

, Mcal/lb (for legumes) = 1.011 – (0.0113 x %ADF)

– Combination of DDM (determined from ADF) and

DMI (determined from NDF) is used to determine

Relative Feed Value (RFV)

• RFV=DDM x DMI / 1.29

• Used for hay marketing

– Nitrogen bound to acid detergent fiber is a measure of heat-damaged protein

• Called ADIN or ADF-CP

– Procedure

Sample→Extract with AD→ADF→Analyze N by

Kjeldahl procedure

ADF-CP, % of total CP= %ADFN x 6.25/%CP x 100%

– Relationship to protein digestibility (called adjusted

CP)

• If ADF-CP, % of total CP <14, ADIN is considered digestible

– Adjusted CP = CP

• If ADF-CP, % of total CP is >14 and <20

– Adjusted CP = ((100 – (ADF-CP, % of CP – 7))/100) x CP

• If ADF-CP, % of total CP is > 20

– Adjusted CP = CP – ADF-CP, % of CP

• N bound to NDF and ADF used to determine rumen degradable, rumen undegradable, and indigestible fractions

Rumen degradable protein = Total CP – (NDFCP, % of CP xTotal CP)

Rumen undegradable protein = (NDFCP, % of CP xTotal CP) –

(ADFCP, % of CP xTotal CP)

Indigestible protein = (ADFCP, % of CP xTotal CP)

OTHER ANALYTICAL PROCEDURES

• Near infrared reflectance spectroscopy

– Determines the concentrations of protein, amino acids, lipids, and carbohydrates based on absorption of near infrared light

– Advantages

• Rapid

• Used by most commercial labs

– Limitations

• Requires calibration

• Inability to measure heterogeneous molecules like lignin

• Inability to measure minerals

• Atomic absorption spectroscopy

– Used for mineral analysis

– Procedure

• Sample ashed and extracted into a solvent

• Dissolved sample sucked into a flame with a light at a specific wavelength going through it

• Absorption of light directly proportional to absorption of light

– Limitation

• Expense

• High performance liquid chromatography

– Used of amino acids and vitamins

– Procedure

• Sample dissolved in organic solvent injected into column

• Column differentially separates components

• Detector measures components as they through the column

– Limitation

• Expense