IPS-E-PR-370(1)

FOREWORD

The Iranian Petroleum Standards (IPS) reflect

the views of the Iranian Ministry of Petroleum

and are intended for use in the oil and gas

production facilities, oil refineries, chemical and

petrochemical plants, gas handling and

processing installations and other such facilities.

IPS is based on internationally acceptable

standards and includes selections from the items

stipulated in the referenced standards. They are

also supplemented by additional requirements

and/or modifications based on the experience

acquired by the Iranian Petroleum Industry and

the local market availability. The options which

are not specified in the text of the standards are

itemized in data sheet/s, so that, the user can

select his appropriate preferences therein.

The IPS standards are therefore expected to be

sufficiently flexible so that the users can adapt

these standards to their requirements. However,

they may not cover every requirement of each

project. For such cases, an addendum to IPS

Standard shall be prepared by the user which

elaborates the particular requirements of the

user. This addendum together with the relevant

IPS shall form the job specification for the

specific project or work.

The IPS is reviewed and up-dated approximately

every five years. Each standards are subject to

amendment or withdrawal, if required, thus the

latest edition of IPS shall be applicable

The users of IPS are therefore requested to send

their views and comments, including any

addendum prepared for particular cases to the

following address. These comments and

recommendations will be reviewed by the

relevant technical committee and in case of

approval will be incorporated in the next revision

of the standard.

Standards and Research department

No.19, Street14, North kheradmand

Karimkhan Avenue, Tehran, Iran .

Postal Code- 1585886851

Tel: 88810459-60 & 66153055

Fax: 88810462

Email: Standards@nioc.org

ﭘﻴﺶ ﮔﻔﺘﺎر

( ﻣﻨﻌﻜﺲ ﻛﻨﻨﺪه دﻳﺪﮔﺎﻫﻬﺎيIPS) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮان

وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ و ﺑﺮاي اﺳﺘﻔﺎده در ﺗﺄﺳﻴﺴﺎت ﺗﻮﻟﻴﺪ

واﺣﺪﻫﺎي ﺷﻴﻤﻴﺎﻳﻲ و، ﭘﺎﻻﻳﺸﮕﺎﻫﻬﺎي ﻧﻔﺖ،ﻧﻔﺖ و ﮔﺎز

ﺗﺄﺳﻴﺴﺎت اﻧﺘﻘﺎل و ﻓﺮاورش ﮔﺎز و ﺳﺎﻳﺮ ﺗﺄﺳﻴﺴﺎت،ﭘﺘﺮوﺷﻴﻤﻲ

.ﻣﺸﺎﺑﻪ ﺗﻬﻴﻪ ﺷﺪه اﺳﺖ

ﺑﺮاﺳﺎس اﺳﺘﺎﻧﺪاردﻫﺎي ﻗﺎﺑﻞ ﻗﺒﻮل،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

ﺑﻴﻦاﻟﻤﻠﻠﻲ ﺗﻬﻴﻪ ﺷﺪه و ﺷﺎﻣﻞ ﮔﺰﻳﺪهﻫﺎﻳﻲ از اﺳﺘﺎﻧﺪاردﻫﺎي

ﻫﻤﭽﻨﻴﻦ ﺑﺮاﺳﺎس ﺗﺠﺮﺑﻴﺎت.ﻣﺮﺟﻊ در ﻫﺮ ﻣﻮرد ﻣﻲﺑﺎﺷﺪ

ﺻﻨﻌﺖ ﻧﻔﺖ ﻛﺸﻮر و ﻗﺎﺑﻠﻴﺖ ﺗﺄﻣﻴﻦ ﻛﺎﻻ از ﺑﺎزار داﺧﻠﻲ و ﻧﻴﺰ

ﻣﻮاردي ﺑﻄﻮر ﺗﻜﻤﻴﻠﻲ و ﻳﺎ اﺻﻼﺣﻲ در اﻳﻦ،ﺑﺮﺣﺴﺐ ﻧﻴﺎز

ﻣﻮاردي از ﮔﺰﻳﻨﻪﻫﺎي ﻓﻨﻲ ﻛﻪ در.اﺳﺘﺎﻧﺪارد ﻟﺤﺎظ ﺷﺪه اﺳﺖ

ﻣﺘﻦ اﺳﺘﺎﻧﺪاردﻫﺎ آورده ﻧﺸﺪه اﺳﺖ در داده ﺑﺮگﻫﺎ ﺑﺼﻮرت

ﺷﻤﺎره ﮔﺬاري ﺷﺪه ﺑﺮاي اﺳﺘﻔﺎده ﻣﻨﺎﺳﺐ ﻛﺎرﺑﺮان آورده ﺷﺪه

.اﺳﺖ

ﺑﺸﻜﻠﻲ ﻛﺎﻣﻼً اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺗﺪوﻳﻦ ﺷﺪه،اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ

.اﺳﺖ ﺗﺎ ﻛﺎرﺑﺮان ﺑﺘﻮاﻧﻨﺪ ﻧﻴﺎزﻫﺎي ﺧﻮد را ﺑﺎ آﻧﻬﺎ ﻣﻨﻄﺒﻖ ﻧﻤﺎﻳﻨﺪ

ﺑﺎ اﻳﻦ ﺣﺎل ﻣﻤﻜﻦ اﺳﺖ ﺗﻤﺎم ﻧﻴﺎزﻣﻨﺪيﻫﺎي ﭘﺮوژه ﻫﺎ را

در اﻳﻦ ﮔﻮﻧﻪ ﻣﻮارد ﺑﺎﻳﺪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﻧﻴﺎزﻫﺎي.ﭘﻮﺷﺶ ﻧﺪﻫﻨﺪ

اﻳﻦ.ﺧﺎص آﻧﻬﺎ را ﺗﺄﻣﻴﻦ ﻣﻲﻧﻤﺎﻳﺪ ﺗﻬﻴﻪ و ﭘﻴﻮﺳﺖ ﻧﻤﺎﻳﻨﺪ

ﻣﺸﺨﺼﺎت ﻓﻨﻲ آن ﭘﺮوژه،اﻟﺤﺎﻗﻴﻪ ﻫﻤﺮاه ﺑﺎ اﺳﺘﺎﻧﺪارد ﻣﺮﺑﻮﻃﻪ

.و ﻳﺎ ﻛﺎر ﺧﺎص را ﺗﺸﻜﻴﻞ ﺧﻮاﻫﻨﺪ داد

اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ ﺗﻘﺮﻳﺒﺎً ﻫﺮ ﭘﻨﺞ ﺳﺎل ﻳﻜﺒﺎر ﻣﻮرد ﺑﺮرﺳﻲ

در اﻳﻦ ﺑﺮرﺳﻲﻫﺎ ﻣﻤﻜﻦ اﺳﺖ.ﻗﺮار ﮔﺮﻓﺘﻪ و روزآﻣﺪ ﻣﻲﮔﺮدﻧﺪ

اﺳﺘﺎﻧﺪاردي ﺣﺬف و ﻳﺎ اﻟﺤﺎﻗﻴﻪاي ﺑﻪ آن اﺿﺎﻓﻪ ﺷﻮد و ﺑﻨﺎﺑﺮاﻳﻦ

.ﻫﻤﻮاره آﺧﺮﻳﻦ وﻳﺮاﻳﺶ آﻧﻬﺎ ﻣﻼك ﻋﻤﻞ ﻣﻲ ﺑﺎﺷﺪ

درﺧﻮاﺳﺖ ﻣﻲﺷﻮد ﻧﻘﻄﻪ ﻧﻈﺮﻫﺎ و،از ﻛﺎرﺑﺮان اﺳﺘﺎﻧﺪارد

ﭘﻴﺸﻨﻬﺎدات اﺻﻼﺣﻲ و ﻳﺎ ﻫﺮﮔﻮﻧﻪ اﻟﺤﺎﻗﻴﻪاي ﻛﻪ ﺑﺮاي ﻣﻮارد

ﻧﻈﺮات و. ﺑﻪ ﻧﺸﺎﻧﻲ زﻳﺮ ارﺳﺎل ﻧﻤﺎﻳﻨﺪ،ﺧﺎص ﺗﻬﻴﻪ ﻧﻤﻮدهاﻧﺪ

ﭘﻴﺸﻨﻬﺎدات درﻳﺎﻓﺘﻲ در ﻛﻤﻴﺘﻪﻫﺎي ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و در

ﺻﻮرت ﺗﺼﻮﻳﺐ در ﺗﺠﺪﻳﺪ ﻧﻈﺮﻫﺎي ﺑﻌﺪي اﺳﺘﺎﻧﺪارد ﻣﻨﻌﻜﺲ

.ﺧﻮاﻫﺪ ﺷﺪ

ﻛﻮﭼﻪ، ﺧﺮدﻣﻨﺪ ﺷﻤﺎﻟﻲ، ﺧﻴﺎﺑﺎن ﻛﺮﻳﻤﺨﺎن زﻧﺪ، ﺗﻬﺮان،اﻳﺮان

19 ﺷﻤﺎره،ﭼﻬﺎردﻫﻢ

اداره ﺗﺤﻘﻴﻘﺎت و اﺳﺘﺎﻧﺪاردﻫﺎ

1585886851 : ﻛﺪﭘﺴﺘﻲ

66153055 و88810459 - 60 : ﺗﻠﻔﻦ

88810462 : دور ﻧﮕﺎر

Standards@nioc.org

:ﭘﺴﺖ اﻟﻜﺘﺮوﻧﻴﻜﻲ

: ﺗﻌﺎرﻳﻒ ﻋﻤﻮﻣﻲ

General Definitions:

Throughout this Standard

definitions shall apply.

the

following

Company :

Refers to one of the related and/or affiliated

companies of the Iranian Ministry of Petroleum

such as National Iranian Oil Company, National

Iranian

Gas

Company,

and

National

Petrochemical Company etc.

Purchaser :

Means the “Company" Where this standard is

part of direct purchaser order by the “Company”,

and the “Contractor” where this Standard is a part

of contract documents.

Vendor And Supplier:

Refers to firm or person who will supply and/or

fabricate the equipment or material.

Contractor:

Refers to the persons, firm or company whose

tender has been accepted by the company.

Executor :

Executor is the party which carries out all or part

of construction and/or commissioning for the

project.

Inspector :

The Inspector referred to in this Standard is a

person/persons or a body appointed in writing by

the company for the inspection of fabrication and

installation work

Shall:

Is used where a provision is mandatory.

Should:

Is used where a provision is advisory only.

Will:

Is normally used in connection with the action

by the “Company” rather than by a contractor,

supplier or vendor.

May:

Is used where a provision is completely

discretionary.

.در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺗﻌﺎرﻳﻒ زﻳﺮ ﺑﻪ ﻛﺎر ﻣﻲ رود

: ﺷﺮﻛﺖ

ﺑﻪ ﺷﺮﻛﺖ ﻫﺎي اﺻﻠﻲ و واﺑﺴﺘﻪ وزارت ﻧﻔﺖ ﻣﺜﻞ ﺷﺮﻛﺖ ﻣﻠﻲ

ﺷﺮﻛﺖ ﻣﻠﻲ ﺻﻨﺎﻳﻊ، ﺷﺮﻛﺖ ﻣﻠﻲ ﮔﺎز اﻳﺮان، ﻧﻔﺖ اﻳﺮان

.ﭘﺘﺮوﺷﻴﻤﻲ و ﻏﻴﺮه اﻃﻼق ﻣﻴﺸﻮد

:ﺧﺮﻳﺪار

ﻳﻌﻨﻲ "ﺷﺮﻛﺘﻲ" ﻛﻪ اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﺳﻔﺎرش

ﺧﺮﻳﺪ ﻣﺴﺘﻘﻴﻢ آن "ﺷﺮﻛﺖ" ﻣﻴﺒﺎﺷﺪ و ﻳﺎ "ﭘﻴﻤﺎﻧﻜﺎري" ﻛﻪ اﻳﻦ

. اﺳﺘﺎﻧﺪارد ﺑﺨﺸﻲ از ﻣﺪارك ﻗﺮارداد آن اﺳﺖ

:ﻓﺮوﺷﻨﺪه و ﺗﺎﻣﻴﻦ ﻛﻨﻨﺪه

ﺑﻪ ﻣﻮﺳﺴﻪ و ﻳﺎ ﺷﺨﺼﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﺗﺠﻬﻴﺰات و ﻛﺎﻻﻫﺎي

. ﻣﻮرد ﻟﺰوم ﺻﻨﻌﺖ را ﺗﺎﻣﻴﻦ ﻣﻴﻨﻤﺎﻳﺪ

:ﭘﻴﻤﺎﻧﻜﺎر

ﻣﻮﺳﺴﻪ وﻳﺎ ﺷﺮﻛﺘﻲ ﮔﻔﺘﻪ ﻣﻴﺸﻮد ﻛﻪ ﭘﻴﺸﻨﻬﺎدش، ﺑﻪ ﺷﺨﺺ

.ﺑﺮاي ﻣﻨﺎﻗﺼﻪ وﻳﺎ ﻣﺰاﻳﺪه ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه اﺳﺖ

: ﻣﺠﺮي

ﻣﺠﺮي ﺑﻪ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ ﺗﻤﺎم ﻳﺎ ﻗﺴﻤﺘﻲ از

.ﻛﺎرﻫﺎي اﺟﺮاﻳﻲ و ﻳﺎ راه اﻧﺪازي ﭘﺮوژه را اﻧﺠﺎم دﻫﺪ

:ﺑﺎزرس

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﺎزرس ﺑﻪ ﻓﺮد ﻳﺎ ﮔﺮوﻫﻲ اﺗﻼق ﻣﻲ ﺷﻮد ﻛﻪ

ﻛﺘﺒﺎً ﺗﻮﺳﻂ ﻛﺎرﻓﺮﻣﺎ ﺑﺮاي ﺑﺎزرﺳﻲ ﺳﺎﺧﺖ و ﻧﺼﺐ ﺗﺠﻬﻴﺰات

.ﻣﻌﺮﻓﻲ ﺷﺪه ﺑﺎﺷﺪ

:ﺑﺎﻳﺪ

.ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺟﺒﺎري اﺳﺖ اﺳﺘﻔﺎده ﻣﻴﺸﻮد

:ﺗﻮﺻﻴﻪ

.ﺑﺮاي ﻛﺎري ﻛﻪ ﺿﺮورت اﻧﺠﺎم آن ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد

:ﺗﺮﺟﻴﺢ

ﻣﻌﻤﻮﻻً در ﺟﺎﻳﻲ اﺳﺘﻔﺎده ﻣﻲﺷﻮد ﻛﻪ اﻧﺠﺎم آن ﻛﺎر ﺑﺮاﺳﺎس

.ﻧﻈﺎرت ﺷﺮﻛﺖ ﺑﺎﺷﺪ

: ﻣﻤﻜﻦ اﺳﺖ

. ﺑﺮاي ﻛﺎري ﻛﻪ اﻧﺠﺎم آن اﺧﺘﻴﺎري ﻣﻴﺒﺎﺷﺪ

IPS-E-PR-370(1)

0

ENGINEERING STANDARD

FOR

PROCESS DESIGN OF

LOADING AND UNLOADING FACILITIES

FOR

ROAD TANKERS

FIRST REVISION

NOVEMBER 2009

اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﺑﺮاي

ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ

ﺗﺎﻧﻜﺮﻫﺎي ﺟﺎدهاي

وﻳﺮاﻳﺶ اول

1388 آﺑﺎن

This Standard is the property of Iranian Ministry of Petroleum.

All rights are reserved to the owner. Neither whole nor any

part of this document may be disclosed to any third party,

reproduced, stored in any retrieval system or transmitted in

any form or by any means without the prior written consent of

the Iranian Ministry of Petroleum.

1

ﺗﻤﺎم ﺣﻘﻮق آن ﻣﺘﻌﻠﻖ.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﺘﻌﻠﻖ ﺑﻪ وزارت ﻧﻔﺖ اﻳﺮان اﺳﺖ

ﺗﻤﺎم،ﺑﻪ ﻣﺎﻟﻚ آن ﺑﻮده و ﻧﺒﺎﻳﺪ ﺑﺪون رﺿﺎﻳﺖ ﻛﺘﺒﻲ وزارت ﻧﻔﺖ اﻳﺮان

ذﺧﻴﺮه، ﺑﻪ ﻫﺮ ﺷﻜﻞ ﻳﺎ وﺳﻴﻠﻪ ازﺟﻤﻠﻪ ﺗﻜﺜﻴﺮ، ﻳﺎ ﺑﺨﺸﻲ از اﻳﻦ اﺳﺘﺎﻧﺪارد

. ﻳﺎ روش دﻳﮕﺮي در اﺧﺘﻴﺎر اﻓﺮاد ﺛﺎﻟﺚ ﻗﺮار ﮔﻴﺮد، اﻧﺘﻘﺎل،ﺳﺎزي

Nov. 2009 / 1388 آﺑﺎن

CONTENTS:

Page

No

IPS-E-PR-370(1)

:ﻓﻬﺮﺳﺖ ﻣﻄﺎﻟﺐ

0. INTRODUCTION ............................................. 3

3 ............................................................. ﻣﻘﺪﻣﻪ-0

1. SCOPE................................................................ 4

4 ..................................................... داﻣﻨﻪ ﻛﺎرﺑﺮد-1

2. REFERENCES .................................................. 4

4 ............................................................. ﻣﺮاﺟﻊ-2

3. DEFINITIONS AND TERMINOLOGY......... 6

6 ............................................... ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3.1 Filling Installations..................................... 6

6 ........................................ ﺗﺎﺳﻴﺴﺎت ﭘﺮﻛﻨﻲ1-3

3.2 Gantry.......................................................... 6

6 ................................................... دارﺑﺴﺖ2-3

3.3 Loading Arm/Hose ..................................... 6

6 .................................. ﺷﻴﻠﻨﮓ ﺑﺎرﮔﻴﺮي/ ﺑﺎزو3-3

3.4 Loading Bay ................................................ 6

6 ........................................... دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي4-3

3.5 Loading Facilities ....................................... 6

6 ..................................... ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي5-3

3.6 Loading Island ............................................ 6

6 .......................................... ﻣﻨﻄﻘﻪ ﺑﺎرﮔﻴﺮي6-3

3.7 Spout ............................................................ 6

6 ...............................( دﻫﺎﻧﻪ ﺧﺮوﺟﻲ )ﭘﺮ ﻛﻨﻲ7-3

4. SYMBOLS AND ABBREVIATIONS ............. 6

6 .......................................... ﻧﺸﺎﻧﻪﻫﺎ و اﺧﺘﺼﺎرات-4

5. UNITS................................................................. 7

7 ........................................................... واﺣﺪﻫﺎ-5

6. TRUCK LOADING AND UNLOADING ....... 7

7 ..................................... ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ ﻛﺎﻣﻴﻮن-6

6.1 Loading........................................................ 7

7 .................................................... ﺑﺎرﮔﻴﺮي1-6

6.2 Truck Unloading......................................... 26

26 ............................................ ﺗﺨﻠﻴﻪ ﻛﺎﻣﻴﻮن2-6

APPENDICES:

:ﭘﻴﻮﺳﺖ ﻫﺎ

APPENDIX A TYPICAL LAYOUTS AND

GANTRY ARRANGEMENTS ... 28

28 ............... ﭘﻴﻮﺳﺖ اﻟﻒ ﻧﻤﻮﻧﻪ ﺟﺎﻧﻤﺎﻳﻲ و آراﻳﺶ دارﺑﺴﺖ

APPENDIX B TYPICAL LOADING SYSTEMS

FLOW SCHEMES ......................... 33

33 ..... ﭘﻴﻮﺳﺖ ب ﻧﻤﻮﻧﻪ ﻧﻤﻮدار ﺟﺮﻳﺎﻧﻲ ﺳﺎﻣﺎﻧﻪ ﻫﺎي ﺑﺎرﮔﻴﺮي

1

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

APPENDIX C FORMULATION AND

CALCULATION OF PUMP

CAPACITY AND NUMBER OF

SPOUTS EXAMPLE TO

ITEM 6.1.7.5 b ................................ 42

ﭘﻴﻮﺳﺖ ج ﺗﻌﻴﻴﻦ ﻣﻌﺎدﻻت و ﻣﺤﺎﺳﺒﻪ ﻇﺮﻓﻴﺖ ﺗﻠﻤﺒﻪ

و ﺗﻌﺪاد دﻫﺎﻧﻪ ﻫﺎي ﺧﺮوﺟﻲ ﻣﺜﺎﻟﻲ ﺑﺮاي ﺑﻨﺪ

42 ..........................................ب-5-7-1-6

APPENDIX D HOSE SPECIFICATIONS.......... 44

44 .................................... ﭘﻴﻮﺳﺖ د ﻣﺸﺨﺼﺎت ﺷﻴﻠﻨﮓ

APPENDIX E TYPICAL TRUCK

DIMENSIONS ............................. 47

47 ................................... ﭘﻴﻮﺳﺖ ﻫ ﻧﻤﻮﻧﻪ اﺑﻌﺎد ﻛﺎﻣﻴﻮن

2

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

ﻣﻘﺪﻣﻪ-0

0. INTRODUCTION

"ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي ﺗﺄﺳﻴﺴﺎت ﺧﺎرج از ﻣﺤﻮﻃﻪ ﺑﺮاي ﻓﺮآﻳﻨﺪﻫﺎي

ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ" ﮔﺴﺘﺮده و ﺷﺎﻣﻞ ﻣﻮﺿﻮﻋﺎت ﻣﺨﺘﻠﻒ،ﻧﻔﺖ

ﺑﻨﺎﺑﺮاﻳﻦ ﻳﻚ ﮔﺮوه از اﺳﺘﺎﻧﺪاردﻫﺎي.ﺑﺎ اﻫﻤﻴﺖ ﺑﺎﻻ ﻣﻲ ﺑﺎﺷﻨﺪ

اﻳﻦ.ﻣﻬﻨﺪﺳﻲ ﻓﺮآﻳﻨﺪ ﺑﺮاي ﭘﻮﺷﺶ اﻳﻦ ﻣﻮﺿﻮع ﺗﻬﻴﻪ ﺷﺪه اﻧﺪ

:ﮔﺮوه ﺷﺎﻣﻞ اﺳﺘﺎﻧﺪاردﻫﺎي زﻳﺮ اﺳﺖ

"Process Design of Offsite Facilities for OGP

Processes" are broad and contain various subjects

of paramount importance. Therefore, a group of

Process Engineering Standards are prepared to

cover this subject. This group includes the

following Standards:

STANDARD CODE

ﻋﻨﻮان اﺳﺘﺎﻧﺪارد

STANDARD TITLE

ﻛﺪ اﺳﺘﺎﻧﺪارد

IPS-E-PR-360

"Engineering Standard for

Process Design of Liquid

and Gas Transfer and

Storage"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

ﻓﺮآﻳﻨﺪي اﻧﺘﻘﺎل و ذﺧﻴﺮه ﺳﺎزي ﻣﺎﻳﻊ

" و ﮔﺎز

IPS-E-PR-360

IPS-E-PR-370

"Engineering Standard for

Process Design of Loading

& Unloading Facilities for

Road Tankers"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

ﻓﺮآﻳﻨﺪي ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ

"ﺑﺮاي ﺗﺎﻧﻜﺮﻫﺎي ﺟﺎدهاي

IPS-E-PR-370

IPS-E-PR-380

"Engineering Standard for

Process Design of Solids

Handling Systems"

IPS-E-PR-380

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻃﺮاﺣﻲ

اﻧﺘﻘﺎل

ﺳﺎﻣﺎﻧﻪﻫﺎي

ﻓﺮآﻳﻨﺪي

"ﺟﺎﻣﺪات

:اﻳﻦ ﻣﺸﺨﺼﺎت اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

This Engineering Standard Specification covers:

"PROCESS DESIGN OF LOADING &

UNLOADING FACILITIES FOR ROAD

TANKERS"

"ﻃﺮﺣﻲ ﻓﺮآﻳﻨﺪي ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ ﺑﺮاي

The loading and unloading facilities in the OGP

industries vary with the size and complexity of

the plant and the location and requirements of the

consumers. Because of seasonal and other

variations and product distribution, loading

facilities shall be quite flexible and its capacity

may far exceed normal plant production.

ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ،ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ در ﺻﻨﺎﻳﻊ ﻧﻔﺖ

ﺑﺎ اﻧﺪازه و ﭘﻴﭽﻴﺪﮔﻲ ﻛﺎرﺧﺎﻧﻪ و ﻣﺤﻞ و اﻟﺰاﻣﺎت ﻣﺸﺘﺮﻳﺎن ﺗﻐﻴﻴﺮ

ﺑﻪ دﻟﻴﻞ ﺗﻐﻴﻴﺮات ﻓﺼﻠﻲ و ﺳﺎﻳﺮ ﺗﻐﻴﻴﺮات و ﺗﻮزﻳﻊ.ﻣﻴﻜﻨﻨﺪ

ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﺑﺎﻳﺪ ﻛﺎﻣﻼ اﻧﻌﻄﺎف ﭘﺬﻳﺮ ﺑﻮده و،ﻓﺮآورده

ﻇﺮﻓﻴﺖ آﻧﻬﺎ ﻣﻤﻜﻦ اﺳﺖ ﺑﺴﻴﺎر ﺑﻴﺸﺘﺮ از ﺗﻮﻟﻴﺪ ﻋﺎدي واﺣﺪ

.ﺑﺎﺷﺪ

" ﺗﺎﻧﻜﺮﻫﺎي ﺟﺎدهاي را ﭘﻮﺷﺶ ﻣﻲ دﻫﺪ

3

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

داﻣﻨﻪ ﻛﺎرﺑﺮد-1

1. SCOPE

This Engineering Standard Specification covers

minimum requirements for process design and

engineering of loading and unloading facilities

for road Tankers in OGP Industries.

ﺣﺪاﻗﻞ اﻟﺰاﻣﺎت ﻃﺮاﺣﻲ،اﻳﻦ ﻣﺸﺨﺼﻪ اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ

ﻓﺮآﻳﻨﺪي و ﻣﻬﻨﺪﺳﻲ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ ﺗﺎﻧﻜﺮﻫﺎي

. ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ را ﭘﻮﺷﺶ ﻣﻴﺪﻫﺪ،ﺟﺎدهاي در ﺻﻨﺎﻳﻊ ﻧﻔﺖ

It should be noted that the scope of this Standard

is limited to liquid applications and road tankers

only. Furthermore in this manual the unloading

part is limited to probable discharges of the

products remaining in the tankers that arrive for

loading.

ﻻزم ﺑﻪ ذﻛﺮ اﺳﺖ ﻛﻪ داﻣﻨﻪ ﻛﺎرﺑﺮد اﻳﻦ اﺳﺘﺎﻧﺪارد ﻓﻘﻂ ﺑﻪ

ﻋﻼوه ﺑﺮ.ﻛﺎرﺑﺮد ﻣﺎﻳﻌﺎت و ﺗﺎﻧﻜﺮﻫﺎي ﺟﺎدهاي ﻣﺤﺪود ﻣﻴﺸﻮد

ﺑﺨﺶ ﺗﺨﻠﻴﻪ ﺑﻪ ﺗﺨﻠﻴﻪ ﻣﻮاد،اﻳﻦ در اﻳﻦ ﻛﺘﺎﺑﭽﻪ راﻫﻨﻤﺎ

،ﺑﺎﻗﻴﻤﺎﻧﺪه اﺣﺘﻤﺎﻟﻲ در ﺗﺎﻧﻜﺮﻫﺎﻳﻲ ﻛﻪ ﺑﺮاي ﺑﺎرﮔﻴﺮي ﻣﻲ آﻳﻨﺪ

.ﻣﺤﺪود ﻣﻴﺒﺎﺷﺪ

اﻳﻦ ﻛﺘﺎﺑﭽﻪ راﻫﻨﻤﺎ ﺑﺨﺸﻲ از ﻣﺠﻤﻮﻋﻪاي اﺳﺖ ﻛﻪ ﻣﻤﻜﻦ اﺳﺖ

ﺗﻮﺳﻌﻪ ﻳﺎﺑﺪ ﺗﺎ در ﻧﻬﺎﻳﺖ ﺗﻤﺎم ﺗﺄﺳﻴﺴﺎت ﻣﺮﺗﺒﻂ ﺑﺎ ﺑﺎرﮔﻴﺮي و

ﻣﺨﺰن واﮔﻦ رﻳﻠﻲ و،ﺗﺨﻠﻴﻪ ﻓﻠﻪاي وﺳﺎﻳﻞ ﻧﻘﻠﻴﻪ ﺟﺎدهاي

ﺗﺨﻠﻴﻪ ﻣﺨﺰن ﻛﺸﺘﻲ را/ﺗﺄﺳﻴﺴﺎت ﺳﺎﺣﻠﻲ ﺑﺮاي ﺑﺎرﮔﻴﺮي

.ﭘﻮﺷﺶ دﻫﺪ

This manual forms part of a series that may be

developed ultimately to embrace all facilities

connected with bulk loading and unloading of

road vehicles, rail tank wagon and on-shore

facilities for loading/discharging of water bore

craft.

:1 ﻳﺎدآوري

Note 1:

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ1383 اﻳﻦ اﺳﺘﺎﻧﺪارد در ﺗﻴﺮ ﻣﺎه ﺳﺎل

1 ﻣﺮﺑﻮﻃﻪ ﺑﺮرﺳﻲ و ﻣﻮارد ﺗﺄﻳﻴﺪ ﺷﺪه ﺑﻪ ﻋﻨﻮان اﺻﻼﺣﻴﻪ ﺷﻤﺎره

. اﺑﻼغ ﮔﺮدﻳﺪ237 ﻃﻲ ﺑﺨﺸﻨﺎﻣﻪ ﺷﻤﺎره

This standard specification is reviewed and

updated by the relevant technical committee on

July 2004, as amendment No. 1 by circular No.

237.

:2 ﻳﺎدآوري

Note 2:

اﻳﻦ اﺳﺘﺎﻧﺪارد دو زﺑﺎﻧﻪ ﻧﺴﺨﻪ ﺑﺎزﻧﮕﺮي ﺷﺪه اﺳﺘﺎﻧﺪارد ﻣﻲﺑﺎﺷﺪ

ﺗﻮﺳﻂ ﻛﻤﻴﺘﻪ ﻓﻨﻲ ﻣﺮﺑﻮﻃﻪ اﻧﺠﺎم و1388 ﻛﻪ در آﺑﺎن ﻣﺎه ﺳﺎل

(0) از اﻳﻦ ﭘﺲ وﻳﺮاﻳﺶ.( اراﻳﻪ ﻣﻲﮔﺮدد1) ﺑﻪ ﻋﻨﻮان وﻳﺮاﻳﺶ

.اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻨﺴﻮخ ﻣﻲﺑﺎﺷﺪ

This bilingual standard is a revised version of the

standard specification by the relevant technical

committee on Nov 2009, which is issued as

revision (1). Revision (0) of the said standard

specification is withdrawn.

:3 ﻳﺎدآوري

Note 3:

ﻣﺘﻦ اﻧﮕﻠﻴﺴﻲ،در ﺻﻮرت اﺧﺘﻼف ﺑﻴﻦ ﻣﺘﻦ ﻓﺎرﺳﻲ و اﻧﮕﻠﻴﺴﻲ

.ﻣﻼك ﻣﻲﺑﺎﺷﺪ

In case of conflict between Farsi and English

languages, English language shall govern.

ﻣﺮاﺟﻊ-2

2. REFERENCES

در اﻳﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ آﻳﻴﻦ ﻧﺎﻣﻪ ﻫﺎ و اﺳﺘﺎﻧﺪاردﻫﺎي ﺗﺎرﻳﺦ دار و

ﺗﺎ ﺣﺪي ﻛﻪ در، اﻳﻦ ﻣﺮاﺟﻊ. ﺑﺪون ﺗﺎرﻳﺦ زﻳﺮ اﺷﺎره ﺷﺪه اﺳﺖ

ﺑﺨﺸﻲ از اﻳﻦ،اﻳﻦ اﺳﺘﺎﻧﺪارد ﻣﻮرد اﺳﺘﻔﺎده ﻗﺮار ﮔﺮﻓﺘﻪ اﻧﺪ

وﻳﺮاﻳﺶ، در ﻣﺮاﺟﻊ ﺗﺎرﻳﺦ دار.اﺳﺘﺎﻧﺪارد ﻣﺤﺴﻮب ﻣﻲﺷﻮﻧﺪ

ﮔﻔﺘﻪ ﺷﺪه ﻣﻼك ﻋﻤﻞ ﺑﻮده و ﺗﻐﻴﻴﺮاﺗﻲ ﻛﻪ ﺑﻌﺪ از ﺗﺎرﻳﺦ

ﭘﺲ از ﺗﻮاﻓﻖ ﺑﻴﻦ ﻛﺎرﻓﺮﻣﺎ و،وﻳﺮاﻳﺶ در آﻧﻬﺎ داده ﺷﺪه اﺳﺖ

آﺧﺮﻳﻦ، در ﻣﺮاﺟﻊ ﺑﺪون ﺗﺎرﻳﺦ.ﻓﺮوﺷﻨﺪه ﻗﺎﺑﻞ اﺟﺮا ﻣﻲﺑﺎﺷﺪ

وﻳﺮاﻳﺶ آﻧﻬﺎ ﺑﻪ اﻧﻀﻤﺎم ﻛﻠﻴﻪ اﺻﻼﺣﺎت و ﭘﻴﻮﺳﺘﻬﺎي آن ﻣﻼك

.ﻋﻤﻞ ﻣﻲﺑﺎﺷﻨﺪ

Throughout this Standard the following dated and

undated standards/codes are referred to. These

referenced documents shall, to the extent

specified herein, form a part of this standard. For

dated references, the edition cited applies. The

applicability of changes in dated references that

occur after the cited date shall be mutually agreed

upon by the Company and the Vendor. For

undated references, the latest edition of the

referenced

documents

(including

any

supplements and amendments) applies.

4

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

( )ﻣﻮﺳﺴﻪ ﻧﻔﺖ آﻣﺮﻳﻜﺎAPI

API (AMERICAN PETROLEUM INSTITUTE)

API RP 2003 "Protection Against Ignitions

Arising Out of Static, Lighting

and Stray Currents"

"ﻣﺤﺎﻓﻈﺖ در ﻣﻘﺎﺑﻞ اﺷﺘﻌﺎل ﻧﺎﺷﻲ ازAPI RP 2003

" رﻋﺪ و ﺑﺮق و ﺳﺮﮔﺮدان،ﺟﺮﻳﺎﻧﻬﺎي ﺳﺎﻛﻦ

API MPMS

"ﻛﺘـــﺎﺑﭽﻪ راﻫﻨﻤﺎي اﺳﺘـــــــﺎﻧﺪاردﻫﺎيAPI MPMS

".اﻧﺪازهﮔﻴﺮي ﻧﻔﺖ

"ﺳﻜﻮي ﺑﺎرﮔﻴﺮي و ﺳﺎﻣﺎﻧﻪﻫﺎي اﻧﺪازهﮔﻴﺮي

"ﻣﺨﺰن ﻛﺎﻣﻴﻮن

"Manual

of

Petroleum

Measurement Standards",

"Loading Rack and Tank Truck

Metering Systems"

( )ﻣﻮﺳﺴﻪ اﺳﺘﺎﻧﺪاردﻫﺎي ﺑﺮﻳﺘﺎﻧﻴﺎBSI

BSI (BRITISH STANDARDS INSTITUTION)

BS SP 3492 "British Standard for Road and

Rail Tanker Hoses and Hose

Assemblies

for

Petroleum

Products,

Including

Aviation

Fuels"

" اﺳﺘﺎﻧﺪارد اﻧﮕﻠﺴﺘﺎن ﺑﺮاي ﺷﻴﻠﻨﮕﻬﺎي

ﺗﺎﻧﻜﺮ ﺟﺎدهاي و رﻳﻠﻲ و اﺗﺼﺎﻻت ﺷﻴﻠﻨﮓ

ﺷﺎﻣﻞ ﺳﻮﺧﺖ،ﺑﺮاي ﻓﺮآوردهﻫﺎي ﻧﻔﺘﻲ

"ﻫﻮاﻳﻲ

BS SP 3492

BS 5173

"روﺷﻬﺎي آزﻣﻮن ﺑﺮاي ﺷﻴﻠﻨﮕﻬﺎي

،ﻻﺳﺘﻴﻜﻲ و ﭘﻼﺳﺘﻴﻜﻲ و اﺗﺼﺎﻻت ﺷﻴﻠﻨﮓ

ﻗﺴﻤﺖ آزﻣﻮنﻫﺎي ﻓﺸﺎر:102 ﺑﺨﺶ

آزﻣﻮن ﻓﺸﺎر ﺿﺮﺑﻪاي:8,102،ﻫﻴﺪروﻟﻴﻚ

ﺑﺮاي ﺷﻴﻠﻨﮓﻫﺎي ﻣﺎرﭘﻴﭻ ﺗﺮﻣﻮﭘﻼﺳﺘﻴﻚ

"ﺗﻘﻮﻳﺖ ﺷﺪه ﺳﺨﺖ

BS 5173

"Methods of test for rubber and

plastics

hoses

and

hose

assemblies Part 102: Hydraulic

pressure tests Section 102.8

Pressure impulse test for rigid

helix reinforced thermoplastics

hoses "

( ) اﻧﺠﻤﻦ ﻣﻠﻲ ﺣﻔﺎﻇﺖ در ﻣﻘﺎﺑﻞ آﺗﺶNFPA

NFPA (NATIONAL FIRE PROTECTION

ASSOCIATION)

NFPA 70

""آﺋﻴﻦ ﻧﺎﻣﻪ ﻣﻠﻲ ﺑﺮق

"National Electrical Code"

NFPA 70

( ) اﺳﺘﺎﻧﺪاردﻫﺎي ﻧﻔﺖ اﻳﺮانIPS

IPS (IRANIAN PETROLEUM STANDARDS)

Standard

for

" "اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي واﺣﺪﻫﺎIPS-E-GN-100

IPS-E-PR-170 "Engineering

Standard

Process Flow Diagram"

for

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻧﻤﻮدار ﺟﺮﻳﺎنIPS-E-PR-170

"ﻓﺮآﻳﻨﺪ

IPS-E-PR-230 "Engineering

Standard

for

Piping

&

Instrumentation

Diagrams (P&IDs)"

"اﺳﺘﺎﻧﺪارد ﻣﻬﻨﺪﺳﻲ ﺑﺮاي ﻧﻤﻮدارﻫﺎيIPS-E-PR-230

"(P&IDs) ﻟﻮﻟﻪﻛﺸﻲ و اﺑﺰار دﻗﻴﻖ

IPS-E-GN-100 "Engineering

Units"

NIST HDBK 44*.

NIST HDBK 44* 7th Ed. ,2007

رواداريﻫﺎ و ﺳﺎﻳﺮ اﻟﺰاﻣﺎت ﻓﻨﻲ ﺑــﺮاي ﺗﻮزﻳﻦ،"ﻣﺸﺨﺼﺎت ﻓﻨﻲ

2007 وﻳﺮاﻳﺶ ﻫﻔﺘﻢ."و اﺑﺰارﻫﺎي اﻧﺪازهﮔﻴﺮي

"Specifications, Tolerances, and other Technical

Requirements for Weighting and Measuring

Devices"

* ﻛﺘﺎب

* Text Book

5

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

ﺗﻌﺎرﻳﻒ و واژﮔﺎن-3

3. DEFINITIONS AND TERMINOLOGY

ﺗﺎﺳﻴﺴﺎت ﭘﺮﻛﻨﻲ1-3

3.1 Filling Installations

.ﺗﺎﺳﻴﺴﺎﺗﻲ ﺑﺮاي ﺑﺎرﮔﻴﺮي ﻛﺎﻣﻴﻮن از زﻣﺎن ورود ﺗﺎ ﺧﺮوج

Facilities for truck loading from entering time up

to leaving.

دارﺑﺴﺖ2-3

3.2 Gantry

داراي ﻳﻚ ﻳﺎ دو،ﭼﺎرﭼﻮﺑﻲ در زﻳﺮ ﻳﺎ ﻛﻨﺎر ﻣﻨﻄﻘﻪ ﺑﺎرﮔﻴﺮي

ﺷﻴﻠﻨﮕﻬﺎي ﺑﺎرﮔﻴﺮي ﻣﻔﺼﻠﻲ/دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﻛﻪ ﺗﻌﺪادي ﺑﺎزوﻫﺎ

.ﺑﺮ روي آن ﻗﺮار داده ﺷﺪه اﺳﺖ

A framework on a loading island, under or

besides which one or two loading bays with some

articulated loading arms/hoses are arranged.

ﺷﻴﻠﻨﮓ ﺑﺎرﮔﻴﺮي/ ﺑﺎزو3-3

3.3 Loading Arm/Hose

.آراﻳﺶ ﻟﻮﻟﻪﻛﺸﻲ ﻳﺎ ﺷﻴﻠﻨﮓ ﺑﺮاي ﭘﺮﻛﺮدن ﻳﻚ ﻛﺎﻣﻴﻮن

A piping or hose arrangement for filling in a

truck.

دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي4-3

3.4 Loading Bay

.ﻳﻚ ورودي ﺑﺮاي ﻛﺎﻣﻴﻮﻧﻬﺎ ﺑﺮاي اﻳﺴﺘﺎدن زﻳﺮ ﺑﺎرﮔﻴﺮي ﻓﺮآورده

An inlet for trucks to stay under product loading.

ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي5-3

3.5 Loading Facilities

Facilities consist

installations.

of

pumping

and

ﺗﺄﺳﻴﺴﺎﺗﻲ ﻛﻪ ﺷﺎﻣﻞ ﺗﻠﻤﺒﻪ ﻛﺮدن و دﺳﺘﮕﺎﻫﻬﺎي ﭘﺮ ﻛﺮدن

.ﺑﺎﺷﺪ

filling

ﻣﻨﻄﻘﻪ ﺑﺎرﮔﻴﺮي6-3

3.6 Loading Island

ﺷﻴﻠﻨﮓﻫﺎ ﺑﺎرﮔﻴﺮي و/ ﻳﻚ ﻣﺤﻮﻃﻪ ﻣﺮﺗﻔﻊ ﻛﻪ در آن ﺑﺎزوﻫﺎ

.ﺗﺄﺳﻴﺴﺎت ﻣﺮﺑﻮﻃﻪ ﻧﺼﺐ ﺷﺪهاﻧﺪ

A raised area over which loading arms/hoses and

related facilities are installed.

( دﻫﺎﻧﻪ ﺧﺮوﺟﻲ )ﭘﺮ ﻛﻨﻲ7-3

3.7 Spout

ﻳﻚ ﺧﺮوﺟﻲ ﺑﺮاي ﺑﺎرﮔﻴﺮي از ﻃﺮﻳﻖ ﺑﺎزو ﻳﺎ ﻳﻚ ﺷﻴﻠﻨﮓ ﻛﻪ ﺑﺎ

."ﻧﻘﻄﻪ ﺑﺎرﮔﻴﺮي" ﻣﺸﺨﺺ ﺷﺪه اﺳﺖ

An outlet for loading through an arm or a hose,

identical with "loading point".

ﻧﺸﺎﻧﻪﻫﺎ و اﺧﺘﺼﺎرات-4

4. SYMBOLS AND ABBREVIATIONS

DN

Diameter Nominal, in (mm).

dw

Number of working days per week.

HVP

High Vapor Pressure.

LNG

Liquefied Natural Gas.

LPG

Liquefied Petroleum Gas.

LVP

Low Vapor Pressure.

nd

Number of truck per spout per day.

Nd

Total number of trucks per day.

nl

Number of simultaneous loading.

Ns

Number of spouts.

.(ﻗﻄﺮ اﺳﻤﻲ )ﻣﻴﻠﻴﻤﺘﺮ

ﺗﻌﺪاد روزﻫﺎي ﻛﺎري در ﻫﻔﺘﻪ

6

DN

dw

ﻓﺸﺎر ﺑﺨﺎر ﺑﺎﻻ

HVP

ﮔﺎز ﻃﺒﻴﻌﻲ ﻣﺎﻳﻊ ﺷﺪه

LNG

ﮔﺎز ﻧﻔﺘﻲ ﻣﺎﻳﻊ ﺷﺪه

LPG

ﻓﺸﺎر ﺑﺨﺎر ﭘﺎﻳﻴﻦ

LVP

ﺗﻌﺪاد ﻛﺎﻣﻴﻮﻧﻬﺎ ﺑﺮ ﻫﺮ دﻫﺎﻧﻪ ﺧﺮوﺟﻲ در روز

nd

ﺗﻌﺪاد ﻛﻞ ﻛﺎﻣﻴﻮﻧﻬﺎ در روز

Nd

ﺗﻌﺪاد ﺑﺎرﮔﻴﺮي ﻫﻤﺰﻣﺎن

nl

ﺗﻌﺪاد دﻫﺎﻧﻪ ﻫﺎي ﺧﺮوﺟﻲ

Ns

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

OGP

Oil, Gas and Petrochemical.

ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ،ﻧﻔﺖ

OGP

RVP

Reid Vapor Pressure.

(Reid)ﻓﺸﺎر ﺑﺨﺎر رﻳﺪ

RVP

q1

Loading capacity per spout, in

(m³/h).

Qa

ﻇﺮﻓﻴﺖ ﺑﺎرﮔﻴﺮي ﻫﺮ دﻫﺎﻧﻪ ﺧﺮوﺟﻲ )ﻣﺘﺮ ﻣﻜﻌﺐ ﺑﺮ

(ﺳﺎﻋﺖ

q1

Average product rate, in (m³/d).

(m³/d) ﻣﻴﺎﻧﮕﻴﻦ ﻣﻴﺰان ﻣﺤﺼﻮل

Qa

qp

Product pumping rate, in (m³/h).

(m³/h) ﻣﻴﺰان ﺗﻠﻤﺒﻪ ﻛﺮدن ﻣﺤﺼﻮل

qp

t1

Loading time per truck (filling only),

in (min).

(زﻣﺎن ﺑﺎرﮔﻴﺮي ﻫﺮ ﻛﺎﻣﻴﻮن )ﻓﻘﻂ ﭘﺮﻛﺮدن( )دﻗﻴﻘﻪ

t1

T1

Total loading time per truck, in

(min).

( )دﻗﻴﻘﻪ،ﻛﻞ زﻣﺎن ﺑﺎرﮔﻴﺮي ﻫﺮ ﻛﺎﻣﻴﻮن

td

Working time, hours per day.

tp

Preparation time of a truck, in (min).

Va

Average truck capacity, in (m³).

(ﻇﺮﻓﻴﺖ ﻣﻴﺎﻧﮕﻴﻦ ﻛﺎﻣﻴﻮن )ﻣﺘﺮ ﻣﻜﻌﺐ

Va

VT

Specific truck capacity, in (m³).

(ﻇﺮﻓﻴﺖ وﻳﮋه ﻛﺎﻣﻴﻮن )ﻣﺘﺮﻣﻜﻌﺐ

VT

T1

ﺳﺎﻋﺖ در روز،زﻣﺎن ﻛﺎرﻛﺮد

td

(زﻣﺎن آﻣﺎده ﻛﺮدن ﻛﺎﻣﻴﻮن )دﻗﻴﻘﻪ

tp

واﺣﺪﻫﺎ-5

5. UNITS

،(SI) ﺑﺮﻣﺒﻨﺎي ﺳﺎﻣﺎﻧﻪ ﺑﻴﻦ اﻟﻤﻠﻠﻲ واﺣﺪﻫﺎ،اﻳﻦ اﺳﺘﺎﻧﺪارد

ﻣﮕﺮ آﻧﻜﻪ در، ﻣﻲﺑﺎﺷﺪIPS-E-GN-100 ﻣﻨﻄﺒﻖ ﺑﺎ اﺳﺘﺎﻧﺪارد

.ﻣﺘﻦ اﺳﺘﺎﻧﺪارد ﺑﻪ واﺣﺪ دﻳﮕﺮي اﺷﺎره ﺷﺪه ﺑﺎﺷﺪ

This Standard is based on International System of

Units (SI) as per IPS-E-GN-100, except where

otherwise specified.

ﺑﺎرﮔﻴﺮي و ﺗﺨﻠﻴﻪ ﻛﺎﻣﻴﻮن-6

6. TRUCK LOADING AND UNLOADING

ﺑﺎرﮔﻴﺮي1-6

6.1 Loading

ﻋﻤﻮﻣﻲ1-1-6

6.1.1 General

اﻳﻦ ﻣﺸﺨﺼﻪ اﺳﺘﺎﻧﺪارد ﺑﻪ ﻣﻼﺣﻈﺎﺗﻲ ﺑﺮاي ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي

ﺗﺄﺳﻴﺴﺎت ﺟﺪﻳﺪ ﺑﺮاي ﺑﺎرﮔﻴﺮي ﻓﻠﻪاي ﺧﻮدرو ﺟﺎدهاي در

ﻣﺤﺪود ﺷﺪه،ﺗﺄﺳﻴﺴﺎت ﻣﺘﺪاول ﺑﺮاي ﻓﺮآوردهﻫﺎي ﻣﺨﺘﻠﻒ

ﺑﻪ ﻫﻤﻴﻦ دﻟﻴﻞ ﻃﺮحﻫﺎي ﻧﺸﺎن داده ﺷﺪه ﺷﺎﻣﻞ.اﺳﺖ

و در زﻣﺎن،وﻳﮋﮔﻲﻫﺎﻳﻲ اﺳﺖ ﻛﻪ در ﻫﻤﻪ ﺷﺮاﻳﻂ ﻻزم ﻧﻤﻴﺒﺎﺷﺪ

ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد ﻛﻪ ﺳﺎدهﺗﺮﻳﻦ،ﻃﺮحرﻳﺰي ﺗﺄﺳﻴﺴﺎت ﺟﺪﻳﺪ

،ﺗﺄﺳﻴﺴﺎﺗﻲ ﻛﻪ ﻓﺮآﻳﻨﺪ ﭘﺮﻛﺮدن را ﺑﻄﻮر ﻣﻮﺛﺮ اﻧﺠﺎم ﻣﻴﺪﻫﻨﺪ

ﻳﺎ ﺗﻮﺳﻌﻪ/ اﻳﻦ اﻟﺰاﻣﺎت ﻫﻤﭽﻨﻴﻦ در ﺑﻬﺴﺎزي و.ﺳﺎﺧﺘﻪ ﺷﻮد

ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻣﻮﺟﻮد ﺑﺮاي ﺗﺎﻧﻜﺮﻫﺎي ﺟﺎدهاي ﻣﻲ ﺗﻮاﻧﻨﺪ

.ﻣﻮرد اﺳﺘﻔﺎده ﺑﺎﺷﻨﺪ

This Standard Specification is limited to

provision of, process design of new facilities for

loading of bulk road vehicles at normal

installations for different products. For this

reason, the designs shown include features which

will not be necessary in all situations; and when

new facilities are planned it is recommended that

the simplest facilities that will efficiently perform

the filling operation should be constructed. These

requirements can also be used for the

modernization and/or extension of existing

loading facilities for road tankers.

اﻧﺪازه ﺗﺎﻧﻜﺮ و اﺟﺰاي،ﺗﻌﻴﻴﻦ ﻇﺮﻓﻴﺖ ﺑﺎرﮔﻴﺮي ﻣﺘﻮﺳﻂ ﺳﺎﻻﻧﻪ

ﺑﺎرﮔﻴﺮي ﻣﻤﻜﻦ اﺳﺖ ﺛﺎﺑﺖ در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﺪه و ﻇﺮﻓﻴﺖ ﺗﻠﻤﺒﻪ

.ﻣﺤﺎﺳﺒﻪ ﺷﻮد

ﻳﺎ اﺟﺰاي/ﻻزم ﺑﻪ ذﻛﺮ اﺳﺖ ﭼﻨﺎﻧﭽﻪ ﺑﺮاي اﻧﺪازه ﺗﺎﻧﻜﺮ و

Specifying the yearly average loading capacity,

the size of tanker and loading assembly may be

fixed and pump capacity will be calculated.

It should be noted that in case there is freedom in

7

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

tanker size and/or loading assembly then

economical evaluation shall be considered for

such selections.

ﺑﺎرﮔﻴﺮي آزادي ﻋﻤﻞ وﺟﻮد داﺷﺘﻪ ﺑﺎﺷﺪ آﻧﮕﺎه ارزﻳﺎﺑﻲ اﻗﺘﺼﺎدي

.ﺑﺮاي ﭼﻨﻴﻦ اﻧﺘﺨﺎﺑﻲ ﺑﺎﻳﺪ اﻧﺠﺎم ﺷﻮد

6.1.2 Loading facilities in the context of the

overall distribution system

ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي در داﺧﻞ ﺳﺎﻣﺎﻧﻪ ﻛﻠﻲ ﺗﻮزﻳﻊ2-1-6

The importance of bulk vehicle loading facilities

as part of the total distribution complex must be

fully realized when plans are made for the

construction of new facilities, or the

modernization and extension of existing

arrangements. It is therefore necessary to examine

the operation of the distribution system in order

to optimize both its efficiency and the size of the

loading facilities. The latter are an integral part of

the distribution system and should not be studied

in isolation; changes in the system and/or

operating procedures can have a considerable

effect upon vehicle loading requirements. In this

context the objective must be to optimize the

number of loading bays, and product loading

spouts per bay, in relation to the overall

distribution system, capital investment and

operating expenditure.

ﺑﺎﻳﺪ زﻣﺎﻧﻲ ﺑﻪ اﻫﻤﻴﺖ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻓﻠﻪاي ﺧﻮدرو ﺑﻪ

ﻋﻨﻮان ﺑﺨﺸﻲ از ﻛﻞ ﻣﺠﻤﻮﻋﻪ ﺗﻮزﻳﻊ ﺗﻮﺟﻪ ﺷﻮد ﻛﻪ ﺑﺮﻧﺎﻣﻪﻫﺎﻳﻲ

ﺑﺮاي ﺳﺎﺧﺖ ﺗﺄﺳﻴﺴﺎت ﺟﺪﻳﺪ ﻳﺎ ﻧﻮﺳﺎزي و ﺗﻮﺳﻌﻪ آراﻳﺶ

ﻟﺬا ﺑﺮرﺳﻲ ﻋﻤﻠﻜﺮد ﺳﺎﻣﺎﻧﻪ ﺗﻮزﻳﻊ ﺑﻪ. ﺗﻬﻴﻪ ﻣﻴﺸﻮﻧﺪ،ﻣﻮﺟﻮد

ﻣﻨﻈﻮر ﺑﻬﻴﻨﻪ ﺳﺎزي راﻧﺪﻣﺎن و اﻧﺪازه ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻻزم

ﺑﺨﺶ ﺟﺪاﻳﻲ ﻧﺎﭘﺬﻳﺮ ﺳﺎﻣﺎﻧﻪ ﺗﻮزﻳﻊ، ﻣﻮﺿﻮع دﻳﮕﺮ.ﻣﻴﺒﺎﺷﺪ

ﺗﻐﻴﻴﺮ،ﻣﻴﺒﺎﺷﺪ ﻛﻪ ﺗﻮﺻﻴﻪ ﻧﻤﻲﺷﻮد ﺑﻪ ﻃﻮر ﻣﺠﺰا ﻣﻄﺎﻟﻌﻪ ﺷﻮد

ﻳﺎ دﺳﺘﻮراﻟﻌﻤﻞ ﻋﻤﻠﻴﺎﺗﻲ اﺳﺖ ﻛﻪ اﺛﺮ ﻗﺎﺑﻞ/در ﺳﺎﻣﺎﻧﻪ و

.ﻣﻼﺣﻈﻪاي در اﻟﺰاﻣﺎت ﺑﺎرﮔﻴﺮي ﺧﻮدرو ﻣﻲﺗﻮاﻧﺪ داﺷﺘﻪ ﺑﺎﺷﺪ

در اﻳﻦ زﻣﻴﻨﻪ ﻫﺪف ﺑﺎﻳﺪ ﺑﻬﻴﻨﻪ ﺳﺎزي ﺗﻌﺪاد دﻫﺎﻧﻪﻫﺎي ﺑﺎرﮔﻴﺮي

در ارﺗﺒﺎط ﺑﺎ ﻛﻞ ﺳﺎﻣﺎﻧﻪ،و ﺗﻌﺪاد دﻫﺎﻧﻪﻫﺎي ﺧﺮوﺟﻲ ﻓﺮآوردهﻫﺎ

. ﺳﺮﻣﺎﻳﻪﮔﺬاري ﻛﻞ و ﻫﺰﻳﻨﻪ ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎﺷﺪ،ﺗﻮزﻳﻊ

Firstly, the cost of own and Contractor’s vehicles

should be assessed for the time spent (vehicle

standing charges) while:

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻫﺰﻳﻨﻪ زﻣﺎن ﺳﭙﺮي ﺷﺪه ﺧﻮدروﻫﺎي،ًاوﻻ

:ﺷﺨﺼﻲ و ﭘﻴﻤﺎﻧﻜﺎر ارزﻳﺎﺑﻲ )ﺧﻮدرو در ﺣﺎل ﺑﺎرﮔﻴﺮي( ﺷﻮد

ﺻﻒ دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي؛-

- Queuing for a loading bay;

اﻧﺘﻈﺎر ﺑﺮاي ﺑﺎزوي ﺑﺎرﮔﻴﺮي زﻣﺎﻧﻲ ﻛﻪ در دﻫﺎﻧﻪ اﺳﺖ؛-

- Waiting for a loading arm while in the

bay;

. ﺑﺎرﮔﻴﺮي در دﻫﺎﻧﻪ-

- Being loaded in the bay.

ﺑﺮاي ﺗﺄﺳﻴﺴﺎت ﻣﻮﺟﻮد ﺗﺮاﻓﻴﻚ ﺣﻤﻞ و ﻧﻘﻞ ﺑﺮاي اﻳﺠﺎد، ًﺛﺎﻧﻴﺎ

اﻟﮕﻮي ورود ﺧﻮدروﻫﺎ در داﺧﻞ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي و ﺣﺘﻲ اوج

، اﻧﻮاع ﺗﺤﻮﻳﻞ ﻣﺜﻞ ﺷﻬﺮي.دورهﻫﺎي ﺑﺎرﮔﻴﺮي ﺑﺎﻳﺪ ﻣﻄﺎﻟﻌﻪ ﺷﻮد

ﺑﺮ اﻟﮕﻮي ورود ﺗﺄﺛﻴﺮﮔﺬر ﺧﻮاﻫﻨﺪ،ﻛﺸﻮري و ﻣﺴﺎﻓﺘﻬﺎي ﻃﻮﻻﻧﻲ

.ﺑﻮد

اﺳﺘﻔﺎده از روﺷﻬﺎي ﺳﺎده ﺗﻜﻨﻴﻚﻫﺎي ﺑﺮﻧﺎﻣﻪ رﻳﺰي در اﻳﻦ

ﻋﻤﻠﻴﺎتﻫﺎ ﻧﺸﺎن ﻣﻴﺪﻫﺪ ﻛﻪ ﭼﮕﻮﻧﻪ ﺑﺎزده ﺑﺎ ﺗﻐﻴﻴﺮ ﻣﻮارد زﻳﺮ

:ﺑﻬﺒﻮد ﻣﻲﻳﺎﺑﺪ

ﺳﺎﻋﺘﻬﺎي ﻛﺎري؛-

Secondly, for existing installations the traffic

flow must be studied to establish the present

arrival patterns of vehicles at the loading facilities

and hence the peak loading periods. The types of

delivery such as urban, country, and over long

distances, will influence arrival patterns.

Application of simple methods planning

techniques to these operations will show whether

efficiency can be improved by changes in:

- Working hours;

اﻟﮕﻮي ﻧﻮﺑﺖ ﻛﺎري؛-

- Shift patterns;

ﭘﺮاﻛﻨﺪﮔﻲ زﻣﺎﻧﻬﺎي ﺷﺮوع ؛-

- Staggered starting times;

ﺑﺎرﮔﻴﺮي ﺷﺒﺎﻧﻪ؛-

- Night loading;

8

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

ﺳﺎﻣﺎﻧﻪﻫﺎي ﺗﺤﻮﻳﻞ و ارﺳﺎل؛-

- Dispatching and delivery systems;

The objective being to improve utilization of

existing facilities and of the existing road

transport fleet.

-ﻫﺪف ﺑﻬﺒﻮد اﺳﺘﻔﺎده از ﺗﺄﺳﻴﺴﺎت و ﻧﺎوﮔﺎن ﺣﻤﻞ و ﻧﻘﻞ ﺟﺎده

.اي ﻣﻮﺟﻮد ﻣﻴﺒﺎﺷﺪ

For new installations the above information may

not be available. In such cases an operational

system must be established in which the various

factors mentioned are carefully considered in

relation to practice in the local industry, and in

consultation with the designers.

اﻃﻼﻋﺎت ﻓﻮق ﻣﻤﻜﻦ اﺳﺖ در دﺳﺘﺮس،ﺑﺮاي ﺗﺄﺳﻴﺴﺎت ﺟﺪﻳﺪ

در ﭼﻨﻴﻦ ﻣﻮاردي ﻳﻚ ﺳﺎﻣﺎﻧﻪ ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎﻳﺪ ﺗﺄﺳﻴﺲ.ﻧﺒﺎﺷﻨﺪ

ﺷﻮد ﻛﻪ در آن ﺑﺎ دﻗﺖ ﺑﻪ ﻋﻮاﻣﻞ ﻣﺨﺘﻠﻒ ذﻛﺮ ﺷﺪه در ارﺗﺒﺎط

. ﺗﻮﺟﻪ ﺷﻮد،ﺑﺎ ﺗﺠﺮﺑﻪ در ﺻﻨﻌﺖ ﻣﺤﻠﻲ و در ﻣﺸﻮرت ﺑﺎ ﻃﺮاﺣﺎن

ﺣﻔﺎﻇﺖ از ﻣﺤﻴﻂ زﻳﺴﺖ3-1-6

6.1.3 Environmental conservation

ﮔﺎز و ﭘﺘﺮوﺷﻴﻤﻲ اﻳﻦ اﺳﺖ، ﺳﻴﺎﺳﺖ ﺻﻨﺎﻳﻊ ﻧﻔﺖ1-3-1-6

6.1.3.1 It is the policy of OGP industries to

conduct their activities in such a way that proper

regard is paid to the conservation of the

environment. This not only means compliance

with the requirements of the relevant legislation,

but also constructive measures for the protection

of the environment, particularly in respect of

avoidance containment of spillages.

ﺑﻪ ﺣﻔﺎﻇﺖ از،ﻛﻪ ﻓﻌﺎﻟﻴﺘﻬﺎي ﺧﻮد را ﺑﻪ ﺷﻴﻮهاي اﻧﺠﺎم دﻫﺪ ﻛﻪ

اﻳﻦ اﻣﺮ ﻧﻪ ﺗﻨﻬﺎ ﺑﻪ ﻣﻌﻨﺎي.ﻣﺤﻴﻂ زﻳﺴﺖ ﺗﻮﺟﻪ ﻣﻨﺎﺳﺐ ﺷﻮد

ﺑﻠﻜﻪ اﻗﺪاﻣﺎت ﺳﺎزﻧﺪه ﺑﺮاي،ﺗﻄﺎﺑﻖ ﺑﺎ اﻟﺰاﻣﺎت ﻣﺮﺑﻮط ﺑﻪ ﻗﺎﻧﻮن

ﺣﻔﺎﻇﺖ از ﻣﺤﻴﻂ زﻳﺴﺖ ﺑﻪ وﻳﮋه اﺟﺘﻨﺎب از رﻳﺨﺖ و ﭘﺎش

.ﻣﻴﺒﺎﺷﺪ

ﺳﺎﻣﺎﻧﻪ ﺑﺎزﻳﺎﺑﻲ ﺑﺨﺎر2-3-1-6

6.1.3.2 Vapor recovery system

ﺑﺎزﻳﺎﺑﻲ ﺑﺨﺎر ﻓﺮآوردهﻫﺎﻳﻲ ﻣﺜﻞ ﺑﻨﺰﻳﻦ ﻧﺎﺷﻲ از ﺗﻮﺟﻪ ﺑﻪ ﻋﻮاﻣﻞ

در اﻛﺜﺮ ﻧﻘﺎﻃﻲ ﻛﻪ. اﻳﻤﻨﻲ و زﻳﺴﺖ ﻣﺤﻴﻄﻲ ﻣﻴﺒﺎﺷﺪ،اﻗﺘﺼﺎدي

ﻛﻞ اﻧﺘﺸﺎر ﺑﺨﺎرات ﺑﻨﺰﻳﻦ ﺑﻪ،ﻛﺎﻣﻴﻮﻧﻬﺎي ﻓﻠﻪاي ﺑﺎرﮔﻴﺮي ﻣﻴﺸﻮد

ﻋﻨﻮان ﻋﺎﻣﻞ ﻣﻬﻤﻲ ﻛﻪ ﻛﻴﻔﻴﺖ ﻣﺤﻴﻂ زﻳﺴﺖ ﻣﺤﻠﻲ را ﺗﺤﺖ

ﺑﺎ اﻳﻦ وﺟﻮد ﺗﻮﺻﻴﻪ. در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﻧﻤﻴﺸﻮد،ﺗﺄﺛﻴﺮ ﻗﺮار دﻫﺪ

ﻣﻲﺷﻮد در ﻣﺮﺣﻠﻪ ﻃﺮاﺣﻲ ﺑﺮرﺳﻲ ﺷﻮد ﻛﻪ آﻳﺎ ﻻزم اﺳﺖ ﻛﻪ

ﻳﻚ ﺧﻂ ﺑﺮﮔﺸﺖ ﺑﺮاي ﺳﺎﻣﺎﻧﻪ ﺟﻤﻊآوري ﺑﺨﺎر ﺑﺮاي ﻣﺤﺼﻮﻻت

ﺧﻄﺮﻧﺎك و ﺑﺎ ﻓﺸﺎر ﺑﺨﺎر ﺑﺎﻻ ﻧﺼﺐ ﺷﻮد ]ﻓﺸﺎر ﺑﺨﺎر رﻳﺪ،ﺳﻤﻲ

[ ﺑﺎر ﻣﻄﻠﻖ0/34 ﺑﻴﺶ از

ﻓﻀﺎي، ﻓﺮض اﻳﻨﻜﻪ ﺑﺎ ﺣﻀﻮر ﺳﺎﻣﺎﻧﻪ ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر،ﻋﻼوه ﺑﺮ اﻳﻦ

درﺳﺖ،اﻳﻤﻦ در داﺧﻞ ﺑﺨﺸﻬﺎي ﻛﺎﻣﻴﻮن وﺟﻮد ﺧﻮاﻫﺪ داﺷﺖ

زﻣﺎﻧﻲ ﻛﻪ ﻓﺮآوردهﻫﺎي ﺑﺎ ﻓﺸﺎر ﺑﺨﺎر ﻣﺨﺘﻠﻒ از.ﻧﺨﻮاﻫﺪ ﺑﻮد

ﻫﻮاي،ﻃﺮﻳﻖ ﺳﺎﻣﺎﻧﻪ ﻣﺸﺘﺮك ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر ﺑﺎرﮔﻴﺮي ﻣﻴﺸﻮﻧﺪ

ﺗﻮﺻﻴﻪ.ﻗﺎﺑﻞ اﺷﺘﻌﺎل ﻣﻤﻜﻦ اﺳﺖ ﺑــﻪ داﺧﻞ ﺑﺨﺸﻬﺎ وارد ﺷﻮد

ﻣﻲﺷﻮد ﭼﻨﻴﻦ ﺳﺎﻣﺎﻧﻪﻫﺎﻳﻲ ﺑﺮاي ﺗﻌﻴﻴﻦ اﻳﻦ ﻛﻪ آﻳﺎ اﻳﻦ ﺧﻄﺮ

ﺑﻪ دﻗﺖ ﺑﺮرﺳﻲ،در آن ﺗﺎﺳﻴﺴﺎت ﻣﺨﺼﻮص ﻗﺎﺑﻞ ﺗﻮﺟﻪ اﺳﺖ

.ﺷﻮﻧﺪ

The recovery of product vapors such as gasoline

is of interest for economic, safety and

environmental reasons. In most locations where

bulk lorries are loaded, the total gasoline vapor

emissions have not been considered a significant

factor affecting the quality of the local

environment. Nevertheless, at the design stage,

system should be reviewed to see if it becomes

necessary to install a vapor collection system

return line for poisonous, hazardous and high

vapor pressure products. [RVP > 0.34 bar (abs)]

In addition, it is not safe to assume that the

presence of a vapor recovery system will ensure a

safe atmosphere within the tank truck

compartments. When different vapor pressure

products are being loaded using a common vapor

recovery system, a flammable atmosphere may be

introduced into the compartments. Such systems

should be carefully reviewed to determine

whether this hazard is significant at the particular

facility.

However, it is essential to minimize the

generation, and hence the emission of vapors

during loading by eliminating the free fall of

volatile products and reducing jetting and

splashing.

ﺑﺎ اﻳﻦ وﺟﻮد ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن ﺗﻮﻟﻴﺪ و اﻧﺘﺸﺎر ﺑﺨﺎرات در ﻃﻮل

ﺑﺎرﮔﻴﺮي ﺑﺎ ﺣﺬف ﺳﻘﻮط آزاد ﻣﺤﺼﻮل ﻫﺎي ﻓﺮار و ﻛﺎﻫﺶ ﺟﺖ

.ﺷﺪن و ﭘﺎﺷﺶ ﻻزم اﺳﺖ

In areas where action has been required by

در ﻣﻨﺎﻃﻘﻲ ﻛﻪ اﻟﺰاﻣﺎت ﻣﻠﻲ ﺑﺮاي ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن اﻧﺘﺸﺎر

9

Nov. 2009 / 1388 آﺑﺎن

National authorities to minimize vapor emissions

at loading facilities, bulk vehicles may have to be

filled with a closed vapor system; this entails the

following modifications to loading arrangements:

IPS-E-PR-370(1)

ﺧﻮدروﻫﺎي ﻓﻠﻪ اي،ﺑﺨﺎر در ﺗﺎﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻧﻴﺎز اﺳﺖ

ﻣﻤﻜﻦ اﺳﺖ ﻣﺠﺒﻮر ﺑﻪ اﺳﺘﻔﺎده از ﺳﺎﻣﺎﻧﻪ ﺑﺴﺘﻪ ﺑﺨﺎر در ﻫﻨﮕﺎم

اﻳﻦ ﻣﻮﺿﻮع ﻣﻮﺟﺐ اﺻﻼﺣﺎت زﻳﺮ در روشﻫﺎي،ﺑﺎرﮔﻴﺮي ﺑﺎﺷﻨﺪ

:ﺑﺎرﮔﻴﺮي ﻣﻲ ﺷﻮد

اﻟﻒ( ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

a) Top loading

،ﺑﻪ ﺟﻬﺖ اﻳﻨﻜﻪ اﻛﺜﺮ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻣﻮرد اﺳﺘﻔﺎده

ﺑﻬﺘﺮﻳﻦ راه ﺣﻞ ﺗﻌﻮﻳﺾ )ﻳﺎ،ﺑﺼﻮرت ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ ﻫﺴﺘﻨﺪ

اﺻﻼح( ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي ﻣﻮﺟﻮد ﺑﻨﺤﻮي اﺳﺖ ﻛﻪ در زﻣﺎن

درﻳﭽﻪ آدم رو ﻧﺸﺖ ﺑﻨﺪي ﺷﺪه، ﺑﺎرﮔﻴﺮي ﻣﺤﺼﻮﻻت ﻓﺮار

ﻣﻮرد.و ﺑﺨﺎرات ﺑﻪ ﺳﺎﻣﺎﻧﻪ ﺑﺨﺎر ﺑﺮﮔﺸﺘﻲ ﻫﺪاﻳﺖ ﺷﻮﻧﺪ

ﺑﻌﺪي ﻣﻤﻜﻦ اﺳﺖ ﺑﻪ ﺑﺎزوي ﺑﺎرﮔﻴﺮي ﻳﺎ ﺑﻪ ﺷﻴﺮ ﭼﻨﺪ راﻫﻪ

،ﺑﺨﺎر روي ﺧﻮدرو ﻛﻪ ﺑﻪ ﺗﻤﺎم ﺑﺨﺸﻬﺎي ﻣﺨﺰن وﺻﻞ اﺳﺖ

ﻫﻤﺮاه ﺑﺎﺷﺪ ﻛﻪ ﺑﺎ ﺳﺎﻣﺎﻧﻪ ﺗﺸﺮﻳﺢ ﺷﺪه در ﺑﻨﺪ )ب( زﻳﺮ

.اﺳﺖ

As the majority of loading facilities in service

are top loading, the best solution would be to

replace (or modify) the existing loading arms

so that when volatile products are loaded, the

manhole is sealed and vapors are diverted into

a vapor return system. The latter may be either

integral with the loading arm or a vapor

manifold on the vehicle connected to all the

tank compartments which would be similar to

the system described in (b) below.

ب ( ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

b) Bottom loading

ﺧﻮدروﻫﺎي ﺣﻤﻞ ﻓﻠﻪاي ﻛﻪ ﺑﺮاي ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ ﺗﺠﻬﻴﺰ

ﺷﺪهاﻧﺪ ﺑﻪ ﻳﻚ اﺗﺼﺎل ﻟﻮﻟﻪ از ﻣﺤﻞ ﺗﺨﻠﻴﻪ ﺑﺨﺎر از ﻫﺮ ﺑﺨﺶ

ﻣﺨﺰن ﺑﻪ ﺷﻴﺮ ﭼﻨﺪراﻫﻪ ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر ﻧﻴﺎز دارﻧﺪ ﻛﻪ ﺗﻮﺻﻴﻪ

ﻣﻲ ﺷﻮد در ﻣﻮﻗﻌﻴﺘﻲ ﻗﺮار ﮔﻴﺮﻧﺪ ﻛﻪ ﺑﻪ راﺣﺘﻲ از ﺳﻄﺢ

زﻣﻴﻦ ﺑﺮاي اﺳﺘﻔﺎده در ﻫﺮ دو دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﻳﺎ

اﺗﺼﺎﻻت.ﺧﺮوﺟﻲﻫﺎي ﺟﺰء ﻣﻄﺎﺑﻖ ﻧﻴﺎز ﻗﺎﺑﻞ دﺳﺘﺮس ﺑﺎﺷﺪ

.ﺟﻔﺖ ﻛﻨﻨﺪه ﺑﺮاي ﻣﺎﻳﻊ و ﺑﺨﺎر ﺑﺎﻳﺪ از اﻧﻮاع ﻣﺘﻔﺎوت ﺑﺎﺷﺪ

Bulk vehicles equipped for bottom loading

require a pipe connection from the vapor

emission vent of each compartment into a

vapor recovery manifold, which should

terminate in a position which is easily

accessible from ground level for use at both

the loading bay or retail outlets as required.

The coupling connections for liquid and vapor

must be different types.

ﻛﺎﻫﺶ اﻧﺘﺸﺎرات ﺑﺨﺎر3-3-1-6

6.1.3.3 Reduction of vapor emissions

ﺟﻠﻮﮔﻴﺮي از، ﺻﺮف ﻧﻈﺮ از ﻧﺼﺐ ﺳﺎﻣﺎﻧﻪ ﺑﺎزﻳﺎﻓﺖ ﻛﺎﻣﻞ ﺑﺨﺎر

رﻳﺰش و ﭘﺎﺷﺶ ﻣﺤﺼﻮﻻت ﻓﺮار در ﻓﺮآﻳﻨﺪ ﭘﺮﻛﺮدن از ﺑﺎﻻ و

ﻛﺎﻫﺶ ﻗﺎﺑﻞ ﻣﻼﺣﻈﻪاي در اﻧﺘﺸﺎر ﺑﺨﺎر را ﻣﻄﺎﺑﻖ زﻳﺮ،ﭘﺎﻳﻴﻦ

:ﻗﺎﺑﻞ دﺳﺘﻴﺎﺑﻲ ﻣﻲ ﻧﻤﺎﻳﺪ

Apart from installing a full vapor recovery

system, considerable reduction in vapor

emissions can be achieved by avoiding free fall

and splashing of volatile products in top and

bottom filling operations, as follows:

ﭘﺮﻛﺮدن از ﺑﺎﻻ-

- Top filling:

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي ﺑﻪ ﮔﻮﻧﻪ اي ﻃﺮاﺣﻲ

ﺷﻮﻧﺪ ﺗﺎ ﺑﻪ ﺑﺨﺶﻫﺎي اﻧﺘﻬﺎﻳﻲ ﻣﺨﺰن ﺧﻮدرو ﺑﺮﺳﻨﺪ در

اﻳﻦ ﺣﺎﻟﺖ ﻟﻮﻟﻪ ﺑﻪ ﺻﻮرت ﻋﻤﻮدي ﺗﺎ ﭘﺎﻳﻴﻦ ﺑﺨﺶ ﻣﺨﺰن

.وارد ﻣﻲﺷﻮد

The loading arms should be designed to reach

the end compartments of a vehicle tank in

such a manner that the down pipe can

penetrate vertically to the bottom of the

compartment.

ﭘﺎﻳﻴﻦ ﻟﻮﻟﻪ ﺧﺮوﺟﻲ در ﻛﻒ ﻣﺨﺰن ﻧﺒﺎﻳﺪ،ﺑﺎ اﻳﻦ وﺟﻮد

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد از ﻳﻚ.ﺑﺼﻮرت داﻳﺮه ﻛﺎﻣﻞ ﺑﺎﺷﺪ

درﺟﻪ در اﻧﺘﻬﺎي45 " ﻳﺎ ﻳﻚ ارﻳﺐT" ﻣﻨﺤﺮف ﻛﻨﻨﺪه

اﮔﺮ از ﻣﻨﺤﺮف ﻛﻨﻨﺪه.ﭘﺎﻳﻴﻦ دﻫﺎﻧﻪ اﺳﺘﻔﺎده ﺷﻮد

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻣﻨﺤﺮف ﻛﻨﻨﺪه ﺑﺮاي،اﺳﺘﻔﺎده ﺷﻮد

ﻣﻤﺎﻧﻌﺖ از ﺑﻠﻨﺪ ﺷﺪن دﻫﺎﻧﻪ ﭘﺎﻳﻴﻦ از ﻛﻒ ﻣﺨﺰن در

.زﻣﺎﻧﻲ ﻛﻪ ﺟﺮﻳﺎن ﺷﺮوع ﻣﻴﺸﻮد ﻃﺮاﺣﻲ ﺷﻮد

However, the downspout should not rest “full

circle " on the bottom. A “T " deflector or a

45-degree bevel should be used on the end of

the downspout. If a deflector is used, it should

be designed to prevent the downspout from

lifting off the tank bottom when flow starts.

10

Nov. 2009 / 1388 آﺑﺎن

- Bottom filling:

IPS-E-PR-370(1)

ﭘﺮ ﻛﺮدن از ﭘﺎﻳﻴﻦ-

ﭘﺮ ﻛﺮدن از ﭘﺎﻳﻴﻦ اﺣﺘﻤﺎل ﺧﻄﺮات اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ را ﻛﻪ

در ﻧﺘﻴﺠﻪ اﺗﺼﺎل ﻧﺎﻣﻨﺎﺳﺐ زﻣﻴﻦ ﻳﺎ ﻗﺮار ﮔﻴﺮي ﻧﺎﻣﻨﺎﺳﺐ

ﻟﻮﻟﻪ ﭘﺮﻛﺮدن در ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ ﻣﻲﺑﺎﺷﺪ را ﺑﻪ ﺣﺪاﻗﻞ

، ﺑﺎ اﻳﻦ ﺣﺎل در ﻣﺮاﺣﻞ اوﻟﻴﻪ ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ.ﻣﻴﺮﺳﺎﻧﺪ

ﭘﺎﺷﺶ ﺑﻪ ﺑﺎﻻي ﻣﺤﺼﻮل ﻣﻤﻜﻦ اﺳﺖ ﺗﻮﻟﻴﺪ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ را

اﻓﺰاﻳﺶ دﻫﺪ و ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺑﺎ ﻛﺎﻫﺶ ﺳﺮﻋﺖ ﭘﺮﻛﺮدن و

اﺳﺘﻔﺎده از ﻣﻨﺤﺮف ﺳﺎز ﭘﺎﺷﺶ ﻳﺎ ﺳﺎﻳﺮ ﺗﺠﻬﻴﺰات ﻣﺸﺎﺑﻪ از

.آن ﺟﻠﻮﮔﻴﺮي ﺷﻮد

Bottom loading minimizes the possibility of

electrostatic hazards that could result from

improper bonding or positioning of the

downspout in top loading. However, in the

initial stages of bottom loading, upward

spraying of the product can increase charge

generation and should be prevented by

reducing the filling velocity and using a spray

deflector or other similar device.

:ﭼﻨﻴﻦ اﻗﺪاﻣﻲ ﻣﺰاﻳﺎي زﻳﺮ را داراﺳﺖ

Such measures have the following advantages:

a) Minimizing the hazard of static electricity,

see 6.1.4.2;

اﻟﻒ( ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن ﺧﻄﺮ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ؛

b) Minimizing the amount of vapor formation;

ب( ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن ﺗﻮﻟﻴﺪ ﺑﺨﺎر؛

. رﺟﻮع ﺷﻮد2-4-1-6 ﺑﻪ ﺑﻨﺪ

ج( ﻛﺎﻫﺶ اﺗﻼف ﻣﺤﺼﻮل ؛

c) Reducing product losses;

ﻏﻠﻈﺖ ﺑﺨﺎرات ﻧﺎﺷﻲ از،د( ﻛﺎﻫﺶ ﺧﻄﺮ آﺗﺶ ﺳﻮزي

d) Reducing the fire risk: the concentration of

vapor emanating from the compartments will

be dissipated faster to below the explosive

limit.

رﻗﻴﻖ،ﺑﺨﺸﻬﺎي ﻣﺨﺰن ﺑﻪ ﺳﺮﻋﺖ ﺑﻪ زﻳﺮ ﺣﺪ اﻧﻔﺠﺎر

.ﻣﻴﺸﻮﻧﺪ

ﻛﻨﺘﺮل رﻳﺨﺖ و ﭘﺎش4-3-1-6

6.1.3.4 Spillage control

ﻣﻮارد ﻋﻤﺪهاي ﻛﻪ در ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي در ﻧﻈﺮ ﮔﺮﻓﺘﻪ

: ﻓﺮاﻫﻢ ﻛﺮدن ﻣﻮارد زﻳﺮ ﻣﻲ ﺑﺎﺷﺪ،ﻣﻲ ﺷﻮﻧﺪ

The main items to be considered at the loading

facilities are provision of:

ﺷﻴﺮﻫﺎي ﻗﻄﻊ اﺿﻄﺮاري ﺟﺮﻳﺎن ﺑﺮاي ﻣﻤﺎﻧﻌﺖ ﻳﺎ ﺧﺮاﺑﻲ ﺷﻴﻠﻨﮓ،ﻛﺎﻫﺶ رﻳﺨﺖ و ﭘﺎش ﺑﻪ ﺧﺎﻃﺮ ﺳﺮرﻳﺰ

و ﻏﻴﺮه؛

، ﻛﻠﻴﺪ ﻓﺸﺎري اﺿﻄﺮاري ﺑﺮاي ﺧﺎﻣﻮش ﻛﺮدن ﺗﻠﻤﺒﻪﻫﺎﻓﻌﺎل ﻛﺮدن آژﻳﺮ و ﺑﺴﺘﻦ ﺗﻤﺎم ﺷﻴﺮﻫﺎي ﻛﻨﺘﺮل و

اﻧﺴﺪاد ﺟﺮﻳﺎن در داﺧﻞ ﻣﺤﻮﻃﻪ ﺑﺎرﮔﻴﺮي؛

. ﺗﺨﻠﻴﻪ زﻣﻴﻨﻲ و ﭼﻴﺪﻣﺎن ﺣﺎﻳﻞ ﻣﻨﺎﺳﺐ-

- Emergency shut-off valve to prevent or

reduce spillage due to overfilling, hose

failure, etc.;

- Emergency push-button switch to stop the

pumps, activate an alarm, and close all flow

control and block valves on the island;

- Adequate drainage and interception

arrangements.

6.1.4 Health and safety

6.1.4.1 General

Loading facilities are labor intensive (because of

numbers of driving personnel) and vulnerable

because of emission of vapors. It is the most

likely source of accidents in a depot and hence

particular attention needs to be paid to working

conditions.

ﺳﻼﻣﺖ و اﻳﻤﻨﻲ4-1-6

ﻋﻤﻮﻣﻲ1-4-1-6

ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﺑﻪ ﻋﻠﺖ ﺗﺮاﻛﻢ ﻛﺎري )ﺑﻪ ﺧﺎﻃﺮ ﺗﻌﺪاد ﻧﻔﺮات

ﻣﺤﻞ. آﺳﻴﺐ ﭘﺬﻳﺮ ﻫﺴﺘﻨﺪ،راﻧﻨﺪه( و ﺑﻪ ﻋﻠﺖ اﻧﺘﺸﺎر ﺑﺨﺎرات

اﻧﺒﺎر ﻳﻜﻲ از ﻣﻨﺎﺑﻊ ﺣﻮادث اﺳﺖ و از اﻳﻦ رو ﺗﻮﺟﻪ وﻳﮋهاي ﺑﺮاي

.ﺷﺮاﻳﻂ ﻛﺎر ﻻزم اﺳﺖ

اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ2-4-1-6

6.1.4.2 Static electricity

ﺑﺮاي ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن ﺧﻄﺮ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ ﺿﺮوري اﺳﺖ

To minimize the hazard of static electricity it is

11

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

essential firstly, to ensure that the vehicle tank

and loading equipment are at the same potential.

This should be arranged by providing a bonding

interlock system connecting the vehicle tanks to

the downspout, piping or steel loading rack flowcontrol valves. If bonding is to the rack, the

piping, rack, and downspout must be electrically

interconnected. Bonding is usually achieved by

means of a bond wire. Grounding the loading

system (i.e. rack, piping and downspout) in

addition to bonding provides no additional

protection from electrostatic ignition. Grounding

of metallic loading rack components, however,

may be necessary for electrical safety. See NFPA

70.

اﻃﻤﻴﻨﺎن ﺣﺎﺻﻞ ﺷﻮد ﻛﻪ ﻣﺨﺰن ﺧﻮدرو و،ﻛﻪ در ﻣﺮﺣﻠﻪ اول

اﻳﻦ ﻛﺎر ﺑﺎﻳﺪ ﺑﺎ اﺗﺼﺎل. ﻫﻢ ﭘﺘﺎﻧﺴﻴﻞ ﻫﺴﺘﻨﺪ،ﺗﺠﻬﻴﺰات ﺑﺎرﮔﻴﺮي

- ﻟﻮﻟﻪ، ﻟﻮﻟﻪ ﭘﺮﻛﻨﻨﺪه از ﭘﺎﻳﻴﻦ،ﺳﺎﻣﺎﻧﻪ ﻫﻢ ﺑﻨﺪ ﺑﻴﻦ ﻣﺨﺰن ﺧﻮدرو

.ﻛﺸﻲ ﻳﺎ ﺷﻴﺮﻫﺎي ﻛﻨﺘﺮل ﺟﺮﻳﺎن روي ﺳﻜﻮي ﻓﻠﺰي اﻧﺠﺎم ﺷﻮد

ﭘﺎﻳﻪ و ﻟﻮﻟﻪ ﭘﺮﻛﻨﻲ از، ﺑﺎﻳﺪ ﻟﻮﻟﻪﻛﺸﻲ،اﮔﺮ ﺑﻪ ﭘﺎﻳﻪ ﻣﺘﺼﻞ ﺑﺎﺷﺪ

اﺗﺼﺎل ﺑﺎ اﺳﺘﻔﺎده از ﺳﻴﻢ.ﻧﻈﺮ اﻟﻜﺘﺮﻳﻜﻲ ﺑﻪ ﻫﻢ ﻣﺘﺼﻞ ﺷﻮﻧﺪ

ﺑﺎ اﺗﺼﺎل زﻣﻴﻦ ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي )ﻳﻌﻨﻲ.اﺗﺼﺎل اﻧﺠﺎم ﻣﻴﮕﻴﺮد

ﻧﻴﺎزي ﺑﻪ، ﻟﻮﻟﻪﻛﺸﻲ و ﻟﻮﻟﻪ ﭘﺮﻛﻦ( ﻋﻼوه ﺑﺮ اﺗﺼﺎل ﺑﻪ ﻫﻢ، ﭘﺎﻳﻪ

ﺑﺎ.ﻫﻴﭻ ﻣﺤﺎﻓﻈﺖ ﺑﻴﺸﺘﺮي از ﺟﺮﻗﻪ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ ﻧﻤﻲﺑﺎﺷﺪ

ﻣﻤﻜﻦ،اﻳﻦ ﺣﺎل اﺗﺼﺎل ﺑﻪ زﻣﻴﻦ اﺟﺰاء ﻓﻠﺰي ﭘﺎﻳﻪ ﺑﺎرﮔﻴﺮي

راNFPA 70 .اﺳﺖ ﺑــﻪ ﺧﺎﻃﺮ اﻳﻤﻨﻲ ﺑﺮﻗﻲ ﻻزم ﺑﺎﺷﺪ

.ﺑﺒﻴﻨﻴﺪ

Secondly, maximum safe flow rates in the

loading system should be considered (see Clause

6.1.7.3).

ﺛﺎﻧﻴﺎً ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺣﺪاﻛﺜﺮ ﻣﻴﺰان ﺟﺮﻳﺎن اﻳﻤﻦ در ﺳﺎﻣﺎﻧﻪ

.( را ﺑﺒﻴﻨﻴﺪ3-7-1-6 ﺑﺎرﮔﻴﺮي در ﻧﻈﺮ ﮔﺮﻓﺘﻪ ﺷﻮد )ﺑﻨﺪ

ﺳﺎﻣﺎﻧﻪﻫﺎي ﺑﺎرﮔﻴﺮي5-1-6

6.1.5 Loading systems

ﻋﻤﻮﻣﻲ1-5-1-6

6.1.5.1 General

Ideally, the loading system should be able to fill

all compartments of the vehicle without needing

to move the vehicle. The spacing between loading

systems at the loading island should allow the

loading arms or hoses to be operated

independently, without interference between each

other, or meter heads, and with minimum

obstruction of access for the operator.

ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﻗﺎدر ﺑﻪ،در ﺣﺎﻟﺖ آرﻣﺎﻧﻲ ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

ﭘﺮﻛﺮدن ﺗﻤﺎم ﺑﺨﺸﻬﺎي ﺧﻮدرو ﺑﺪون ﻧﻴﺎز ﺑــﻪ ﺣﺮﻛﺖ ﺧﻮدرو

ﻓﺎﺻﻠﻪ ﮔﺬاري ﺳﺎﻣﺎﻧﻪﻫﺎي ﺑﺎرﮔﻴﺮي در ﻧﺎﺣﻴﻪ ﺑﺎرﮔﻴﺮي.ﺑـﺎﺷـﺪ

ﺑﺎﻳﺪ اﺟﺎزه ﺑﺪﻫﺪ ﺗﺎ ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي ﻳﺎ ﺷﻴﻠﻨﮕﻬﺎ ﺑﻪ ﻃﻮر

ﻣﺴﺘﻘﻞ و ﺑﺪون ﺗﺪاﺧﻞ ﺑﺎ ﻳﻜﺪﻳﮕﺮ ﻳﺎ ﺻﻔﺤﻪ ﻧﺸﺎﻧﮕﺮ ﺟﺮﻳﺎن ﺳﻨﺞ

ﻓﻌﺎﻟﻴﺖ،و ﺑﺎ ﺣﺪاﻗﻞ ﻣﻤﺎﻧﻌﺖ ﺑﺮاي دﺳﺘﺮﺳﻲ ﻣﺘﺼﺪي واﺣﺪ

.ﻛﻨﻨﺪ

Appendix A Figs. A.1 through A.7, presents

typical lay-outs for filling installations and typical

gantry arrangements. In Appendix B Figs. B.1,

B.2, B.3 and B.4 typical flow schemes for top and

bottom loading systems and corresponding

drainage are given. Symbols used for these

schemes are generally according to IPS-E-PR-170

and IPS-E-PR-230, but some additional

compound symbols or schematic ones are given

in the above figures and Figs. B.5, B.6 and B.7

for convenience. These symbols are valid only for

illustration purposes, if they have some

deviations with those accepted standard symbols

as indicated in IPS-E-PR-170 and IPS-E-PR-230.

6.1.5.2 Choice of loading system-top or bottom

ﺟﺎﻧﻤﺎﻳﻲ ﻧﻤﻮﻧﻪ ﺑﺮاي7- ﺗﺎ اﻟﻒ1- ﺷﻜﻠﻬﺎي اﻟﻒ،ﭘﻴﻮﺳﺖ اﻟﻒ

.ﺗﺄﺳﻴﺴﺎت ﭘﺮﻛﺮدن و ﻧﻤﻮﻧﻪ ﭼﻴﺪﻣﺎن دارﺑﺴﺖ را اراﺋﻪ ﻣﻴﺪﻫﻨﺪ

ﻧﻤﻮدار4- و ب3- ب،2- ب،1- ﺷﻜﻠﻬﺎي ب،در ﭘﻴﻮﺳﺖ ب

ﺟﺮﻳﺎﻧﻲ ﻧﻤﻮﻧﻪ ﺑﺮاي ﺳﺎﻣﺎﻧﻪﻫﺎي ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ و ﭘﺎﻳﻴﻦ و ﺗﺨﻠﻴﻪ

ﻧﺸﺎﻧﻪﻫﺎي اﺳﺘﻔﺎده ﺷﺪه در اﻳﻦ.ﻣﺮﺑﻮﻃﻪ داده ﺷﺪه اﺳﺖ

وIPS-E-PR-170 ﻧﻤﻮدارﻫﺎ ﻋﻤﻮﻣﺎً ﻣﻄﺎﺑﻖ ﺑﺎ

اﻣﺎ ﺑﺮﺧﻲ ﻧﺸﺎﻧﻪ ﻫﺎي ﺗﺮﻛﻴﺒﻲ ﻳﺎ، ﻣﻴﺒﺎﺷﺪIPS-E-PR-230

ﺑﺮاي7- و ب6- ب،5-ﺗﺼﻮﻳﺮي در ﺷﻜﻠﻬﺎي ﺑﺎﻻ و ﺷﻜﻠﻬﺎي ب

اﻳﻦ ﻧﺸﺎﻧﻪﻫﺎ ﻓﻘﻂ ﺑﻪ ﻣﻨﻈﻮر ﺗﻮﺻﻴﻒ ﻣﻌﺘﺒﺮ.راﺣﺘﻲ داده ﺷﺪه

ﻫﺴﺘﻨﺪ ﻣﮕﺮ آﻧﻜﻪ ﺑﺮﺧﻲ اﻧﺤﺮاﻓﺎت ﺑــﺎ ﻋﻼﺋــﻢ اﺳﺘــﺎﻧﺪارد

داﺷﺘﻪIPS-E-PR-230 وIPS-E-PR-170 ﭘﺬﻳﺮﻓﺘﻪ ﺷﺪه در

.ﺑﺎﺷﻨﺪ

اﻧﺘﺨﺎب ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي – ﺑﺎﻻ ﻳﺎ ﭘﺎﻳﻴﻦ2-5-1-6

The first criteria for selection of loading system is

the volatility characteristics of the product. If

RVP (Reid Vapor Pressure) of the product at

ﻣﺸﺨﺼﺎت ﻓﺮارﻳﺖ،اوﻟﻴﻦ ﻣﻌﻴﺎر ﺑﺮاي اﻧﺘﺨﺎب ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي

)ﻓﺸﺎر ﺑﺨﺎر رﻳﺪ( ﻣﺤﺼﻮل درRVP اﮔﺮ.ﻣﺤﺼﻮل ﻣﻴﺒﺎﺷﺪ

ﺑﺎر )ﻣﻄﻠﻖ( ﻳﺎ0/55 درﺟﻪ ﺳﺎﻧﺘﻴﮕﺮاد ﺑﻴﺸﺘﺮ از38 ﺗﺎﺑﺴﺘﺎن در

12

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

38°C is higher than 0.55 bar (abs) in summer or

0.83 bar (abs) in winter then bottom loading shall

be used.

ﺑﺎﻳﺪ ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ، ﺑﺎر )ﻣﻄﻠﻖ( ﺑﺎﺷﺪ0/83 در زﻣﺴﺘﺎن

.اﻧﺠﺎم ﺷﻮد

The second aspect is the requirements to restrict

emissions from a specific product which dictates

to use bottom loading.

اﻟﺰاﻣﺎت ﻣﺤﺪودﻳﺖ اﻧﺘﺸﺎر ﻳﻚ ﻣﺤﺼﻮل ﻣﺸﺨﺺ،دوﻣﻴﻦ ﺟﻨﺒﻪ

.اﺳﺖ ﻛﻪ اﺳﺘﻔﺎده از ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ را ﺗﺤﻤﻴﻞ ﻣﻴﻜﻨﺪ

Besides above mentioned limitations, the relative

merits of top and bottom loading system are

summarized in Table 1.

ﻣﺰاﻳﺎي ﻧﺴﺒﻲ ﺳﺎﻣﺎﻧﻪ،در ﻛﻨﺎر ﻣﺤﺪودﻳﺘﻬﺎي ذﻛﺮ ﺷﺪه در ﺑﺎﻻ

. ﺧﻼﺻﻪ ﺷﺪه اﺳﺖ1 ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ و ﭘﺎﻳﻴﻦ در ﺟﺪول

TABLE 1 - THE RELATIVE MERITS OF TOP AND BOTTOM LOADING

ﻣﺰاﻳﺎي ﻧﺴﺒﻲ ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ و ﭘﺎﻳﻴﻦ-1 ﺟﺪول

14

BOTTOM LOADING

TOP LOADING

ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

Safety Features

وﻳﮋﮔﻲ ﻫﺎي اﻳﻤﻨﻲ

١۵

Worksite

Ground level

ﺳﻄﺢ زﻣﻴﻦ

ﻣﺤﻞ ﻛﺎر

Vapor emissions (no vapor recovery)

(اﻧﺘﺸﺎر ﺑﺨﺎر )ﺑﺪون ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر

ﺑﺎ ﺗﻌﺒﻴﻪ رﻳﻞ ﻫﺎي ﻣﺤﺎﻓﻆ و راه دﺳﺘﺮﺳﻲ ﺑﻪ ﺧﻮدروﻫﺎ،روي ﺳﻜﻮ

ﻣﻴﺘﻮاﻧﺪ اﻳﻤﻦ ﺷﻮد اﻣﺎ ﺑﺎ ﻫﺰﻳﻨﻪ اﺿﺎﻓﻲ

Closed manhole covers gives rise to small pressure build-up

to operate the vents resulting in marginally less vapor

emission.

درﻳﭽﻪ ﻫﺎي ادم رو ﺑﺴﺘﻪ ﻣﻨﺠﺮ ﺑﻪ اﻓﺰاﻳﺶ ﻛﻢ ﻓﺸﺎر ﻣﻴﺸﻮﻧﺪ و ﺗﺨﻠﻴﻪ آﻧﻬﺎ

.ﻣﻨﺠﺮ ﺑﻪ اﻧﺘﺸﺎر ﻛﻢ ﺑﺨﺎر ﻣﻴﺸﻮد

Control of product flow assuming

meter preset does not work

ﻛﻨﺘﺮل ﺟﺮﻳﺎن ﻣﺤﺼﻮل ﺑﺎ ﻓﺮض اﻳﻦ ﻛﻪ ﭘﻴﺶ

On platform. Can be made safe by provision of guard

rails and access ramps to vehicles, but at extra cost.

Reliance on overspill protection equipment.

اﺗﻜﺎ ﺑﻪ ﺗﺠﻬﻴﺰات ﻣﺤﺎﻓﻈﺖ از ﺳﺮرﻳﺰ

.ﺗﻨﻈﻴﻢ ﺟﺮﻳﺎن ﺳﻨﺞ ﻛﺎر ﻧﻤﻴﻜﻨﺪ

Open manhole covers therefore slightly greater vapor

emission.

ﺳﺒﺐ اﻧﺘﺸﺎر ﺑﺨﺎر ﻧﺴﺒﺘﺎ ﺑﻴﺸﺘﺮ،درﻳﭽﻪ ادم روي ﺑﺎز

Positive visual control by loader assuming 'hold-open'

valve is correctly used.

Two-arm loading requires overspill protection when

the conditions are the same as for bottom loading.

ﻛﻨﺘﺮل ﻣﻮﺛﺮ ﭼﺸﻤﻲ ﺗﻮﺳﻂ ﻣﺘﺼﺪي ﺑﺎرﮔﻴﺮي ﺑﺎ ﻓﺮض اﻳﻦ ﻛﻪ ﺷﻴﺮ

.ﻧﮕﻬﺪار" درﺳﺖ ﻛﺎر ﻣﻴﻜﻨﺪ-"ﺑﺎز

ﺑﺎرﮔﻴﺮي دوﺑﺎزوﻳﻲ ﻧﻴﺎز ﺑﻪ ﻣﺤﺎﻓﻈﺖ از ﺳﺮرﻳﺰ دارد ﻣﺎﻧﻨﺪ ﺷﺮاﻳﻂ

.ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

Product handling equipment

ﺗﺠﻬﻴﺰات ﺣﻤﻞ ﻓﺮآورده

Arms and particularly hoses filled with product are heavier

to handle. Generally, hose diameters should be limited to

DN 80 (3 inches).

ﺑﺎزوﻫﺎ و ﻣﺨﺼﻮﺻﺎً ﺷﻴﻠﻨﮓﻫﺎﻳﻲ ﻛﻪ ﭘﺮ از ﻣﺤﺼﻮل ﺑﺎﺷﻨﺪ ﺑﺮاي ﺣﻤﻞ ﻛﺮدن

اﻳﻨﭻ( ﻣﺤﺪود3) DN80 ﻋﻤﻮﻣﺎً ﻗﻄﺮ ﺷﻴﻠﻨﮕﻬﺎ ﺑﺎﻳﺪ ﺑﻪ.ﺳﻨﮕﻴﻦﺗﺮ ﻫﺴﺘﻨﺪ

ﺷﻮد

Electrostatic precautions

اﺣﺘﻴﺎط ﻫﺎي اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ

Flow rates restricted to 75% of that for equivalent top

loading system.

. درﺻﺪ ﻣﻌﺎدل ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ ﻣﻴﺒﺎﺷﺪ75 ﻣﻴﺰان ﺟﺮﻳﺎن ﻣﺤﺪود ﺑﻪ

13

Care is needed to ensure that the down-pipe of

loading arms is correctly positioned in each

compartment. DN 100 and DN 150 (2 and 6 inches)

diameter counter-balanced arms are easily handled.

ﺑﺮاي اﻳﻦ ﻛﻪ ﻟﻮﻟﻪ ﻋﻤﻮدي ﺑﺎزوي ﺑﺎرﮔﻴﺮي در ﻫﺮ ﺑﺨﺶ ﺑﻪ ﻃﻮر

ﺣﻤﻞ ﺑﺎزوﻫﺎي ﺗﻮازن – ﻣﺘﻘﺎﺑﻞ. ﺗﻮﺟﻪ ﺑﺎﻳﺪ ﺷﻮد،ﺻﺤﻴﺢ ﻗﺮار ﮔﻴﺮد

. اﻳﻨﭻ( راﺣﺖﺗﺮ ﻣﻲﺑﺎﺷﻨﺪ6 و2) DN150 وDN100

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

BOTTOM LOADING

TOP LOADING

ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

Vehicles must be fitted with a vapor recovery

manifold connecting each compartment; of

sufficient capacity to cope with simultaneous

loading of 2, 3 or 4 compartments.

Each product loading arm must be fitted

with a vapor sealing head so that vapors are

diverted into a vapor recovery system; either

(a) on loading arm, or (b) manifold provided

for gasoline deliveries to retail outlets. Care

must be taken to position collar seal in fill

opening. Liquid level sensing equipment

must be fitted on loading arms or in each

vehicle tank compartment.

Environmental Conservation

ﻣﻼﺣﻈﺎت زﻳﺴﺖ ﻣﺤﻴﻄﻲ

Vapor recovery (loading bay)

(ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر )دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي

ﺧﻮدرو ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﭼﻨﺪ راﻫﻪ ﺑﺎزﻳﺎﻓﺖ ﻣﺘﺼﻞ ﺑﻪ ﻫﺮ ﺑﺨﺶ

ﻳﺎ3 ،2 ﻣﺨﺰن و داراي ﻇﺮﻓﻴﺖ ﻛﺎﻓﻲ ﺑﺮاي ﺑﺎرﮔﻴﺮي ﻫﻤﺰﻣﺎن

ﺑﺨﺶ ﺑﺎﺷﺪ4

ﻫﺮ ﺑﺎزوي ﺑﺎرﮔﻴﺮي ﻣﺤﺼﻮل ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ ﻳﻚ ﻛﻼﻫﻚ

ﻧﺸﺖ ﺑﻨﺪي ﺑﺨﺎر ﺑﺎﺷﺪ ﺑﻪ ﮔﻮﻧﻪ اي ﻛﻪ از آن ﺑﺨﺎرات ﺑﻪ

ﻳﺎ،ﺳﺎﻣﺎﻧﻪ ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر ﻳﺎ )اﻟﻒ( روي ﺑﺎزوي ﺑﺎرﮔﻴﺮي

)ب( ﭼﻨﺪ راﻫﻪ اي ﻛﻪ ﺑﺮاي ﺗﺤﻮﻳﻞ ﺑﻨﺰﻳﻦ ﺑﻪ

ﺑﺎﻳﺪ ﺑﺮاي ﻗﺮاردادن.ﺧﺮوﺟﻲﻫﺎي ﺟﺰﺋﻲ ﻫﺪاﻳﺖ ﺷﻮد

.ﻧﺸﺖ ﺑﻨﺪي دورﺗﺎدور درِ ﺳﻮراخ ﭘﺮﻛﺮدن دﻗﺖ ﺷﻮد

ﺗﺠﻬﻴﺰات ﺳﻨﺠﺶ ﺳﻄﺢ ﻣﺎﻳﻊ ﺑﺎﻳﺪ ﺑﺎ ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي

.ﻳﺎ در ﻫﺮ ﺑﺨﺶ ﻣﺨﺰن ﺧﻮدرو ﻧﺼﺐ ﺷﺪه ﺑﺎﺷﺪ

Vapor recovery (service stations)

(ﺑﺎزﻳﺎﻓﺖ ﺑﺨﺎر )اﻳﺴﺘﮕﺎه ﻛﺎرﺑﺮي

Vehicles already equipped with vapor return

manifold for use when loading.

Vehicles must be fitted with vapor return

manifold.

ﺧﻮدرو ﻫﻤﻴﺸﻪ ﺑﻪ ﭼﻨﺪ راﻫﻪ ﺑﺎزﮔﺸﺖ ﺑﺨﺎر ﺑﺮاي اﺳﺘﻔﺎده در

ﺻﻮرت ﺑﺎرﮔﻴﺮي ﻣﺠﻬﺰ اﺳﺖ

ﺧﻮدرو ﺑﺎﻳﺴﺘﻲ ﺑﻪ ﭼﻨﺪ راﻫﻪ ﺑﺎزﮔﺸﺖ ﺑﺨﺎر ﻣﺠﻬﺰ ﺑﺎﺷﺪ

Performance

ﻛﺎرآﻳﻲ

Preparation for loading (normal)

(آﻣﺎده ﻛﺮدن ﺑﺮاي ﺑﺎرﮔﻴﺮي) ﻋﺎدي

Removal of caps and connecting couplings is

contained within small operating envelope.

(No significant difference between systems.)

Greater area of operation because of

positioning of manhole covers.

(No significant difference between systems.)

ﺑﺎزﻛﺮدن ﻛﻼﻫﻚ ﻫﺎ و اﺗﺼﺎل ﺟﻔﺖ ﻛﻨﻨﺪه داراي ﭘﻴﭽﻴﺪﮔﻲ

.ﻋﻤﻠﻴﺎﺗﻲ ﻛﻤﻲ اﺳﺖ

(.)ﺗﻔﺎوت ﻣﺸﺨﺼﻲ ﺑﻴﻦ ﺳﺎﻣﺎﻧﻪﻫﺎ وﺟﻮد ﻧﺪارد

Preparation for loading (vapor return)

(آﻣﺎده ﺳﺎزي ﺑﺮاي ﺑﺎرﮔﻴﺮي )ﺑﺎزﮔﺸﺖ ﺑﺨﺎر

Additional coupling connection to vapor

manifold.

(No significant difference between systems.)

اﺗﺼﺎل ﺟﻔﺖ ﻛﻨﻨﺪه اﺿﺎﻓﻲ ﺑﺮاي ﭼﻨﺪ راﻫﻪ ﺑﺨﺎر

(.)ﺗﻔﺎوت ﻣﺸﺨﺼﻲ ﺑﻴﻦ ﺳﺎﻣﺎﻧﻪﻫﺎ وﺟﻮد ﻧﺪارد

Loading arrangement

ﺗﺮﺗﻴﺐ ﺑﺎرﮔﻴﺮي

Simultaneous loading of 2 or more compartments

more easily arranged.

.ﺑﺎرﮔﻴﺮي ﻫﻤﺰﻣﺎن دو ﻳﺎ ﭼﻨﺪ ﺑﺨﺶ ﺑﻪ راﺣﺘﻲ ﺗﻨﻈﻴﻢ ﻣﻴﺸﻮد

25% slower per compartment than equivalent top

handling system because of electrostatic hazard

in certain filling operations.

Product flow rates

ﻣﻴﺰان ﺟﺮﻳﺎن ﻣﺤﺼﻮل

درﺻﺪ ﻛﻨﺪﺗﺮ در ﻫﺮ ﺑﺨﺶ ﻧﺴﺒﺖ ﺑﻪ ﺳﺎﻣﺎﻧﻪ ﺑﺎرﮔﻴﺮي از25

ﺑﺎﻻي ﻣﻌﺎدل ﺑﻪ ﺧﺎﻃﺮ ﺧﻄﺮ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ در ﻋﻤﻠﻴﺎت

14

ﺳﻄﺢ ﻋﻤﻠﻴﺎﺗﻲ ﺑﺰرﮔﺘﺮ ﺑﻪ ﺧﺎﻃﺮ ﻣﻮﻗﻌﻴﺖ درﭘﻮش

.درﻳﭽﻪ آدم رو

(.)ﺗﻔﺎوت ﻣﺸﺨﺼﻲ ﺑﻴﻦ ﺳﺎﻣﺎﻧﻪﻫﺎ وﺟﻮد ﻧﺪارد

Care must be taken to position arm/vapor

head in fill opening.

(No significant difference between systems.)

ﻛﻼﻫﮓ ﺑﺨﺎر در ﺳﻮراخ ﭘﺮﻛﺮدن/ﺑﺮاي ﻗﺮار دادن ﺑﺎزو

.ﺑﺎﻳﺪ دﻗﺖ ﺷﻮد

(.)ﺗﻔﺎوت ﻣﺸﺨﺼﻲ ﺑﻴﻦ ﺳﺎﻣﺎﻧﻪﻫﺎ وﺟﻮد ﻧﺪارد

Nov. 2009 / 1388 آﺑﺎن

16

IPS-E-PR-370(1)

BOTTOM LOADING

TOP LOADING

ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

Costs

ﻫﺰﻳﻨﻪﻫﺎ

Capital costs

ﻫﺰﻳﻨﻪ ﺳﺮﻣﺎﻳﻪ ﮔﺬاري

1. Approximately 17% more loading space is required

than that of an equivalent top- loading gantry.

Additional cost for greater roof area.

Additional structure and safety equipment for

working platform.

ﺳﺎزه و ﺗﺠﻬﻴﺰات اﻳﻤﻨﻲ اﺿﺎﻓﻲ ﺑﺮاي ﺳﻜﻮي ﻛﺎر

درﺻﺪ ﻓﻀﺎي ﺑﺎرﮔﻴﺮي ﺑﻴﺸﺘﺮي ﻧﺴﺒﺖ ﺑﻪ دارﺑﺴﺖ17 ً ﺗﻘﺮﻳﺒﺎ.1

ﻫﺰﻳﻨﻪﻫﺎي اﺿﺎﻓﻲ ﺑﺮاي.ﻣﻌﺎدل ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ ﻻزم اﺳﺖ

.ﺳﻄﻮح ﺑﻴﺸﺘﺮ ﺳﻘﻒ

2. i) All vehicle compartments must be fitted with

loading dry-break couplings.

( ﺗﻤﺎم ﺑﺨﺸﻬﺎي ﻣﺨﺰن ﺧﻮدرو ﺑﺎﻳﺪ ﺑﻪ ﺟﻔﺖ ﻛﻨﻨﺪه ﺧﺸﻚ ﻗﻄﻊi .2

.ﺑﺎرﮔﻴﺮي ﻣﺠﻬﺰ ﺷﻮﻧﺪ

ii) To minimize over-filling risk, vehicles must be

fitted with liquid level sensing equipment.

ﺧﻮدروﻫﺎ ﺑﺎﻳﺪ ﺑﻪ،( ﺑﺮاي ﺑﻪ ﺣﺪاﻗﻞ رﺳﺎﻧﺪن اﺣﺘﻤﺎل ﺳﺮرﻳﺰii

.ﺗﺠﻬﻴﺰات ﺳﻨﺠﺶ ﺳﻄﺢ ﻣﺎﻳﻊ ﻣﺠﻬﺰ ﺷﻮﻧﺪ

iii) Deflectors must be fitted to foot valves to

minimize jetting and turbulence.

( ﻣﻨﺤﺮف ﺳﺎزﻫﺎ ﺑﺎﻳﺪ ﺑﻪ ﺳﻮﭘﺎپ ﻣﺠﻬﺰ ﺑﺎﺷﻨﺪ ﺗﺎ ﻓﻮران ﻛﺮدن وiii

.اﻏﺘﺸﺎش را ﺑﻪ ﺣﺪاﻗﻞ ﺑﺮﺳﺎﻧﺪ

iv) Additional product handling equipment on islands.

Depending upon by group's requirements, this may

be about 30-50 more.

( ﺗﺠﻬﻴﺰات اﺿﺎﻓﻲ ﺣﻤﻞ ﻣﺤﺼﻮل در ﻫﺮ ﻧﺎﺣﻴﻪ و ﺑﺴﺘﻪ ﺑﻪiv

درﺻﺪ ﺑﻴﺸﺘﺮ50-30 اﻟﺰاﻣﺎت ﻣﺠﻤﻮﻋﻪﻫﺎ ﻛﻪ ﻣﻤﻜﻦ اﺳﺖ

.ﺷﻮد

Maintenance Costs

ﻫﺰﻳﻨﻪﻫﺎي ﺗﻌﻤﻴﺮات

The additional equipment above will require to be

maintained/replaced. Out-of-service time of vehicles

for maintenance may be increased.

Maintenance of working platform and

features.

safety

ﻧﮕﻬﺪاﺷﺖ ﺳﻜﻮي ﻛﺎر و ﺗﺠﻬﻴﺰات اﻳﻤﻨﻲ

زﻣﺎن ﻛﺎر.ﺗﻌﻮﻳﺾ ﺧﻮاﻫﺪ داﺷﺖ/ﺗﺠﻬﻴﺰات اﺿﺎﻓﻲ ﻧﻴﺎز ﺑﻪ ﺗﻌﻤﻴﺮ

.ﻧﻜﺮدن ﺧﻮدرو ﺑﻪ ﺟﻬﺖ ﺗﻌﻤﻴﺮات ﻣﻤﻜﻦ اﺳﺖ اﻓﺰاﻳﺶ ﻳﺎﺑﺪ

Constraints

ﻣﺤﺪودﻳﺖﻫﺎ

Vehicle accommodation

ﻣﻜﺎن ﺧﻮدرو

Compatibility

with

Contractors vehicles

competitors

and

ﺳﺎزﮔﺎري ﺑﺎ ﺧﻮدروي رﻗﺒﺎ و ﭘﻴﻤﺎﻧﻜﺎر

Compartment outlets full or empty

ﺧﺮوﺟﻲ ﭘﺮ ﻳﺎ ﺧﺎﻟﻲ از ﺑﺨﺸﻬﺎي ﻣﺨﺰن

Can more easily accept range of vehicle capacities and

heights (present and future).

Less flexible than bottom loading arrangement.

.اﻧﻌﻄﺎف ﻛﻤﺘﺮ ﻧﺴﺒﺖ ﺑﻪ اﻟﮕﻮي ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

ﺑﻪ راﺣﺘﻲ ﻃﻴﻒ وﺳﻴﻌﻲ از ﺧﻮدروﻫﺎ ﺑﺎ ﻇﺮﻓﻴﺘﻬﺎ و ارﺗﻔﺎﻋﺎت ﻣﺨﺘﻠﻒ

.(را ﻣﻲ ﭘﺬﻳﺮد )ﺣﺎل و آﻳﻨﺪه

All vehicles likely to use loading bays must be fitted

with suitable equipment. Industry agreement to adopt

similar practices should be encouraged.

More flexible.

اﻧﻌﻄﺎف ﭘﺬﻳﺮي ﺑﻴﺸﺘﺮ

ﺗﻤﺎم ﺧﻮدروﻫﺎﻳﻲ ﻛﻪ ﻧﻴﺎز ﺑﻪ اﺳﺘﻔﺎده از دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي دارﻧﺪ ﺑﺎﻳﺪ ﺑﺎ

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻣﻮاﻓﻘﺖ ﻧﺎﻣﻪ ﺻﻨﻌﺘﻲ.ﺗﺠﻬﻴﺰات ﻣﻨﺎﺳﺐ ﻣﺠﻬﺰ ﺷﻮﻧﺪ

.ﻣﻄﺎﺑﻖ ﺑﺎ ﻣﺸﺎﺑﻬﺖ ﻫﺎي ﻋﻤﻠﻴﺎﺗﻲ ﺑﺎﺷﺪ

Possible need to persuade authorities to change law to

permit outlet pipes filled with product, otherwise

drainage must be arranged with consequent

measurement and operational problems.

No problem.

.ﻣﺸﻜﻠﻲ ﻧﻴﺴﺖ

ﻧﻴﺎز اﺣﺘﻤﺎﻟﻲ ﺑﻪ ﻣﺘﻘﺎﻋﺪ ﻛﺮدن ﻣﺴﺌﻮﻻن ﺑﺮاي ﺗﻐﻴﻴﺮ ﻗﺎﻧﻮن ﺑﺮاي

در ﻏﻴﺮ اﻳﻦ ﺻﻮرت،اﺟﺎزه ﺑﻪ ﭘﺮ ﺑﻮدن ﻟﻮﻟﻪﻫﺎي ﺧﺮوﺟﻲ از ﻣﺤﺼﻮل

ﺗﺨﻠﻴﻪ ﺑﻪ زﻣﻴﻦ ﺑﺎ در ﻧﻈﺮ ﮔﺮﻓﺘﻦ ﻣﺸﻜﻼت ﻋﻤﻠﻴﺎﺗﻲ و اﻧﺪازهﮔﻴﺮي

.ﺑﺎﻳﺴﺘﻲ اﻧﺠﺎم ﺷﻮد

Sophistication

ﭘﻴﭽﻴﺪﮔﻲ

Less flexible operation. Increased maintenance.

Need for greater control of maintenance.

ﻧﻴﺎزﻣﻨﺪ ﺑﻪ ﭘﺎﻳﺶ ﺑﻴﺸﺘﺮ. ﺗﻌﻤﻴﺮات ﺑﻴﺸﺘﺮ،اﻧﻌﻄﺎف ﻋﻤﻠﻴﺎﺗﻲ ﻛﻤﺘﺮ

.ﺗﻌﻤﻴﺮات

15

More flexible operation.

.اﻧﻌﻄﺎف ﭘﺬﻳﺮي ﺑﻴﺸﺘﺮ ﻋﻤﻠﻴﺎﺗﻲ

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

ﺳﺎﻣﺎﻧﻪ ﻛﻨﺘﺮل6-1-6

6.1.6 Control system

ﻛﻨﺘﺮل ﺟﺮﻳﺎن ﻓﺮآورده1-6-1-6

6.1.6.1 Control of product flow:

اﻟﻒ( ﭘﺮﻛﺮدن ﺣﺠﻤﻲ

a) Filling by volume

Measurement of product volume governs the

amount of product filled into each

compartment and this is normally arranged by

flow through a positive displacement meter.

اﻧﺪازه ﮔﻴﺮي ﺣﺠﻤﻲ ﻣﺤﺼﻮل ﺑﻪ ﻣﻘﺪار ﻣﺤﺼﻮل ﻛﻪ ﺑﻪ ﻫﺮ

ﺑﺨﺶ ﭘﺮ ﻣﻴﺸﻮد دﻻﻟﺖ دارد و ﺑﻪ ﻃﻮر ﻋﺎدي ﺗﻮﺳﻂ ﻋﺒﻮر

.ﺟﺮﻳﺎن از ﺟﺮﻳﺎن ﺳﻨﺞ ﻧﻮع ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﻗﺮار ﻣﻲ ﮔﻴﺮد

However, truck loading racks were designed

for use with displacement meters, however,

technological

advances

and

blending

applications have encouraged the introduction

of other meter designs such as turbine and

Coriolis meters. When retrofitting existing

displacement metering systems with turbine

and Coriolis meters, care should be taken to

ensure

proper

application

of

these

technologies. At a minimum, to ensure proper

operating performance, meters should be

installed

according

to

manufacturers’

recommended practices.

ﺳﻜﻮﻫﺎي ﺑﺎرﮔﻴﺮي ﻛﺎﻣﻴﻮن ﺑﺮاي اﺳﺘﻔﺎده ﺑﺎ،ﺑﺎ اﻳﻦ ﺣﺎل

ﺑﺎ اﻳﻦ،ﺟﺮﻳﺎن ﺳﻨﺞ ﻫﺎي ﻧﻮع ﺟﺎﺑﺠﺎﻳﻲ ﻃﺮاﺣﻲ ﺷﺪهاﻧﺪ

اﺳﺘﻔﺎده از ﺳﺎﻳﺮ،ﺣﺎل ﻣﺰاﻳﺎي ﻓﻨﺎوري و ﻛﺎرﺑﺮدﻫﺎي اﺧﺘﻼط

ﺟﺮﻳﺎن ﺳﻨﺞ ﻫﺎ ﻣﺜﻞ ﺟﺮﻳﺎن ﺳﻨﺞ ﺗﻮرﺑﻴﻨﻲ و ﻛﻮرﻳﻮﻟﻴﺲ را

زﻣﺎﻧﻲ ﻛﻪ ﺑﺎ ﺑﺮوز در آوردن ﺳﺎﻣﺎﻧﻪﻫﺎي.ﺗﺮﻏﻴﺐ ﻣﻴﻜﻨﺪ

ﺟﺮﻳﺎن ﺳﻨﺞ ﻧﻮع ﺟﺎﺑﺠﺎﻳﻲ ﻣﻮﺟﻮد ﺑﺎ ﺟﺮﻳﺎن ﺳﻨﺞ ﻧﻮع

ﺗﻮرﺑﻴﻨﻲ و ﻛﻮرﻳﻮﻟﻴﺲ ﺗﻌﻮﻳﺾ ﻣﻴﺸﻮﻧﺪ ﻣﺮاﻗﺒﺖ از ﻛﺎرﺑﺮد

ﺑﻪ ﻋﻨﻮان ﻳﻚ.ﺻﺤﻴﺢ اﻳﻦ ﻓﻦ آوري ﻫﺎ ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد

ﺗﻮﺻﻴﻪ،ﺣﺪاﻗﻞ ﺑﺮاي اﻃﻤﻴﻨﺎن از ﻋﻤﻠﻜﺮد ﺻﺤﻴﺢ ﻋﻤﻠﻴﺎﺗﻲ

ﻣﻲﺷﻮد ﻧﺼﺐ ﺟﺮﻳﺎن ﺳﻨﺞ ﻣﻄﺎﺑﻖ ﺑﺎ ﺗﺠﺮﺑﻴﺎت ﺗﻮﺻﻴﻪ ﺷﺪه

.ﺳﺎزﻧﺪه ﺑﺎﺷﺪ

ﻛﺎﻫﺶ ﺟﺮﻳﺎن و ﻗﻄﻊ آن ﻣﻌﻤﻮﻻ ﺗﻮﺳﻂ ﻳﻚ وﺳﻴﻠﻪ

ﻛﻨﺘﺮل ﻣﻘﺪار ﭘﻴﺶ ﺗﻨﻈﻴﻢ ﻛﻨﺘﺮل ﻣﻴﺸﻮد ﻛﻪ ﻗﺪم اول

در ﺻﻮرت ﺑﺮوز ﻫﺮﮔﻮﻧﻪ ﻣﻮرد.ﻛﻨﺘﺮل را ﻧﺸﺎن ﻣﻴﺪﻫﺪ

اﺿﻄﺮاري ﺑﻪ ﻋﻨﻮان ﻣﺜﺎل اﻳﺮاد در ﻋﻤﻠﻜﺮد ﻳﺎ ﺗﻨﻈﻴﻢ

اﺣﺘﻤﺎل ﺳﺮرﻳﺰ،ﻧﺎدرﺳﺖ ﻣﻘﺪار ﭘﻴﺶ ﺗﻨﻈﻴﻤﻲ و ﻏﻴﺮه

.ﺑﻮﺟﻮد ﻣﻲآﻳﺪ و ﻣﺮﺣﻠﻪ دوﻣﻲ از ﻛﻨﺘﺮل ﻻزم اﺳﺖ

:روﺷﻬﺎي دﺳﺘﻴﺎﺑﻲ ﻋﺒﺎرﺗﻨﺪ از

Slowing down and stopping the flow is

usually controlled by a preset quantity

control device which represents the first

line of control. In the event of any

emergency, e.g., malfunction of the

mechanism, or incorrect setting of the

preset, etc. the possibility of a spillover

occurs, and a second line of control is

necessary. Methods of achieving this are

as follows:

( ﭘﺮﻛﺮدن از ﺑﺎﻻ1-اﻟﻒ

a.1) Top filling

The fitting of a ’deadman control’ in the form

of a ’hold-open’ valve also enables the

operator-when filling through an open

manhole-to watch the level of the product and

to stop the flow immediately in any

emergency. The valve operating lever (or

control rod) must be located so that the filler

can see the product in the compartments at

high level, while avoiding the vapor plume

emitted from the manhole. However, the

temptation to tie the hold-open valves in the

open position, has resulted in spillovers.

،"" ﺑﻪ ﺻﻮرت ﺷﻴﺮ "ﺑﺎزﻧﮕﻬﺪارDead man" اﺗﺼﺎل ﻛﻨﺘﺮل

ﻣﺘﺼﺪي را ﻗﺎدر ﻣﻴﺴﺎزد ﻛﻪ در ﻃﻮل ﭘﺮﻛﺮدن از ﻃﺮﻳﻖ

درﻳﭽﻪ آدم رو ﺑﺎز ﺳﻄﺢ ﻣﺤﺼﻮل را ﻣﺸﺎﻫﺪه و در ﺻﻮرت

اﻫﺮم ﻋﻤﻠﻴﺎﺗﻲ ﺷﻴﺮ )ﻳﺎ ﻣﻴﻠﻪ.اﺿﻄﺮار ﺟﺮﻳﺎن را ﻗﻄﻊ ﻛﻨﺪ

ﻛﻨﺘﺮل( ﺑﺎﻳﺪ در ﻣﻮﻗﻌﻴﺘﻲ ﻗﺮار ﮔﻴﺮد ﻛﻪ ﻣﺘﺼﺪي ﭘﺮﻛﻦ

ﺑﺘﻮاﻧﺪ ﻣﺤﺼﻮل را در ﺑﺨﺶ در ﺳﻄﺢ ﺑﺎﻻ ﺑﺒﻴﻨﺪ در ﺣﺎﻟﻲ

ﻛﻪ از ﺳﺎﻃﻊ ﺷﺪن اﺑﺮ ﺑﺨﺎر از درﻳﭽﻪ آدم رو ﺑﺎﻳﺪ اﺟﺘﻨﺎب

ﺑﺎ اﻳﻦ ﺣﺎل آزﻣﺎﻳﺶ ﺑﺴﺘﻦ ﺷﻴﺮ ﺑﺎزﻧﮕﻬﺪار در وﺿﻌﻴﺖ.ﺷﻮد

.ﺑﺎز ﻣﻨﺠﺮ ﺑﻪ ﺳﺮرﻳﺰ ﺷﺪه اﺳﺖ

This factor, together with the necessity for

operators to stand on vehicles while fillings,

has led to the increasing use of liquid-level

control equipment as a positive secondary

means of stopping product flow in an

emergency.

اﻳﻦ ﻋﺎﻣﻞ ﺑﻪ ﻫﻤﺮاه اﻟﺰام اﻳﺴﺘﺎدن ﻣﺘﺼﺪي در ﺧﻮدرو در

ﻃﻮل ﭘﺮﻛﺮدن ﺑﻪ اﻓﺰاﻳﺶ اﺳﺘﻔﺎده از ﺗﺠﻬﻴﺰات ﻛﻨﺘﺮل ﺳﻄﺢ

ﻣﺎﻳﻊ ﺑﻪ ﻋﻨﻮان وﺳﻴﻠﻪ ﺛﺎﻧﻮﻳﻪ ﻋﻤﻠﻲ ﺑﺮاي ﻗﻄﻊ ﺟﺮﻳﺎن

.ﻣﺤﺼﻮل در ﺣﺎﻟﺖ اﺿﻄﺮاري ﻣﻨﺠﺮ ﺷﺪه اﺳﺖ

16

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

Where two or more compartments are required

to be filled at the same time, liquid level

control equipment is strongly recommended as

a secondary means of stopping the flow of

product.

زﻣﺎﻧﻲ ﻛﻪ ﻻزم اﺳﺖ دو ﻳﺎ ﭼﻨﺪ ﺑﺨﺶ در ﻳﻚ زﻣﺎن

ﺗﺠﻬﻴﺰ ﻛﻨﺘﺮل ﺳﻄﺢ ﻣﺎﻳﻊ ﺑﻪ ﻋﻨﻮان وﺳﻴﻠﻪ ﺛﺎﻧﻮﻳﻪ،ﭘﺮﺷﻮﻧﺪ

ﻋﻤﻠﻲ ﺑﺮاي ﺑﺴﺘﻦ ﺟﺮﻳﺎن ﻣﺤﺼﻮل ﺑﻪ ﺷﺪت ﺗﻮﺻﻴﻪ

.ﻣﻲﺷﻮد

Access from the loading rack platform to the

top of the truck is usually afforded by ramps,

adjustable stairways, or platforms that are

hinged to the side of the loading rack

platforms and can be swung down to the top of

the truck. A handrail should be provided for

the safety of truck loaders standing on top of

the truck or platform.

ًدﺳﺘﺮﺳﻲ از ﺳﻜﻮي ﺑﺎرﮔﻴﺮي ﺑﻪ ﺑﺎﻻي ﻛﺎﻣﻴﻮن ﻣﻌﻤﻮﻻ

ﺗﻮﺳﻂ ﺳﻄﻮح ﺷﻴﺐدار ﭘﻠﻪﻫﺎي ﻗﺎﺑﻞ ﺗﻨﻈﻴﻢ ﻳﺎ ﺳﻜﻮﻫﺎﻳﻲ

ﻛﻪ ﺑﻪ ﻛﻨﺎر ﺳﻜﻮي ﺑﺎرﮔﻴﺮي آوﻳﺰان ﻫﺴﺘﻨﺪ اﻣﻜﺎن ﭘﺬﻳﺮ

ﺗﻮﺻﻴﻪ. ﻛﻪ ﻣﻴﺘﻮاﻧﻨﺪ ﺑﺮ روي ﻛﺎﻣﻴﻮن ﭘﺎﻳﻴﻦ ﺑﻴﺎﻳﻨﺪ،اﺳﺖ

ﻣﻲﺷﻮد ﻧﺮدهاي ﺑﺮاي اﻳﻤﻨﻲ ﻣﺘﺼﺪي ﭘﺮﻛﻦ ﻛﺎﻣﻴﻮن ﻛﻪ

.روي ﻛﺎﻣﻴﻮن ﻳﺎ ﺳﻜﻮ اﻳﺴﺘﺎده اﺳﺖ ﺗﻌﺒﻴﻪ ﺷﻮد

( ﭘﺮﻛﺮدن از ﭘﺎﻳﻴﻦ2-اﻟﻒ

a.2) Bottom filling

With all loading operations at ground level,

and vehicle manhole covers remaining closed,

the use of an overfill protection system based

upon liquid-level detection equipment

becomes essential. The system shall be

equipped with a preset device to shut off the

flow of product after a predetermined amount

has been metered. Also, an overfill shutdown

system shall be provided in case too large a

volume is entered into the preset device or the

vehicle

compartment

is

not

empty

immediately before loading starts.

در ﺗﻤﺎم ﻋﻤﻠﻴﺎتﻫﺎي ﺑﺎرﮔﻴﺮي در ﺳﻄﺢ زﻣﻴﻦ و ﺑﺴﺘﻪ

اﺳﺘﻔﺎده از ﻳﻚ،ﺑﺎﻗﻴﻤﺎﻧﺪن ﻣﺎﻧﺪن درﻳﭽﻪ آدم رو ﺧﻮدرو

ﺳﺎﻣﺎﻧﻪ ﻣﺤﺎﻓﻈﺖ از ﺳﺮ رﻳﺰ ﺑﺮاﺳﺎس ﺗﺠﻬﻴﺰات ﺗﺸﺨﻴﺺ

اﻳﻦ ﺳﺎﻣﺎﻧﻪ ﺑﺎﻳﺪ ﻣﺠﻬﺰ ﺑﻪ وﺳﻴﻠﻪ.ﺳﻄﺢ ﻣﺎﻳﻊ ﻻزم ﻣﻴﺒﺎﺷﺪ

ﭘﻴﺶ ﺗﻨﻈﻴﻢ ﺑﺮاي ﺑﺴﺘﻦ ﺟﺮﻳﺎن ﻣﺤﺼﻮل ﭘﺲ از

ﻫﻤﭽﻨﻴﻦ ﺳﺎﻣﺎﻧﻪ ﻗﻄﻊ.اﻧﺪازهﮔﻴﺮي ﻣﻘﺪار ﺗﻌﻴﻴﻦ ﺷﺪه ﺑﺎﺷﺪ

در اﺛﺮ ﺳﺮ رﻳﺰ در ﺣﺎﻟﺘﻲ ﻛﻪ ﺣﺠﻢ ﺑﺴﻴﺎر ﺑﺰرﮔﻲ وارد

دﺳﺘﮕﺎه ﭘﻴﺶ ﺗﻨﻈﻴﻢ ﺷﺪه ﻳﺎ ﺑﺨﺶ ﻣﺨﺰن ﺧﻮدرو ﺑﻼﻓﺎﺻﻠﻪ

. ﺑﺎﻳﺪ ﺗﻌﺒﻴﻪ ﺷﻮد،ﻗﺒﻞ از ﺷﺮوع ﺑﺎرﮔﻴﺮي ﺧﺎﻟﻲ ﻧﺒﺎﺷﺪ

The liquid-level control equipment should be

linked into an interlock system which covers

bonding of the vehicle, and access to the

products by means of controls on the loading

arms. This enhances safety and provides the

basis for an automatic control system.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد وﺳﻴﻠﻪ ﻛﻨﺘﺮل ﺳﻄﺢ ﻣﺎﻳﻊ ﺑﻪ ﺳﺎﻣﺎﻧﻪ ﻫﻤﺒﻨﺪ

ﻛﻪ ﺷﺎﻣﻞ اﺗﺼﺎل زﻣﻴﻦ ﺧﻮدرو و دﺳﺘﺮﺳﻲ ﺑﻪ ﻣﺤﺼﻮﻻت ﺑﺎ

ﻣﺘﺼﻞ،ﺗﺠﻬﻴﺰات ﻛﻨﺘﺮل روي ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي ﻣﻴﺒﺎﺷﺪ

اﻳﻦ ﻣﻮﺟﺐ ﺗﻘﻮﻳﺖ اﻳﻤﻨﻲ ﺷﺪه و اﺳﺎس ﺳﺎﻣﺎﻧﻪ.ﺷﻮد

.ﻛﻨﺘﺮل ﺧﻮدﻛﺎر را ﻓﺮاﻫﻢ ﻣﻴﻜﻨﺪ

ب( ﭘﺮﻛﺮدن ﺟﺮﻣﻲ

b) Filling by mass

،زﻣﺎﻧﻲ ﻛﻪ ﺳﻜﻮي ﺗﻮزﻳﻊ در دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﻗﺮار داده ﺷﻮد

ﻛﻨﺘﺮل ﻣﻴﺸﻮد ﻛﻪ،ﭘﺮﻛﺮدن ﺗﻮﺳﻂ ﺳﺎز و ﻛﺎر ﭘﻴﺶ ﺗﻨﻈﻴﻢ

در دو ﻣﺮﺣﻠﻪ ﻗﺒﻞ از ﺑﺴﺘﻪ ﺷﺪن ﻛﻞ ﺟﺮم ﺑﺎرﮔﻴﺮي ﺷﺪه

در اﻳﻦ روش ﻓﻘﻂ ﻳﻚ ﺑﺨﺶ در ﻳﻚ زﻣﺎن.ﻓﻌﺎﻟﻴﺖ ﻣﻴﻜﻨﺪ

اﻟﺰاﻣﺎت ﻣﺤﺎﻓﻈﺖ ﺛﺎﻧﻮﻳﻪ در ﻣﻘﺎﺑﻞ.ﻣﻴﺘﻮاﻧﺪ ﺑﺎرﮔﻴﺮي ﺷﻮد

:ﺳﺮرﻳﺰ ﺑﺎﻳﺪ ﻣﻄﺎﺑﻖ

Where the weighbridge is positioned at the

loading bay, the filling can be controlled by a

preset mechanism operating in two stages

before cutting off at the total loaded mass.

Only one compartment can be loaded at a time

with this method. The requirement of

secondary protection against overfilling is

met:

.( ﺑﺎﻻ2- ﻣﻄﺎﺑﻖ ﺑﻨﺪ )اﻟﻒ، ﺑﺮاي ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ-

- For bottom loading; as for (a.2) above.

از ﻳﻚ ﺷﻴﺮ ﻧﻮع "ﺑﺎزﻧﮕﻬﺪار" روي: ﺑﺮاي ﺑﺎرﮔﻴﺮي از ﺑﺎﻻﺑﺎزوي ﺑﺎرﮔﻴﺮي ﺑﻪ ﻫﻤﺮاه ﻣﺘﺼﺪي واﺣﺪ ﻛﻪ روي ﺳﻜﻮي

دارﺑﺴﺖ )ﻧﻪ روي ﺧﻮدرو( در وﺿﻌﻴﺖ اﻳﺴﺘﺎده ﻛﻪ ﺑﺨﺶ

ﺑﺮاي ﻳﻚ. اﺳﺘﻔﺎده ﺷﻮد، ﺑﺎرﮔﻴﺮي ﺷﻮﻧﺪه را ﻣﺸﺎﻫﺪه ﻛﻨﺪ

ﭘﺮﻛﻨﻨﺪه ﻛﺎر/ﻣﺨﺰن )ﻳﺎ ﺑﺨﺶﻫﺎي ﺑﺰرگ( اﮔﺮ راﻧﻨﺪه

- For top loading: use of a ’hold-open’ type

valve on loading arm with operator standing

on gantry platform (NOT VEHICLE) in a

position to observe compartment being loaded.

For single (or large compartments) it may be

17

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

دﻳﮕﺮي روي ﺳﻜﻮ داﺷﺘﻪ ﺑﺎﺷﻨﺪ ﻣﻤﻜﻦ اﺳﺖ ﻣﺠﻬﺰ ﻛﺮدن

.ﺑﻪ وﺳﻴﻠﻪ ﻛﻨﺘﺮل ﺳﻄﺢ ﻣﺎﻳﻊ ﻣﻄﻠﻮب ﺑﺎﺷﺪ

desirable to fit liquid-level control equipment

if the driver/loader has other things to do on

the loading platform.

ﺧﻮدﻛﺎر ﻛﺮدن2-6-1-6

6.1.6.2 Automation

ﻋﻤﻮﻣﻲ1-2-6-1-6

6.1.6.2.1 General

ﺑﻪ وﺳﻴﻠﻪ ﺳﺎﻣﺎﻧﻪ ﻫﻤﺒﻨﺪ ﻣﺤﺼﻮل ﺟﺮﻳﺎن ﻧﻤﻲﻳﺎﺑﺪ ﻣﮕﺮ و زﻣﺎﻧﻲ

:ﻛﻪ

An interlock system whereby product will not

flow unless and until:

- The vehicle is properly earthed or bonded;

- The loading arm is in its correct position.

،ﺧﻮدرو ﺑﻪ ﻃﻮر ﺻﺤﻴﺢ اﺗﺼﺎل زﻣﻴﻦ ﻳﺎ وﺻﻞ ﺷﻮد

-

.ﺑﺎزوي ﺑﺎرﮔﻴﺮي در ﻣﻮﻗﻌﻴﺖ ﺻﺤﻴﺢ ﻗﺮار داﺷﺘﻪ ﺑﺎﺷﺪ

-

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد اﻧﺪازهﮔﻴﺮي ﺟﺮﻳﺎن ﻣﺤﺼﻮل ﺑﻪ ﺑﺨﺸﻬﺎي ﻣﺨﺰن

اﻳﻦ.ﺧﻮدرو از ﻃﺮﻳﻖ ﺟﺮﻳﺎن ﺳﻨﺞ ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ اﻧﺠﺎم ﮔﻴﺮد

ﻛﺎر ﺳﺎﻣﺎﻧﻪﻫﺎ را ﻗﺎدر ﻣﻴﺴﺎزد ﺗﺎ ﻃﻮري ﺗﻮﺳﻌﻪ ﻳﺎﺑﻨﺪ ﻛﻪ

اﻃﻼﻋﺎت ﻣﺤﺼﻮل و ﻣﻘﺪار ﺑﺎرﮔﻴﺮي ﺑﻪ ﻳﻚ ﺧﻮدروي ﻣﺸﺨﺺ

.ﻗﺒﻞ از ﺷﺮوع ﺟﺮﻳﺎن ﻣﺤﺼﻮل در ﺻﻮرت ﻟﺰوم ﺷﻨﺎﺳﺎﻳﻲ ﺷﻮد

Measurement of product flow into vehicle

compartments should be through a positive

displacement meter. This enables systems to be

developed which capture the data for the product

and quantity loaded into a specific vehicle which

is required to identify itself before product will

flow.

ﺗﻤﻬﻴﺪاﺗﻲ ﺑﺮاي ﺧﻮدﻛﺎر ﻛﺮدن2-2-6-1-6

6.1.6.2.2 Provision for automation

ﺗﺠﻬﻴﺰات اﺳﺎﺳﻲ ﻛﻪ ﺑﺎﻳﺪ در ﻣﺤﻮﻃﻪ ﺑﺎرﮔﻴﺮي در دﺳﺘﺮس

:ﺑﺎﺷﻨﺪ ﻋﺒﺎرﺗﻨﺪ از

The basic equipment which must be available on

the loading islands comprises:

- An earth interlock system;

- A positive displacement meter with preset

unit and/or 2-stage product flow-control

valve, at each product loading point;

- A meter pulse unit transmitting per unit

volume;

- Means for taking temperature into account,

for example:

ﺳﺎﻣﺎﻧﻪ ﻫﻤﺒﻨﺪ اﺗﺼﺎل زﻣﻴﻦ؛

-

ﺟﺮﻳﺎن ﺳﻨﺞ ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﺑﺎ واﺣﺪ ﭘﻴﺶ ﺗﻨﻈﻴﻢ

ﻳﺎ ﺷﻴﺮ ﻛﻨﺘﺮل ﺟﺮﻳﺎن ﻣﺤﺼﻮل دو ﻣﺮﺣﻠﻪاي در ﻫﺮ/و

ﻧﻘﻄﻪ ﺑﺎرﮔﻴﺮي ﻓﺮآورده؛

ﻳﻚ ﺟﺮﻳﺎن ﺳﻨﺞ ﻛﻪ ﺑﻪ ازاي ﻫﺮ واﺣﺪ ﺣﺠﻢ ﻳﻚ

ﭘﺎﻟﺲ ﻣﻨﺘﻘﻞ ﻣﻲﻛﻨﺪ؛

-

:وﺳﻴﻠﻪاي ﺑﺮاي در ﻧﻈﺮ ﮔﺮﻓﺘﻦ دﻣﺎ ﻣﺜﻞ

-

اﻧﺪازه ﮔﻴﺮﻫﺎي ﺗﺼﺤﻴﺢ ﻛﻨﻨﺪه دﻣﺎ؛

• Temperature compensating meters;

-

ﭼﺎﻫﻚ دﻣﺎ ﺳﻨﺞ در ﺧﻄﻮط ﻣﺤﺼﻮل ﺑﺮاي

.اﻧﺪازه ﮔﻴﺮي دﻣﺎ ﺗﻮﺳﻂ دﻣﺎﺳﻨﺞﻫﺎي ﻣﻘﺎوﻣﺘﻲ ﻳﺎ ﺛﺒﺎت دﻣﺎ

• Thermometer pocket in product lines for

measuring

temperature

by

resistance

thermometers or temperature recorders.

ﻛﺎﺑﻠﻬﺎ ﺑﺮاي اﻧﺘﻘﺎل اﻃﻼﻋﺎت ﻣﺤﺼﻮل و ﻣﻘﺪار ﺟﺮﻳﺎن ﺑﺎﻳﺴﺘﻲ در

ﻳﻚ ﺗﺮاﻧﺸﻪ ﻛﺎﺑﻞ ﻣﺠﺰا ﺑﻮده و در ﺗﺮاﻧﺸﻪ ﻣﺸﺘﺮك ﺑﺎ ﻛﺎﺑﻠﻬﺎي

. روﺷﻨﺎﻳﻲ و ﺷﻴﺮ ﻛﻨﺘﺮل ﻧﺒﺎﺷﺪ،ﺣﺎﻣﻞ ﺑﺮق

Cables for transmission of data on product and

flow quantities must be run in separate wiring

conduits and not in the same conduit carrying

power, lighting and control valve cables.

ﻋﻮاﻣﻞ ﻃﺮاﺣﻲ ﻓﺮآﻳﻨﺪي7-1-6

6.1.7 Process design parameters

ﻋﻤﻮﻣﻲ1-7-1-6

6.1.7.1 General

ﻋﻮاﻣﻞ ﻣﺸﺨﺼﻲ ﻛﻪ ﺑﺮ ﻫﺰﻳﻨﻪ ﻛﻠﻲ ﺧﻮدروﻫﺎي ﺑﺎرﮔﻴﺮي اﺛﺮ

:ﻣﻴﮕﺬارﻧﺪ ﻋﺒﺎرﺗﻨﺪ از

The individual factors that contribute to the total

cost of loading vehicles are:

18

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

- Vehicle capacities and dimensions;

ﻫﺰﻳﻨﻪ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي )ﺳﺮﻣﺎﻳﻪ ﮔﺬاري ﺑﺮاي، اﻧﺪازه ﮔﻴﺮﻫﺎ، ﺧﻄﻮط، ﺗﻠﻤﺒﻪﻫﺎ، ﺳﺎزهﻫﺎ،دﻫﺎﻧﻪﻫﺎ

ﺑﺎﺳﻜﻮلﻫﺎ و ﻏﻴﺮه(؛

ﻫﺰﻳﻨﻪ زﻣﺎن ﺧﻮدرو ﻛﻪ در دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﻗﺮار دارد وزﻣﺎﻧﻲ ﻛﻪ در ﺻﻒ ﺑﺮاي دﻫﺎﻧﻪ ﺑﺎرﮔﻴﺮي ﺑﻮده ﻳﺎ ﻣﻨﺘﻈﺮ

ﺑﺎزوي ﺑﺎرﮔﻴﺮي ﺑﺎﺷﺪ )ﺧﻮدرو در ﺣﺎل ﺑﺎرﮔﻴﺮي ﻣﺘﻮﻗﻒ

ﺑﺎﺷﺪ(؛

اﺑﻌﺎد و ﻇﺮﻓﻴﺖ ﺧﻮدرو؛-

- Shift patterns, including staggered starts

and night loading. In this context the

method of operation can be single or

double shift patterns, or 24-hour service, or

a combination of these.

ﻧﺤﻮه ﺷﻴﻔﺖ ﻛﺎري ﺷﺎﻣﻞ ﺗﻨﺎوب ﺷﺮوع و ﺑﺎرﮔﻴﺮي در اﻳﻦ ﭼﺎرﭼﻮب روش ﻋﻤﻠﻴﺎت ﻣﻴﺘﻮاﻧﺪ،ﺷﺒﺎﻧﻪ

24 اﻟﮕﻮﻫﺎي ﺷﻴﻔﺖ ﻛﺎري ﻳﻜﻲ ﻳﺎ دوﺗﺎﻳﻲ ﻳﺎ ﻛﺎرﺑﺮي

ﺳﺎﻋﺘﻪ ﻳﺎ ﺗﺮﻛﻴﺒﻲ از اﻳﻦﻫﺎ ﺑﺎﺷﺪ؛

- The cost of the loading facilities (capital

charges for bays, structures, pumps, lines,

meters, weighbridges, etc.);

- The cost of vehicle time while occupying

the loading bay and while queuing for a

loading bay, or waiting for a loading arm

while in the bay (vehicle standing charges);

اﺑﻌﺎد و،داﺷﺘﻦ اﻟﮕﻮ ﺑﺮاي رﺳﻴﺪن ﺧﻮدروﻫﺎ در ﺳﺎﻋﺎت ﺷﻠﻮﻏﻲ

ﻫﺰﻳﻨﻪ روﺷﻬﺎي ﺟﺎﻳﮕﺰﻳﻦ ﺑﺎرﮔﻴﺮي و ﻣﻴﺰان ﺑﺎرﮔﻴﺮي ﻣﻴﺘﻮاﻧﺪ

ﺗﻌﻴﻴﻦ و ﻗﻴﻤﺖ ﮔﺬاري ﺷﻮد و ﺗﻮازن اﻗﺘﺼﺎدي ﺑﻴﻦ ﻫﺰﻳﻨﻪ

ﺗﺄﺧﻴﺮ در ﺻﻒ ﺧﻮدرو و ﻫﺰﻳﻨﻪ ﺗﻬﻴﻪ ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي اﺿﺎﻓﻲ

. ﺑﻪ دﺳﺖ آﻳﺪ،ﻛﻪ ﺻﻒ را ﻛﺎﻫﺶ ﻳﺎ ﺣﺬف ﻣﻴﻜﻨﺪ

Having established the likely future pattern of

vehicle arrivals during peak hours, the extent and

cost of alternative loading methods and loading

rates can be determined and costed, and the

economic balance obtained between the cost of

vehicle queuing delays and the cost of providing

extra loading facilities which will reduce or

eliminate them.

اوج ﺗﻘﺎﺿﺎ2-7-1-6

6.1.7.2 Peak demand

Any loading facility should be designed to meet

the forecast loading demand during peak periods.

To calculate the facilities required, it is necessary

to determine the quantity to be loaded in the peak

hour for each product, at the same time

establishing the quantities required for each

multi-product vehicle loading combination; and

to forecast the future peak demands on which the

size (number of loading bays) will be based.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻃﻮري ﻃﺮاﺣﻲ ﺷﻮﻧﺪ ﺗﺎ

ﺑﺮاي.ﺗﻘﺎﺿﺎي ﺑﺎرﮔﻴﺮي در ﻃﻮل دوران اوج را ﺑﺮآورد ﻛﻨﻨﺪ

ﺗﻌﻴﻴﻦ ﻣﻘﺎدﻳﺮي از ﻫﺮ ﻣﺤﺼﻮل،ﻣﺤﺎﺳﺒﻪ ﺗﺴﻬﻴﻼت ﻣﻮرد ﻧﻴﺎز

در ﻫﻤﺎن زﻣﺎن ﺗﻌﻴﻴﻦ،ﻛﻪ در ﺳﺎﻋﺎت اوج ﺑﺎﻳﺪ ﺑﺎرﮔﻴﺮي ﺷﻮد

ﻣﻘﺎدﻳﺮ ﻻزم ﺑﺮاي ﻫﺮ ﺗﺮﻛﻴﺐ ﺧﻮدروي ﭼﻨﺪ ﻣﺤﺼﻮﻟﻪ؛ و ﭘﻴﺶ

ﺑﻴﻨﻲ ﺗﻘﺎﺿﺎي اوج آﺗﻲ ﻛﻪ ﺑﻪ ﭼﻪ اﻧﺪازهاي )ﺗﻌﺪاد دﻫﺎﻧﻪ

. ﻻزم اﺳﺖ،ﺑﺎرﮔﻴﺮي( ﺑﺎﻳﺪ ﺗﻌﻴﻴﻦ ﮔﺮدد

After establishing the total number of loading

bays, the effect of major sensitivities should be

studied, in particular the reduction of loading

bays by one (or more) on the waiting time for all

vehicles, and vice versa, in order to ensure that an

economic optimum for the whole system is

chosen.

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد،ﭘﺲ از ﺗﻌﻴﻴﻦ ﺗﻌﺪاد ﻛﻞ دﻫﺎﻧﻪ ﻫﺎي ﺑﺎرﮔﻴﺮي

ﺣﺴﺎﺳﻴﺖﻫﺎي ﻋﻤﺪه ﺑﺨﺼﻮص اﺛﺮ ﻛﺎﻫﺶ دﻫﺎﻧﻪ ﻫﺎي ﺑﺎرﮔﻴﺮي

ﺑﻪ ﺗﻌﺪاد ﻳﻚ )ﻳﺎ ﭼﻨﺪ( در زﻣﺎن اﻧﺘﻈﺎر ﺑﺮاي ﺗﻤﺎم ﺧﻮدروﻫﺎ و

ﺑﻪ ﻣﻨﻈﻮر اﻃﻤﻴﻨﺎن از اﻧﺘﺨﺎب ﺑﻬﺘﺮﻳﻦ ﺳﺎﻣﺎﻧﻪ اﻗﺘﺼﺎدي،ﺑﺮﻋﻜﺲ

.ﺑﺮاي ﻛﻞ ﺳﺎﻣﺎﻧﻪ ﻣﻄﺎﻟﻌﻪ ﺷﻮد

ﻣﻴﺰان ﺟﺮﻳﺎن ﻓﺮآورده3-7-1-6

6.1.7.3 Product flow rates

Flow rates are generally restricted by safety

precautions (i.e., prevention of excessive static

electricity generation), also the economic size of

pumps, pipework and measuring equipment.

ﻣﻤﺎﻧﻌﺖ از،ًﻣﻴﺰان ﺟﺮﻳﺎن ﻋﻤﻮﻣﺎ ﺑﻌﻠﺖ ﺟﻨﺒﻪﻫﺎي اﻳﻤﻨﻲ )ﻣﺜﻼ

ﻫﻤﭽﻨﻴﻦ ﺑﻌﻠﺖ اﻧﺪازه اﻗﺘﺼﺎدي،(ﺗﻮﻟﻴﺪ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ زﻳﺎد

ﺷﺒﻜﻪ ﻟﻮﻟﻪﻛﺸﻲ و ﺗﺠﻬﻴﺰات اﻧﺪازه ﮔﻴﺮي ﻣﺤﺪود،ﺗﻠﻤﺒﻪﻫﺎ

.ﻣﻲﺷﻮد

As regards safety precautions, concerning static

electricity on flow rates, the rate of flow should

ﺷﺎﻣﻞ ﺗﻮﻟﻴﺪ اﻟﻜﺘﺮﻳﺴﻴﺘﻪ،ﺑﺎ ﺗﻮﺟﻪ ﺑﻪ اﻗﺪاﻣﺎت اﺣﺘﻴﺎط اﻳﻤﻨﻲ

ﺗﻮﺻﻴﻪ ﻣﻲﺷﻮد ﻣﻴﺰان ﺟﺮﻳﺎن،ﺳﺎﻛﻦ در ﻣﻴﺰانﻫﺎي ﺟﺮﻳﺎن

19

Nov. 2009 / 1388 آﺑﺎن

not normally exceed the figures as given in Table

2 below.

17

IPS-E-PR-370(1)

. ﺗﺠﺎوز ﻧﻤﺎﻳﺪ2 ﻣﻌﻤﻮﻻً از ارﻗﺎم داده ﺷﺪه در ﺟﺪول

TABLE 2 - FLOW RATE LIMITATION FOR STATIC ELECTRICITY

ﻣﺤﺪودﻳﺖ ﻣﻴﺰان ﺟﺮﻳﺎن ﺑﺮاي اﻟﻜﺘﺮﻳﺴﻴﺘﻪ ﺳﺎﻛﻦ-2 ﺟﺪول

MAXIMUM LOADING RATE, m³/h

3

m /h ﻣﻴﺰان ﺑﺎرﮔﻴﺮي ﺣﺪاﻛﺜﺮ

PRODUCT

ﻣﺤﺼﻮل

Top loading

Bottom loading

DN 80

(3 inches)

DN 100

(4 inches)

DN 150

(6 inches)

( اﻳﻨﭻ3)

( اﻳﻨﭻ4)

( اﻳﻨﭻ6)

ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

108

144

216

ﺑﺎرﮔﻴﺮي از ﭘﺎﻳﻴﻦ

78

105

6.1.7.4 Simultaneous loading using two or

more arms/hoses

ﺑﺎرﮔﻴﺮي ﻫﻤﺰﻣﺎن ﺑﺎ اﺳﺘﻔﺎده از دو ﻳﺎ ﭼﻨﺪ4-7-1-6

Considerable benefit can be achieved by loading

a vehicle using two or more loading arms or

hoses simultaneously. The additional cost of

meters or loading arms, etc. is usually well

compensated by the savings from reduced vehicle

time in the bay, and in a reduction in the number

of loading bays required.

ﻓﻮاﻳﺪ ﻗﺎﺑﻞ ﻣﻼﺣﻈﻪاي در ﺑﺎرﮔﻴﺮي ﺧﻮدرو ﺑﺎ اﺳﺘﻔﺎده از دو ﻳﺎ

ﻫﺰﻳﻨﻪ اﺿﺎﻓﻲ.ﭼﻨﺪ ﺑﺎزو ﻳﺎ ﺷﻴﻠﻨﮓ ﺑﻪ ﻃﻮر ﻫﻤﺰﻣﺎن وﺟﻮد دارد

ﻋﻤﻮﻣﺎً ﺑﺎ ﺻﺮﻓﻪ،ﺟﺮﻳﺎن ﺳﻨﺞ ﻫﺎ ﻳﺎ ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي و ﻏﻴﺮه

ﺟﻮﻳﻲ از ﻛﺎﻫﺶ زﻣﺎن ﺗﻮﻗﻒ ﺧﻮدرو در دﻫﺎﻧﻪ و ﻛﺎﻫﺶ در

.ﺗﻌﺪاد دﻫﺎﻧﻪﻫﺎي ﺑﺎرﮔﻴﺮي ﻣﻮرد ﻧﻴﺎز ﺑﺨﻮﺑﻲ ﺟﺒﺮان ﻣﻲﺷﻮد

In the case of top loading, the simultaneous use of

two or more arms will result in the need for

additional equipment to prevent overfilling which

may not be necessary for single arm operation.

The cost and other consequences arising from

such equipment must be taken into account in the

economic comparison.

اﺳﺘﻔﺎده ﻫﻤﺰﻣﺎن دو ﻳﺎ ﭼﻨﺪ ﺑﺎزو ﻧﻴﺎز ﺑﻪ،در ﺑﺎرﮔﻴﺮي از ﺑﺎﻻ

ﺗﺠﻬﻴﺰات اﺿﺎﻓﻲ ﺑﺮاي ﻣﻤﺎﻧﻌﺖ از ﺳﺮرﻳﺰ دارد ﻛﻪ ﻣﻤﻜﻦ اﺳﺖ

ﻫﺰﻳﻨﻪ و ﺳﺎﻳﺮ ﻧﺘﺎﻳﺞ.ﺑﺮاي ﻋﻤﻠﻴﺎت ﺑﺎ ﻳﻚ ﺑﺎزو ﻻزم ﻧﺒﺎﺷﺪ

.اﻓﺰاﻳﺶ ﭼﻨﺎن ﺗﺠﻬﻴﺰاﺗﻲ ﺑﺎﻳﺪ در ارزﻳﺎﺑﻲ اﻗﺘﺼﺎدي ﻟﺤﺎظ ﺷﻮﻧﺪ

6.1.7.5 Calculation of number of spouts and

pumping capacity

ﻣﺤﺎﺳﺒﻪ ﺗﻌﺪاد دﻫﺎﻧﻪﻫﺎي ﺧﺮوﺟﻲ و ﻇﺮﻓﻴﺖ5-7-1-6

ﺷﻴﻠﻨﮓ/ﺑﺎزو

ﺗﻠﻤﺒﻪ ﻛﺮدن

a) General

اﻟﻒ( ﻋﻤﻮﻣﻲ

The determination of the optimum number of

spouts for loading facilities is important

because it directly affects capital costs of the

facilities on the one hand, and operating costs

of vehicle fleet on the other hand.

ﭼﻮن ﺗﻌﻴﻴﻦ ﺗﻌﺪاد ﺑﻬﻴﻨﻪ دﻫﺎﻧﻪﻫﺎي ﺧﺮوﺟﻲ از ﻳﻚ ﻃﺮف

ﺑﻪ ﻃﻮر ﻣﺴﺘﻘﻴﻢ ﺑﺮ ﻫﺰﻳﻨﻪ ﺳﺮﻣﺎﻳﻪ ﮔﺬاري روي ﺗﺎﺳﻴﺴﺎت و

،از ﻃﺮف دﻳﮕﺮ ﺑﺮ ﻫﺰﻳﻨﻪ ﻋﻤﻠﻴﺎﺗﻲ ﻧﺎوﮔﺎن ﺧﻮدرو ﺗﺄﺛﻴﺮ دارد

.ﺑﺮاي ﺗﺄﺳﻴﺴﺎت ﺑﺎرﮔﻴﺮي ﻣﻬﻢ اﺳﺖ

ﻣﻴﺰان ﺑﺎرﮔﻴﺮي و ﺗﻌﺪاد دﻫﺎﻧﻪﻫﺎي ﺧﺮوﺟﻲ ﻻزم ﺑﺮاي

:ﻫﺮ ﻣﺤﺼﻮل ﺑﺎ ﻣﻮارد زﻳﺮ ﺗﻐﻴﻴﺮ ﻣﻴﻜﻨﺪ

Loading rates and the number of spouts

required for each product varies with:

( اﻧﺪازه ﻛﺎﻣﻴﻮن؛1

1) Truck size,

2) Number of loading hours per day;

( ﺗﻌﺪاد ﺳﺎﻋﺖ ﻫﺎي ﺑﺎرﮔﻴﺮي در روز ؛2

3) Number of loading days per week;

( ﺗﻌﺪاد روزﻫﺎي ﺑﺎرﮔﻴﺮي در ﻫﻔﺘﻪ؛3

20

Nov. 2009 / 1388 آﺑﺎن

IPS-E-PR-370(1)

ﭘﻴﺪا ﻛﺮدن و ﺧﺮوج،( زﻣﺎن ﻻزم ﺑﺮاي اﺳﺘﻘﺮار4

4) Time required for positioning, lookup and depositioning of truck; and

ﻛﺎﻣﻴﻮن و

.( اﻧﺪازه ﻣﺠﻤﻮﻋﻪ ﺑﺎرﮔﻴﺮي5

5) Size of loading assemblies.

ب ( ﺗﻌﻴﻴﻦ ﻣﻌﺎدﻻت

b) Formulation

ﭘﻴﻮﺳﺖ ج را در اﻳﻦ،ﺑﺮاي ﺗﻌﻴﻴﻦ ﻣﻌﺎدﻻت و ﻳﻚ ﻣﺜﺎل

.ﻣﺸﺨﺼﻪ اﺳﺘﺎﻧﺪارد ﺑﺒﻴﻨﻴﺪ

For formulation and an example see

Appendix

C

in

this

Standard

Specification.

ﮔﺮﻣﺎﻳﺶ ﺑﺎزوﻫﺎي ﺑﺎرﮔﻴﺮي6-7-1-6

6.1.7.6 Heating for loading arms

ﺧﻄﻮط ﻟﻮﻟﻪ ﺗﺎ،زﻣﺎﻧﻲ ﻛﻪ از ﻟﻮﻟﻪﻛﺸﻲ ﮔﺮم ﺷﺪه اﺳﺘﻔﺎده ﺷﻮد

.ﺷﻴﺮ ﻧﻬﺎﻳﻲ و ﺷﺎﻣﻞ آن روي ﺑﺎزوي ﺑﺎرﮔﻴﺮي ﺑﺎﻳﺪ ﮔﺮم ﺷﻮﻧﺪ

ﻧﻈﺮ ﺑﻪ اﻳﻦ ﻛﻪ ﮔﺮﻣﺎﻳﺶ اﻏﻠﺐ در آب و ﻫﻮاي ﺳﺮد ﻳﺎ در ﻃﻮل

اﺳﺘﻔﺎده از ﮔﺮﻣﺎﻳﺶ اﻟﻜﺘﺮﻳﻜﻲ،ﺷﺮوع ﺑﻪ ﻛﺎر ﻻزم ﻣﻲﺑﺎﺷﺪ

اﻗﺘﺼﺎدي،اﻧﻔﺠﺎر ﻛﻪ ﺑﺎ ﺗﺮﻣﻮﺳﺘﺎت ﻛﻨﺘﺮل ﻣﻲ ﺷﻮد/ﺿﺪﺷﻌﻠﻪ

.اﺳﺖ

When heated pipelines are used, the pipework up

to and including the final valve on the loading

arm should be heated. Since heating is often

required only in cold weather or during start up, it

is economical to consider using thermostatically

controlled flame/explosion-proof electric heating.

6.1.8 Equipment

ﺗﺠﻬﻴﺰات8-1-6

6.1.8.1 General

ﻋﻤﻮﻣﻲ1-8-1-6

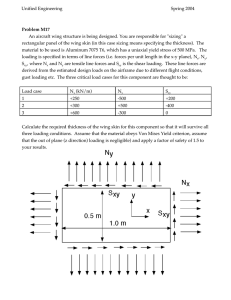

Typical equipment required for a truck loading

operation is shown in Fig. 1.

1 ﺗﺠﻬﻴﺰات ﻧﻤﻮﻧﻪ ﻻزم ﺑﺮاي ﻓﺮآﻳﻨﺪ ﺑﺎرﮔﻴﺮي ﻛﺎﻣﻴﻮن در ﺷﻜﻞ

.ﻧﺸﺎن داده ﺷﺪهاﻧﺪ

Air eliminators are used to disengage air and

other vapors which would affect the accuracy of

metering. Disengaging of vapor is done at about 2

bar (ga) and if there is not at least this amount of

static head difference between the air eliminator

and the loading spout discharge, a back pressure

valve must be provided. This may be a swingtype check valve.

از ﺣﺬف ﻛﻨﻨﺪه ﻫﺎي ﻫﻮا ﺑﺮاي ﺟﺪاﺳﺎزي ﻫﻮا و ﺳﺎﻳﺮ ﺑﺨﺎرات ﻛﻪ

. اﺳﺘﻔﺎده ﻣﻴﺸﻮد،دﻗﺖ اﻧﺪازه ﮔﻴﺮي را ﺗﺤﺖ ﺗﺄﺛﻴﺮ ﻗﺮار ﻣﻴﺪﻫﻨﺪ

ﺑﺎر )ﻧﺴﺒﻲ( اﻧﺠﺎم ﺷﺪه و2 ﺟﺪاﺳﺎزي ﺑﺨﺎرات در ﻓﺸﺎر ﺣﺪود

اﮔﺮ ﺣﺪاﻗﻞ اﺧﺘﻼف ارﺗﻔﺎع اﻳﺴﺘﺎ ﺑﻴﻦ ﺣﺬف ﻛﻨﻨﺪه ﻫﻮا و

ﻳﻚ ﺷﻴﺮ ﻓﺸﺎر،ﺧﺮوﺟﻲ ﻟﻮﻟﻪ ﺑﺎرﮔﻴﺮي ﻣﻮﺟﻮد ﻧﺒﺎﺷﺪ ﺑﺎﻳﺴﺘﻲ

ﻛﻪ ﻣﻴﺘﻮاﻧﺪ ﻳﻚ ﺷﻴﺮ ﻳﻚ ﻃﺮﻓﻪ ﻧﻮع.ﺑﺮﮔﺸﺘﻲ ﺗﻌﺒﻴﻪ ﺷﻮد

.ﮔﺮدان ﺑﺎﺷﺪ

ﻧﻮﺳﺎن ﮔﻴﺮﻫﺎ ﺑﺮاي ﻛﺎﻫﺶ ﺷﻮك،در ﺑﺮﺧﻲ از ﺗﺄﺳﻴﺴﺎت

ﺻﺎﻓﻲﻫﺎ.ﻫﻴﺪروﻟﻴﻜﻲ ﻧﺎﺷﻲ از ﺑﺴﺘﻪ ﺷﺪن ﺳﺮﻳﻊ ﻧﺼﺐ ﻣﻴﺸﻮﻧﺪ

ﺑﺮاي ﮔﺮﻓﺘﻦ آﺷﻐﺎل و ﺳﺎﻳﺮ ذرات ﺧﺎرﺟﻲ ﻗﺒﻞ از ﺟﺮﻳﺎن ﺳﻨﺞ

ﻛﻪ ﻋﻤﻮﻣﺎً از ﻧﻮع ﺟﺮﻳﺎن ﺳﻨﺞ ﺟﺎﺑﺠﺎﻳﻲ ﻣﺜﺒﺖ ﻣﺠﻬﺰ ﺑﻪ ﺛﺒﺎت

ﺷﻴﺮﻫﺎي ﺗﻨﻈﻴﻤﻲ ﻗﻄﻊ ﺟﺮﻳﺎن ﺑﺮاي. ﺗﻌﺒﻴﻪ ﻣﻴﺸﻮﻧﺪ،ﻫﺴﺘﻨﺪ

ﻗﻄﻊ ﺟﺮﻳﺎن ﻣﺤﺼﻮل ﺑﻪ ﺻﻮرت ﺧﻮدﻛﺎر در ﻣﻘﺪار از ﭘﻴﺶ

اﺳﺘﻔﺎده،ﺗﻌﻴﻴﻦ ﺷﺪه در ﺷﻤﺎرﻧﺪه ﺗﻨﻈﻴﻢ – ﻗﻄﻊ ﺟﺮﻳﺎن ﺳﻨﺞ

اﻳﻦ ﺷﻴﺮﻫﺎ ﺑﺮاي ﺳﺎﻣﺎﻧﻪﻫﺎي ﻛﻨﺘﺮل از راه دور.ﻣﻴﺸﻮﻧﺪ

ﻫﻤﭽﻨﻴﻦ ﻣﻴﺘﻮاﻧﻨﺪ ﺑﻪ ﻋﻨﻮان ﺷﻴﺮ.ﻣﻴﺘﻮاﻧﻨﺪ اﺳﺘﻔﺎده ﺷﻮﻧﺪ

ﻣﺴﺪودﻛﻨﻨﺪه ﻋﻤﻞ ﻛﻨﻨﺪه از راه دور ﺑﺮاي ﻣﻤﺎﻧﻌﺖ از ﺑﺮداﺷﺖ

.ﻏﻴﺮ ﻣﺠﺎز ﻣﺤﺼﻮل ﺑﻜﺎر روﻧﺪ

ﺷﻴﺮﻫﺎي ﻛﻨﺘﺮل داراي،ﺟﺮﻳﺎن-ﻛﻨﺘﺮل ﻛﻨﻨﺪهﻫﺎي ﻣﻴﺰان

ﻧﺸﺎﻧﮕﺮ داﺧﻠﻲ – ﺟﺮﻳﺎن ﻫﺴﺘﻨﺪ ﻛﻪ ﺑﺮاي ﻣﻤﺎﻧﻌﺖ از ﺳﺮﻋﺖ

ﻧﺸﺎﻧﮕﺮ ﺟﺮﻳﺎن.زﻳﺎد و ﻓﺮﺳﺎﻳﺶ ﺟﺮﻳﺎن ﺳﻨﺞ ﺑﻜﺎر ﻣﻴﺮوﻧﺪ

Desurgers are installed in some installations to

decrease hydraulic shock resulting from quick

shut-off. Strainers are provided to keep dirt and

other foreign particles out of the meters, which

are normally of the positive-displacement

recording type. Set stop valves are used to stop

product flow automatically at a predetermined

quantity set on the set-stop counter of the meter.

These valves can be used in remote-controlled

systems and can also serve as a remotely operated

block valve to prevent unauthorized withdrawal

of product.

Rate-of-flow controllers are self-contained flowindicating control valves used to prevent

overspeeding and wear of meters. The flow

21

آﺑﺎن Nov. 2009 / 1388

)IPS-E-PR-370(1

indicator is usually a pitot venture, and a straight

meter run of at least six pipe diameters is

recommended when the controller is downstream

of a strainer, globe valve, or short-radius elbow.

The loading arm is a mass or spring balanced

assembly of pipe and swing joints which will

reach various points on trucks of a range of

heights. A controlled closing loading valve is

included in the assembly. This decreases the flow

rate rapidly to a small percentage of capacity,

after which shut-off is slow to prevent shock.

ﻣﻌﻤﻮﻻً ﻳﻚ ﻟﻮﻟﻪ ﭘﻴﺘﻮت اﺳﺖ و زﻣﺎﻧﻲ ﻛﻪ ﻛﻨﺘﺮل ﻛﻨﻨﺪه در

ﭘﺎﻳﻴﻦ دﺳﺖ ﻳﻚ ﺻﺎﻓﻲ ،ﺷﻴﺮ ﮔﻠﻮﻳﻲ و زاﻧﻮﻳﻲ ﺷﻌﺎع ﻛﻮﺗﺎه

ﺑﺎﺷﺪ ،ﺗﻮﺻﻴﻪ ﻣﻴﺸﻮد ﻃﻮل ﻟﻮﻟﻪ ﻣﺴﺘﻘﻴﻢ ﺑﺎ ﺣﺪاﻗﻞ ﺷﺶ ﺑﺮاﺑﺮ

ﻗﻄﺮ داﺷﺘﻪ ﺑﺎﺷﺪ .ﺑﺎزوي ﺑﺎرﮔﻴﺮي ﺑﻪ ﺻﻮرت ﻣﺠﻤﻮﻋﻪ ﻣﺘﻮازن

ﻓﻨﺮي ﻳﺎ ﺟﺮﻣﻲ از ﻟﻮﻟﻪ و اﺗﺼﺎﻻت ﻣﻔﺼﻠﻲ اﺳﺖ ﻛﻪ در ارﺗﻔﺎﻋﺎت

ﻣﺨﺘﻠﻒ ﺑﻪ ﻧﻘﺎط ﻣﺘﻔﺎوت ﻛﺎﻣﻴﻮن ﻣﻴﺮﺳﺪ .ﻳﻚ ﺷﻴﺮ ﺑﺎرﮔﻴﺮي ﺑﺎ

ﺑﺴﺘﻦ ﻛﻨﺘﺮل ﺷﺪه ﻧﻴﺰ ﺷﺎﻣﻞ ﻣﺠﻤﻮﻋﻪ ﻣﻴﺒﺎﺷﺪ .اﻳﻦ ﺷﻴﺮ دﺑﻲ

ﺟﺮﻳﺎن را ﺑﻪ ﺳﺮﻋﺖ ﺑﻪ درﺻﺪ ﻛﻮﭼﻜﻲ از ﻇﺮﻓﻴﺖ ﻛﺎﻫﺶ

ﻣﻴﺪﻫﺪ ﻛﻪ ﭘﺲ از آن ﻗﻄﻊ ﻛﺮدن ﺑﺼﻮرت آرام ﺑﻮده و ﻣﺎﻧﻊ

اﻳﺠﺎد ﺷﻮك ﻣﻴﺸﻮد.

ﺑﺎزوي ﺑﺎرﮔﻴﺮي

ﻛﻨﺘﺮل ﻛﻨﻨﺪه ﻣﻴﺰان ﺟﺮﻳﺎن

)در ﺻﻮرت ﻧﻴﺎز(

ﺷﻴﺮ ﻗﻄﻊ ﺗﻨﻈﻴﻤﻲ

)اﺧﺘﻴﺎري(

ﺗﺨﻠﻴﻪ اﻧﺒﺴﺎط

ﺻﺎﻓﻲ

ﻧﻮﺳﺎنﮔﻴﺮ )درﺻﻮرت ﻧﻴﺎز(

ﺗﺨﻠﻴﻪ ﻫﻮاﻳﻲ

ﺑﻪ ﺗﺠﻬﻴﺰات ﺑﺎرﮔﻴﺮي

ﺷﻴﺮ اﻧﺴﺪاد ﻋﻤﻠﮕﺮ از دور

) ﺟﺎﻳﮕﺰﻳﻦ ﺷﻴﺮ دﺳﺘﻲ(

ﺣﺬف ﻛﻨﻨﺪه ﻫﻮا

ﺷﻴﺮ ﻓﺸﺎر ﭘﺸﺖ ﺷﻴﺮ)در ﺻﻮرت ﻧﻴﺎز(

ﺗﺨﻠﻴﻪ اﻧﺒﺴﺎط

ﺟﺠﺞ

ﻣﺨﺰن اﻧﺒﺎرش ﻓﺮآورده

ﺗﻠﻤﺒﻪ

ﺻﺎﻓﻲ

Fig. 1- TYPICAL SCHEMATIC DIAGRAM OF USUAL EQUIPMENT NEEDED

FOR TANK-TRUCK LOADING

ﺷﻜﻞ -1ﻧﻤﻮﻧﻪ ﻧﻤﻮدار ﺗﺠﻬﻴﺰات ﻣﺘﺪاول ﻣﻮرد ﻧﻴﺎز ﺑﺮاي ﺑﺎرﮔﻴﺮي ﻣﺨﺰن ﻛﺎﻣﻴﻮن

22

Nov. 2009 / 1388 آﺑﺎن